Contents Page 3/57

Installation and starting instructions

Contents

I. Generality...................................................................................................................... 5

1) Scope ................................................................................................................................5

2) FCC conformity...................................................................................................................6

3) Use of the document ..........................................................................................................7

4) Symbols and signs ..............................................................................................................7

5) Storage and transport .........................................................................................................8

6) Packaging ..........................................................................................................................8

7) Warranty ...........................................................................................................................8

II. Safety and environmental instructions ......................................................................... 9

1) Use of the equipment .........................................................................................................9

2) User obligations .................................................................................................................9

3) Risk prevention ..................................................................................................................9

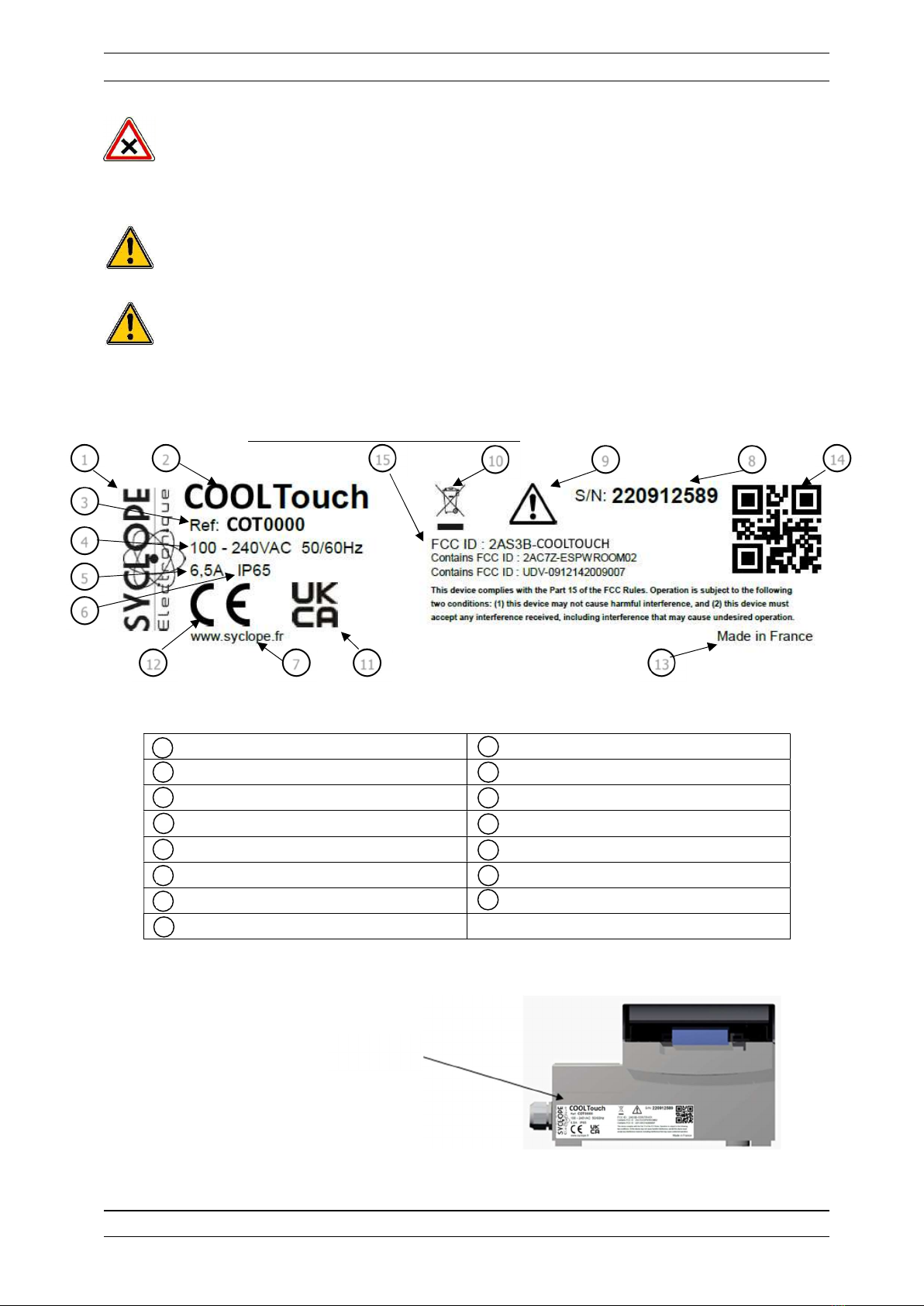

4) Identification and location of nameplate ............................................................................ 10

5) Disposal and conformity .................................................................................................... 11

III. Technical characteristics and functions ......................................................................12

1) Technical characteristics ................................................................................................... 12

2) Main functions .................................................................................................................. 13

3) Radio technologies in equipment ....................................................................................... 13

4) Parameters and measurement scales ................................................................................. 13

IV. Installation et connections .........................................................................................16

1) Installation conditions ....................................................................................................... 16

2) Wall installation of the device ............................................................................................ 16

3) Open / Close transparent door .......................................................................................... 17

4) Open / Close the terminal cover ........................................................................................ 17

5) Tightening torque ............................................................................................................. 18

a) Cable gland ............................................................................................................. 18

b) Terminal blocks ....................................................................................................... 18

6) Electrical connections ....................................................................................................... 18

7) Changing the internal fuse of PO1 output .......................................................................... 19

8) Primary power connections ............................................................................................... 20

9) Measurement inputs connections ....................................................................................... 21

a) PT100 / Pt1000 input RI1 ........................................................................................ 21

b) Conductivity input RI2 ............................................................................................. 21

c) Isolated analog inputs 4…20mA AI1 & AI2 ................................................................ 22

d) Digital inputs DI1 to DI5 .......................................................................................... 23

e) Serial input SI1 ....................................................................................................... 24

10) Self-powered relays outputs connections PO1 .................................................................... 25

11) Potential-free relay connections (FO1 to FO4) .................................................................... 25

12) Electronic relay outputs connections RO1 ........................................................................... 27

13) 4…20mA outputs connections (AO1 to AO2) ...................................................................... 28

14) Power supply output connection (PWR) ............................................................................. 29

15) RS485 communication bus connections .............................................................................. 30

a) Connection to a USB port on a computer .................................................................. 30

b) Polarization and termination of the RS485 bus .......................................................... 31

V. General use .................................................................................................................32

VI. Commissioning the SYCLOPE COOLTouch® ................................................................33

VII. Display mode and type................................................................................................34