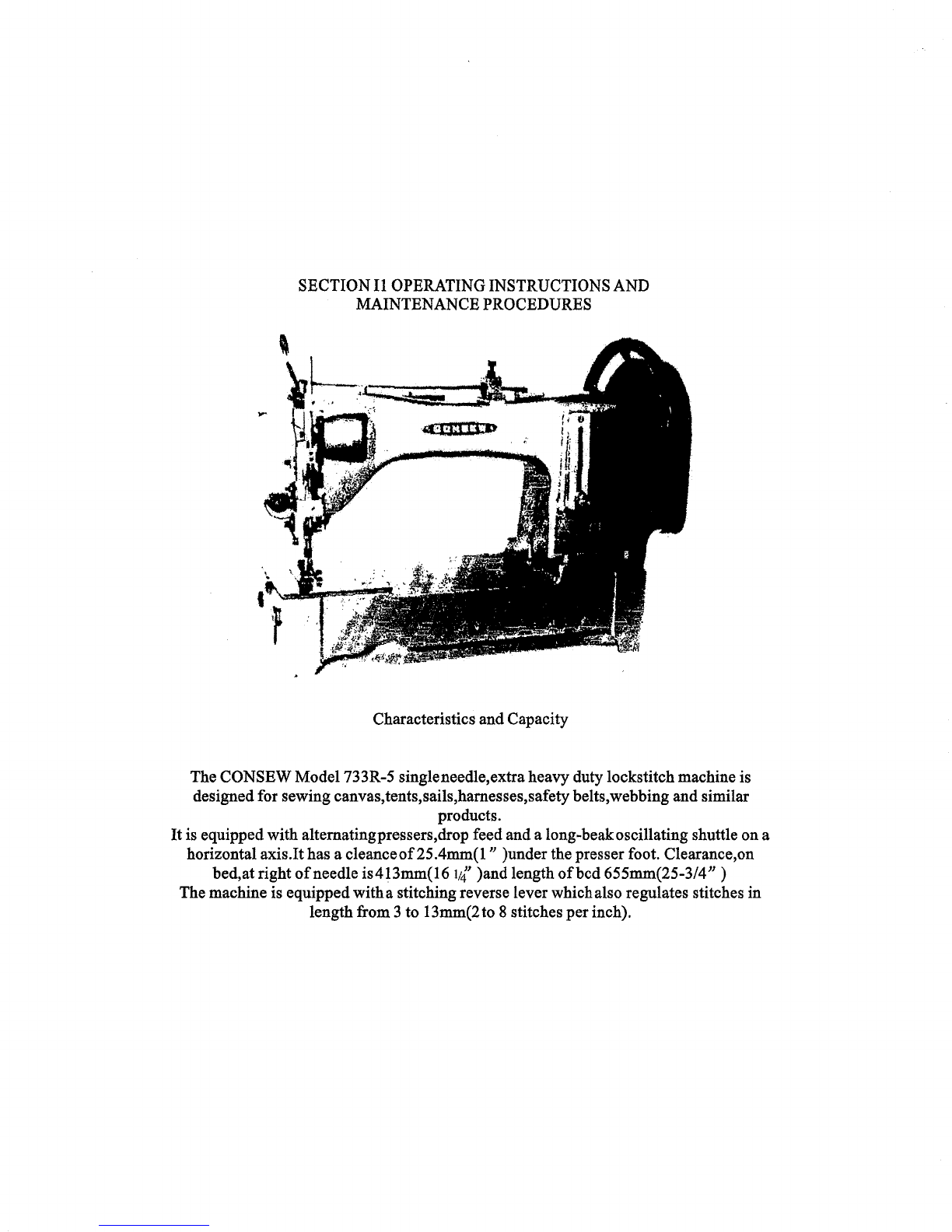

Consew 733R-5 Use and care manual

Other Consew Sewing Machine manuals

Consew

Consew 328RB-1 User manual

Consew

Consew P1206RB Technical manual

Consew

Consew 277RFS-3 Datasheet

Consew

Consew 133A-1 User manual

Consew

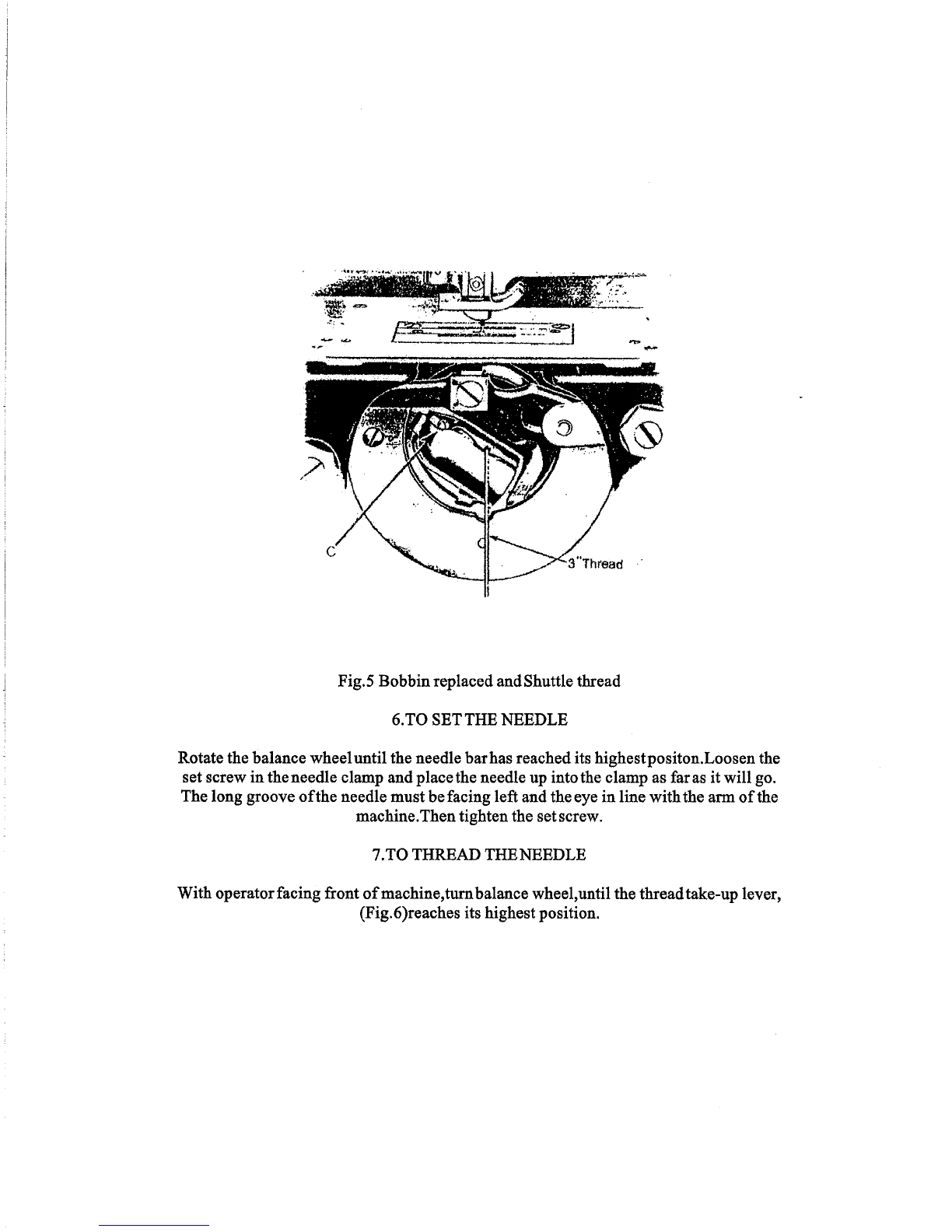

Consew 104-1T User manual

Consew

Consew 104-10T User manual

Consew

Consew 744R10-1 User manual

Consew

Consew CP206R User manual

Consew

Consew 315R-2 Parts list manual

Consew

Consew CN3115RB-1 User manual

Consew

Consew DLS600 User manual

Consew

Consew CN 2230 R Datasheet

Consew

Consew CN2053R-1A User manual

Consew

Consew 7360R-7DD Guide

Consew

Consew 206RB-5 User manual

Consew

Consew Sewing Machine User manual

Consew

Consew 328RB-1 User manual

Consew

Consew P1206RB-7 Technical manual

Consew

Consew 227r-2 Guide

Consew

Consew 318RK-2 Datasheet