ESKA ERG-SR Service manual

1

MODEL ERG-SR

GAS PRESSURE REGULATOR WITH DIRECT

EFFECTIVE SAFETY SHUTDOWN SYSTEM

INSTALLATION, USE AND MAINTENANCE MANUAL

“Read carefully before all procedures and follow the instructions. Do not carry out any procedure

unspecified in this manual.”

“Retain this manual for future references.”

“The products must only be installed by authorized people.”

“This product must be assembled in accordance with current regulations and guidelines.”

ESKA VALVE A.Ş

Sakarya 1. Organize Sanayi Bölgesi Mahallesi, 11.Cadde, No:6-8, Arifiye /Sakariya/TURKEY

Telefon: +90 (264)502 54 34-35 Fax: +90 (264)502 54 84 E-mail: [email protected]

Web: www.eskavalve.com

The right to change this manual in accordance with the technical developments is reserved. 2014/68/EU Pressure Equipment Directive

has been applied and the manual has been prepared accordingly.

2

1-GENERAL WARNINGS AND REQUIRED CONTROLS

Please read this instruction carefully before proceeding and do not perform undefined operations, use the product in

accordance with the information contained in this instruction manual and its label, otherwise the product may not operate

properly, or be injured or damaged. All operations described in this manual should only be carried out by qualified

personnel who have been approved by the competent authorities.

End users and unauthorized persons should read this instruction, comply with all safety rules that may concern them, in

any case not to interfere with the product or even to interfere, to change the setting and to try to make physical entry, to

detect malfunction or gas leak. The regulator must close the inlet valve on the front and inform the relevant gas

distribution company and the specialist. The regulator is not allowed to smoke or fire until 2 meters away.

Do not start operations without accessing and reading this instruction. If you cannot reach this instruction, there are topics

that are not understood, unknown or sure before starting any operation, or you cannot carry out the operation if you

follow the instructions written in the instructions during operation and if you are having problems, please contact us or

our representative.

For all operations in this order and during use; Use appropriate tools and methods. We ensure that products or boxes are

not dropped, thrown, shaken, overburdened, force and impacted, not crushed, no weight placed on them, no damage to

external parts and external protrusions, no heavy loads and no overturns in all processes and use.

During any operation, before, during and after all use of the product; provide to take all necessary precautions including

personal protection, take the necessary legislations, regulations, procedures in accordance with the technical standards

and rules of the gas organizations, take all necessary precautions against the risk of fire, take in the inhalation of the gas,

take the necessary legal precautions, inform and warn all the interested parties about the transactions, take precautions

against hazard combinations, take adequate precautions against possible flushing of liquids in line, prevent foreign matter

from entering the discharge hole, avoid explosion and fire-related substances such as fire, sparks and cigarette smoke due

to combustible gas and to not used.

Parts other than those supplied with the product and box that are not original and do not belong to my company should

not be used. Contact us to supply spare parts. All necessary actions and precautions should be taken in consideration that

they may be exposed to natural phenomena as Product earthquake, flood etc.. At the end of its life, products must be

replaced with new ones.

Do not attempt to remove the product shut-off bracket and product bracket from the ground, allow mechanical damage

to be exposed, move to the right or to the left unnecessarily, and do not overstress during any stage and use in this manual.

Keep this instruction in a safe area after all operations. Failure, damage, accident etc. due to failure to follow the rules and

information in this instruction The manufacturer is not responsible for these situations. Do not exceed the technical limits

in this instruction.

2-OPERATION-TERMS OF USE AND TECHNICAL SPECIFICATIONS:

The gas pressure regulator helps the subsequent devices in the gas line to operate safely. The gas pressure regulator

maintains the outlet pressure within the tolerance range by lowering the inlet pressure to the desired / adjusted outlet

pressure and automatically detects the outlet pressure in the event that the outlet pressure does not reach undesirable

levels on the safety regulator, or automatically detects this situation, Has a high and low pressure gas safety shut-off device

3

associated with the ongoing gas pressure regulator. The gas pressure regulator may have a type of evacuation system

which is opened to the air if ordered. The auxiliary equipment of the regulator may temporarily evacuate the gas. In this

case, the necessary precautions regarding the gas to be evacuated must be taken before mounting. 84/5000

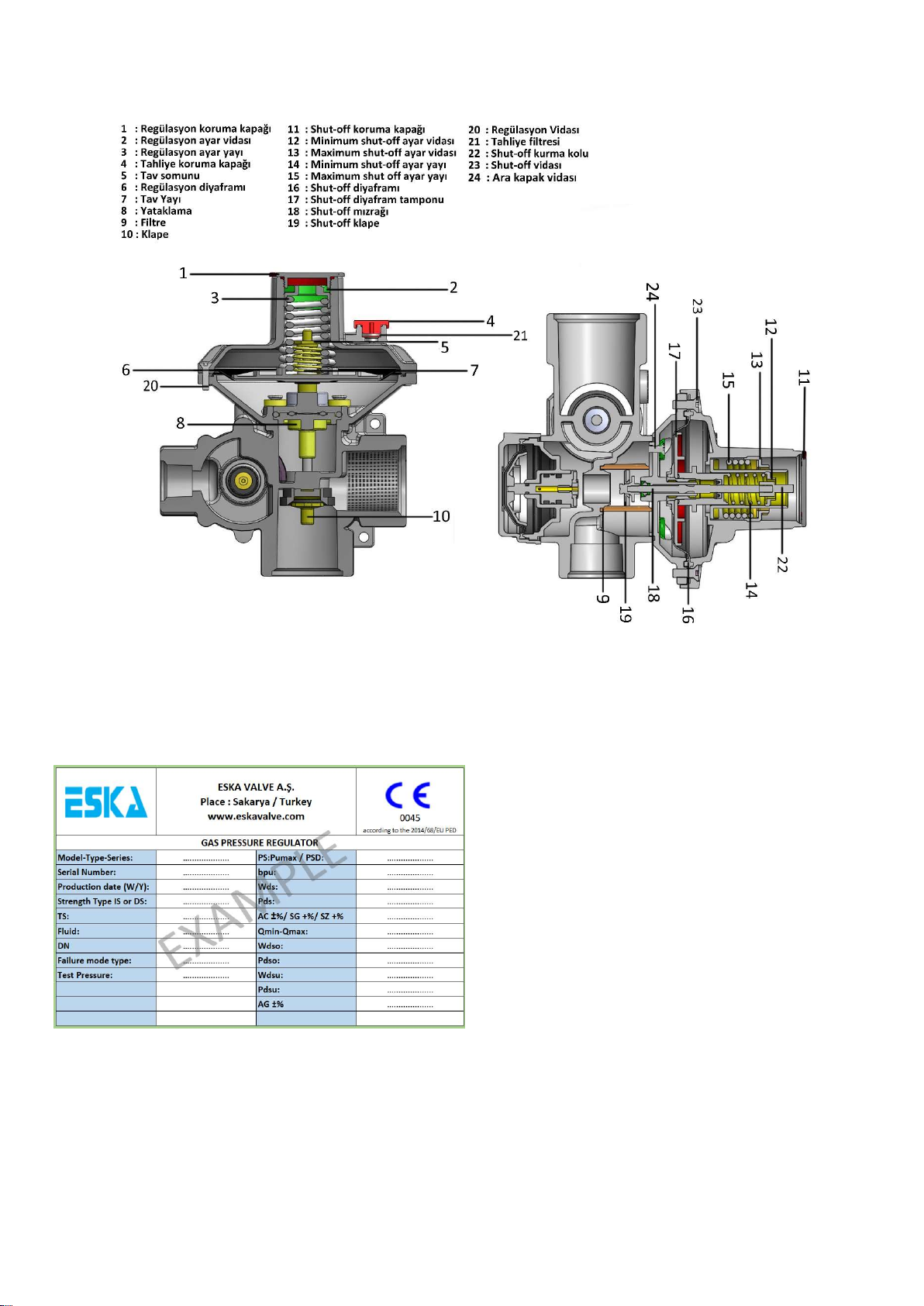

The detail of the safety closing and evacuation system on the product is shown in figure-3.

The gas pressure regulator is not pilot controlled, it does not have a controller feature, it does not need a bypass unit to

operate it, it is not used as a backup control device, it is double stage, direct working principle, internal sensing and spring

drive

The technical specification ranges of the products are as follows. These values are output to product, outlet pressure, inlet

pressure range etc. Depending on the factors. The final technical information of the product is stated on the product label.

In no case should the following restrictions be used.

Area of Use: Service stations and service boxes on gas lines, commercial and industrial gas pipeline applications

Suitable Fluids: Natural gas, LPG and non-corrosive gases

Permissible Maximum Input Pressure: PS6, PSD0,6

Connection: Inlet DN25 threaded, outlet DN32 threaded (modular connection up to DN50 on request),

Operating Temperature Range: -10 ° C; 60 ° C or -20 ° C; 60 ° C or (LT version on request -40 ° C to 60 ° C)

Line Connection Directions: Inline Type and Angle Type

Accuracy Class - Output Pressure Tolerance: AC5 / AC10

Output Pressure Setting Range (Wd): 15-360 mbar

High Pressure Safety Closure Setting Range (Wdo): 35-520 mbar

Low Pressure Safety Closure Setting Range (Wdu): 8-250 mbar

Working Pressure Range (bpu): 0,5-6 Bar

Min and Maximum Flow (Qmin-Qmax): 5 m3/h – 100m3/h (Natural Gas)

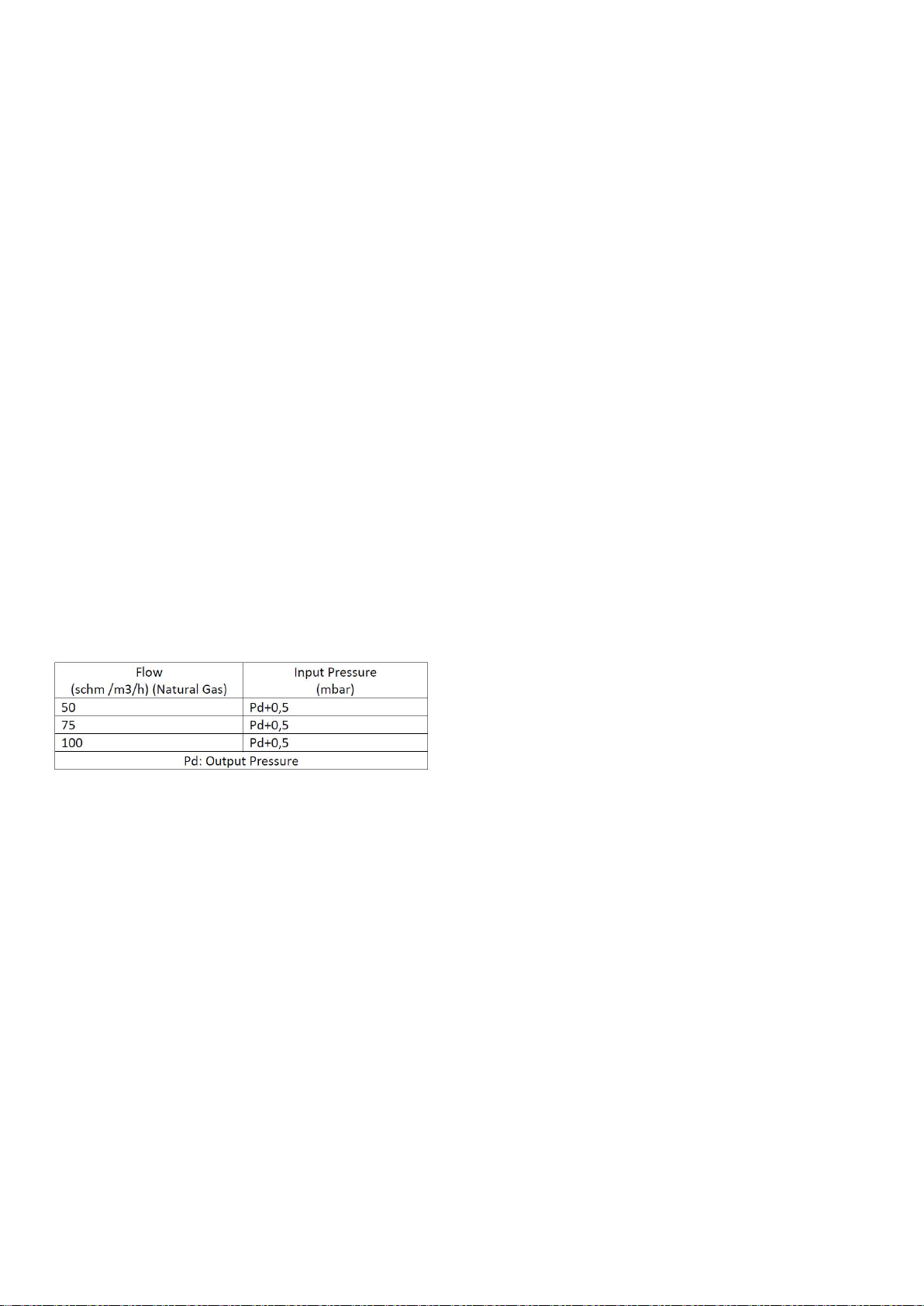

Flow Rate Parameters:

Natural gas is converted to LPG by multiplying by 1,2

4

Material Standards: Aluminum EN 1706, Rubbers EN 549, Brasses EN 12164-EN 12165

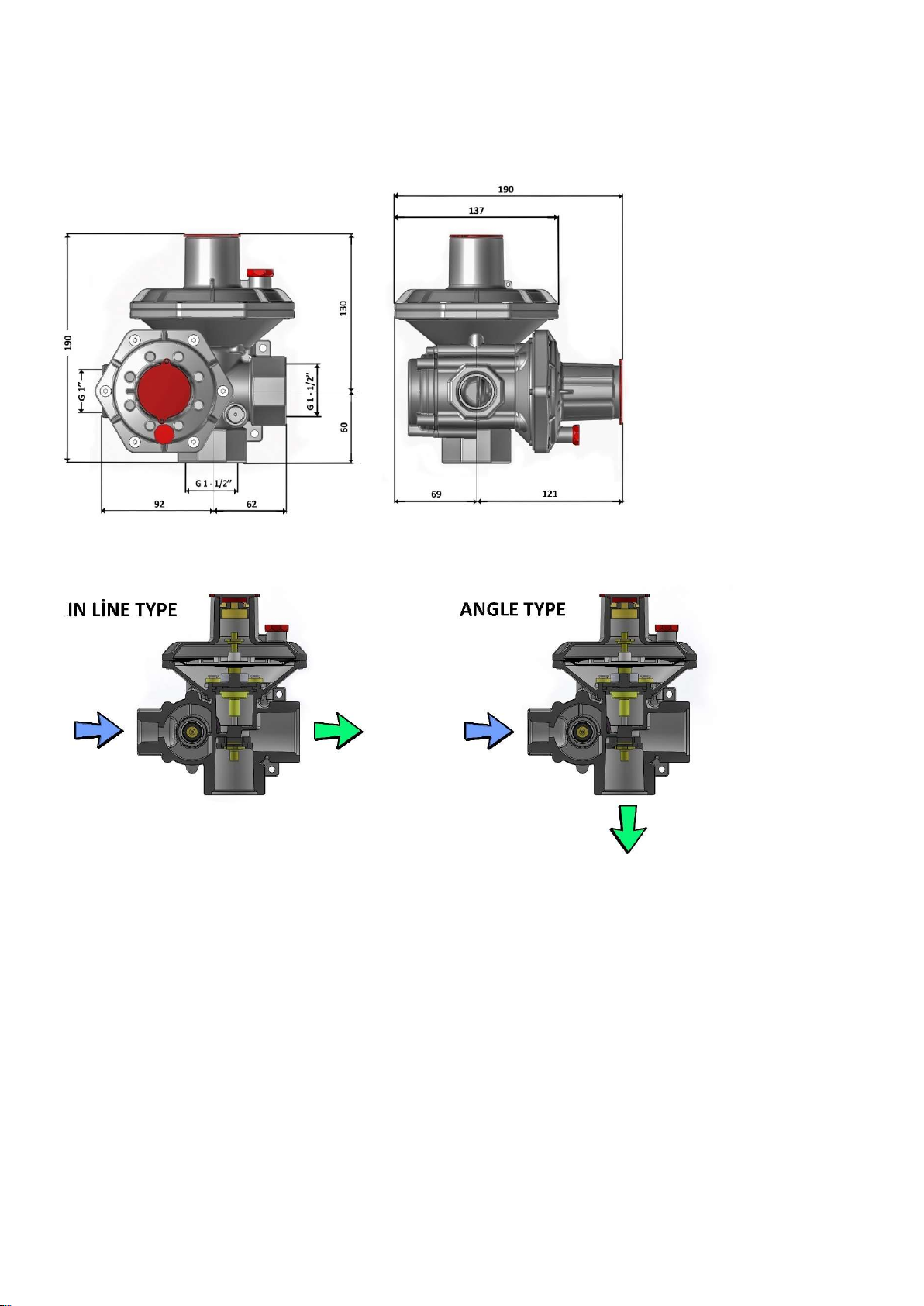

Figure – 3

3-MOUNTING

Determine which features should be used before mounting, and check that the correct selection is made by examining the

pressure and other information on the product label, especially with regard to labeling and labeling information, check the

product and accessories that may be on the box Input filter, way shut-off protective lid no.1, if equipped, protective tapes,

if available, pressure set seals no.4) (Working pressure range, outlet pressure, fluid, flow rate, environmental conditions,

clean line and fluid, selection of reciprocal connection type and diameter, compatibility of line and product dimensions

etc.)

There must be an inlet and outlet shutdown valve before and after the regulator to be installed. Ensure that there is no

pressurized gas trapped between the line and the product before and during mounting, and that the gas supply is

completely covered and opened. Before mounting, it should be checked that the line pressure is within the inlet pressure

range stated on the product label and that the regulator capacity will not be exceeded during use. Sufficient tampon

volume should be left at the line outlet after the regulator before assembly. For products with outlet pressures of up to

300 mbar, 1/500 nominal flow and 1/1000 nominal flow at outlet pressures above 300 mbar are recommended. Necessary

precautions should be taken to avoid sound and vibration from the line. It should not even be misplaced. Clamp on the

line side to reduce the torsional and torsional loads from the pipeline and the shake at the line inlet and outlet before

mounting etc. Take appropriate precautions by means of roads, even at short distances at the entrance and exit of the

product, make sure that there are no diameter reductions and expansions, testing, maintenance, dismantling etc. Ensure

that the required dimensions and areas are ensured by considering the subsequent operations, in each case check that

the product inlet pressure is higher than the product outlet pressure, clean the inside of the pipe with compressed air

when the product is not yet installed and the welding particles, dirt etc. Remove foreign objects, generally check the line

and system for pressure and tightness, ensure that the external filter is installed before the gas pressure regulator to filter

5

the gas, ensure that the products are directly exposed to external environment and external corrosion conditions (sun,

rain, snow, humidity, water, Etc.) with the necessary precautions so that they are not exposed to any external damage and

impact (e.g. into the protective box)

To start the mounting; manually remove the input-output connection protection tapes, if the additional modular

connection is present, manually insert the molded input and output seals into the input and output connection ports

(always use approved and new gaskets) and set the flow direction of the product so that the gas flow direction is indicated,

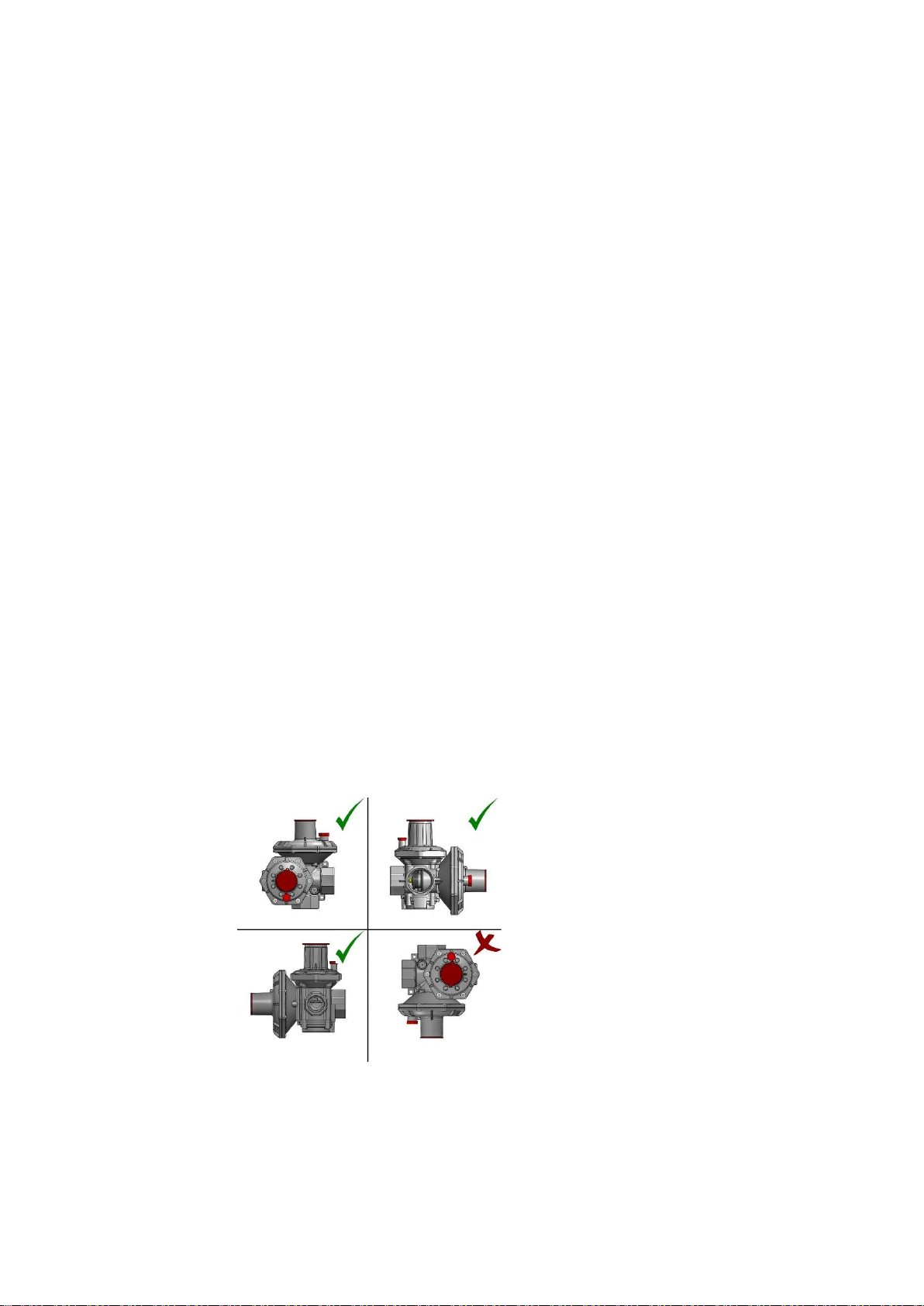

the product mounting position does not look at the side where the outlet pressure adjustment part for dry gases is located.

An example of the vertical position in the horizontal direction by the slit is as shown in figure 1 and the flow lpg is the

downstream side of the regulator , ensure that the assembly components to be used during assembly comply with the

regulations and that the product will not be obstructed by the product or even the manual overload, and do not expose

the mechanical strut, tighten it as tightly as you can to ensure that the inlet and outlet connections of the product do not

leak outside without applying excessive force, force or impact using appropriate switches. After tightening, it is fully seated

in the groove of the connections and there is no cracking in the connections. check that there are no mechanical problems

and that there is no mechanical stress from the line, pipe and connector.

If fittings with a connection greater than the diameter of the connection on the product's body are to be fitted to the inlet

and outlet of the product for assembly, the forces and moments which are exceeded by the main connection diameter on

the body shall not be applied and the limitations should not be applied.

If the products are to be used in floor type applications, make sure that the products coated on the outer surface are used

properly. Appropriate precautions should be taken to prevent entry and also ensure that products are not used completely

in water or liquids. The exhaust line should be connected to the breathing console of the regulator when necessary. This

connection must be at least DN10 threaded. The threaded adapter that may be needed for this connection is required and

must be used. Gas pressure regulators with discharge system are required measures to transport the gas to be delivered

to the safe zone (e.g. at least DN 10 pipe to the outside atmosphere conditions of the gas to be evacuated) If the products

are to be used in floor type applications, make sure that the products coated on the outer surface are used properly.

Appropriate precautions should be taken to prevent entry and also ensure that products are not used completely in water

or liquids. The exhaust line should be connected to the breathing console of the regulator when necessary. This connection

must be at least DN10 threaded. The threaded adapter that may be needed for this connection is required and must be

used. Necessary precautions must be taken to move the gas pressure regulators, which are discharge systems, to the safe

zone of the gas to be evacuated. (E.g. a pipe of at least DN 10 to the outside atmosphere conditions of the gas to be

evacuated)

Figure-1

6

4-INSTALLATION, TRANSMISSION AND OPERATION

Before installation, check and make sure that all users and persons at the outlet are not in use, do not change the factory

settings. The factory settings are adjusted according to the desired values in the order specifications and are stated in the

model. The adjustment devices are sealed if requested in the order specification.

To start the installation; partially open the outlet valve on the line, slowly open the inlet valve on the line gradually, remove

the protective cover 11 by turning it clockwise by hand, in this case, 22 lightly pull the set-up without manually applying

excessive force, force and impact, verify that there is a gas flow at the outlet side for a few seconds while pulling it, pull

the set-up slightly further and then release slowly so that the product will be set up. If installation does not occur, repeat

the procedure. Once the installation has taken place, replace the protection cover 11 with the cover 22, in which case the

installation path 11 will move forward with the protection cover 11, which will not adversely affect the installation.

(Installation process figure-6).

If you encounter difficulty in pulling the 22-bolt-up bar during installation and encounter the closure of the bolt-hole,

opening of the inlet valve at a very small amount, not a full amount, allowing a small amount of gas out of the test nipple

in the outlet line. You can process transactions after processing nipple test. Replace parts.

After the product has been installed, the gas flow is at the exit, the gas line 22 is in the installed position, the gas can be

mixed into the atmosphere and the gas leakage can be detected by suitable foam, detector etc. check with the gauges,

inform the gas users about the gas usage.

Depending on the temperature difference during the set-up process or seasonal transitions, there may be momentary gas

outflow from the product discharge and this is normal. It is important that the gas output does not continue, and if it

continues, it may be considered a malfunction

If the installation process does not work, please go with us

After the installation;

For testing outlet pressure, high pressure shutoff, low pressure shutoff, discharge functions;

First of all, take all necessary precautions to prevent dangerous atmosphere on the side of the evacuation gas that may be

formed from the regulator before all the following operations and do not work in closed areas

Connect the pressure gauge and pressure source to the appropriate test valve on the outlet line of the regulator with a

tight seal. When the gas consumption is present in the regulator line, check the outlet pressure and check the

appropriateness within the tolerances. Close the outlet valve at the outlet of the regulator and wait for a while, and check

that the outlet pressure is stable and that the value is within tolerance.

Slowly increase the pressure in the pressure source and verify that the product is evacuating at the correct pressure. Slowly

increase the pressurized high pressure in the pressure source to the safety shut-off setting and check that the shut-off set-

up 22 is closed. Then reinstall the device, then close the inlet valve and reduce the pressure source under the pressure

outlet, and verify that the product automatically turns itself off.

Disconnect the pressure source, close the test valves, check that there are no external leaks on the line, and replace the

device by following the rules in this order

7

If the gas pressure regulator is closed for various reasons during operation, the inlet valve must be closed, the problem

must be identified and reinstalled according to the above rules. During the operation, the gas is not clean and the internal

leak due to the foreign objects on the line, obstruction of the breathing line, product failure etc. the outlet pressure can

increase due to the situation and the gas can be cut off by closing the product high pressure safety shutdown device.

During operation, if the outlet pressure of the regulator drops due to various reasons and reaches the set safety pressure,

the low pressure safety shut-off system will be activated and the gas passage can be closed. In either case, the product 22

maintains the starting position of the shut-off installation. In either case, the installation process must be re-established.

Note: In no case shall the operation of the product be caused to pass over to the inlet opening of the inlet opening of 6

bar and the outlet opening of the product to a pressure of more than 0.6 bar over the top cover, and this shall not be

allowed to ocur

Figure -6

5-PARAMETERS

For various reasons, if necessary, the product outlet pressure and safety shutdown pressure settings should be made as

follows.

The settings should not be changed by more than ± 10% and not beyond the limitations on the label.

The seals are removed if the product has the relevant setting parts. When pressure settings are made, the setting

mechanisms and springs should not be over-tightened or forced. To see the values of the settings, connect the pressure

gauge or manometer to a suitable test valve between the regulator and the outlet pipe. In all adjustments to be made, the

pressure increase in the clockwise rotations is reversed and the pressure decrease in the opposite directions. When the

outlet pressures are increased, the safety pressures must also be increased.

To change the output adjustment pressure; Remove the relevant seal if necessary, remove the way cover no.1 manually

by turning it counterclockwise; turn the adjustment ring 2 with the 27 mm hex key in the appropriate direction, mark the

adjustment pressure made.

To change the high pressure safety pressure; Remove the corresponding seal if necessary, remove the turn cover no.11

manually by turning it clockwise; turn the way adjuster ring no.13 in the appropriate direction with the 27 mm hex key,

mark the adjustment pressure made.

8

To change the low pressure safety pressure; Remove the relevant seal if necessary, remove the 11-way cover manually by

turning it clockwise; turn the 12-way adjuster ring into the appropriate direction with the 13 mm hex key, mark the set

pressure. Mark the adjustment pressure made.

After the setting changes made, please check with the appropriate methods in this manual that the specifications and

limits on the product are not exceeded. It is recommended that the setting devices be sealed after the relevant pressure

settings have been made or in order to ensure that the settings are not changed in the products for which usage has been

made. If this is the case, the seal inside the box can be used.

6-PERIODIC MAINTENANCE AND INSPECTION

Periodic maintenance-inspection period for healthy and safe operation of the regulator. Periodic maintenance-monitoring

intervals. To adjust the maintenance time according to the operating conditions.

The rules in this instruction must be complied with in all transactions. In no case do not discharge suddenly to clean the

line after the regulator or to make maintenance-inspection of the product.

For periodic care; Disconnect the product from the line in accordance with the dismantling rules in this instruction. If there

are, manually remove the seals on the inlet and outlet connections side and replace with new ones. Take out the cover

screws no 20 and 23 on the regulator with suitable tools in a way that there will be no contraction and remove the covers

manually. (If there is a paint, lacquering, etc. seal on the cap screws, do not perform these operations and maintenance,

send the product to our company) Do not disassemble the parts inside the covers that you have removed, keep the covers

as a group and clean them gently with a clean cloth.

22 by pulling the money by hand, raising the 17-up part, then 22-part then 17-part. Remove the 24-way screws and remove

the 9-way filter, replace it at the side, change the color in your color.

After changing the filter, using the same screws number 20 and 23, fix the screws to the same places by mutual tightening

without excessive force so that the screws will not contract and the holes are overlapped, make sure that it is not loose

and mechanically damaged. Assemble and install the product whose maintenance has been completed, according to this

instruction.

In no case do not perform maintenance operation while the product is on the line.

For periodic examination; Check that the inlet and outlet valves are open and there is pressure at the outlet. Suitable foam,

liquid, detector etc. Using methods, look at all external parts of the product, including connections, and check that there

is no external leakage and that there is no excessive noise and vibration in the line and the product. In addition, review

the "Output pressure, high pressure shutdown, low pressure shutdown, test of relief functions" described in the

installation section of this instruction, taking all relevant safety precautions.

After the relevant maintenance and inspection procedures, shut-off protection cap no.11, pressure adjustment seals, if

any, drain protection plug no.4, drain filter no.21 etc. Check that all accessories and apparatus are attached to the product.

Note: In all cases, make sure that the necessary lines are opened to the atmosphere, since there is not and will not be in a

closed area in all cases that may cause gas to exit from the product or the line.

If a problem is detected during periodic maintenance and inspection, necessary actions can be performed according to the

rules described in the breakdown section.

9

7-DISCONTINUE, REMOVAL AND REPLACEMENT

Before, during and after all disassembly and replacement, please observe all the rules and procedures required in this

manual. We ensure that there is no pressurized gas trapped between the line and the product before the dismantling and

replacing operations and also the product during the dismantling process, the gas supply is completely closed and the

possibility of opening is ensured.

Close the inlet and outlet valve on the line at the front and rear of the regulator and reliably discharge the trapped gas

between the line and the product, gradually from the area between the gas pressure regulator and the outlet valve. Do

not swing the input and output connections of the product without using excessive force and force using the appropriate

switch. If a new product is to be replaced, install and install the new product in accordance with this instruction.

Table-1

Problems and

Solutions

Proble

m

Code

Problem Transaction codes that will be performed In

order

P1 Dirty filter 10,11

P2 Self-organization 12,1

P3 Mechanical damage 1

P4 Failure in drying 13,9,25,1

P5 No gas flow 26, 3,14,15 ,16,18,10,11,5,2,4,25,1

P6 External leakage 16,18,1

P7 High exit pressure except tolerances

8,7,2,1

P8 Low exit pressure except tolerances

16,18,5,6,3,2,1

P9 Evacuation system mistakes 7,8,2,1

P10 Insufficient flow 3,10,11,4,2,1

P11 Shut-off mistakes 19,27,Measure the output pressure and

control that it is increasing, if it is, apply transactions

no.7,8,2. 20,21,25,1

P12 Missing accessory 23

P13 Sound and Vibration 24

8-TROUBLE-REPAIR-PROBLEMS AND SOLUTIONS

Before, during and after all breakdown procedures, please obey all the rules stated in this manual as necessary and take

necessary actions, especially inform the end users and take necessary precautions against pressure gas hazards.

In case of failure you are advised to perform the operations indicated in Table 1 according to the type of problem and if

you do not wish to do these operations and if you have not resolved the problem in question then you should remove the

product and disassemble the product according to the disassembly rules described below without further intervention, ,

Even install new products. Repairs, repairs and alterations shall not be made in such a way as to interfere with the internal

parts of the product other than the filter and spring change.

Repairs and repairs should be done in empty systems and products removed from the line.

10

9- DIMENSIONS, LINE CONNECTIONS AND PART INFORMATION

Dimensions are in mm

Table 1

Transaction Codes Explanations that can be applied with sequence during problem

1-New product exchange

2-Measure the output adjustment pressure and correct if it is faulty

3-Check that the wrong product is not selected as the flow rate and outlet pressure

4-Check that the inlet pressure is not below the pressure and the inlet pressure

5-Have traction on the capacity of the product check

6-Examine external leakage at the output line

7-Check that there is no excessive diameter contraction in the output line

8-Stop the gases flow at the outlet, close the inlet valve, then open it, re-engage the product and check the result

9-Remove and reattach the product and try again

10-Remove the product, remove and clean the filter, attach a new filter if necessary, mount the product back on the line.

11-Take precautions for line cleanliness

12-Confirm whether or not the product has automatic installation system

13- Check if the shut-off arm no.2 is closed, if it is closed check that there is no excessive contraction in the line outlet and

hold the way shut-off arm no.2 by holding the handle while continuing the installation, if necessary, loosen the removing

protection cover no.14, relieves the valve a bit, relieves the pressure squeeze out instantaneously, and then restore all

operations

14- Set up shut-off no.2 if the door is closed, replace the product and check the result

15- Check whether there is freezing in the water or in the water that might enter the product

16- If there is loose screw, check it regularly according to rules. (Do this if there is a seal on the screw)

18- If there is a leak from the outlet, check that there is no excessive diameter contraction on the outlet line. If there is no

problem, stop the outlet gas outlet, close the inlet valve.

19- Check whether there is traction and inclination in set up shut-off line the arm.

20- Check that there is no contraction in the output sensing line.

21-Adjust the shut-off setting pressure and correct if it is faulty.

23- Shut-off protection cap, if available pressure setting seals, if available way discharge protection plug no.14, if available

way discharge filter no.15 etc. Identify the missing pieces and insert the new ones manually.

24- Is the mounting position correct, whether there is fluctuation in the input pressure, the diameter at the close distance

on the output side is not wanted. Check for shrinks.

25- Try to install the product again.

If the 26-2 shut-off line is closed, inform all interested parties, ensure that no gas is used, and re-install the product in

accordance with the rules.

27- Flow in the outlet boiler, etc. Check if there has been a pressure increase due to sudden stop.

11

Figure-2

Figure-4

12

Figure-8

10-LABEL INFORMATION

Pds: Output Setting Pressure

Pdso: High Pressure Safety Closure Setting Pressure

Pdsu: Low Pressure Safety Closure Setting Pressure

13

Pdso: Evacuation Pressure

TS: Working Environment Temperature Range

PS: Maximum Resistance Pressure

Pumax: Maximum Input PressurePSD : Farkli Dayanimli Kisimlar İçin Maximum Dayanım Basıncı

PSD: Maximum Strength Pressure For Different Resistant Parts

Bpu: Input Pressure Range

DN: Connection Diameter

Qmin-Qmax: Minimum and Maximum Flow

Wd: Output Pressure Setting Range

Wdo: High Pressure Safety Closure Setting Range

Wdu: Low Pressure Safety Closure Setting Range

NG-LPG: Natural Gas-LPG

11-STORAGE-STORAGE-LIFTING-LOWERING-MOVE-LOADING-TRANSPORT

Do not remove the product from its original box and their sleeves unless the use is started, do not change the box and its

sleeve. Store the products and spare parts in closed and ventilated environments in clean room conditions. Ensure that

during transport, transportation and storage, products are exposed to rain, water, snow, extreme heat and cold. You are

protected from the circumstances. Ensure that the floors where the operations are made are flat and clean, not wet and

slippery. Do not overload and remove during transport. Pay special attention to external protrusions and external parts.

14

EU DECLARATION OF CONFORMITY

AB UYGUNLUK BEYANI

According to Pressure Equipment Directive (2014/68/EU)

Basınçlı Ekipmanlar Yönetmeliği’ne Göre (2014/68/AB)

Declaration Number

(Deklarasyon No)

DEC_012_R00

Manufacturer and Owner Of Certificate

(Üretici ve Sertifika Sahibi Adı)

ESKA VALVE A.Ş.

Trade Mark

(Ticari Marka)

ESKA VALVE / ESKA

Manufacturer Adress and Place

(Üretici Adresi ve Üretici Yeri)

Sakarya 1. Organize Sanayi Bölgesi Mahallesi, 11. Cadde, No:6-8,

Arifiye/Sakarya/Türkiye

Product Description

(Ürün Tanımı)

Gas Pressure Regulator With Safety Shutoff Valve

Emniyet Kapatmalı Gaz Basınç Regülatörü

Product Model / Type / Serie

(Ürün Modeli / Tipi / Seri)

ERG-SR Series

ERG-SR Serisi

Product Information

(Ürün Bilgileri)

PS6, PSD0.6 , TS: -10;60°C , -20;60°C , (LT version -40;60°C) , DN25xDN40

Threaded Connection (on request modular connection) , AC 5/10, SG 10/20/30, AG

10/20

PS6, PSD0.6 , TS: -10;60°C , -20;60°C , (LT versiyon -40;60°C) , DN25xDN40 Dişli Bağlantı

(istek üzerine modüler bağlantı) , AC 5/10, SG 10/20/30, AG 10/20

Declaration Issue Date

(Deklarasyon Yayın Tarihi)

01.11.2020

The name of the Notified Body and No

(Onaylanmış Kuruluşun Adı ve Numarası)

TÜV SÜD Industrie Service GmbH – 0036

WestendstraBe 199 80686 München/Germany

EU Conformity Assessment Method

(AB Uygunluk Değerlendirme Yöntemi)

2014/68/EU PED Category IV, Modul B+D

Modul B Certificate No / Valid Until

Modul D Certificate No / Valid Until

07/202/9280/Z/0040/18/D/0062 / 24.01.2028

07/202/9280/Z/0088/18/D0062 / 22.02.2021

Declaration

(Deklarasyon)

Up defined in our products, we declare that meets the essential safety requirements of the directives

to in this document. This declaration of conformity has been published under the responsibility of

Eska Valve A.Ş.

Yukarı da tanımlanan üzerinde seri no olan ürünlerimizin, bu belgede belirtilen yönetmeliklerin

temel güvenlik gerekliliklerini karşıladığını beyan ederiz. Bu uygunluk beyanı Eska Valve A.Ş. nin

sorumluluğu altında yayınlanmıştır.

Note

(Not)

The compliance with Directives applies only to the product if the product is integrated in a system

or combined with other units .The system manufacturer is responsible fort he compliance of the

complete system with Directives. By altering the device without approval the declaration would

invalidate.

Ürünün bir sistemle entegre olarak ya da diğer bir birimle birleştirilerek kullanıldığı durumlarda

direktiflerle uyumluluk yalnızca ürünü kapsar. Sistem üreticisi sistemin tamamının direktiflere

uyumluluğundan sorumludur. Onayımız alınmadan cihaz üzerinde değişiklik yapıldığında bu

beyan geçerli değildir.

Manufacturers Authorized Signature

(Üretici İmza Yetkilisi)

Erhan SARDAL

General Manager (Genel Müdür)

Sakarya/Türkiye, 01.11.2020

15

WARRANTY CERTIFICATE

The Manufacturing Company's;

Title: ESKA VALVE A.Ş.

Address: Sakarya 1. Organize Sanayi Bölgesi Mahallesi, 11. Cadde, No: 6-8, Arifiye/Sakarya/Turkey

Telephone : +90 (264) 502 54 34-35

Fax : +90 (264) 502 54 84

E-mail : info@eskavalve.com

Authorized Signature:

Company Stamp:

The Vendor's;

Title:

Address:

Telephone:

Fax:

E-mail:

Authorized Signature:

Company Stamp:

The Product's;

Type: Gas Pressure Regulator

Brand: ESKA / ESKA VALVE

Model-Series: ERG-SR

Warranty: 2 years

Maximum Time To Repair: 20 business days

Invoice Date and Number:

Date of Delivery to the Consumer:

Place of Delivery to the Consumer:

Banderole and Series Number:

16

TERMS OF WARRANTY

1) The warranty period starts with the delivery of the product and is 2 years.

2) The entire product, including all parts thereof, is covered by the warranty.

3) In such cases where the replacement of the defective goods by those free of defects would cause disproportionate challenges

to the Seller, the Consumer shall be entitled to either rescission of the agreement or a discount over the sales price in proportion

to such defects thereof. For determination of disproportionality, factors such as the value of the goods free of defects, the severity

of the defect, and whether resorting to other rights of choice would constitute any problem for the Consumer are taken into

consideration thereof. In cases where the Consumer chooses rescission of the agreement or a discount over the sales price in

proportion to such defects, the Seller shall be obliged to refund the Consumer the sales price of the goods in full or the discount

amount as applicable without delay. In case the Consumer chooses the replacement of the defective goods by those free of

defects, then the Seller, the manufacturer, or the importer shall be obliged to fulfill such a request within thirty (30) business

days from the date of notification for the replacement of such defective goods by those free of defects thereof.

4) In case the Consumer chooses the repair of the goods free of charge, among such other options, then the Seller shall be obliged

to perform or cause to perform the repair of such defective goods without any claim for workmanship cost, cost of replaced parts,

or any other cost or expense under any title whatsoever. The Consumer may also exercise its right of repair free of charge against

the manufacturer or importer thereof. The Seller, the manufacturer, and the importer shall be jointly and severally liable for the

Consumer to exercise such rights thereof.

5) In the case that the Consumer uses the right to receive free repair, if the product breaks down again within warranty period, -

if the maximum time provided for repair is exceeded, - if the authorized service station, Seller, manufacturer or importer

determines with a report that repair is not possible; the Consumer can request the refunding of the price paid for the product,

or price discount at the rate of the defect, or, if possible, replacement of the good with a faultless equivalent. The Seller cannot

reject such request of the Consumer. If this request is not fulfilled, the Seller, manufacturer and the importer are jointly and

severally responsible.

6) The maximum period of repair of defective goods is 20 business days. Such period commences on the date of notification of

the relevant defects in the goods to the service station or the Seller within its warranty period, or otherwise, upon delivery of the

defective goods to the service station in case the warranty period of the goods has expired. In case of any defects in the goods

within the warranty period, the repair period is added to the warranty period thereof. It is mandatory to determine whether such

defects are attributable to misuse by the Consumer by a formal report to be issued by the service stations, or otherwise, in case

such service stations are not available, by the Seller, the importer, or the manufacturer of the goods, respectively, as applicable

within the maximum period of repair of the goods, and provide the Consumer with a copy of such report thereof. The warranty

period of the replaced goods under warranty shall be limited to the remaining warranty period of the originally purchased goods

thereof.

7) The defects caused by usage of the product against the provisions of the user’s manual and failures caused by usage errors are

not covered by warranty.

8) The Consumer shall be entitled to refer to the Consumer Arbitration Committee or the Consumer Court of the Consumer’s

residence or of the jurisdiction where consumer proceedings take place in case of any disputes arising out of or in relation to

exercising the rights under such warranty thereof.

Table of contents

Other ESKA Controllers manuals