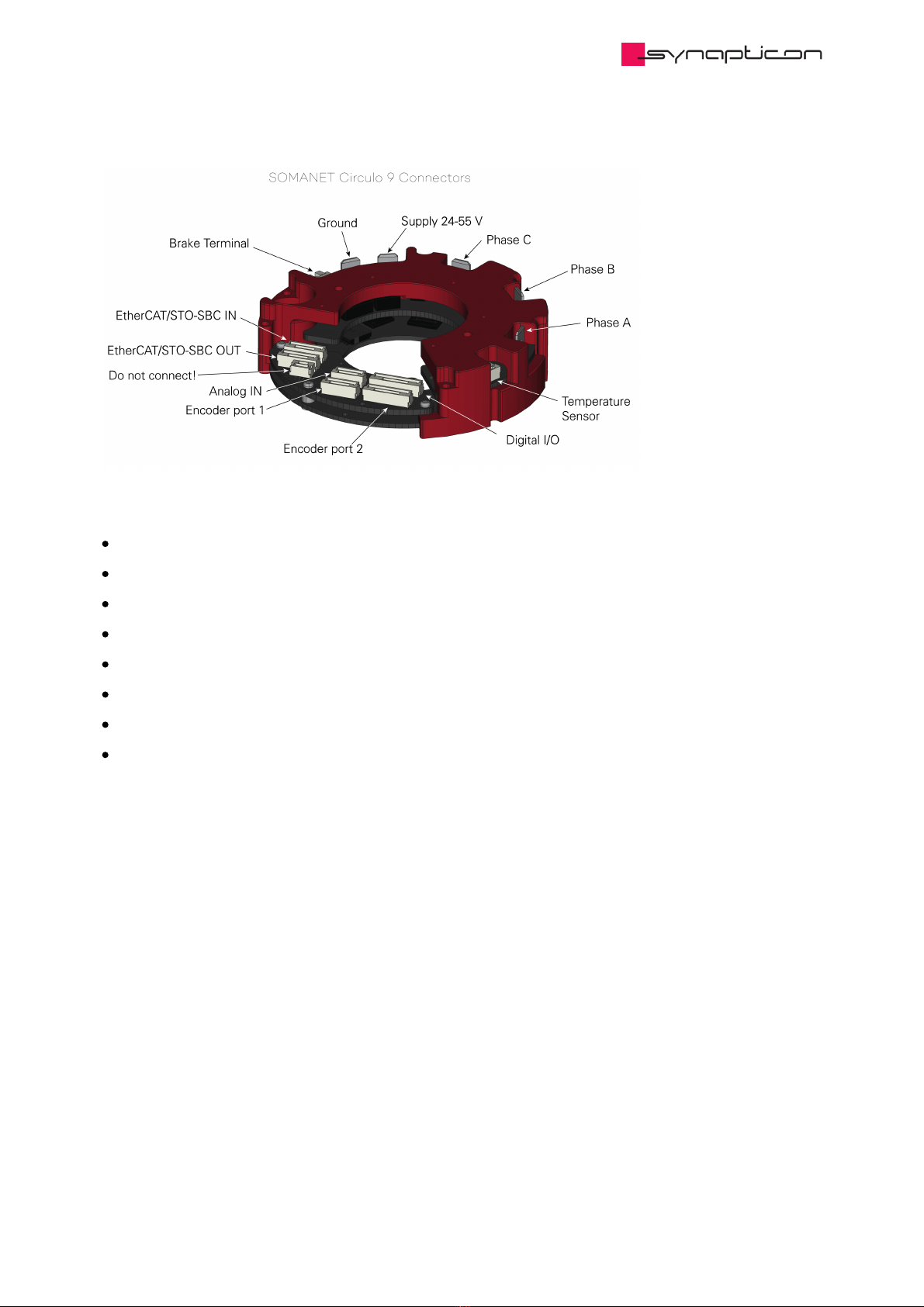

1.1.6.3.2.2 Wire details and pinout

1.1.6.3.2.3 Connectorization

1.1.6.3.3 Y-Splitter Cable

1.1.6.3.3.1 Overview

1.1.6.3.3.2 Wire details and pinout

1.1.6.3.3.3 Connectorization

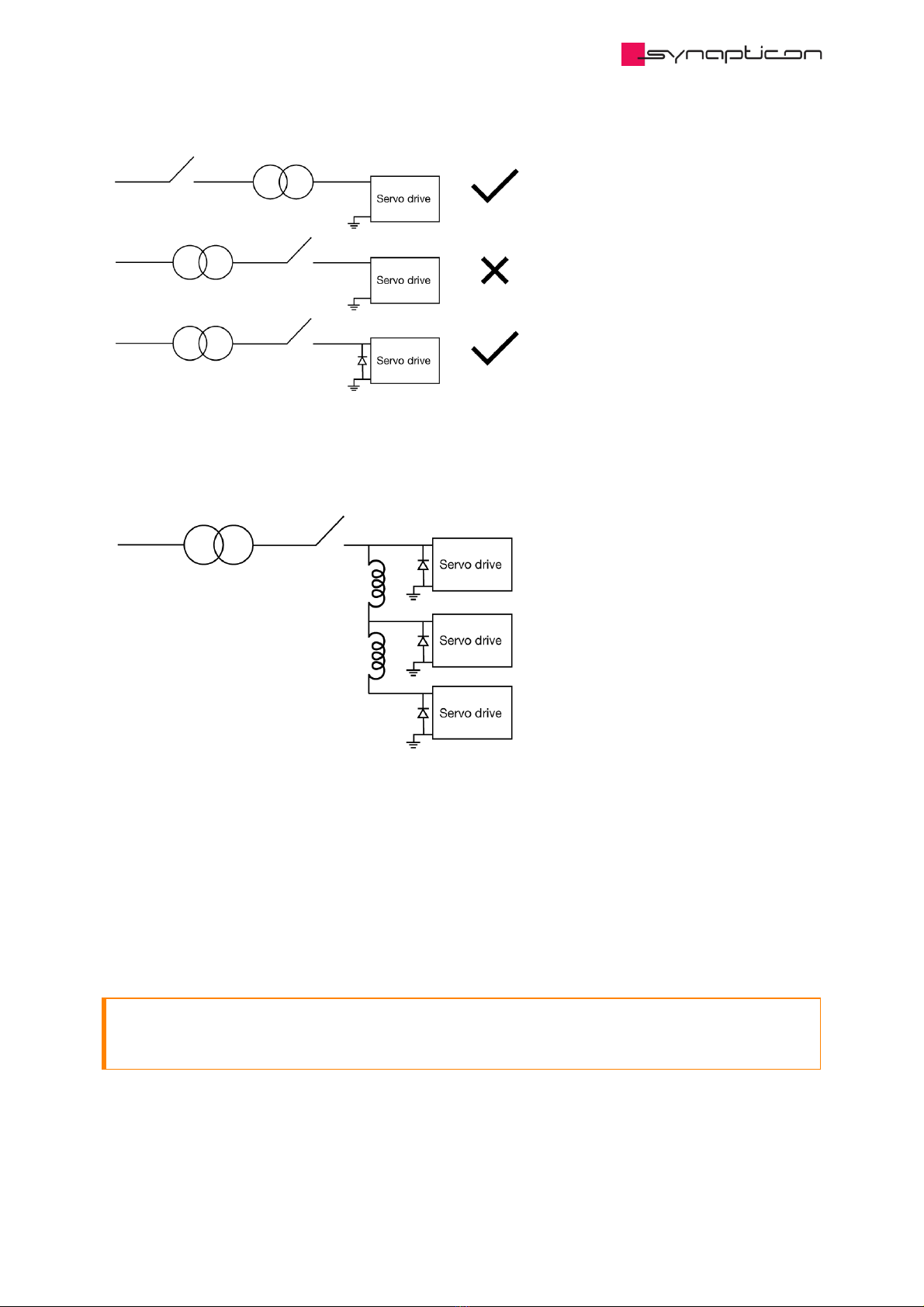

1.1.6.3.3.4 Insulation Voltage

1.1.6.3.3.5 Cable Thickness and Flexibility

1.1.7 Maximum cable lengths

1.1.8 Mating parts

1.1.8.1 Connector details and mating part numbers

1.2 Mechanical integration

1.2.1 Circulo Mounting Example

1.2.1.1 Mounting the encoder disc

1.2.1.2 Mounting a hollow-shaft secondary bearing

1.2.1.3 Routing the motor phase cables

1.2.2 Dimensions and Drawings

1.2.2.1 Dimensions

1.2.2.2 Weight and inertia of the encoder rings

1.2.2.3 Drilling patterns

1.2.2.4 Mounting a bearing

1.2.2.5 Side view with phase connectors

1.2.3 Mounting encoder rings

1.2.3.1 Axial distance tolerances

1.2.3.2 Planar displacements

1.2.3.2.1 Radial displacement (r)

1.2.3.2.2 Tangential displacement (t)

1.2.3.2.3 Mounting eccentricity or radial runout (e)

1.2.4 Thermal Mounting Considerations

1.2.4.1 Current as a function of mounting temperature

1.2.4.2 Ambient air

1.3 Encoder Calibration

1.3.1 Encoder accuracy

1.3.1.1 Narrow angle errors (encoder system-specific non-linearity)

1.3.1.1.1 Analogue signals errors

1.3.1.1.2 Magnetic ring magnetization errors

1.3.1.2 Wide angle error (installation-dependent non-linearity)

1.3.1.3 Detecting the encoder non-linearity

40

41

41

42

42

43

43

43

44

45

45

47

48

49

50

51

53

53

57

57

60

61

63

63

65

65

66

66

67

68

70

71

72

73

74

74

74

75