2

2.2 SAFETY MEASURES

Before putting your equipment into operation, read this instruction manual carefully. Incorrect handling by untrained persons can cause

serious accidents.

Do not make adaptations or improvisations; they compromise your equipment and put your security and that of third parties at risk. Any

modifications or adaptations you make are at your own risk and this voids the warranty.

Do not allow the presence of children, the elderly, people with special capacities or animals near the equipment during its use,

maintenance, and even during storage.

Always keep the equipment in perfect condition.

When transporting your equipment, verify that the coupling to the vehicle that will tow it is correct. Do not exceed 25 km/h.

If, due to the needs of your work with this equipment, you need to travel on federal or state highways, follow the road regulations. Keep

hands, feet, and loose clothing away from moving parts.

When disconnecting your equipment make sure it is done on flat and firm ground.

Do not allow the operator of the equipment be under the influence of alcohol, drugs, or medication, it is very dangerous.

Do not operate the equipment in an enclosed area for a long period of time as the engine generates carbon monoxide.

Follow the instructions on the labels affixed to the equipment.

Avoid accidents due to lack of knowledge and not following the safety rules described in this manual.

WARNING!

Engine exhaust gases contain carbon monoxide, which is harmful and can cause death.

Do not run the engine inside a building or an enclosed area.

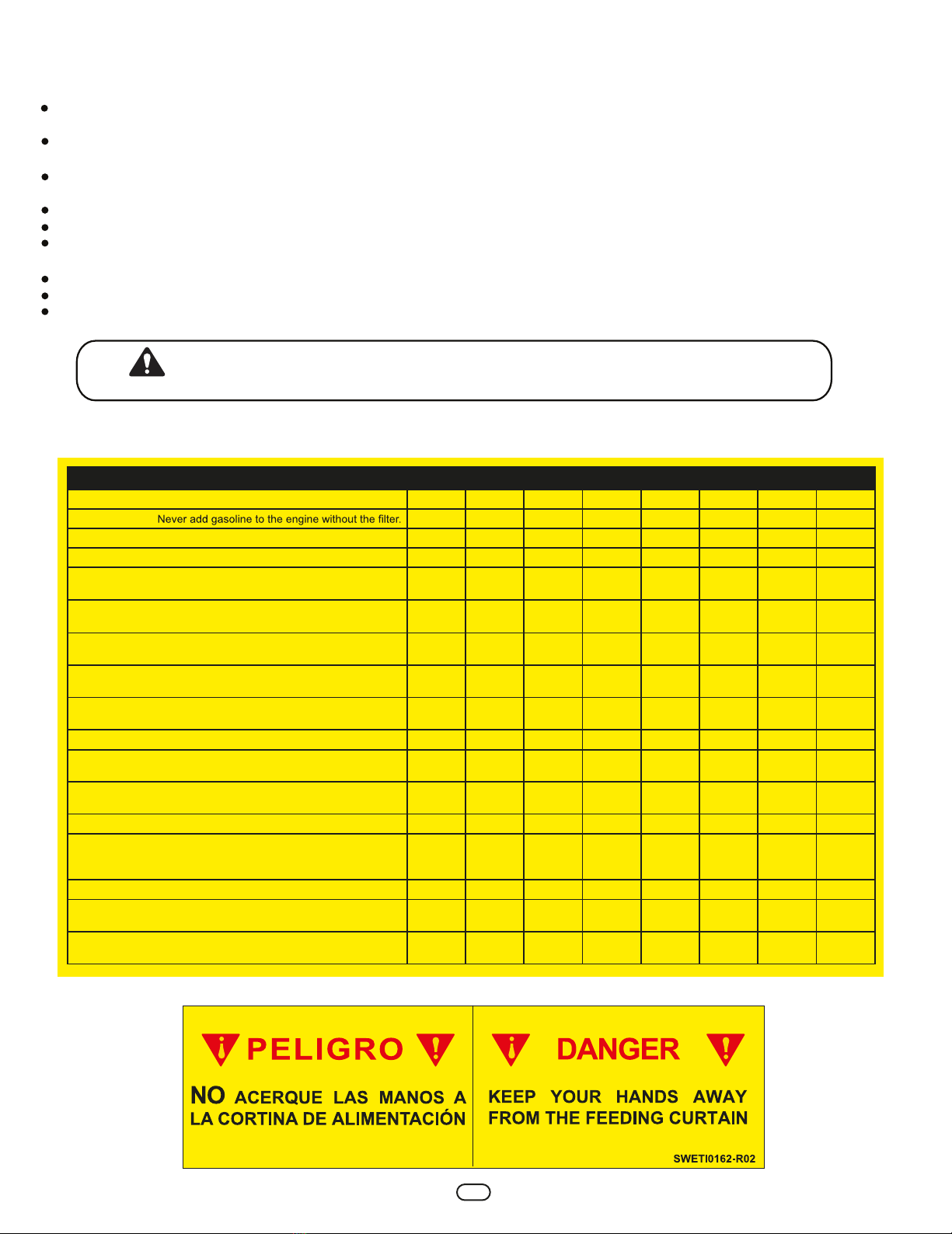

IMPORTANT!

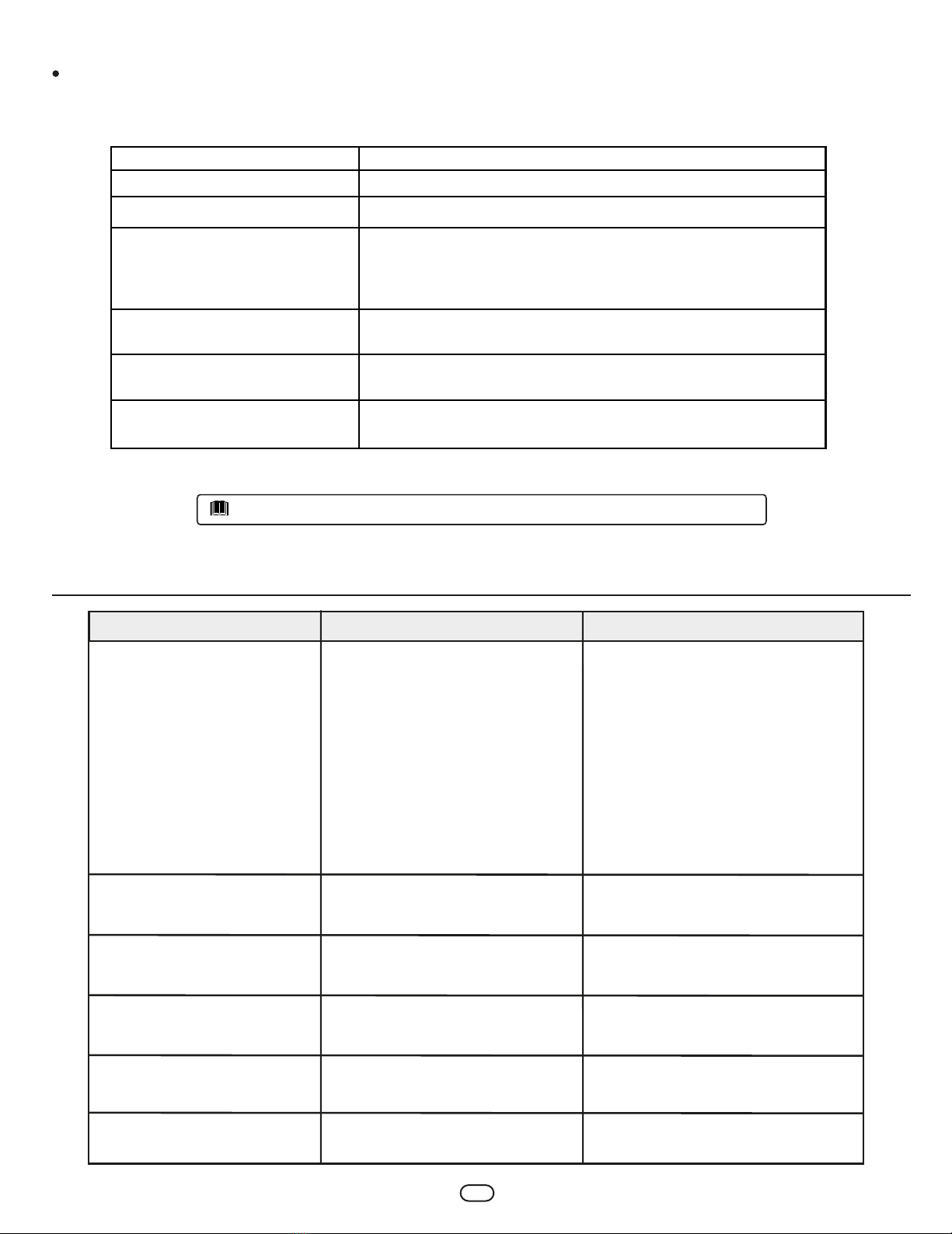

610200 610300 610350 610370 610500 610510 610540 610550

X X X X X X

Never start the engine without checking the oil level. X X X X X X

Do not touch the exhaust protective cover and do not remove it. X X X X X X

Do not work in very windy conditions. Avoid material

covering cooling slots. X XXXXXX

Start the engine with the belts slack and never remove the

protection. XXXXX XX

Never run your engine tilted more than 15º, because

the engine can break down X X X X X X

Do not exceed 540 RPM on the tractor PTO. Always keep the

gearbox level and constantly check that the belts tension is correct. X

Always engage the PTO at low revs and go up

gradually until 540 RPM is achieved. X

It is forbidden to put your hands beyond the feeding curtain. XXXXXXXX

Do not introduce materials not indicated in the user’s manual and

alternate the feeding in both ports to avoid overloading. XXXXXXXX

When grinding dry material, use the feed port on the opposite side

from where the engine is placed. XXXXX XX

Do not use the screens when grinding green material. XXXXXXXX

If you transport the equipment, make sure not to exceed 25 km/h.

Always check the air level in the tires and lubricate the wheel hub

periodically.

XXXXXXXX

Grease the bearings at the end of each working day XXXXXXXX

Always use appropriate personal protective equipment. Avoid using

loose clothing XXXXXXXX

Continuous operation of the equipment should not exceed 50

minutes with a 10 minute break. X X X X