③ Assemble the thread holder angle with spool stand.

(Insert spool stand to the groove of thread holder angle frame)

④ Fix the thread holder angle frame to the spool stand with fixing bolts. (Use 4mm T wrench)

⑤ Fix the spool stand to the spool stand stud bolt. (Use 2.5mm L wrench)

※If the fixing bolts are not properly locked to the spool stand and the angle, the spool stand

and the angle may shake or vibrate and make the actual machine vibration seem stronger.

5 Runing Test

3) Test runing 600rpm with design.

4) Check if lower shaft bearin

bushin

has de

arted, drive is overheated, and noise from fra

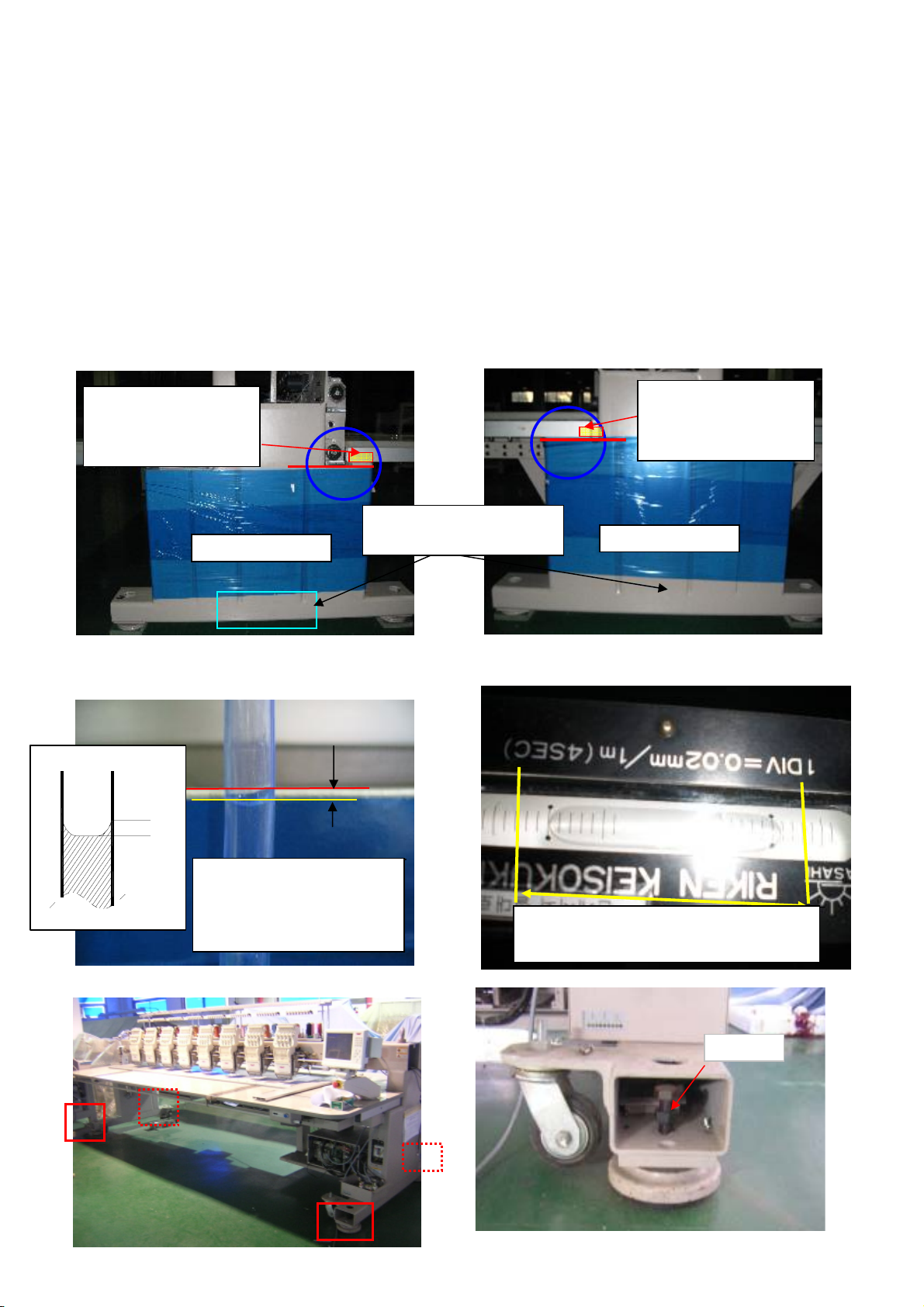

5) Check the vibration of machine.

6) Check the machine conditions after finishing the running test.

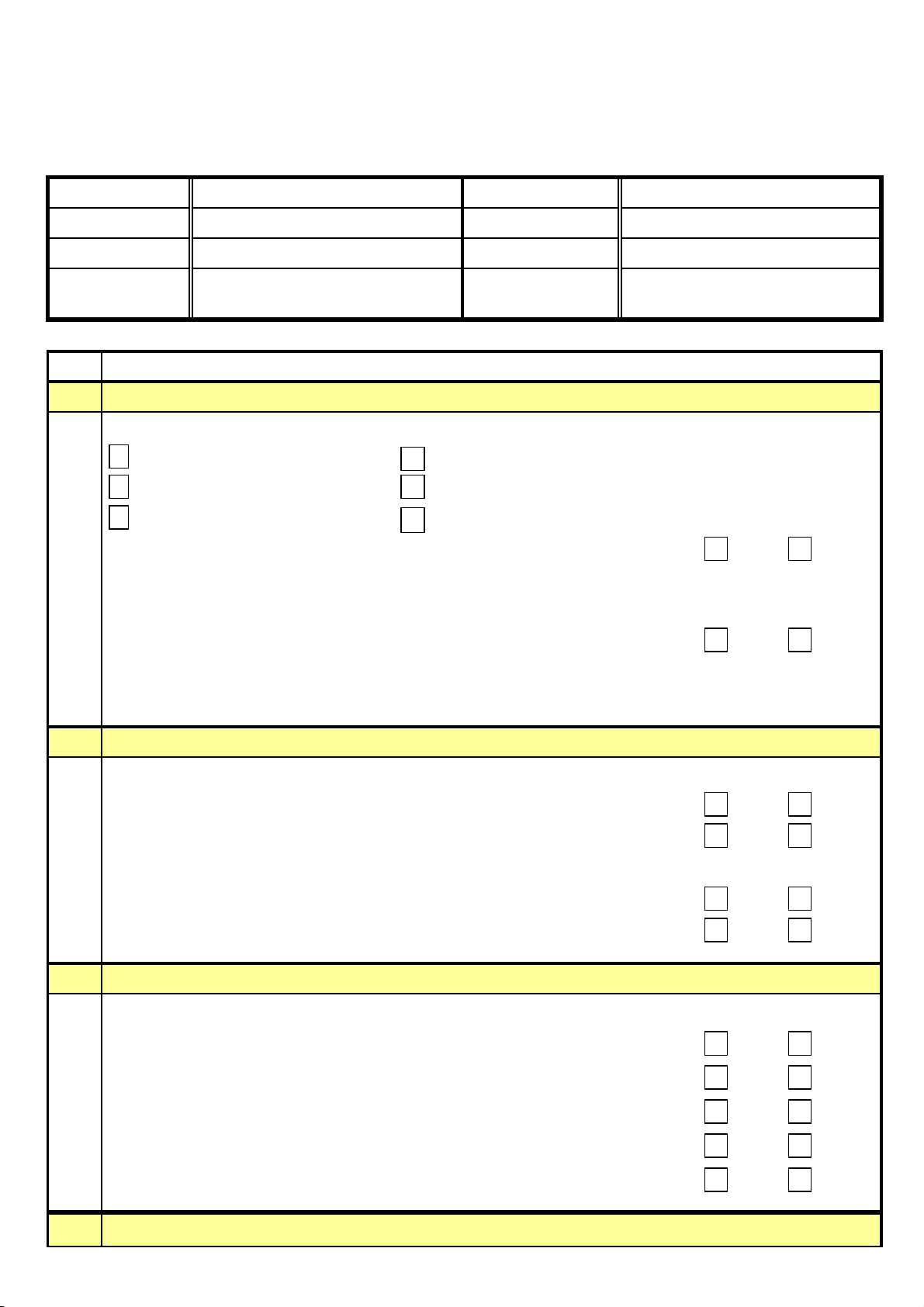

6 Check and adjust needle drop position

(1) Check the looseness of head.

1) Check the gap in between front and rear from the head at middle needle bar.

2) Change needle bar to the needle bar no.1 and check gap.

3 If there is a gap to front and rear of the head, use M3 L wrench to set the gap

to be within 0.1mm range (minimum). (Picture 10, 11 )

※ If the head gap/looseness is big/serious, thread cut and needle damage may occur.

If there is no gap/looseness, the part undergoes heavy load during C/C. Must be set

with the minimum gap/looseness.

(2) Check needle drop position.

1) Change C/C to Middle Needle Bar and Check Needle Position aroudn in 130~140˚.

--> Check Needle Spec. (DBK5#11) and Set it.

2) If it is not proper, reset it in middle needle bar and then check first and last needle bar.

(1) In case that needle drop position is in left and right

1) Check Needle Bar Position, Rotary Hook in first, middel, last needle bar.

(If Needle Bar Position, Rotary Hook is wrong, set it and then test runing.)

2) Cehck lubrication conditon in manual suply with 24cc in 10 times for ARM & BED.

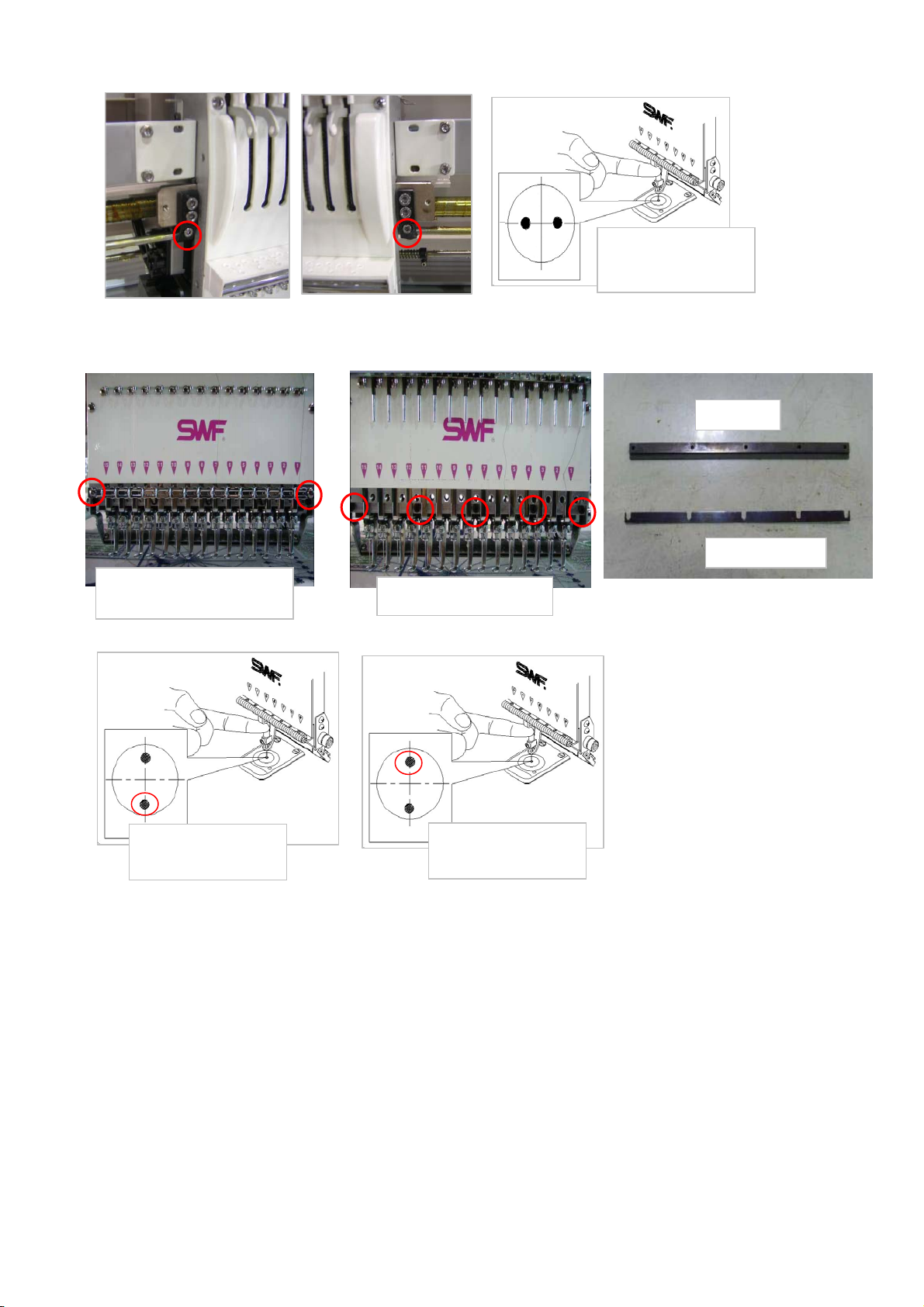

Head Rail Holde Fix

Bolt

Picture 10

Head Rail

Head Rail Holder

Picture 11

SUNSTAR Co.Ltd Page 5 Of 11 SWF CS Center