1-3-1 L0601DC

CABINET DISASSEMBLY INSTRUCTIONS

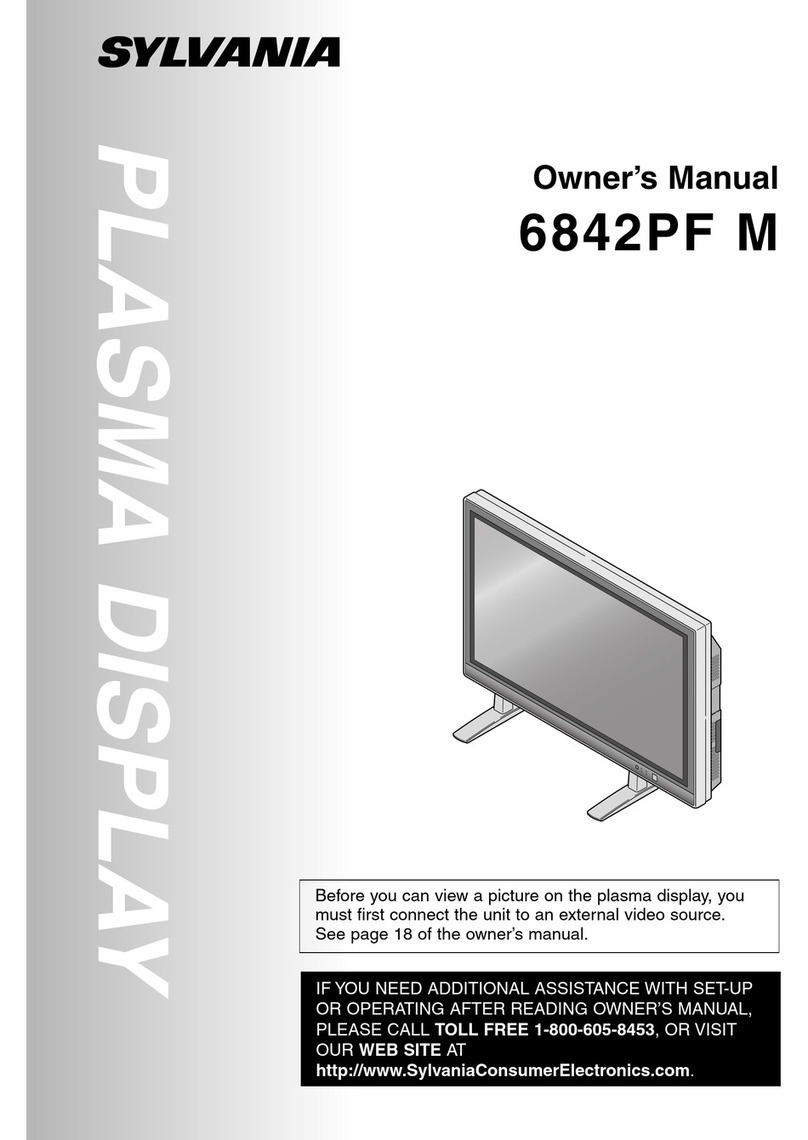

1. Disassembly Flowchart

This flowchart indicates the disassembly steps for the

cabinet parts, and the CBA in order to gain access to

item(s) to be serviced. When reassembling, follow the

steps in reverse order. Bend, route and dress the

cables as they were.

2. Disassembly Method

↓↓ ↓ ↓ ↓

(1) (2) (3) (4) (5)

Note:

(1) Order of steps in procedure. When reassembling,

follow the steps in reverse order. These numbers

are also used as the Identification (location) No. of

parts in figures.

(2) Parts to be removed or installed.

(3) Fig. No. showing procedure of part location

(4) Identification of part to be removed, unhooked, un-

locked, released, unplugged, unclamped, or des-

oldered.

S=Screw, P=Spring, L=Locking Tab, CN=Con-

nector, *=Unhook, Unlock, Release, Unplug, or

Desolder

2(S-2) = two Screws (S-2)

(5) Refer to the following "Reference Notes in the

Table.

Step/

Loc.

No. Part Removal

Fig.

No Remove/*unlock/release/

unplug/unclamp/desolder Note

1 Rear Cabinet 1 26(S-1) 1

2Front Cabinet

Assembly 2 14(S-2) 2

3 Filter Holder(L) 2 6(S-3) 3

4 Filter Holder(S) 2 6(S-4) 4

5 Optical Filter 2 ---------- -

6 Decoration Panel 3 14(S-3) 5

7 Front Cabinet 3 ---------- -

8 Jack Bracket 4 4(S-6) 6

9 Jack Holder 4 2(S-7), (S-8) 7

10 Jack CBA 4

10 2(S-9), *CN751 8

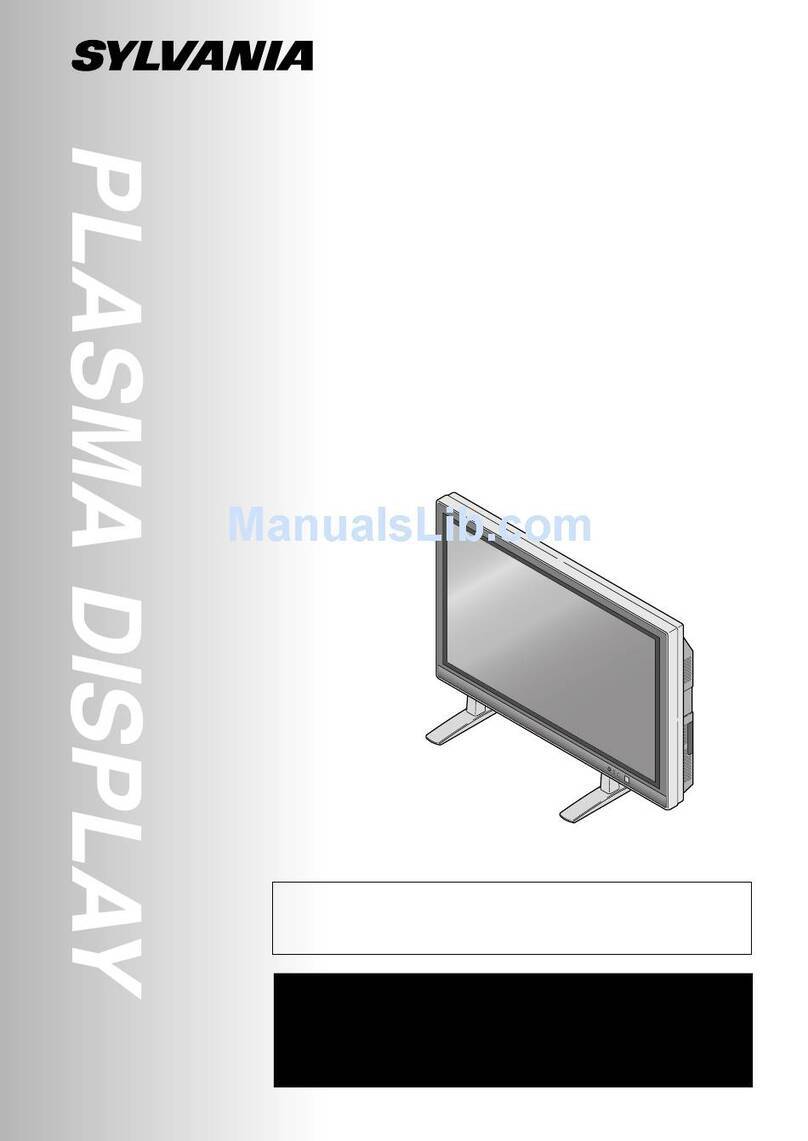

[6] Decoration

Panel

[7] Front

Cabinet

[8] Jack Bracket

[9] Jack Holder

[10] Jack CBA [15] Filter CBA[16] PCB Holder

[24] Chassis

Bracket

[25] Panel

Spacer

[26] Jack Cover

[27] Plasma

Display Module

[28] Panel

Holder Assembly

[17] Stand Cover

[11] PCB

Shield Plate [12] Shield Box

[13] Digital CBA [14] Analog CB

[18] Stand

[19] Stand Base

[20] Rubber

Foot

[22] Speaker

Cover

[21] Speaker

Holder

[23] Speaker

[1] Rear Cabinet

[2] Front Cabinet

Assembly [3] Filter

Holder(L)

[4] Filter

Holder(S)

[5] Optical

Filter

11 PCB Shield Plate 4 18(S-10), CLN8 9

12 Shield Box 4 14(S-11) 10

13 Digital CBA 5

9

*CN1701, *CN1702,

*CN1703, *CN1704,

*CN1706, *CN1707,

4(S-12), 3(S-13)

11

14 Analog CBA 5

10

*CN201, *CN203, *CN204,

*CN501, *CN502, *CN701,

*CN702, *CN801, *CN802,

4(S-14), 2(S-15)

12

15 Filter CBA 5

11 *CN801, Inlet Holder, AC

Cord, (S-16A), (S-17) 13

16 PCB Holder 5 4(S-18) 14

17 Stand Cover 6 4(S-19), 6(S-19B) 15

18 Stand 6 4(S-20) 16

19 Stand Base 6 8(S-21) 17

20 Rubber Foot 6 ----------

21 Speaker Holder 7 8(S-22) 18

22 Speaker Cover 7 2(S-23) 19

23 Speaker 7 8(S-24) 20

24 Chassis Bracket 7 8(S-25) 21

25 Panel Spacer 7 8(S-26) 22

26 Jack Cover 7 2(S-28) 23

27 Plasma Display

Module 8 ---------- -

28 Panel Holder

Assembly 8 ---------- -

Step/

Loc.

No. Part Removal

Fig.

No Remove/*unlock/release/

unplug/unclamp/desolder Note