Partialdisconnectionofhoseorleakingconnection.

BrokenHose

Lowairfloworpressure

Noorlowoilsupply

Inclinedorvibratinglubricator

Excessiveoilinoilreservoir.

Excessiveoildriprate

Moistureintheoilreservoir.

Moistureintheairfilter.

Noairflow

Damagedmotorbearings

Contaminantsinsidethechuckorthespindle.

ColletNutisnotproperlypositioned

Cuttingtoolisbent

Ballbearingiswornout

Usethebenttool

GroundParticlesstuckinthecolletchuckor

spindle.

Ballbearingiswornout.

11 Troubleshooting

Whenthetroubleisfound,pleasecheckthefollowingpriortoconsultingyourdealer.

Trouble Cause Inspect/CorrectiveAction

Checkalljointsandre-tightensealconnections.

Replacethehose.

Checktheaircircuit.

Checktheoilvolumeintheoilreservoirandincreasethedriprate.When

using NAKANISHIs lubricator, adjust to 30-40 drops/min,1-3 drops/min

forotherlubricatorsthatsupplyoildirectlyintotheairhose.

Ifthelubricatorisinclinedorsubjecttovibration,alargevolumeofoilwill

flowandthespindlewillrotateirregularly.

Alargevolumeofoilwillflowandthespindlewillrotateirregularly.Drain

oiltotheappropriatevolumebylooseningthevalve.

Decreasedripratetostabilizemotorspeed.

Drainmoisturefromthelubricatorandreplaceoil.

Drainmoistureintheairfilter.

Check the regulator and set at the appropriate air pressure. Check all

hoseconnections.

Check air compressor power supply and air outlet. Check hoses for

leaks,bendsordisconnections.

SendtoNAKANISHIforRepair

Cleantheinsideofthechuckandthespindle.

Setthechuckthechucknutproperly

Replacecuttingtool.

SendtoNAKANISHIforRepair

Changethetool.

SendtoNAKANISHIforRepair

Low

Rotation

Speed

NoRotation

Excessive

Runout

Noiseor

vibration

during

rotation

13

6

!

!

"#"$

①AttachHTS1501Sintothequillofthemachiningcenter.

②Securetheairhosetoasuitableplaceonthemachiningcenterandcheckthatyouhaveallowed

enoughslackforthequillsfullrangeofmotion.

※Ifthemainspindleisrotatedbymistake,checktheairhoseandmachiningcenterfordamage.And

useitonlyaftertest-running.

7

% & # ' ( )'*+,-

①ConnecttheFilterJointoftheAirIntakeHoseofHTS1501StotheHoseConnectorontheAir

LineKit.

②AttachtheotherendoftheAirIntakeHosetotheeasyconnectionjointontheHTS1501S.

③Filloil reservoir through theOil Filler Cap withrecommended NAKANISHI oil(liquid paraffin ISO

VG15)toupperlimitontheReservoir.DisconnectfromairsupplypriortoopeningOilFillerCap.

Donotoverorunderfill.

④AttachthehoseforairpipingtotheconnectorontheAirlinekit.

⑤Attachtheoppositesideofthehoseforairpipingtotheaircompressor.

⑥Supply air from the air compressor and turn regulator knob clockwise(clockwise=high)to set air

pressurebetween0.5MPa.

⑦Run the motor at the proper pressure. Close the Oil Drip Rate Adjusting Screw by turning

clockwiseandthenturnOilDripRateAdjustingScrewcounterclockwisetoadjustdriprateto30-40

drops/min.(IfyourenotusinganNAKANISHIlubricator,adjustbetween1-3drops/min.)

⑧Aftersettingtheproperdroprateyouareallreadytousetheairmotor/spindle.

"("##

. /! +0 . .

! 1

. ,*

!

%2#3"

①

4 ! ! 5 1

6 ! . "("##

5

! ! 7 5 .

! # ! ! 6

! ! .

②

%5

8 / 71 5

# / 71 !

.

③

. ' ( 9 ' ( 3

7:

!

% ' (

③AdjustingtheOilDripRate(

;<

)

RunHTS1501Satthespecifiedairpressureandadjusttheoildrip

ratetotherecommendedratebyturningtheOilDripRateAdjusting

Screw.(About30to 40 drips/min) Turnthescrew counterclockwise

to increase the rate and clockwise to decrease. When using non-

NAKANISHIlubricator,adjusttheoildripratetoabout1-3drips/min.

④RemoveOilandMoistureRegularly(

;=

)

Remove and replace the oil in the Reservoir once a month, to

ensureapureoilsourceforthemotor.Moisturemaycollectandmix

withtheoilintheReservoiranddamagethemotor.OpentheDrain

Valveatthebottomofthereservoirbyturningitcounterclockwise.

⑤Oil

LiquidparaffinISOVG15isrecommended.

Increase

Decrease

OilFiller

OilReservoir

DrainValve

9

% %

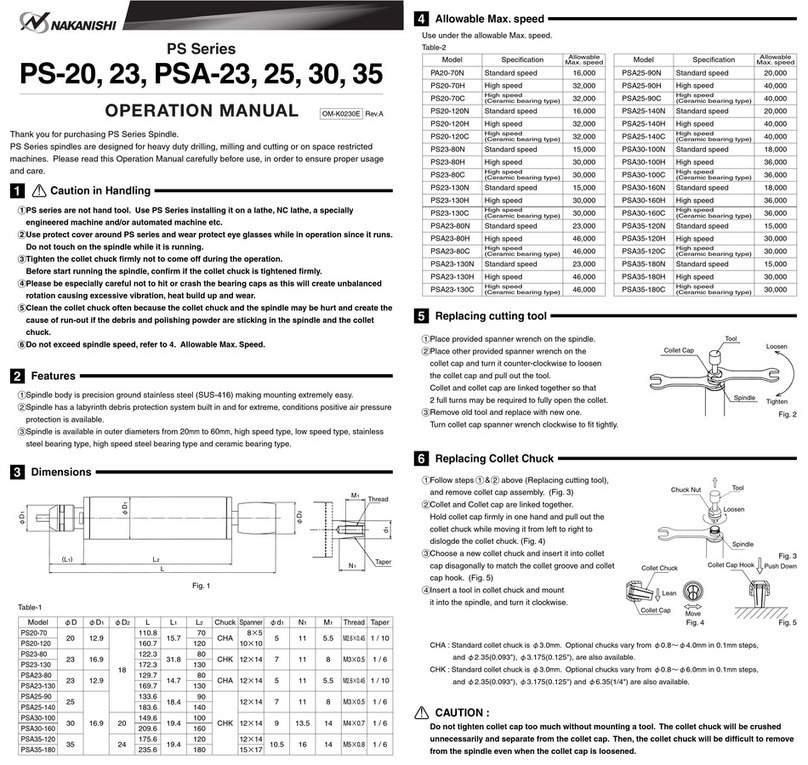

①Thepropersurfacespeedforvitrifiedgrindstonesis600-1,800m/min.

10

2 %

HTS1501 is designed to prevent coolant from entering the motor/spindle by using the air used for

driving the turbine as an air purge. Never spray coolant directly on the HTS1501S main body,

because coolant may enter the motor/spindle. Coolant or foreign particle contamination of the

spindle,sinternalcomponentswilldramaticallyshortenbearinglife.

②Do not exceed 13㎜ overhang for mounted grindstones. In case overhang must exceed 13㎜

reducethemotorspeedinaccordancewithFig.19.

③Donotusetoolswithbentorbrokenshanks,cracksorexcessiverunout.

④Dressthegrindstonepriortouse.

⑤Forgrindingthemaximumdepthofcutshouldnotexceed0.01㎜radiallyoraxially.Reciprocatethe

toolseveraltimesaftereachinfeedstep.

⑥Always operate tools within the tool manufacturers recommended speed limits. Use of a tool

outsideofthemanufacturersrecommendedspeedlimitscouldcausedamagetothespindleand

injurytotheoperator.

⑦Keepthetoolshankandcolletclean.Ifcontaminantsareleftinthecollettheycancauseexcessive

runoutanddamagethetoolandspindle.

⑧Donotdroporhitspindle.

SurfaceSpeed(m/min)= 3.14×Diameter(㎜)×rotationSpeed(min

−

1)

1,000

Overhang(㎜)

20

25

50

Speed(min

−

1)

N×0.5

N×0.3

N×0.1

Table1.OverhangandSpeed

N:Max.OperatingSpeedat13㎜Overhang

8 / >6

!

%2#3"

;?

2014.09.20 002

HoseConnector

;,

EasyJoint

Sidedome

OilFillerCap

FilterJoint

AirsupplyHose

ToAirCompressor

AirSupplyHoseConnector

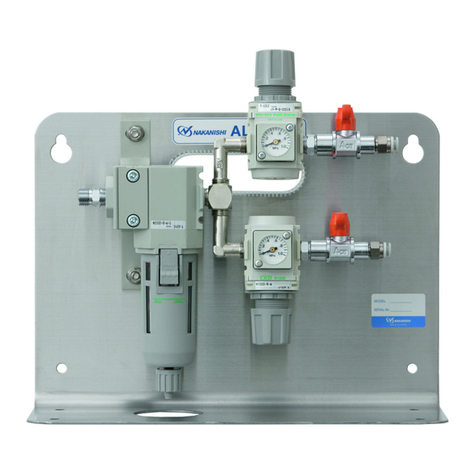

AirFilter RegulatorKnob Lubricator

8

' ( 3

①OilVolume(

;

)

Checktheoilvolumeatleastonceaweek.Iftheoillevelislow,

fill to the upper limit. If the oil level is above the upper limit,

removetheexcessoil.Takecarenottooverorunderfilltheoil

reservoirasthiscancausetheoildeliveryratetovary.

②MoistureintheAirFilter(

;@

)

Drain moisture from the Air Filter by pushing the Drain Valve

sideways.

.

! %

3 ; %

!

OilfillerCap

OilReservoir

DrainValve

OilGauge

UpperOilLimit

LowerOilLimit

PushRight&Left

DrainValve

%2#3"

;@

;

SideDome OilDripRate

AdjustingScrew

;<

;=

PressureGauge

OilDripRate

AdjustingScrew