9

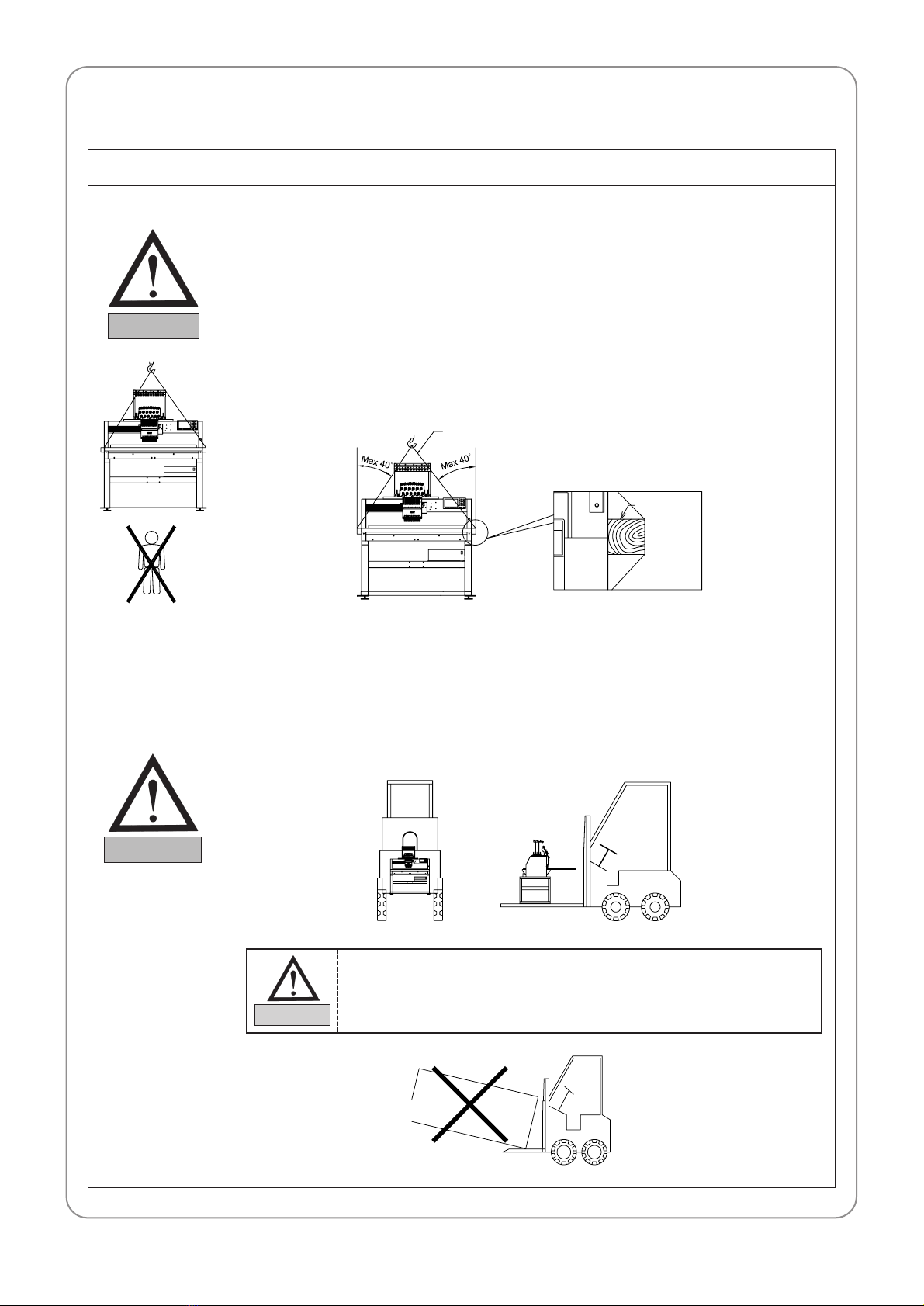

2.3) MACHINE INSTALLATION

DANGER

Depending on the installation environment, function errors, breakdown, or other

physical damage might result. Make sure to meet the following conditions for machine

installation:

1) The place where the machine is installed shall have the structure to endure the weight

of the machine (some 500 kg).

2) Dust and humidity are the cause of machine pollution and erosion. Please install an air

conditioner and conduct regular maintenance of the machine.

3) Install the machine at the place where it is not exposed to direct sunlight (if the machine

is exposed to direct sunlight for a long time, it may cause discoloration or deformation).

4) Secure the space around the machine. Place the machine at least 50cm away from the

left, right, and rear walls to secure sufficient space for maintenance activities.

[Note] For more details on machine installation, see "2. Machine Installation and

Assembly."

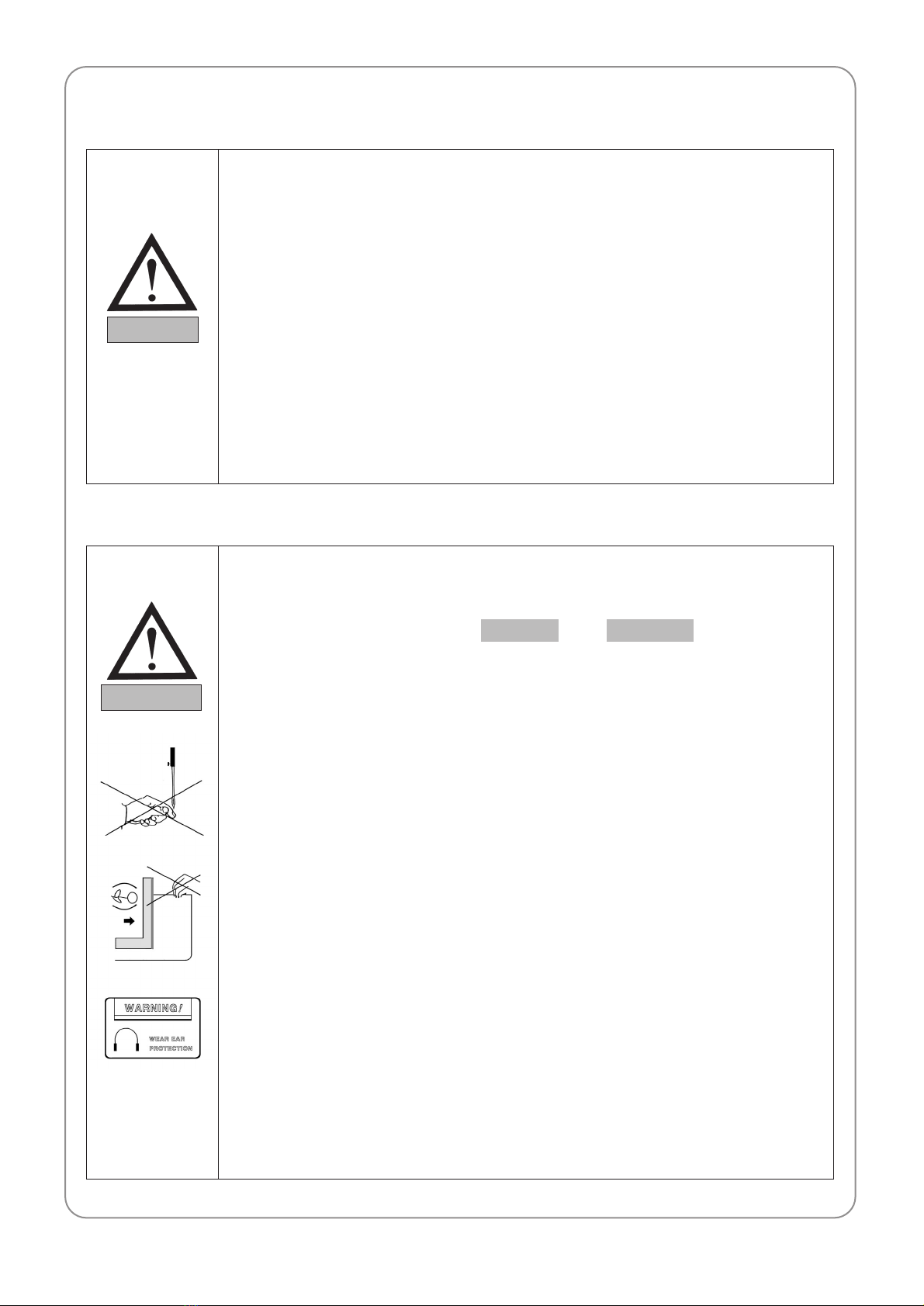

2.4) MACHINE OPERATION

The SWF automatic embroidery machine is designed to conduct embroidery on

textiles and similar materials for industrial purposes.

The machine body is attached with " " and " " stickers at

dangerous parts to emphasize safety instructions. With the full understanding of the

safety instructions, make sure to observe the following during machine operation:

1) Before using the machine, read this manual thoroughly and have a full understanding of

machine operation.

2) Get properly dressed. Long hair, necklace, bracelet, or wide sleeves might be fed into

the machine during operation. Wear slip-free shoes to prevent slipping on the floor.

3) Make sure that no one is working within the operating scope of the machine before

starting the machine.

4) Keep hands and head away from the machine parts where accidents might occur

(needle, hook, thread take-up, pulley, etc.) during operation.

5) Do not remove the safety cover which protects pulley and shaft during machine

operation for user's safety.

6) Cut the power supply before disassembling the electric box such as the control box, and

double-check that the power switch is "Off."

7) Make sure that the power switch is "Off" when the upper shaft is manually rotated.

8) Stop the machine when threading the needle or examining embroidery work after

embroidery is done.

9) Do not lean against the workbench and keep your hands away from the guide home of

the panto-graph. You may hurt your finger while the machine is in operation.

10) When the machine operates at the full speed, the noise level might go over 85db.

However, since this is only the standard value, to protect users and prevent disturbance

of other work by the noises, it is better to use ear plugs or install the soundproof device.

WARNINGCAUTION

WARNING