5.9.1 Basic setting .................................................................................................................................... 5-24

5.9.2 EMB parameter setting .................................................................................................................. 5-30

5.9.3 M/C parameter setting .................................................................................................................... 5-34

5.9.4 Needle setting(color setting) ........................................................................................................ 5-38

5.9.5 Frame offset setting .......................................................................................................................... 5-50

5.9.6 Option setting .................................................................................................................................. 5-52

5.9.7 The others setting ............................................................................................................................ 5-59

5.10.0 Ready ............................................................................................................................................................. 5-63

5.10.1 Position ............................................................................................................................................. 5-64

5.10.2 Gauge ............................................................................................................................................... 5-65

5.10.3 Exclude ............................................................................................................................................ 5-66

5.10.4 Fastview ........................................................................................................................................... 5-67

5.10.5 Trace ................................................................................................................................................. 5-70

5.11.0 Repeat ............................................................................................................................................................. 5-71

5.11.1 General repeat ................................................................................................................................. 5-72

5.11.2 Special repeat .................................................................................................................................. 5-80

5.11.3 Repeat load ...................................................................................................................................... 5-85

5.12.0 Edit ............................................................................................................................................................. 5-86

5.12.1 Stitch edit .......................................................................................................................................... 5-87

5.12.2 Stitch divide ..................................................................................................................................... 5-94

5.12.3 Design filtering ............................................................................................................................... 5-99

5.12.4 Design zoom in ...............................................................................................................................5-100

5.13.0 Machine setting ..............................................................................................................................................5-102

5.13.1 Machine service ..............................................................................................................................5-103

5.13.2 Machine information .....................................................................................................................5-103

5.13.3 Machine test ....................................................................................................................................5-104

5.13.4 Frame origin ....................................................................................................................................5-106

5.13.5 Error information ............................................................................................................................5-107

5.13.6 Thread break information .............................................................................................................5-107

5.13.7 Memory Initial ................................................................................................................................5-107

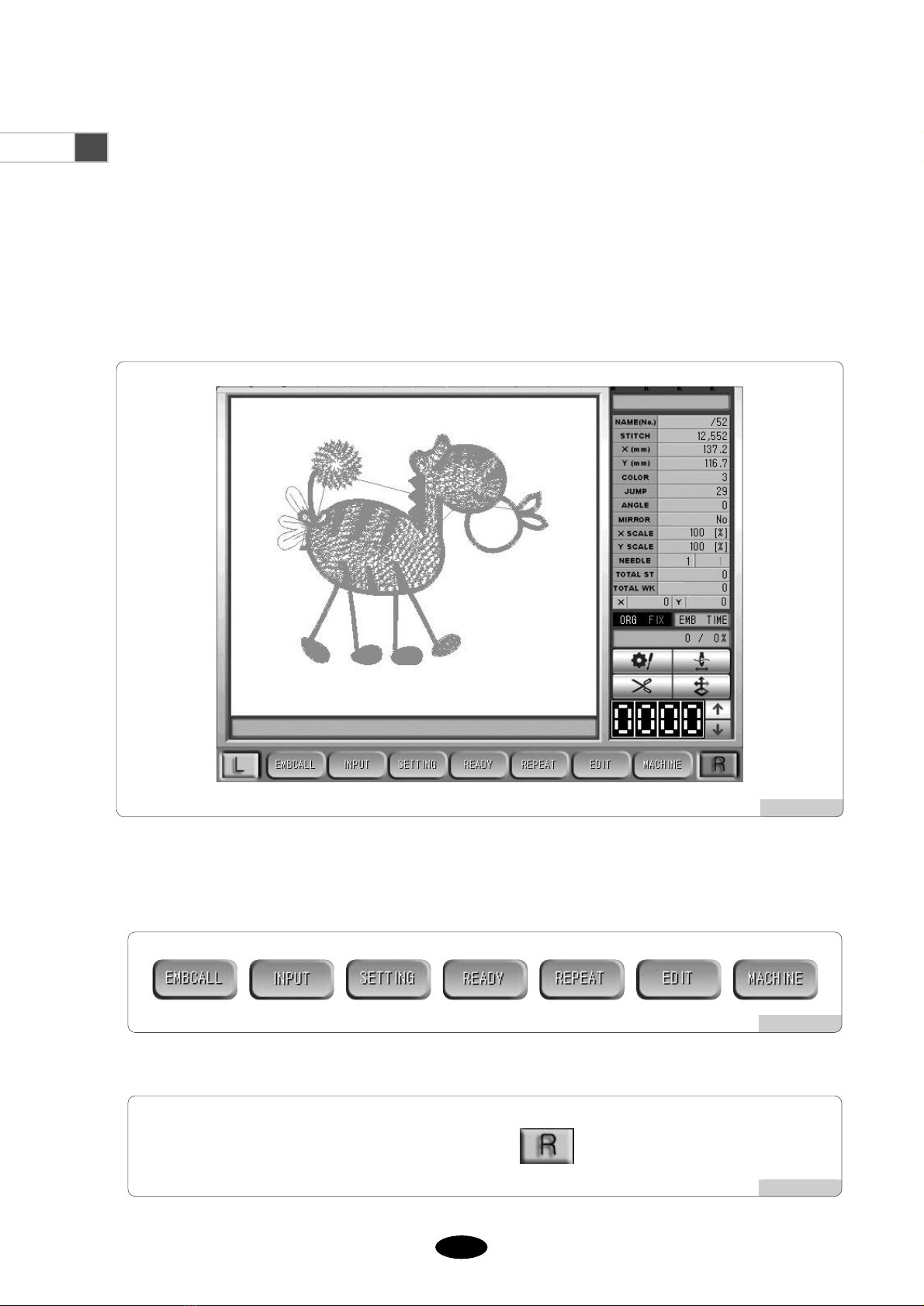

6.0

Function Menu during Embroidery

..................................................................................................................... 6-1

6.1 Menu structure during embroidery ............................................................................................................. 6-3

6.2 EMB Call ....................................................................................................................................................... 6-4

6.3 Setting ............................................................................................................................................................. 6-5

6.4 Float ............................................................................................................................................................. 6-6

6.5 Frame ............................................................................................................................................................. 6-7

6.6 S-Code ............................................................................................................................................................. 6-8

7.0

Troubleshooting

......................................................................................................................................................... 7-1

7.1.0 Error displays and troubleshooting ............................................................................................................. 7-1

7.1.1 Main shaft motor and others........................................................................................................... 7-1

7.1.2 X,Y motors........................................................................................................................................ 7-1

7.1.3 Needle(color) change ...................................................................................................................... 7-2

7.1.4 Encoder ............................................................................................................................................ 7-2

7.1.5 Repeat ............................................................................................................................................... 7-2

7.1.6 Floppy disks and communication ................................................................................................ 7-3

7.1.7 Memory ............................................................................................................................................ 7-4

7.1.8 Communication Error .................................................................................................................... 7-4

7.1.9 USB Memory .................................................................................................................................. 7-5

7.2.0 Machine Setting and Troubleshooting (※Dual Function 1×1 Embroidery Machine) ..................... 7-6

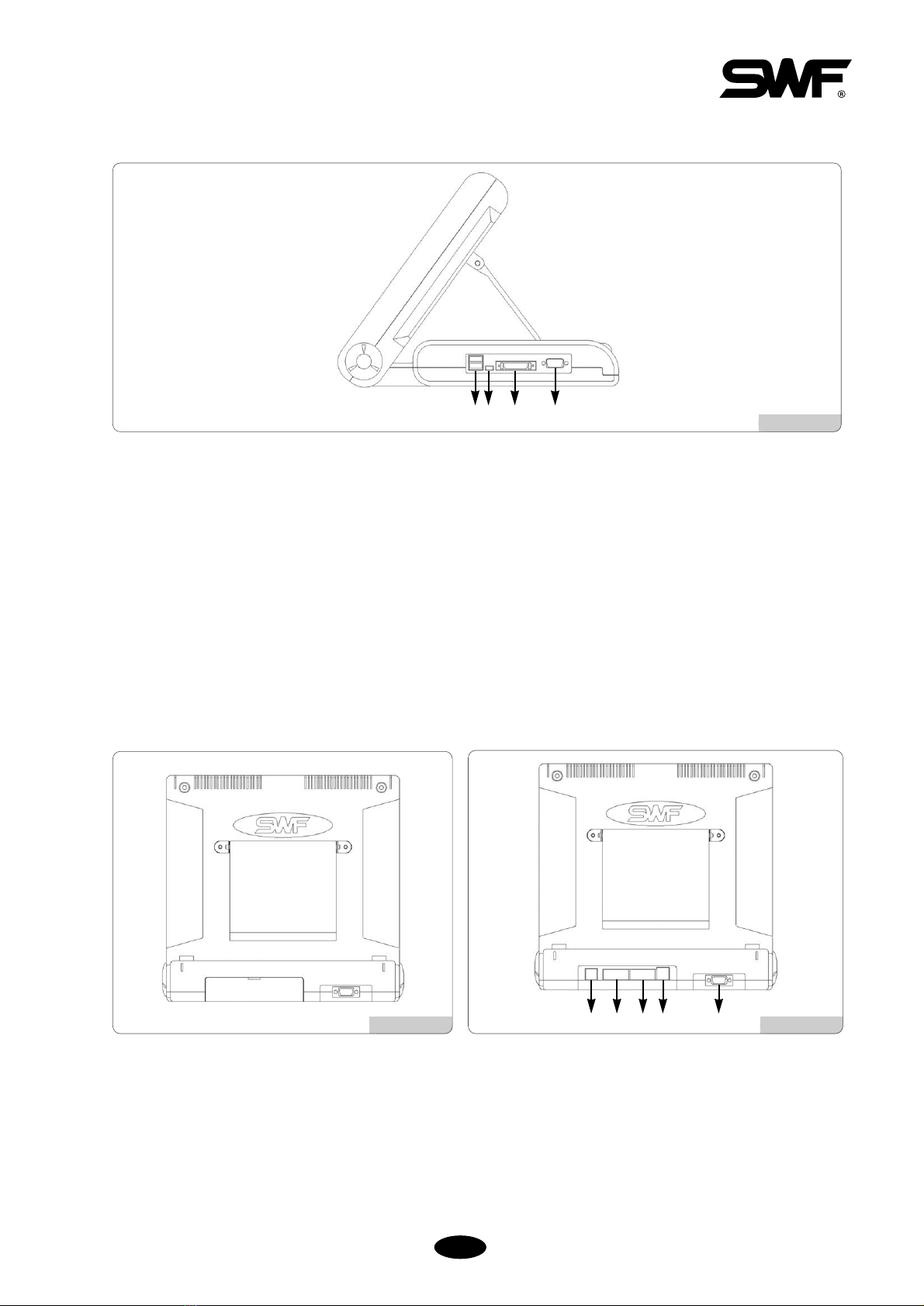

7.2.1 Rear Side of Control Box ............................................................................................................... 7-6

7.2.2 I/O Board, X/Y Driver Board Dip Switch Setting ..................................................................... 7-7

7.2.3 When the Power is not Turned On ............................................................................................... 7-10

7.3.0 Machine Setting and Troubleshooting (※In case of Dual Function 2×2 or above) ................................. 7-11

7.3.1 Rear Side of Control Box ................................................................................................................. 7-11

7.3.2 I/O Board , X/Y Driver Board Dip Switch Setting.......................................................................... 7-12

7.3.3 Power Supply Troubleshooting......................................................................................................... 7-14

7.4.0 Machine Setting and Troubleshooting (※Dual DM Series) ........................................................................ 7-15

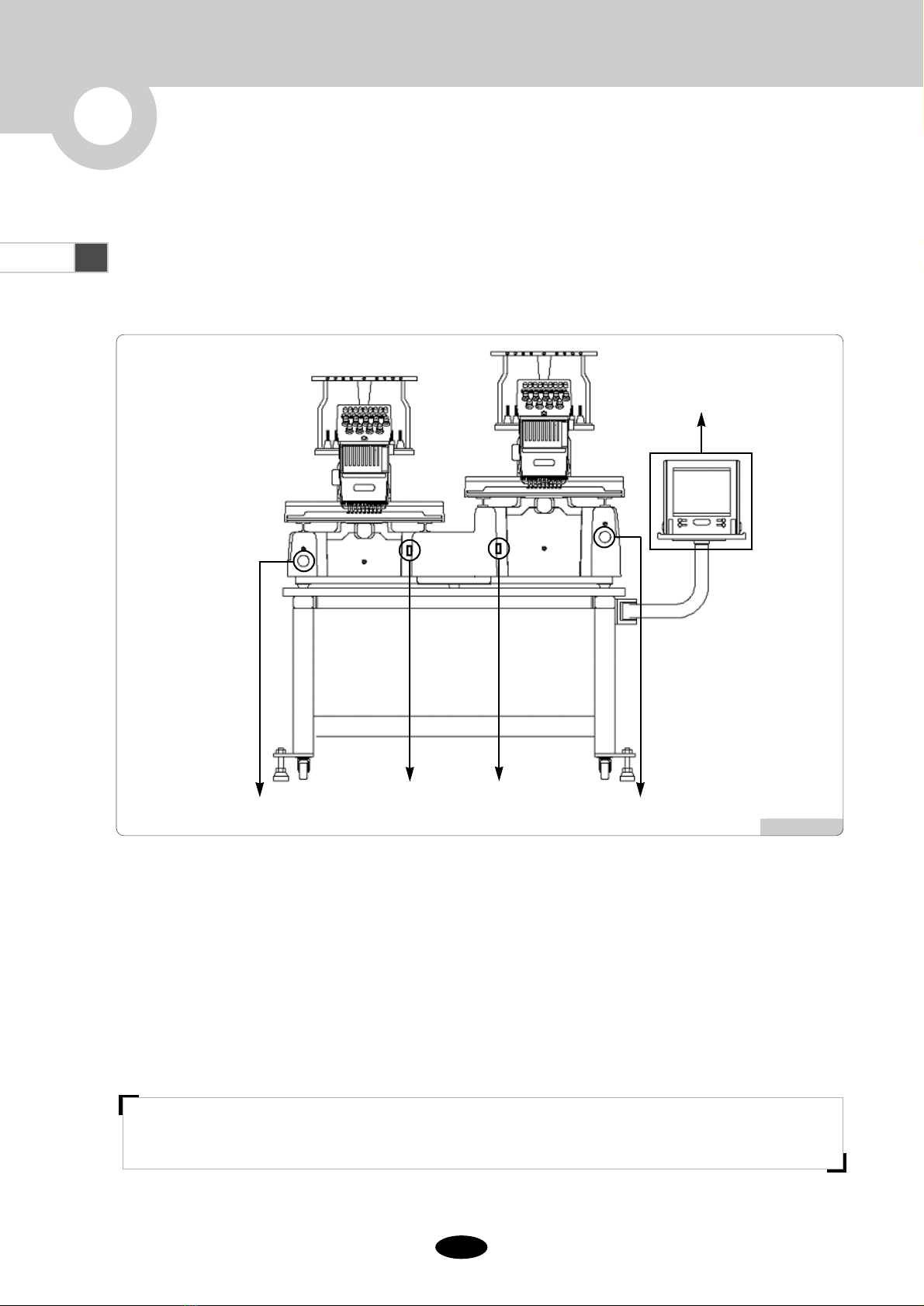

7.5 System Block Diagram..................................................................................................................................... 7-17