MODEL 3000-STDX, 3000-LX / WAND OPERATION / PAGE

OF 4

CARE OF THE SENSING WAND AND THE PHOTO-FIBER-OPTIC SENSOR

1. After each day's use extend the wand sections completely and wipe all surfaces dry. This

will reduce corrosion and prevent future difficulty in lengthening the sections. If possible

allow the sections to completely air dry before collapsing and storing the wand. A light film of

oil or silicone grease will help the sections slide and helps to prevent the normal corrosion

which occurs.

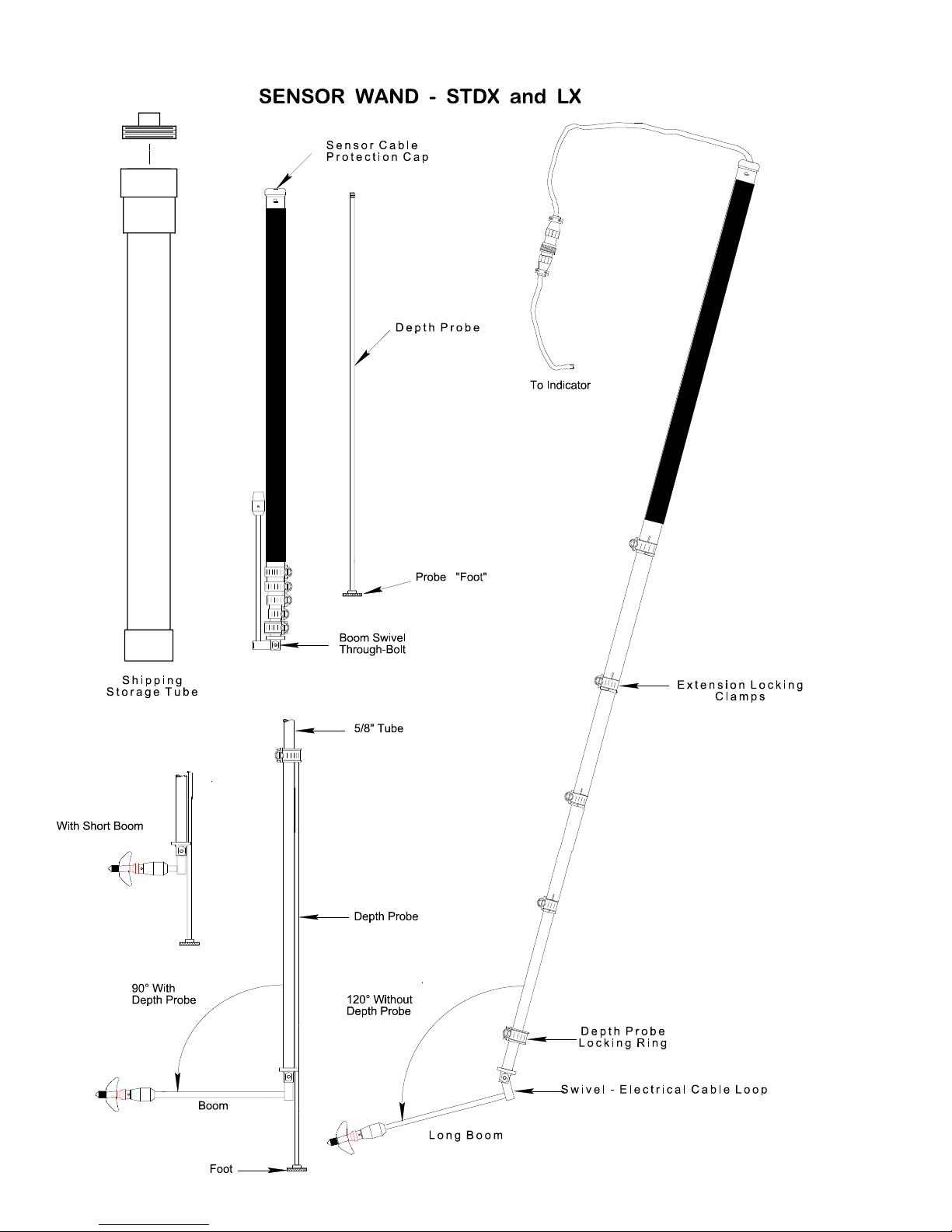

2. Treat the sensor boom gently. When swiveling into and out of position grasp only the BOOM,

not the SENSOR BODY or PROPELLER ASSEMBLY. The sensor swivel can be tightened by

adjusting the through-bolt and nut (see back page diagrams).

3. Take care that the electrical cable loop which passes through the sensor swivel does not

protrude from the groove provided for the cable. Carefully take up the slack in the cable when

the loop extends beyond the back side of the swivel bar.

4. The electrical connector is water resistant at the mating faces only and then only when the

two halves are mated. Keep both ends as dry as possible when not in use.

CARE OF THE 3000 (2100) SENSOR

The Sensor of the Model 3000 Current Meter is the single most important part of the

instrument and great care must be observed for its continued accurate output.

Keep the Sensor/Propeller assembly above the stream bed when taking readings and avoid rocks and other

hazards when moving from one measuring site to another. This will prevent damage to the Rotor, Rotor

Shaft, Propeller and the Sensor Body.

Never transport or store the sensor wand with the propeller rotor installed.Use the 1/16" hex

screwdriver to loosen the set screw and remove the entire rotor assembly when not using the Model 3000.

Always replace the batteries in the Model 3000 Indicator with fresh ones.

1. During rough use check the propeller frequently for frayed leading edges and for cracks. Chipped or

cracked props should be replaced. Frayed leading edges can be brought back to acceptable levels of

operation by reshaping them with 150 grit (or finer) sandpaper. Propellers which show signs of being

bent or misshapen should be discarded.

2. Rotational friction is by far the biggest cause of erroneous data especially at velocities below 2 feet

per second. Check the freedom of rotation frequently especially in turbid water or after rough

handling. In some measuring situations it may be necessary to completely disassemble the rotor and

clean the parts with clear water after each immersion. Use spare rotor assemblies and interchange

them often. Never leave the rotor assembly attached to the sensor after taking readings.

3. Water is the lubricant for the 2100 rotor. "Canned air" and spray type degreasers should be used to

regularly clean the "bore" of the Rotor (2100-A27) and the polished surface of the Rotor Shaft (2100-

A26). Avoid oil & grease if possible.

4. The Rotor Assembly (2100-A21) should spin very freely when held in the vertical position (propeller

pointing up) and simply blow lightly on the propeller. If it does not, clean the bore of the Rotor and

the surface of the Rotor Shaft thoroughly.

One method to determine an acceptable level of low-velocity performance by a particular Rotor

Assembly is to perform a "Spin Test":

Install the Rotor on the sensor, connect the sensor to the Indicator, and place the Indicator in the

COUNT mode. With the propeller pointing upward, blow very hard straight down on the propeller. At

the instant you stop blowing hit the ENTER key on the indicator and allow the rotor to coast to a stop.