Swienty

A/S

|Hørtoftvej

16,

Ragebøl

|DK-6400

Sønderborg

|Tel.

+45

7448

6969

|www.swienty.com | [email protected]Swienty

A/S

|Hørtoftvej

16,

Ragebøl

|DK-6400

Sønderborg

|Tel.

+45

7448

6969

|www.swienty.com | [email protected]Page 2

Contents

Read before use .................................................................................................. 3

Description .......................................................................................................... 4

Packing list DANA api MATIC 1000 ................................................................ 4

Operation............................................................................................................. 4

Key overview ................................................................................................ 5

The Display..................................................................................................... 5

Anti-drip operation.......................................................................................... 6

Speed regulation of the motor ......................................................................... 6

Pumping ......................................................................................................... 6

Preparing the machine ....................................................................................... 7

Preparation for dosing..................................................................................... 8

Calibration .................................................................................................... 10

Cleaning ............................................................................................................. 11

Possible konfigurations ................................................................................... 15

Antidrip mounting............................................................................................. 16

The Menu .......................................................................................................... 17

Parameter .................................................................................................... 17

LOG ............................................................................................................. 19

Language...................................................................................................... 19

RESET .......................................................................................................... 19

Functional Diagram ...................................................................................... 20

Programming default values .......................................................................... 21

Maintenance...................................................................................................... 22

How to install a new seal ............................................................................... 22

Plug socket connections................................................................................... 23

Fittings and extra parts .................................................................................... 24

Exploded view................................................................................................... 26

FAQ..................................................................................................................... 27

Conversion Table.......................................................................................... 28

Air in the honey ............................................................................................ 29

Quick Start ......................................................................................................... 30

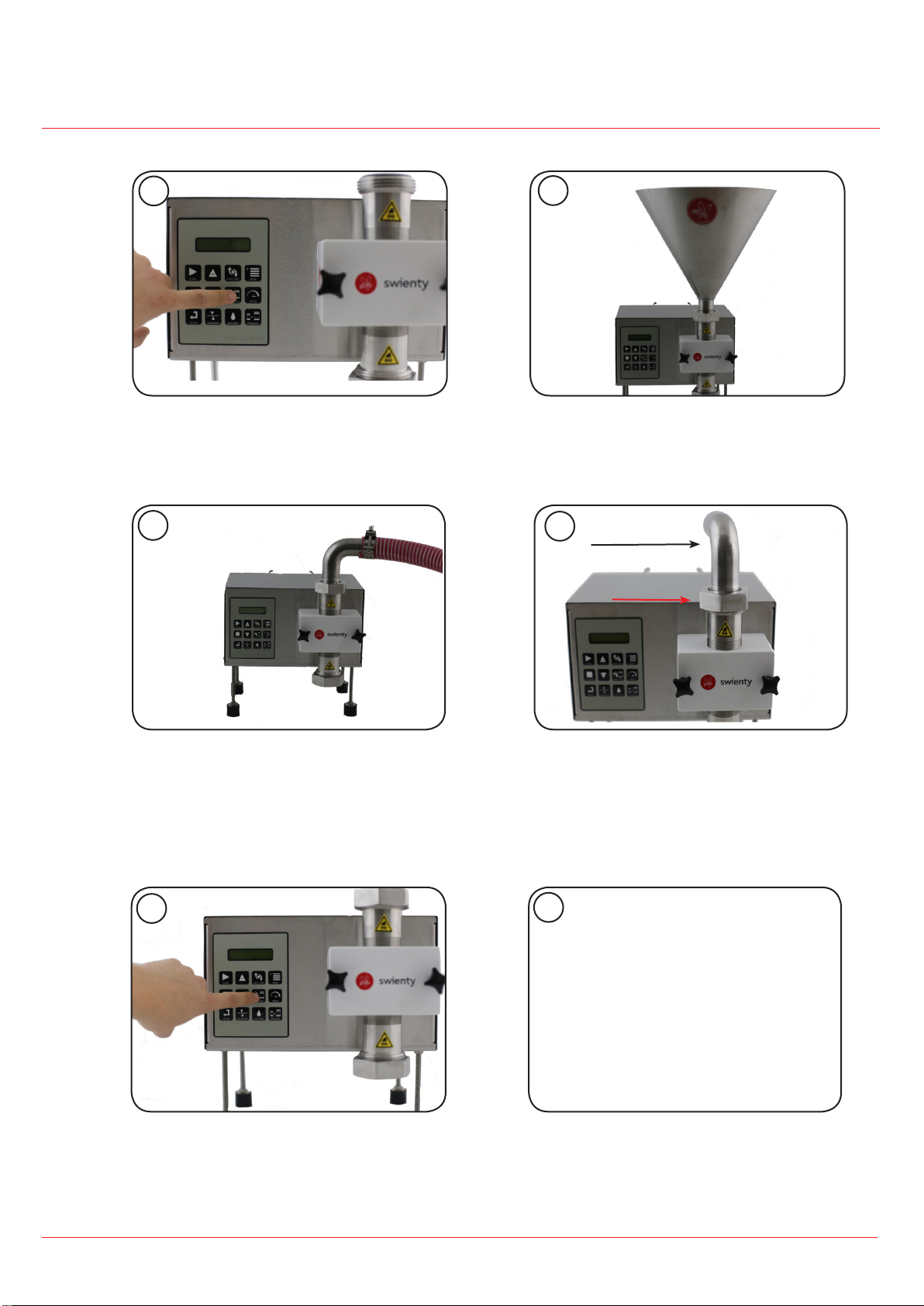

Installation .................................................................................................... 30

Set the filling weight...................................................................................... 31

Calibration .................................................................................................... 31

Anti drip ....................................................................................................... 31

Speed regulation of the motor ....................................................................... 31

Pumping ....................................................................................................... 31