SystemCables

DMXCables

AllSyncroliteproductsuseDMXprotocol.WerecommendamaximumDMXcablelengthof

2000’,thoughthesystemwilloperateupto1milefromtheDMXsourcewithqualitycableand

aDMXsplitter.ForarchitecturalSeriesunits,Syncroliteprovidesa6‐wayand12‐wayDMX

splitter.ThesearenecessaryinsystemsinwhichSyncrolitestatusmonitorproductsareused‐

normallyinlargefixedinstallations.

ACPowerCables/Feeder

SyncrolitepowerdistrosacceptstandardCamlocfivewireinput(3phases,ground,neutral)and

distributeoutputtoSyncroliteballastsvia8/5wirewithaHubbelltwistlockconnector.Euro

powerdistrosacceptPowerlockmainsinputsandareequippedwithgroundfaultprotection.

CAUTION:makesureyouusethecorrectcolorinputwiththecorrectoutput.Failure

todosocouldcauseafireorotherseriousinjuries.

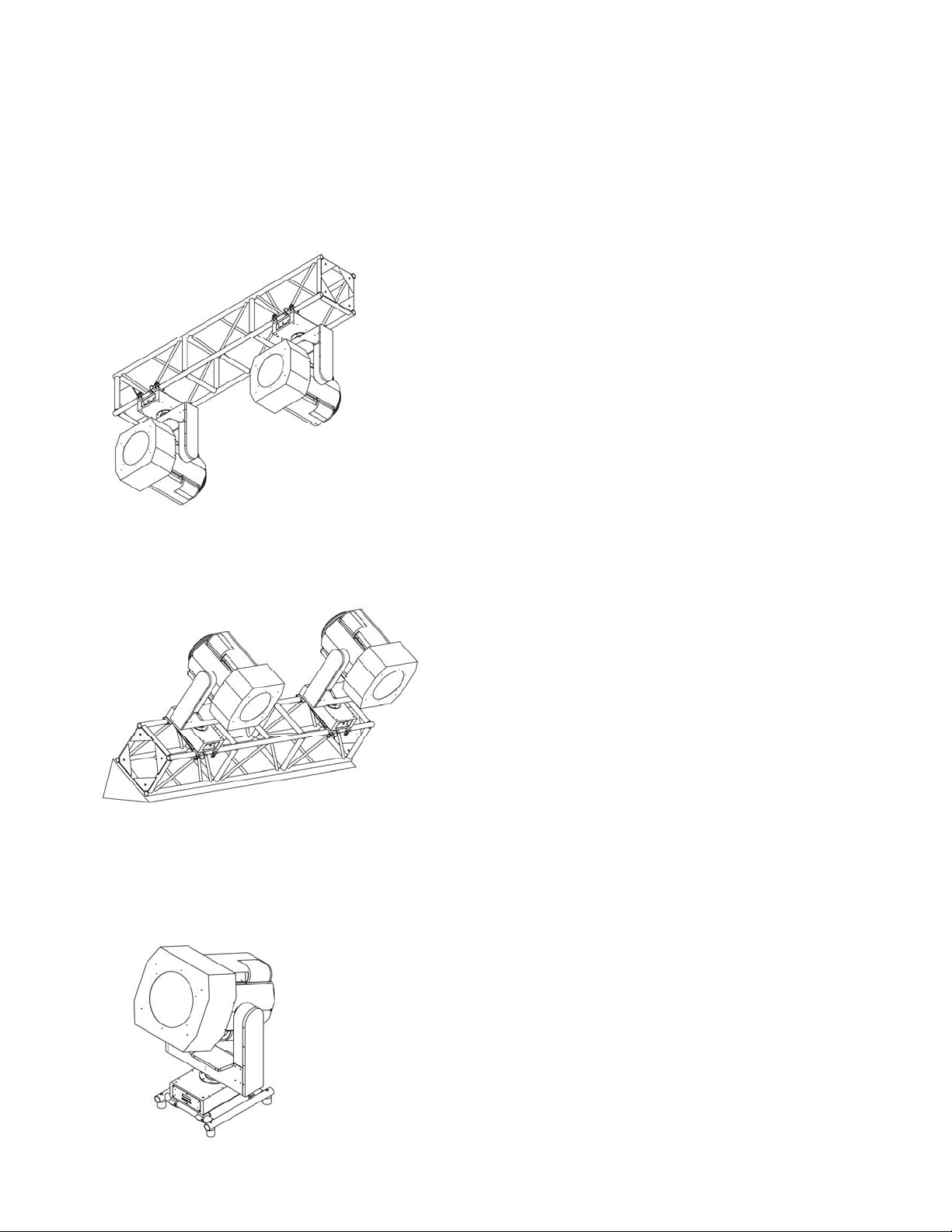

LampheadPowerCables

DClamppowerisprovidedbetweentheballastandlampheadviaapairofCamlocconnectors

on#1AWGentertainmentcable,tripedwithaproprietarySyncrolitecableemploying9‐pin

AmpmaleandfemalelineconnectionsprovidingdataandACforrobotandelectronicspower.

STSerieslampheadsinfixedorpermanentinstallationscanalsobehardwiredviaappropriate

cablingandconduit.

ACPower

The8/5ACprovidespowerfromthedistrototheballast.Itcontainsfiveinputs(3phases,

ground,neutral)anddistributesoutputtotheballastswithaHubbelltwistlockconnector.

Tail

Thetailswillnormallybehangingdownfromthegeneratororhousepowerforyoutoconnect

thefemalefeederintothetail.

7