System Sensor D4P120 User manual

Other System Sensor Smoke Alarm manuals

System Sensor

System Sensor INNOVAIR DH100LP User manual

System Sensor

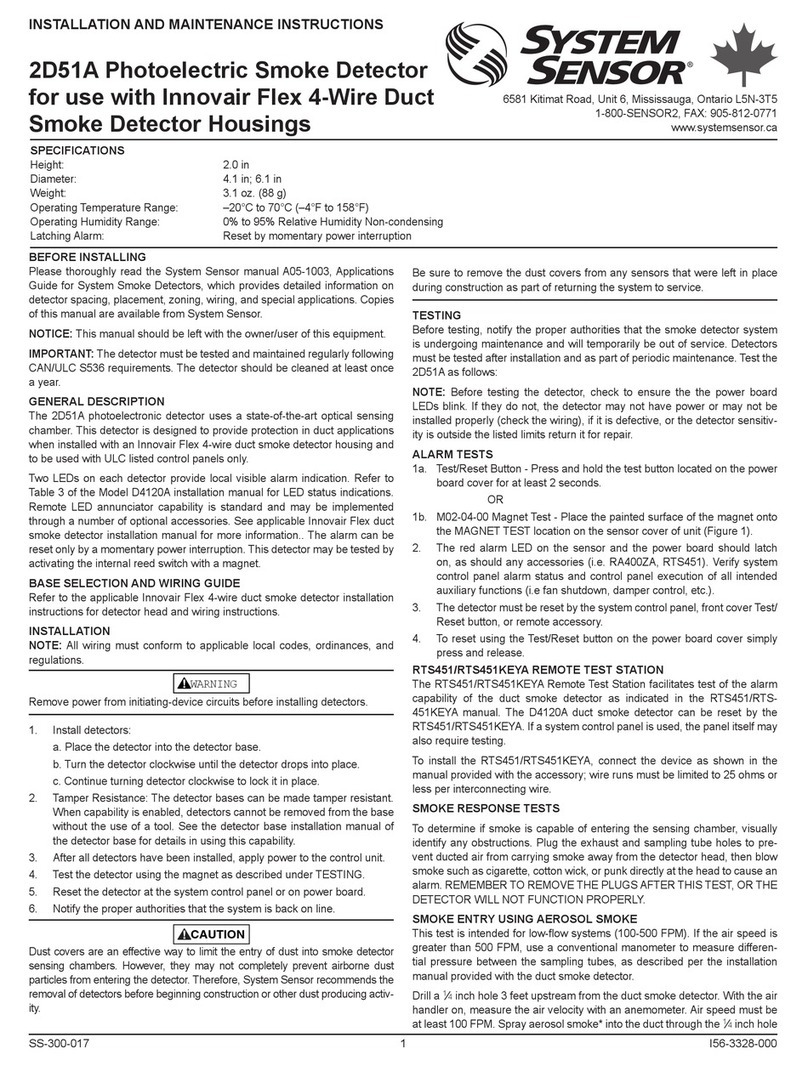

System Sensor 2D51A User manual

System Sensor

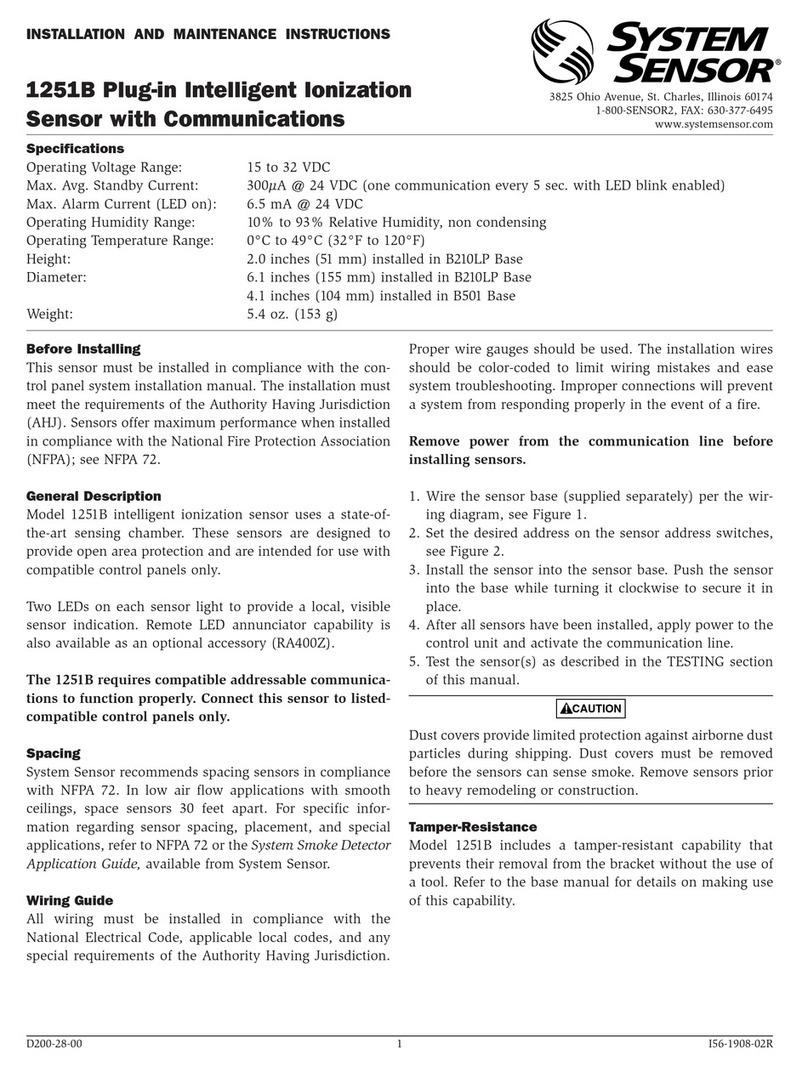

System Sensor 1251B User manual

System Sensor

System Sensor 2151TA User manual

System Sensor

System Sensor 2112 User manual

System Sensor

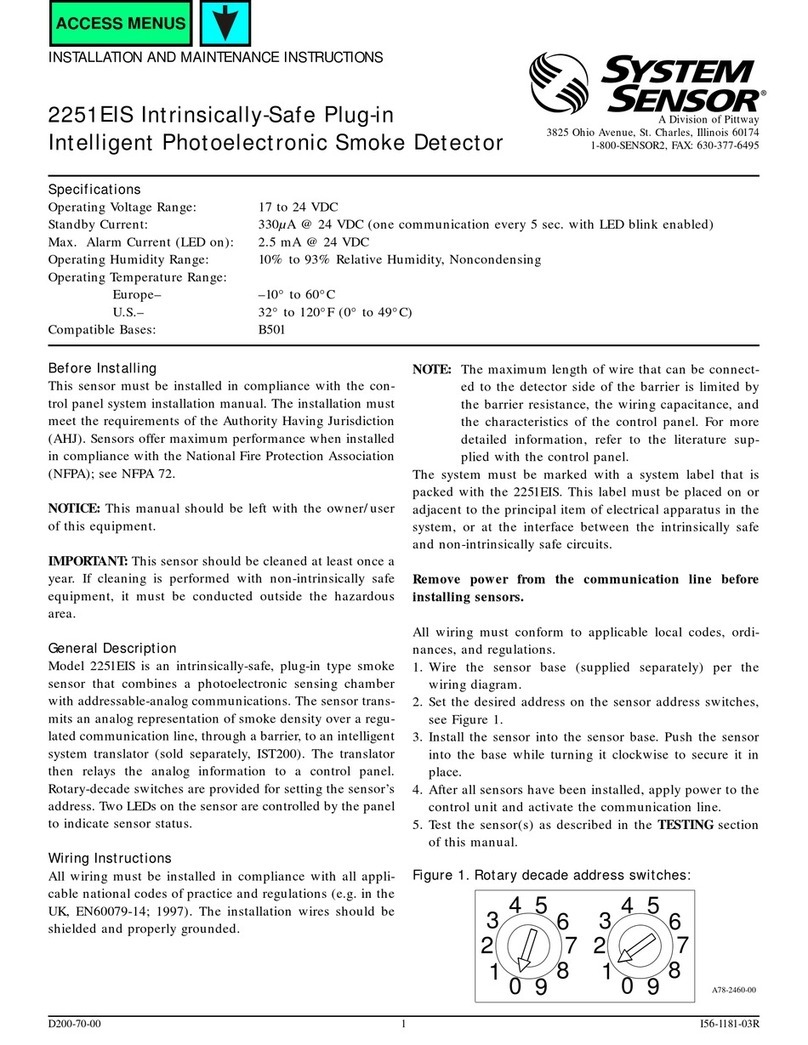

System Sensor 2251EIS User manual

System Sensor

System Sensor 2351E User manual

System Sensor

System Sensor Innovair DH100ACDCLPX User manual

System Sensor

System Sensor innovair flex D4120W User manual

System Sensor

System Sensor 5351E User manual

System Sensor

System Sensor 2012JA User manual

System Sensor

System Sensor i4 Series COSMO-2W User manual

System Sensor

System Sensor Innovair DH100LP User manual

System Sensor

System Sensor 2112TL User manual

System Sensor

System Sensor 2451, 2451TH User manual

System Sensor

System Sensor 1424 User manual

System Sensor

System Sensor BEAM1224 User manual

System Sensor

System Sensor 1112/24B User manual

System Sensor

System Sensor DH500ACDC User manual

System Sensor

System Sensor 7251 User manual

Popular Smoke Alarm manuals by other brands

Family Gard

Family Gard FG225 user manual

Regin

Regin SDD-S65 instruction manual

Aparton

Aparton ASD-10 Instructions for use

Greystone

Greystone DSD120 Installation and maintenance instructions

LST

LST ÜMS-55000-841 Specification sheet

Radal Technology

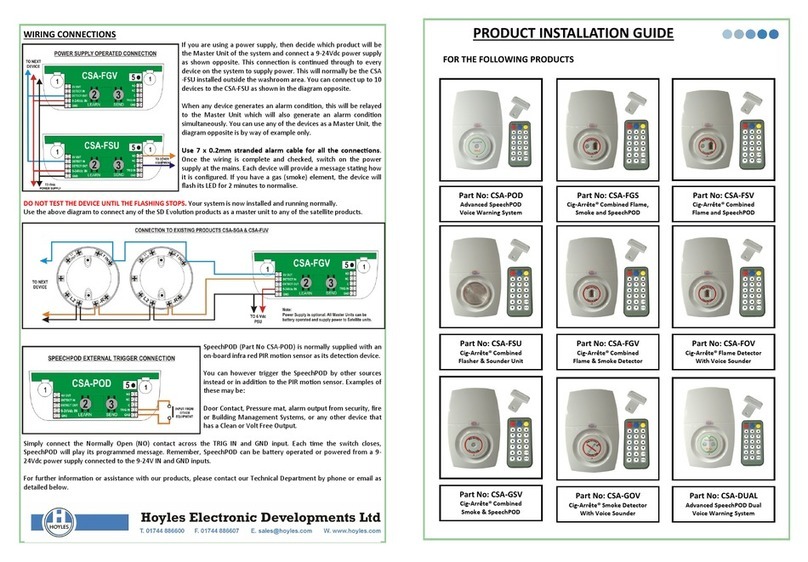

Radal Technology Cig-Arrête CSA-POD Product installation guide