Flamic SF450 User manual

DOUGH SHEETER

SF450 - SF500 - SF600

All rights reserved. Reproduction in whole or in part of this manual is prohibited.

FLAMIC SRL Via dell’Artigianato, 5 36035 MARANO VICENTINO (VICENZA) - Italy

Vat No. and Tax Code 03198710240 e-mail: info@flamic.it Web: www.flamic.it Tel. +39 0445 576659 Fax +39 0445 277203

OPERATION AND MAINTENANCE MANUAL

TRANSLATION OF THE ORIGINAL INSTRUCTIONS

Ed. 10/2016

Rev.02 10/2017

FLAMIC S.R.L. 5 Via dell’Artigianato, 36035 Marano Vicentino (Vicenza) - Italy

2

Dough sheeter SF450 - SF500 - SF600 Operation and maintenance manual (translation of original instructions) – Ed. 10/2016

Rev.02 10/2017

All rights reserved. Reproduction in whole or in part of this manual is prohibited.

TABLE OF CONTENTS

EC DECLARATION OF CONFORMITY....................................................................................................................................4

1INTRODUCTION .............................................................................................................................................................5

1.1 FOREWORD...............................................................................................................................................................5

1.2 INSTRUCTIONS AND GENERAL PRECAUTIONS....................................................................................................6

1.3 MAIN CIRCUMSTANCES IN WHICH THE COMPANY DISCLAIMS LIABILITY ........................................................6

1.4 TERMINOLOGY .........................................................................................................................................................7

1.5 VALIDITY OF THE CE MARKING AND EC DECLARATION OF CONFORMITY ......................................................8

2CHARACTERISTICS OF THE MACHINE.......................................................................................................................9

2.1 DESCRIPTION AND INTENDED USE .......................................................................................................................9

2.2 MACHINE MODELS AND VERSIONS .....................................................................................................................11

2.3 CUTTING UNIT ST600 (OPTIONAL)........................................................................................................................11

2.4 CONTROL DEVICES................................................................................................................................................12

2.5 ROLLING THICKNESS ADJUSTMENT LEVER (HANDLE) .....................................................................................13

2.6 MAIN TECHNICAL SPECIFICATIONS.....................................................................................................................14

2.7 IDENTIFICATION PLATE .........................................................................................................................................16

3INSTALLATION AND USE ...........................................................................................................................................17

3.1 INSTRUCTIONS REGARDING THE PLACE OF INSTALLATION ...........................................................................17

3.2 TRANSPORT, HANDLING AND POSITIONING ......................................................................................................17

3.3 ELECTRICAL CONNECTIONS ................................................................................................................................19

3.4 INSTALLING/REMOVING THE TABLES OF A SHEETING MACHINE (MOD. SF600) ...........................................20

3.4.1 INSTALLING A TABLE (MOD. SF600)................................................................................................................20

3.4.2 REMOVING A TABLE (MOD. SF600) .................................................................................................................21

3.5 LIFTING AND LOWERING THE INTERLOCKED GUARDS ....................................................................................22

3.5.1 MOD. SF450........................................................................................................................................................22

3.5.2 MOD. SF500 AND SF600 ...................................................................................................................................22

3.6 PLACING THE BENCHES IN THE WORK POSITION OR RAISING THEM WHEN NOT IN USE ..........................23

3.6.1 MOD. SF450........................................................................................................................................................23

3.6.2 MOD. SF500........................................................................................................................................................24

3.6.3 MOD. SF600........................................................................................................................................................25

3.7 MOD. SF450B: POSITIONING AND FASTENING THE MACHINE ON THE TROLLEY (OPTIONAL) ....................26

3.8 UNDER-TABLE AND CENTRAL DUST AND RESIDUE COLLECTION TRAY(S) ...................................................26

3.9 CATCH PANS FOR COLLECTING THE DOUGH SHEET THAT IS TOO LONG FOR THE CONVEYORS ............27

3.10 CUTTING UNIT (only for SF600V with bench lengths of 1400 mm or greater).........................................................28

3.10.1 INSTALLING AND POSITIONING THE CUTTING UNIT ....................................................................................28

3.10.2 DISABLING THE CUTTING UNIT .......................................................................................................................29

3.10.3 ADJUSTING THE FORCE EXERTED ON THE BENCH BY THE CUTTING ROLLERS ....................................30

3.10.4 REMOVING / INSTALLING THE CUTTING ROLLERS ......................................................................................30

3.10.5 REMOVING THE CUTTING UNIT.......................................................................................................................31

3.11 OPERATION AND USE............................................................................................................................................32

3.11.1 GENERAL INFORMATION FOR USE ................................................................................................................32

3.11.2 SWITCHING THE MACHINE ON AND OFF .......................................................................................................33

3.11.3 PREPARING THE MACHINE..............................................................................................................................33

3.11.4 USING THE MACHINE AS A SHEETER ............................................................................................................33

3.11.5 USING THE MACHINE FOR PRODUCING DOUGH SHAPES FROM THE ROLLED SHEET...........................33

3.12 PUTTING THE MACHINE TEMPORARILY OUT OF SERVICE AND STORING IT.................................................34

3.13 TRAINING OF PERSONNEL ASSIGNED TO THE MACHINE.................................................................................34

4MAINTENANCE ............................................................................................................................................................35

4.1 FOREWORD.............................................................................................................................................................35

4.2 MAINTENANCE AND PERIODIC CHECKS .............................................................................................................35

4.3 DRIVE BELT TENSION ADJUSTMENT AND REPLACEMENT...............................................................................35

4.3.1 GENERAL RULES FOR CHECKING THE TENSION OF A DRIVE BELT..........................................................35

4.3.2 SHEETER MOD. SF450......................................................................................................................................36

4.3.3 SHEETER MOD. SF500 - SF600 ........................................................................................................................37

4.4 ADJUSTING THE TENSION AND CENTRING OF THE CONVEYOR BELTS.........................................................38

4.5 REMOVING/INSTALLING THE SCRAPERS............................................................................................................39

4.5.1 UPPER ROLLER SCRAPERS ............................................................................................................................39

4.5.2 LOWER ROLLER SCRAPERS ...........................................................................................................................40

4.5.2.1 MOD. SF450 ....................................................................................................................................................40

4.5.2.2 MOD. SF500 ....................................................................................................................................................41

4.5.2.3 MOD. SF600 ....................................................................................................................................................42

4.6 REPLACING THE CONVEYOR BELTS ...................................................................................................................43

4.6.1 SHEETER MOD. SF450 and sf500 .....................................................................................................................43

4.6.2 SHEETER MOD. SF600......................................................................................................................................50

4.7 REPLACING A DRIVE CHAIN..................................................................................................................................50

4.8 ELECTRICAL SYSTEM MAINTENANCE .................................................................................................................51

4.9 REPLACING THE MICRO SWITCHES OF THE INTERLOCKED GUARDS ...........................................................51

4.10 CLEANING................................................................................................................................................................52

4.11 POSSIBLE FAILURES AND / OR FAULTS ..............................................................................................................53

4.12 SPARE PARTS.........................................................................................................................................................53

4.13 PROLONGED STOP OR TAKING THE MACHINE OUT OF SERVICE...................................................................53

FLAMIC S.R.L. 5 Via dell’Artigianato, 36035 Marano Vicentino (Vicenza) - Italy

3

Dough sheeter SF450 - SF500 - SF600 Operation and maintenance manual (translation of original instructions) – Ed. 10/2016

Rev.02 10/2017

All rights reserved. Reproduction in whole or in part of this manual is prohibited.

5 SAFETY....................................................................................................................................................................54

5.1 FOREWORD.............................................................................................................................................................54

5.2 HAZARDS, SAFETY DEVICES AND RESIDUAL RISKS .........................................................................................54

5.2.1 HAZARDS ASSOCIATED WITH THE MACHINE................................................................................................54

5.2.2 MACHINE SAFETY DEVICES ............................................................................................................................55

5.2.3 CHECKING THE WORKING ORDER OF SAFETY EQUIPMENT ......................................................................57

5.2.4 RESIDUAL RISKS ...............................................................................................................................................57

5.2.4.1 RESIDUAL RISKS OF A MECHANICAL NATURE............................................................................................57

5.2.4.2 RESIDUAL RISKS DUE TO THE MACHINE TIPPING OVER ...........................................................................57

5.2.4.3 RESIDUAL RISKS ASSOCIATED WITH THE MACHINE STARTING UNEXPECTEDLY ...............................58

5.2.4.4 RESIDUAL RISKS DUE TO INHALING DUST.................................................................................................58

5.2.4.5 RESIDUAL RISKS DUE TO POOR HYGIENE.................................................................................................58

5.2.4.6 RESIDUAL RISKS ASSOCIATED WITH ERGONOMICS................................................................................58

5.2.4.7 RESIDUAL RISKS OF AN ELECTRICAL ORIGIN ...........................................................................................58

5.2.5 MACHINE NOISE LEVELS .................................................................................................................................59

5.3 SAFETY SIGNS........................................................................................................................................................60

6DISPOSAL ....................................................................................................................................................................60

ATTACHMENTS: WIRING DIAGRAMS

INDEX TO FIGURES

Figure 1 - Main parts of the machine.......................................................................................................................................10

Figure 2 - Support trolley for SF450B......................................................................................................................................11

Figure 3 - Cutting unit..............................................................................................................................................................11

Figure 4 - Control devices .......................................................................................................................................................12

Figure 5 - Rolling thickness adjustment...................................................................................................................................13

Figure 6 - Dimensions .............................................................................................................................................................15

Figure 7 - Identification plate and its position ..........................................................................................................................16

Figure 8 - Handling the palletised machine using a forklift truck .............................................................................................17

Figure 9 - Lifting slings for model SF450.................................................................................................................................18

Figure 10 - Wheel brake levers ...............................................................................................................................................18

Figure 11 - Power cable plug ..................................................................................................................................................19

Figure 12 - Installing the benches (mod. SF600) ....................................................................................................................20

Figure 13 - Removing the benches (SF600 only)....................................................................................................................21

Figure 14 - Raising/lowering the interlocked guards (mod. SF450).........................................................................................22

Figure 15 - Raising/lowering the interlocked guards (mod. SF500 - SF600)...........................................................................22

Figure 16 - Raising/lowering the benches (mod. SF450) ........................................................................................................23

Figure 17 - Raising/lowering the benches (mod. SF500) ........................................................................................................24

Figure 18 - Raising/lowering the benches (mod. SF600) ........................................................................................................25

Figure 19 - Fastening the sheeting machine mod. SF450 to the carriage (optional) ...............................................................26

Figure 20 - Under-table and central (only SF500 and SF600) residue collection trays ...........................................................26

Figure 21 - Catch pan..............................................................................................................................................................27

Figure 22 - Installing the cutting unit .......................................................................................................................................28

Figure 23 - Disabling the cutting unit.......................................................................................................................................29

Figure 24 - Adjusting the force exerted on the bench by the cutting rollers.............................................................................30

Figure 25 - Removing/installing the cutting rollers...................................................................................................................30

Figure 26 - Removing the cutting unit .....................................................................................................................................31

Figure 27 - Rolling pin and relative supports...........................................................................................................................33

Figure 28 - Machine with benches raised................................................................................................................................34

Figure 29 - Diagram showing the parameters used for tensioning a drive belt........................................................................35

Figure 30 - Mod. SF450: adjusting the tension of the drive belt ..............................................................................................36

Figure 31 - Mod. SF500 and SF600: adjusting the tension of the drive belt(s)........................................................................37

Figure 32 - Conveyor belt tensioning and centring system......................................................................................................38

Figure 33 - Removing/installing the upper roller scrapers .......................................................................................................39

Figure 34 - Mod. SF450: removing/installing the lower roller scrapers....................................................................................40

Figure 35 - Mod. SF500: removing/installing the lower roller scrapers....................................................................................41

Figure 36 - Mod. SF600: removing/installing the lower roller scrapers....................................................................................42

Figure 37 - SF450 and SF500: Removing the tables and replacing conveyor belts................................................................45

Figure 38 - SF450 and SF500: installing the table support rod between the uprights.............................................................46

Figure 39 - SF450 and SF500: preparing the belt before installing the drive roller .................................................................47

Figure 40 - SF450 and SF500: installing a conveyor belt drive roller ......................................................................................48

Figure 41 - SF450 and SF500: installing the handle and other parts ......................................................................................49

Figure 42 - Replacing a drive chain.........................................................................................................................................50

Figure 43 - Drive chains ..........................................................................................................................................................51

Figure 44 - Safety micro switches associated with the interlocked guards in the rolling zone.................................................52

Figure 45 - Hazards of a mechanical nature ...........................................................................................................................54

Figure 46 - Interlocked guards in front and behind the rolling zone.........................................................................................55

Figure 47 - Guards fastened with screws or similar means.....................................................................................................56

Figure 48 - Sound level measurement points..........................................................................................................................59

FLAMIC S.R.L. 5 Via dell’Artigianato, 36035 Marano Vicentino (Vicenza) - Italy

4

Dough sheeter SF450 - SF500 - SF600 Operation and maintenance manual (translation of original instructions) – Ed. 10/2016

Rev.02 10/2017

All rights reserved. Reproduction in whole or in part of this manual is prohibited.

EC DECLARATION OF CONFORMITY

The company

FLAMIC s.r.l. Via dell’Artigianato, 5 36035 Marano Vicentino (VICENZA) - Italy

(Vat No. and Tax Code 03198710240)

through its legal representative, dott. Michele Stella

HEREBY DECLARES

that the DOUGH SHEETER Serial No. ………….

MODEL

(see ticked item)

SF450B SF500 SF600

SF450BV SF500V SF600V

SF500B SF600V + ST600

SF500BV

the function of which is to roll dough by passing it repeatedly between two rollers, by reversing its direction; the

distance between the rollers of which can be adjusted between one pass and another in order to obtain a sheet

of the required thickness and (only for the SF600V + ST600) regularly shaped pieces of dough that will undergo

further processing outside the machine in order to obtain pastry and bakery products,

complies with the relevant provisions of:

- Directive 2006/42/EC of the European Parliament and of the Council of 17 May 2006 on machinery, and

amending directive 95/16/EC (and implemented by the Italian State with Legislative Decree No. 17 of

27/01/2010)

- Directive 2014/30/EU of the European Parliament and of the Council

- Regulation (EC) No 1935/2004 of the European Parliament and of the Council of 27 October 2004 on

materials and articles intended to come into contact with food and repealing Directives 80/590/EEC and

89/109/EEC.

The technical file of the machine is held by dott. Michele Stella, as the legal representative.

Dott. Michele Stella

(Legal Representative)

Marano Vicentino, ……………….

FLAMIC S.R.L. 5 Via dell’Artigianato, 36035 Marano Vicentino (Vicenza) - Italy

5

Dough sheeter SF450 - SF500 - SF600 Operation and maintenance manual (translation of original instructions) – Ed. 10/2016

Rev.02 10/2017

All rights reserved. Reproduction in whole or in part of this manual is prohibited.

1 INTRODUCTION

1.1 FOREWORD

This instructions manual is intended be used by anyone who may in any way be assigned to, in charge

of or authorized the use and/or control the machine. It is also intended for the employer, managers and

supervisors of the company that uses the machine. They should read it carefully and understand it in its

entirety so that it can be used as a valid tool for fulfilling some of the obligations required by current laws and

regulations regarding health and safety at work.

The employer, managers and supervisors of the staff that are authorized to use the machine must ensure that

they receive adequate information and training, including practical training (it must be simple and

understandable in relation to the perspicacity that can reasonably be expected from those involved) on its

proper and safe use and on both general and specific hazards and/or duties in the workplace.

The manual consists of several sections, which can be broadly summarized as follows:

Instructions for handling, transport, assembly (SF600) and installation

This is covered in the first paragraphs of Chapter 3. It is intended for the personnel who are responsible for

handling, transporting, installing and starting up the machine for the first time. Its purpose is to provide all the

important information, apart from that which relates to the general level of culture of an experienced and/or

professional and/or skilled technician in order for these tasks to be performed correctly.

Use and ordinary maintenance instructions

This is covered in Chapter 2 and part of Chapters 3, 4 and 5. It is intended for the employer of the machine

operators, the managers and supervisors of the company that uses the machine and to the operators

themselves.

As well as containing general guidelines for using the machine, it also includes instructions regarding

maintenance, cleaning and inspection tasks, which, because of their ease and low risk, do not require particular

experience or professional skills and can be carried out by the machine operator.

Extraordinary maintenance instructions

This is covered in the remaining part of Chapters 4 and 5. It is intended for the employer of the machine

operators, the managers and supervisors of the company that uses the machine, the operators and the

specialised personnel who carry out routine and/or extraordinary maintenance on the machine. It includes some

important safety instructions that should be followed during maintenance, adjustment and inspections, which

due to their complexity and/or dangerous nature, require specialised, experienced and professionally trained

personnel who possess the technical and regulatory knowledge to carry them out safely and in a workmanlike

manner.

Given the specific experience that the personnel responsible for this type of work must possess, the technical

instructions that are not required for safely performing the work are not included. Neither are those which,

considering their professional profile, such personnel cannot not be aware of.

Instructions for dismantling and/or disposal

This is covered in Chapter 6.

References made to specific chapters or sections shall also be intended as referring to all the relative sub-

sections. Where, for example, section is mentioned. 3.6 The reference is to be considered to refer to all

sections from 3.6.1 to 3.6.3.

Before carrying out any operation on/with the machine (assembly, installation, operation, repair etc.) read both

the general and specific instructions carefully that are contained in this manual. Fully understand their

purpose and meaning in the context of correctly operating and maintaining the machine and acquire an

adequate knowledge of the safety devices provided with it and any residual risks that its use involves.

Keep the manual and any enclosed publications (drawings, diagrams etc.) in a safe place that is known to the

personnel authorised to use and/or maintain the machine. Store it in a dry place and protected from atmospheric

agents, which over time could cause it to deteriorate (e.g. in an opaque plastic bag). It is recommended to leave

a copy close to the machine so that it is available to operators for quick reference.

If the manual is lost or damaged, immediately request a replacement from Flamic s.r.l. clearly specifying all

the machine identification data (year of manufacture, model, serial number, etc.).

The manual reflects the state of technology at the time the machine was put onto the market or put into

operation and cannot be regarded as inappropriate simply because of later updates based on additional

experience or because of new technical solutions.

The manufacturer shall not under any circumstances be held liable for the suitability of the place in which the

machine is used and related utilities, even some important instructions are provided in this manual regarding its

correct installation. The company reserves the right to make updates to machines and manuals, without

implying any obligation to update machines and/or manuals that were previously produced.

WARNING

Once the machine(s) has/have been positioned and/or installed in its/their final location, make sure that

all the devices, especially safety devices described in this manual and in any commercial

documentation provided, have been fitted before authorising its use or starting it up.

This manual is an integral part of the machine and should accompany the machine if it is sold or

transferred for whatever reason, even if it is given away.

The intended 2.1 use of the machine is indicated in section together with details regarding permitted and non-

permitted uses.

FLAMIC S.R.L. 5 Via dell’Artigianato, 36035 Marano Vicentino (Vicenza) - Italy

6

Dough sheeter SF450 - SF500 - SF600 Operation and maintenance manual (translation of original instructions) – Ed. 10/2016

Rev.02 10/2017

All rights reserved. Reproduction in whole or in part of this manual is prohibited.

1.2 INSTRUCTIONS AND GENERAL PRECAUTIONS

Flamic s.r.l. declines all liability for injury or damage to persons, animals or property caused by the failure to

comply with instructions, directions, recommendations etc. contained in this manual, and in particular the

following:

- DO NOT tamper with the machine’s safety guards and safety devices

-DO NOT remove the guards and DO NOT disable the machine’s safety devices, unless it absolutely

necessary to do so, and with the machine stationary and the power disconnected and maintained in this

condition until all the guards and safety devices have been properly replaced/re-enabled, and after having

taken all possible measures to minimize risks that may arise

-Replace the guards and re-enable the safety devices as soon as there is no longer any reason for them to be

removed/disabled

- DO NOT use the machine for purposes and/or loads other than those indicated by the manufacturer

-Carry out daily checks on the guards, safety devices and the general condition of the machine

- Clean the machine and its parts thoroughly every day

-Adopt the necessary safety measures and precautions when carrying out adjustments, cleaning,

maintenance etc. to prevent the machine or its parts from being started by others, even accidentally

-Comply with the European Directives and the laws of the country in which the machine is used regarding the

workplace. In particular (but not limited to) those relating to safety signs, food hygiene, health and safety in the

workplace, personal protective equipment and environmental protection

-Comply with the permitted limits of the operating environment and conditions: maximum relative

humidity 90%, ambient temperature min. 5°C max. 40°C, maximum altitude 1000 m a.s.l.

-The employer must provide employees with adequate information and training, including practical training,

regarding the proper and safe use of the machine.

-The operator should wear only tight-fitting clothing, without loose parts. Jackets, open shirts etc. or

jewellery (rings, bracelets, necklaces etc.) should never be worn. Long hair should be collected (e.g. in a cap)

and work clothing must also be appropriate for the hygiene requirements of the food that is handled /

processed.

- Do not allow unauthorised persons, untrained personnel, children or anyone who is not expressly

authorised to enter the room in which the machine is used or to approach the machine;

- when the machine is connected to other equipment or incorporated in a complex assembly, the manufacturer

of the assembly resulting from said connection or incorporation must carry out a risk assessment for any

additional or greater risks resulting from said operation, take appropriate measures to eliminate or minimize

the risk, comply with all the relevant requirements of the Law, Directives, Regulations etc. (including the

Directive 2006/42/EC) and declare that the assembly is compliant with them.

- If parts of the machine need to be replaced,

use only original spare parts by submitting a request to Flamic

s.r.l. Flamic s.r.l will not under any circumstances be held liable for any injuries or damage to people, animals

or property caused by the use of non-original spare parts.

- Any arbitrary modification made to the machine shall release the manufacturer from all liability for any

injuries or damage to people, animals and/or property as a result of it.

1.3 MAIN CIRCUMSTANCES IN WHICH THE COMPANY DISCLAIMS LIABILITY

Flamic s.r.l. shall not be held liable for any direct or indirect damage or injury or for the loss of production if/by:

•the machine is used for purposes other than its intended use or in ways different to those described

•installation does not conform to the manner specified in this manual

•the machine is used by insufficiency skilled personnel and, where necessary, not adequately trained for

its safe and proper use.

•inappropriate energy sources are used or that are anyway different from those indicated in this manual

and/or the enclosed documentation (e.g. wiring diagrams)

•the lack of or poor maintenance or if it is not carried out in the manner indicated herein

•the failure or partial failure to comply with the instructions provided in this manual

•the arbitrary modification of the original characteristics and equipment of the machine without having

received a formal authorization from the manufacturer.

•the connection/incorporation with/of the machine with parts and/or equipment applied or otherwise to the

machine that are not supplied, intended or authorized by Flamic s.r.l. In this case, the CE marking placed

on the machine by the manufacturer, it would no longer be valid.

FLAMIC S.R.L. 5 Via dell’Artigianato, 36035 Marano Vicentino (Vicenza) - Italy

7

Dough sheeter SF450 - SF500 - SF600 Operation and maintenance manual (translation of original instructions) – Ed. 10/2016

Rev.02 10/2017

All rights reserved. Reproduction in whole or in part of this manual is prohibited.

•the incorporation of the machine or its parts into a complex assembly, if this where to cause new or

increased risks compared to the machine if used on its own as it was supplied.

•failure to comply with laws and regulations in the country in which the machine is used

•exceptional events and force majeure beyond the control of Flamic s.r.l.

1.4 TERMINOLOGY

In order to improve the understanding of the manual, below we have defined some of the terms and expressions

used in it:

OPERATOR: person assigned to use the machine or its parts.

MACHINE, DOUGH SHEETER: the subject of this manual

USE OF THE MACHINE: every operation performed or that can be performed with/on the machine within the

permissible limits and stated in this manual. The term assumes the meaning of the relevant subject that is dealt

with from time to time (for example, production, maintenance, cleaning etc.).

CUSTOMER: natural or legal person who purchased the machine from Flamic s.r.l.

USER: natural or legal person that actually uses the machine, in particular for production purposes

MANUFACTURER of the machine, FLAMIC:

Flamic s.r.l. Via dell’Artigianato, 5 36035 Marano Vicentino (VICENZA) - Italy

PPE: personal protective equipment (e.g. gloves, shoes, glasses etc.)

INGREDIENTS: food products/substances (e.g. animal/vegetable fats, flour etc.) added to dough during the

rolling process in order to obtain a new mass of sufficiently homogeneous dough.

DOUGH: homogeneous easily malleable mixture at room temperature (obtained mainly from processes external to

the machine, but also in certain cases with the addition of ingredients to be incorporated in the mixture with the

machine itself) to undergo progressive rolling in order to obtain a sheet of dough/pastry of the required thickness.

SHEET, DOUGH SHEET: dough sheet made using the machine during the various rolling stages by passing the

dough forward / backward between two rollers, the distance between which (rolling thickness) is adjusted by the

operator according to requirements.

DOUGH PIECES/SHAPES:pieces of regularly shaped dough (triangular, circular, etc.) produced by the cutting

unit to be sent for subsequent processing outside the machine.

ROLLERS (THICKNESSING): powered opposing metal cylinders with a mutually opposite rotational movement

which, by compressing the dough in the various forward / backward steps and from time to time by varying the

gap between them, enables the sheet of the required thickness to be obtained.

ROLLING THICKNESS: the distance (gap) between the rollers.

BENCH, TABLE, SURFACE: machine element consisting essentially of a flat structure with two cylinders at

each end on which a conveyor belt moves. In this manual, this term refers to the assembly consisting of the

structure, cylinders, conveyor belt, residue collection tray (under-table), catch pan, table support etc.

CONVEYOR BELT, BELT: mobile component, the function of which is to receive the dough from the rollers

and to forward it to the subsequent rolling stage by reversing its direction of movement.

SCRAPER: plastic plate, the edge of which is in contact with a roller, parallel to its axis and whose function is to

keep the roller as free as possible from residues of dough, flour etc. by producing a “scraping” action. There are

two scrapers for each roller

BASE, FRAME: metal structure that supports the other parts of the machine

CONTROLS SIDE: the side of the machine on which the rolling thickness adjustment handle is located.

RESIDUE COLLECTION TRAY: edged metal sheet located under the table for collecting dust and residues of dough

CATCH PAN: concave stainless steel sheet at the ends of the benches that supports the rolled dough that

would otherwise fall on the floor during processing.

ORDINARY MAINTENANCE: operations carried out to keep the machine in good condition and in working

order that do not require special training or specific skills and that can be carried out by unskilled personnel,

provided that the instructions in this manual are followed.

SPECIAL / EXTRAORDINARY MAINTENANCE: work carried out to keep the machine in good condition and in

working order that do require special training and/or specific skills and that can and must only be carried out by

skilled personnel and (where required by the law and current regulations) professionally trained personnel who

possess the technical and regulatory knowledge to carry them out safely and in a workmanlike manner.

DANGER ZONE,any zone within and/or around the machine in which the presence of an exposed person

constitutes a risk to the health or safety of that person.

EXPOSED PERSON, any person wholly or partially in a danger zone.

FLAMIC S.R.L. 5 Via dell’Artigianato, 36035 Marano Vicentino (Vicenza) - Italy

8

Dough sheeter SF450 - SF500 - SF600 Operation and maintenance manual (translation of original instructions) – Ed. 10/2016

Rev.02 10/2017

All rights reserved. Reproduction in whole or in part of this manual is prohibited.

WARNING: very important information regarding health and safety

IMPORTANT: important information regarding the use and care of the machine

1.5 VALIDITY OF THE CE MARKING AND EC DECLARATION OF CONFORMITY

In this manual, all references and/or information regarding:

• CE marking

• EC declaration(s) of conformity

• declaration(s) of incorporation of partly completed machinery

• directives and regulations issued by the institutional bodies of the European Union (Parliament, Council,

Commission etc.) and related acts of transposition of the EU Member States

• harmonised European standards (EN)

are to be considered valid only for the machines intended for sale in the European Union or for which

compliance with laws, directives etc. issued by the European Union has been specifically requested by the

customer and formally accepted by Flamic s.r.l.

For all the machines that are not intended for use in the European Community, with the exceptions mentioned

above, these references and indications should be considered to be totally meaningless and of no value.

FLAMIC S.R.L. 5 Via dell’Artigianato, 36035 Marano Vicentino (Vicenza) - Italy

9

Dough sheeter SF450 - SF500 - SF600 Operation and maintenance manual (translation of original instructions) – Ed. 10/2016

Rev.02 10/2017

All rights reserved. Reproduction in whole or in part of this manual is prohibited.

2 CHARACTERISTICS OF THE MACHINE

2.1 DESCRIPTION AND INTENDED USE

The "Sheeter" is intended to be used to roll a batch of dough by passing it repeatedly through two

opposing rollers by reversing its direction. The distance between the rollers can be adjusted between

one pass and another in order to obtain a sheet of the required thickness.

It is also possible (only for the SF600V + ST600) to produce regularly shaped pieces of dough that will

undergo further processing outside the machine in order to obtain pastry and bakery products.

The machine has been designed for professional use only in places that are not accessible to the general

public, untrained persons, children, unauthorized persons etc., unless in the case of trade fairs and/or

demonstrations and, in any case, only after having taken suitable precautions to prevent the persons present

from being exposed to risks.

Do not use the machine for purposes and/or products and/or in ways other than the one(s) specified

Do not use the machine before all connections have been made to the utilities at the installation site, as

required in this manual.

Do not use the machine in environments in which there is:

●a risk of fire and/or explosion or anyway a risk of major accidents occurring and close to open flames

●high humidity and/or wet ●excessive steam ●excessive oil vapour

●excessive dust ●corrosive substances and/or gasses ●adverse climatic conditions

Do not use the machine in places in which there is dust (except for the dust generated by the machine itself,

which is anyway a minimal amount) and/or airborne substances, especially if hazardous to human health or that

could contaminate the product processed by the machine.

Do not use the machine next to open flames (e.g. burners), sources of sparks (e.g. welding machines), heat

sources (e.g. heaters).

Do not use the machine in areas that are subject to vibration (other than that of the machine) or abnormal

shocks

Do not use the machine outdoors or in places that are inadequately protected against atmospheric agents

Do not use the tables of the machine as work tables on which to use excessive force or anyway beyond those

of the normal intended use of the machine; for example by exerting a continuous force (when resting on it) or an

impulsive force (beating using rigid bodies) on masses of dough to reduce their height).

Do not leave the dough or any other product, ingredient etc. on the benches for longer than 30 minutes (even if

not continuously).

Do not use the machine if it is connected to other equipment or incorporated into other machinery

before the manufacturer of the assembly has declared that the final machinery is compliant with the relevant

requirements of the law, directives, standards, etc.

For reasons of health, safety and for the guarantee to be valid, do not use the machine for products and/or

materials and/or in ways other than those described in this manual, or anyway for purposes other than its

intended use. Any use other than that stated here is to be considered incorrect, improper and not

intended by the manufacturer and therefore potentially dangerous for the health and safety of exposed

persons, as well as for animals and/or property.

With reference to Figure 1, the main parts that make up the machine are:

ref. 1 support structure

ref. 2 tables with conveyor belts

ref. 3 rollers

ref. 4 interlocked mobile guards to protect the infeed zone to the rollers ref. 3. The part furthest from the rollers

can be raised and the guard can be rotated about a horizontal axis parallel to the rollers at the part closest

to the rollers.

ref. 5 flour tray

ref. 6 rolling pin supports

ref. 7 control devices

ref. 8 table supports (only SF600 and SF500, excluding version B). Referred to as “supports” from here

onwards.

Ref. 9 residue collection trays (See section 1.4). These are separate from the catch pans ref. 13 only on models

SF500 and SF600, whilst on mod. SF450 it is integral with the catch pan and therefore moves with it.

ref. 10 manual start and reverse control device:

- joystick type (models SF450 and SF500)

- lever type (model SF600)

ref. 11 start and reverse control pedal (only SF600 and SF500, excluding version B)

ref. 12 lever (handle) for regulating the rolling thickness (see section 2.5).

ref. 13 catch pan (see section 1.4). On model SF450 it is integral with the residue collection tray.

FLAMIC S.R.L. 5 Via dell’Artigianato, 36035 Marano Vicentino (Vicenza) - Italy

10

Dough sheeter SF450 - SF500 - SF600 Operation and maintenance manual (translation of original instructions) – Ed. 10/2016

Rev.02 10/2017

All rights reserved. Reproduction in whole or in part of this manual is prohibited.

Figure 1 - Main parts of the machine

13

4

SF600

1

10

3

5

6

6

2

7

8

9

11

12

4

13

11 SF500

2

1

3

5

6 6

7

8 9

10

12

1

SF450

5

7

2

3

4

66

9

10

12

13

13

FLAMIC S.R.L. 5 Via dell’Artigianato, 36035 Marano Vicentino (Vicenza) - Italy

11

Dough sheeter SF450 - SF500 - SF600 Operation and maintenance manual (translation of original instructions) – Ed. 10/2016

Rev.02 10/2017

All rights reserved. Reproduction in whole or in part of this manual is prohibited.

2.2 MACHINE MODELS AND VERSIONS

There are three models of the sheeter, based mainly on the width of the conveyor belts.

SF450: belt width 450 mm

SF500: belt width 500 mm

SF600: belt width 600 mm

The letters "B" and/or "V” may be added as a suffix to the aforementioned

machine identification codes. Their meanings are as follows:

B"bench” type machine that can only be used if placed on a raised

surface. Its small size and in particular its height, means that it cannot be

used when placed on the floor.

Model SF450 is only a “B” type machine. Upon request, Flamic can

supply a trolley, shown in Figure 2, to place it on. This makes the height

of the top of the tables approximately 1010 mm from the floor.

Model SF500 can be supplied as a version "B” machine.

Model SF600 is never supplied as a version "B” machine.

Figure 2 - Support trolley for SF450B

Vvariable speed machine (only for 230 V single-phase)

Example: mod. SF500BV = “bench type” adjustable speed sheeter with 500 mm wide conveyor belts.

2.3 CUTTING UNIT ST600 (OPTIONAL)

This device is shown in Figure 3. This unit is used to make pieces of dough from the sheet produced by rolling,

that are to be subsequently processed to make specific products. The most common of these are triangular

pieces that are used to make croissants.

The unit can be installed only on the SF600V machines that have been prepared specifically for it and

specifically requested by the customer at the time the order was placed. It is not possible to install the cutting

unit on machines that were not originally designed for it without making considerable modifications to them.

The cutting unit consists essentially of:

ref. 1 cutting discs mounted on a single shaft in the direction in which the sheet moves

ref. 2 cutting roller (Figure 3 shows a roller for cutting triangular shaped pieces of dough)

ref. 3 manual device for regulating the cutting force of the discs ref. 1 against the bench.

ref. 4 manual device for regulating the cutting force of the roller ref. 2 against the bench.

ref. 5 disc ref. 1 and roller ref. 2 guard. This acts as a support structure for the discs ref. 1 and rollers ref. 2

ref. 6 release lever to release the cutting unit from the bench so that it can be raised.

Figure 3 - Cutting unit

1

2

4

5

3

6

FLAMIC S.R.L. 5 Via dell’Artigianato, 36035 Marano Vicentino (Vicenza) - Italy

12

Dough sheeter SF450 - SF500 - SF600 Operation and maintenance manual (translation of original instructions) – Ed. 10/2016

Rev.02 10/2017

All rights reserved. Reproduction in whole or in part of this manual is prohibited.

2.4 CONTROL DEVICES

With reference to Figure 4, the machine's control devices are as follows:

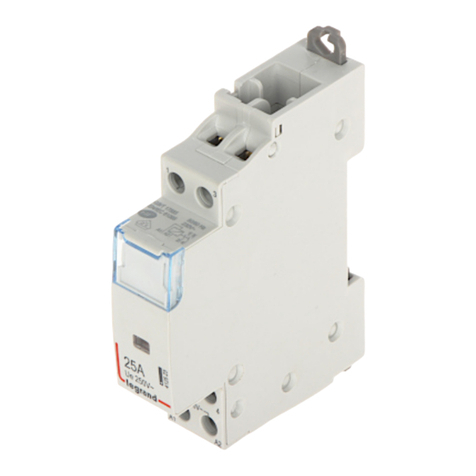

ref. 1main switch (selector), two-position: 0= OFF I= ON

ref. 2main enable/START push-button (green): before pressing it make sure that the start and reverse device(s)

ref. 5 and ref. 6 are in neutral.

ref. 3stop button: pressing it stops the machine and disconnects power to the motor.

ref. 4(only version “V”) graduated continuous operating speed adjustment knob.

ref. 5manual start and reverse control device (ref. 5/L lever, ref. 5/J joystick)

ref. 6start and reverse control pedal (excluding version “B”, bench top)

The conveyors move towards the side to which the lever ref. 5/L has been lowered, the joystick has been

moved ref. 5/J or the pedal ref. 6 has been pressed. Bringing the lever, the joystick or control pedal to the

central neutral position, or pressing the button ref. 2, stops the machine if it is moving.

Figure 4 - Control devices

3

1

2

4

SF450

5/J

1

3 2

4

5/J

SF500

1

2

3

4

5/L

6

SF600

FLAMIC S.R.L. 5 Via dell’Artigianato, 36035 Marano Vicentino (Vicenza) - Italy

13

Dough sheeter SF450 - SF500 - SF600 Operation and maintenance manual (translation of original instructions) – Ed. 10/2016

Rev.02 10/2017

All rights reserved. Reproduction in whole or in part of this manual is prohibited.

2.5 ROLLING THICKNESS ADJUSTMENT LEVER (HANDLE)

With reference to Figure 5, adjusting the position of lever ref. 1 (handle) modifies the distance between the

rollers and allows the thickness of the sheet of dough to be regulated. Turning the handle clockwise decreases

the rolling thickness, turning it anticlockwise increases it.

There is a graduated scale ref. 2 above the axis of rotation of the lever, the pointer of which ref. 3, provides an

indication of the rolling thickness.

To move the lever ref.1 you must press and hold the locking lever ref.4 under the handle. When the locking

lever is released, the tooth ref. 5, pushed by a spring, will tend to be inserted into one of the notches on the

bottom of the rack ref. 6. This will allow the handle to remain in a fixed position during the rolling process and

keep the rolling thickness constant. If the handle is released in an intermediate position between two adjacent

notches on the rack ref. 6, the force exerted by the dough against the upper roller may cause it to move, but

only until the tooth ref. 5 encounters the first notch.

The minimum required rolling thickness can be set using the limit stop ref. 7. It can be moved manually along

the slot ref. 9 after loosening the knob ref. 10. Once the correct position has been found, secure it in place using

the knob ref. 10. In this way, the limit stop ref. 7 will act as a mechanical stop for the handle ref. 1.

Figure 5 - Rolling thickness adjustment

1

23

6

7

9 10

4

5

FLAMIC S.R.L. 5 Via dell’Artigianato, 36035 Marano Vicentino (Vicenza) - Italy

14

Dough sheeter SF450 - SF500 - SF600 Operation and maintenance manual (translation of original instructions) – Ed. 10/2016

Rev.02 10/2017

All rights reserved. Reproduction in whole or in part of this manual is prohibited.

2.6 MAIN TECHNICAL SPECIFICATIONS

Principal dimensions of the machines

Model BL BW A B C D E F G H L M

SF450B 500 450 1120 1280 - - 700 870 540 690 - 430

SF500B 850 500 1250 1860 2110 150 770 910 620 880 950 455

1000 500 1250 2160 2410 150 770 910 620 1030 1000 455

SF500

850 500 800 1860 2110 880 770 910 1335 1620 950 -

1000 500 800 2160 2410 880 770 910 1335 1760 1020 -

1200 500 800 2560 2810 880 770 910 1335 1920 1180 -

SF600

850 600 800 1860 2190 900 920 1065 1225 1619 960 -

1000 600 800 2160 2490 900 920 1065 1225 1757 1100 -

1200 600 800 2560 2890 900 920 1065 1225 1940 1250 -

1400 600 800 2960 3290 900 920 1065 1225 2123 1400 -

1600 600 800 3480 3810 900 920 1065 1225 See

Note

-

Note. When not in use, the BL ≤1400 mm tables can be folded for storage. The BL > 1400 mm tables can only

be positioned horizontally.

Key

BL = conveyor belt length

BW = conveyor belt width

For all other parameters see Figure 6

with maximum bench length

thick gauge cardboard box on pallet

The minimum rolling thickness can be adjusted down to zero (in this case, the force exerted by the passage

of the dough would tend to slightly “separate” the rollers because it creates a small gap for it to pass through.

The minimum thickness used anyway depends on the type of dough being processed.

Maximum batch size: SF450: 3 kg SF500: 5-6 kg SF600: 7-8 kg

POWER SUPPLY

All machines except version “V”

3-phase + earth (L1 + L2 + L3 + PE)

Supply voltage: 230 Volt or 400 Volt

Frequency: 50 Hz, 60 Hz

Version “V” machines

Single phase + earth (L + N + PE)

Supply voltage: 230 Volt

Frequency: 50 Hz, 60 Hz

Other technic

al specifications

Weigh

t

with packaging

Roller

diam.

Rolling thickness

Nominal

power

Max belt

speed

Weight Dimensions min. max

Model [kg] [kg] [cm] [mm] [mm] [mm] [kW] [cm/s]

SF450

B

95 111 93 x 55 x 112 60 0 35 0.55 50

SF500

B

132 154 100 x 100 x 116 60 0 35 0.55 50

SF500 186 215 97 x 97 x 218 60 0 35 0.55 50

SF600 247 283 120 x 120 x 165 70 0 40 0.75 50

Cutting

unit 23 30 70 x 51.5 x 23.5

Trolley

for

SF450

B

70 x 50 x 74

FLAMIC S.R.L. 5 Via dell’Artigianato, 36035 Marano Vicentino (Vicenza) - Italy

15

Dough sheeter SF450 - SF500 - SF600 Operation and maintenance manual (translation of original instructions) – Ed. 10/2016

Rev.02 10/2017

All rights reserved. Reproduction in whole or in part of this manual is prohibited.

Figure 6 - Dimensions

FLAMIC S.R.L. 5 Via dell’Artigianato, 36035 Marano Vicentino (Vicenza) - Italy

16

Dough sheeter SF450 - SF500 - SF600 Operation and maintenance manual (translation of original instructions) – Ed. 10/2016

Rev.02 10/2017

All rights reserved. Reproduction in whole or in part of this manual is prohibited.

2.7 IDENTIFICATION PLATE

The CE marking, manufacturer’s data, serial number, year of construction, weight and electrical data have been

indelibly marked (screen printed and punched) on the data plate, shown in Figure 7, which has been fixed

permanently (via screws or rivets) to the machine in the position indicated in the same figure.

Figure 7 - Identification plate and its position

Holes for screws or rivets

SF600

SF500

SF450

FLAMIC S.R.L. 5 Via dell’Artigianato, 36035 Marano Vicentino (Vicenza) - Italy

17

Dough sheeter SF450 - SF500 - SF600 Operation and maintenance manual (translation of original instructions) – Ed. 10/2016

Rev.02 10/2017

All rights reserved. Reproduction in whole or in part of this manual is prohibited.

3 INSTALLATION AND USE

3.1 INSTRUCTIONS REGARDING THE PLACE OF INSTALLATION

The place in which the machine is to be kept and/or used must comply with the applicable law and provide

adequate protection against impact, damage, deterioration and atmospheric agents. Access routes to the place

of installation must be of a size and type to allow the machine to pass easily without the risk of causing injury to

people or damage to the machine itself. The floor, supporting structures and walls must have characteristics that

are compliant with laws and regulations, also in consideration of the overall load that is to be supported and

relative safety coefficients. The floor and walls of the room must be easy to clean and, if it necessary, to

disinfect and disinfest. The floor must be flat, not sloping, solid and free from holes and bumps.

The electrical system and the equipotential protection circuit (ground) of the site must comply with current laws

and regulations. They must be installed, maintained and, if required by law, inspected by authorised and

professionally qualified technicians who are able to issue a declaration of conformity.

Suitable safety devices must be installed on the upstream power supply panel to provide overcurrent and short

circuit protection and, if necessary, against phase-phase, phase-neutral (if applicable) and phase-ground

failures.

3.2 TRANSPORT, HANDLING AND POSITIONING

Depending on the destination and the contractual agreements, the machine will be shipped:

- wrapped in “bubble wrap”, stretch film and fixed to a pallet (see example in Figure 8/A)

- without wrapping materials, fixed to a pallet (see example in Figure 8/B)

- only wrapped in “bubble wrap” and stretch film (without pallet)

- without wrapping materials, contained in thick gauge cardboard box fixed to a pallet

- (by sea) in a “barrier bag” and a thick gauge cardboard box fixed to a pallet.

The load should be secured to the floor of the transport vehicle using suitably positioned wooden blocks and/or

lashed above 2/3 of its height to fastening points on the vehicle to prevent it from moving during transport.

To handle the machine when it is on the wooden support (pallet, packaging base with carton etc.) use a forklift

truck having an adequate lifting capacity for the total weight to be lifted (see section 2.6). Insert the forks inside

the end stringers and as close as possible to them to avoid sideways movements (be careful not to damage

parts of the machine).

Figure 8 - Handling the palletised machine using a forklift truck

Remove the machine from its packaging, separate the materials by type (plastic, wood etc.), place them in a

storage area that is only accessible to authorised personnel and arrange for disposal according to current

regulations.

In Italy and other countries, especially in the European Union, waste disposal and environmental

protection regulations are clearly defined by current legislation.

Check that the machine and its parts are intact. If in doubt, consult the manufacturer.

To lift the machine on its own (e.g. to move it from the pallet and place it on to the floor):

- model SF450: the benches must be in the folded position and secured (see section 3.5.1). Place two slings ref.

1 having a suitable lifting capacity (the weight of the machine is indicated in section 2.6, as well as on the

plate), under the crosspieces ref. 2 (one on each side) as shown in Figure 9. Then connect them to lifting

equipment with a hook, such as a crane, hoist, etc. (do not for any reason connect them to the forks of a

forklift truck).

The distance between the crosspieces ref. 2 and the lifting hook must be at least 2000 mm. The smaller the

angle formed by the slings, the lower is the pressure exerted on the raised tables (lower risk of damage) and

the lower is the possibility of them approaching one another (the lower the risk of the load tipping and falling).

Benches

Cutting unit

SF600

SF500

SF450B

A

B

C

FLAMIC S.R.L. 5 Via dell’Artigianato, 36035 Marano Vicentino (Vicenza) - Italy

18

Dough sheeter SF450 - SF500 - SF600 Operation and maintenance manual (translation of original instructions) – Ed. 10/2016

Rev.02 10/2017

All rights reserved. Reproduction in whole or in part of this manual is prohibited.

- models SF500, SF500B and SF600: insert the forks of the forklift truck from the side opposite the controls,

inside and as close to the points at which the base rests on the floor (wheels for SF500 and SF600, feet for

SF500B). The forks must protrude by at least 200 mm from the opposite side.

Model SF600 machines are shipped with the benches dismounted and packaged together with the rest of the

machine. The cutting unit, if ordered, will also be included in the same package (see Figure 8/A).

Models SF450 and SF500 are shipped with the benches installed and folded (Figure 8/B-C).

Accessories and optionals are usually packaged together with the machine.

Figure 9 - Lifting slings for model SF450

WARNING

Do not use handling devices and/or systems other than those described here.

The removal of packaging materials, handling and positioning should and must only be carried out by

skilled personnel (mechanical technicians, handling equipment operators trained to use forklift trucks) that are

wearing safety footwear with reinforced toecaps and a puncture-resistant sole (because of the possible

presence of nails), abrasion resistant work gloves and a hard hat.

When handling and/or transporting the machine or its parts, take all the necessary precautions to avoid

or to minimize risks to people, animals and property.

Only lift the machine as much as is strictly necessary, avoid jolting it and place it on the floor as soon as

possible. The machine is fitted with 4 wheels (except for version “B”) so once on the floor, it can be moved by

simply pushing it.

WARNING

When moving the machine on its wheels, the tables must be in the lowered position and, if for any

reason, they need to be raised (for example to save space during storage) it should be done only at the last

moment.

Moving the machine on its wheels with the benches in the upright position may pose a tipping over and

falling hazard (for example if it were to hit an obstacle on the floor or a wheel were to go into a hole in the floor)

and the impact could cause severe bruising to the exposed persons.

The same applies for model SF450 machines that are mounted and properly secured on the trolley (optional)

supplied by Flamic (see Figure 2).

When positioning the machine, leave adequate clearance around it, not only for work related to production, but

also for any other work that needs to be carried out, for example, cleaning. It is usually sufficient to leave 1000

mm of free space on each side, unless the machine is at the edge of an escape route, in which case at least

1200 mm of space should be left. All doors close to the machine must be unobstructed and easy to open. The

same applies to doors of furniture, appliances, machines etc. Before using the machine, lock the wheels (if

present) with the brake levers ref. 1 Figure 10

Figure 10 - Wheel brake levers

Controls side

Side opposite the controls

1

1

1

2

Tables folded and

secured (see section

3.6.1)

FLAMIC S.R.L. 5 Via dell’Artigianato, 36035 Marano Vicentino (Vicenza) - Italy

19

Dough sheeter SF450 - SF500 - SF600 Operation and maintenance manual (translation of original instructions) – Ed. 10/2016

Rev.02 10/2017

All rights reserved. Reproduction in whole or in part of this manual is prohibited.

3.3 ELECTRICAL CONNECTIONS

All electrical work in connection with the machine and/or the place in which it is used, must be carried out by

skilled and experienced technicians, who possess the technical and regulatory knowledge to carry it out safely,

in a workmanlike manner and according to the law. If required, they must also issue a declaration of conformity

provided for by law.

When the machine is delivered and anyway before connecting it to the mains power supply, make sure that the

mains voltage is the same as that indicated by the manufacturer on the identification plate (section 2.7) and

in the wiring diagrams.

The machine is supplied with a power cable and usually with a plug. If at the request of the customer, the

machine is supplied without a plug, it is up to the customer to take responsibility for providing a suitable plug for

the electrical outlets on site. Obviously it must also be suitable as regards polarity and current (assign this task

to an experienced electrician) according to the indications and information provided on the wiring diagram and

on the machine identification plate.

Use an earthing system, the working order of which must be checked periodically. Do not connect to gas or

water pipes or to other generic metal parts.

Keep the power cable away from hot and/or moving parts. It should not obstruct the passage of people, animals

or things.

The plug must be easily accessible and clearly visible at all times from any position in which the operator could

find himself/herself, even if only a short time.

For machines using three-phase power, when the machine is first started up, check the direction of rotation of

the motor: the conveyor belts must move according to the start control and reverse device as described in

section 2.4. If this is not the case, invert two phase wires (be careful not to swap a phase wire with the earth

wire, the latter can be recognized because it is yellow-green).

Some indications for doing this are shown in Figure 11:

- Separate the cap of the plug from the terminal block

- Pass the cable through the hole at the top of the cap, then connect the individual conductors to the plug

terminals

- tighten the terminals and close the terminal block with the cap, as shown in Figure 11.

Figure 11 - Power cable plug

.

Terminal block

Terminal block

3-phase 230 V (L1 – L2 – L3) + earth (PE)

Earth wire terminal

block (PE)

Phase wire terminal

blocks

Cap

400 V 230 V

Closed power plugs (3 phase + PE)

3-phase 400 V (L1 – L2 – L3) + earth (PE)

Earth wire terminal

block (PE)

Phase wire terminal

blocks

Cap

FLAMIC S.R.L. 5 Via dell’Artigianato, 36035 Marano Vicentino (Vicenza) - Italy

20

Dough sheeter SF450 - SF500 - SF600 Operation and maintenance manual (translation of original instructions) – Ed. 10/2016

Rev.02 10/2017

All rights reserved. Reproduction in whole or in part of this manual is prohibited.

2

3.4 INSTALLING/REMOVING THE TABLES OF A SHEETING MACHINE (MOD. SF600)

The instructions 3.4.1 for installing the tables of a model SF600 sheeting machine are given in section 3.2,

which, as explained in section , when supplied by Flamic, have to be installed on the machine (even if they are

received in the same package. See Figure 8/A).

Instructions 3.4.2 for their removal are given in section

Models SF450 and SF500 on the other hand, are supplied with the tables already installed. Their removal and

installation, which is only necessary for maintenance purposes (for example to replace the conveyor belts),

involves complex tasks which must be carried out by FLAMIC technicians, or anyway by very experienced

(special/extraordinary maintenance) mechanical technicians. The instructions are given in section 4.6.

The installation/removal of tables for model SF600 machines requires two operators at the same time to carry

out the work, of which at least one has mechanical installation experience. The second operator is required to

help support the table while the work is being carried out. Before starting, lock the wheels of the machine with

the brake levers (see Figure 10) and wear at least safety footwear with reinforced toecaps and abrasion

resistant work gloves.

To make the work easier, completely raise the interlocked guards in the roller infeed zone (see section 3.5.2).

3.4.1 INSTALLING A TABLE (MOD. SF600)

Wear at least the PPE indicated in section 3.4. With reference to Figure 12, raise the guard ref. 6 completely

(see section 3.5.2) on the side on which the table is to be installed (photo A) and remove the scraper ref. 7

(section 4.5 and section 4.5.2.3).

The table must be kept in a horizontal position by holding it at points far enough apart so that it can be easily

supported. Whilst operator Xsupports his side of the table ref. 1, operator Y(experienced mechanic), whilst also

supporting the table, engages the end of the roller ref. 3

with the cylinder ref. 2 that protrudes from the upright. He must then push the bench in the direction indicated by

the arrow F1 in order to compress the spring (not visible in the figure) that pushes the cylinder ref. 2 outwards.

Immediately afterwards (almost at the same time) he must move the bench in the direction indicated by arrow

F2 so that the cylinder ref. 5 is inserted in the other end of the roller ref. 4. Rest the table in a horizontal position

on its support (section 3.6.3). Then install and fasten the scraper ref. 7 (see section 4.5 and section 4.5.2.3).

Figure 12 - Installing the benches (mod. SF600)

X

3

1

Y

F1

F2

4

5

6

A

B

7

This manual suits for next models

2

Table of contents

Popular Industrial Equipment manuals by other brands

Haufftechnik

Haufftechnik HSI150 DFK installation instructions

Ditch Witch

Ditch Witch 410SX Operator's manual

JackRabbit

JackRabbit CO-JACK 197+ Owner's/operator's manual

Delta

Delta LE-412523 user manual

Alfalaval

Alfalaval AlfaNova 14-76, AXP AN instruction manual

KEBCO

KEBCO COMBILINE E6 Series Instructions for use