System Sensor 1112/24B User manual

Other System Sensor Smoke Alarm manuals

System Sensor

System Sensor B501 User manual

System Sensor

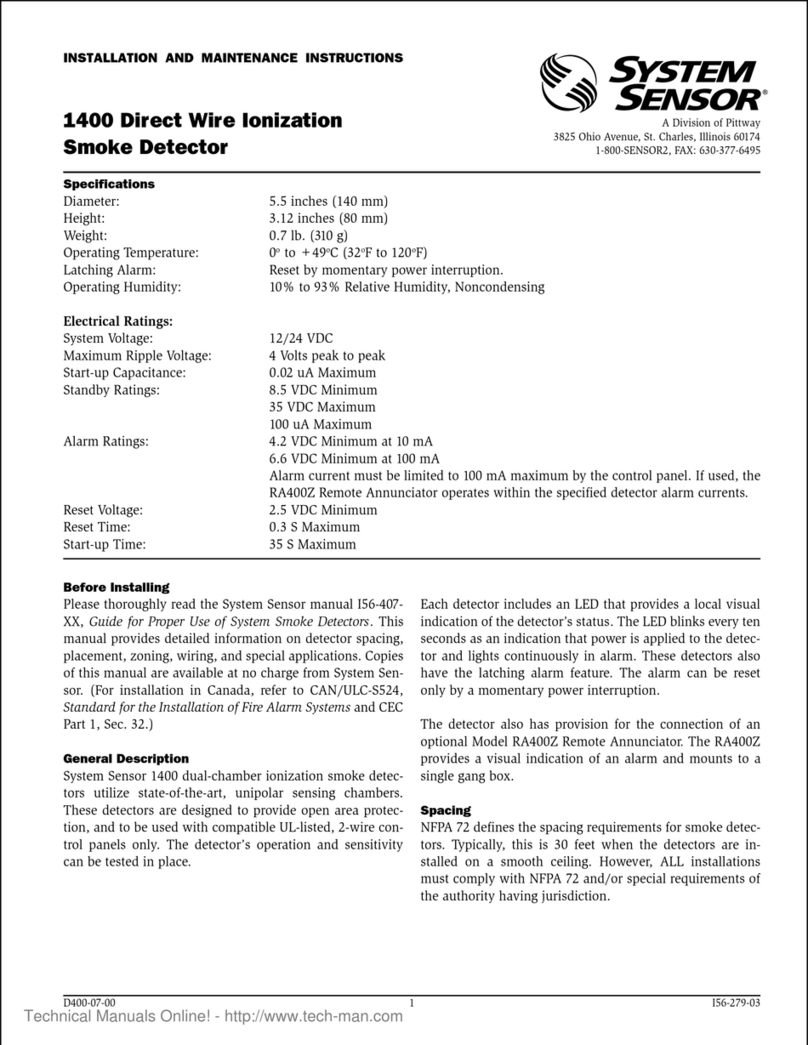

System Sensor 1400 User manual

System Sensor

System Sensor 2112 User manual

System Sensor

System Sensor 1400 User manual

System Sensor

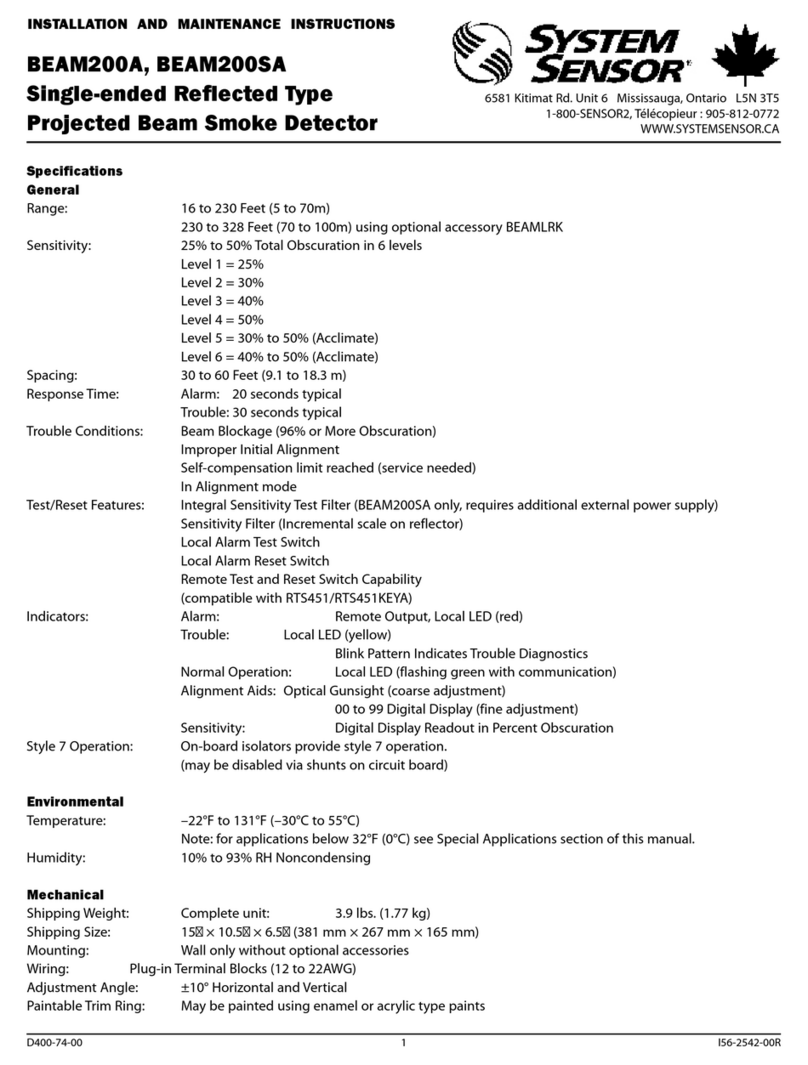

System Sensor BEAM200A User manual

System Sensor

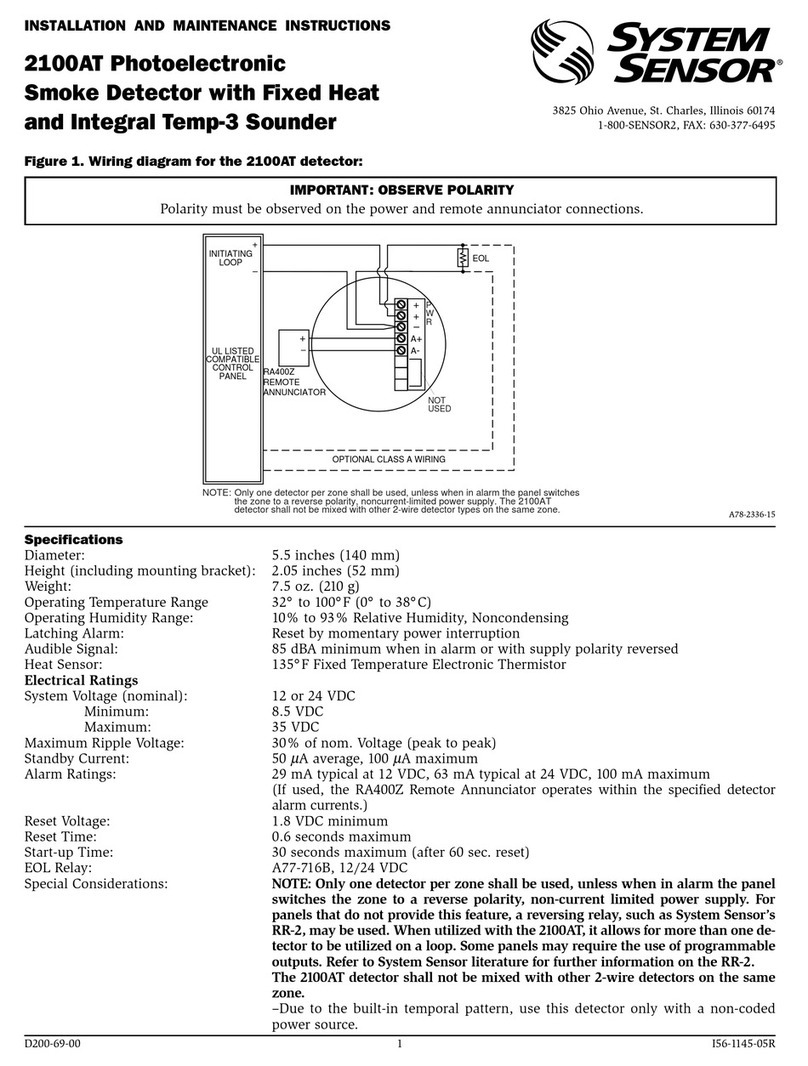

System Sensor 2100AT User manual

System Sensor

System Sensor Innovair Flex DNRE User manual

System Sensor

System Sensor WMSOU-RR-P01 User manual

System Sensor

System Sensor Innovair DH100ACDCLWP User manual

System Sensor

System Sensor ECO1003ABLINK User manual

System Sensor

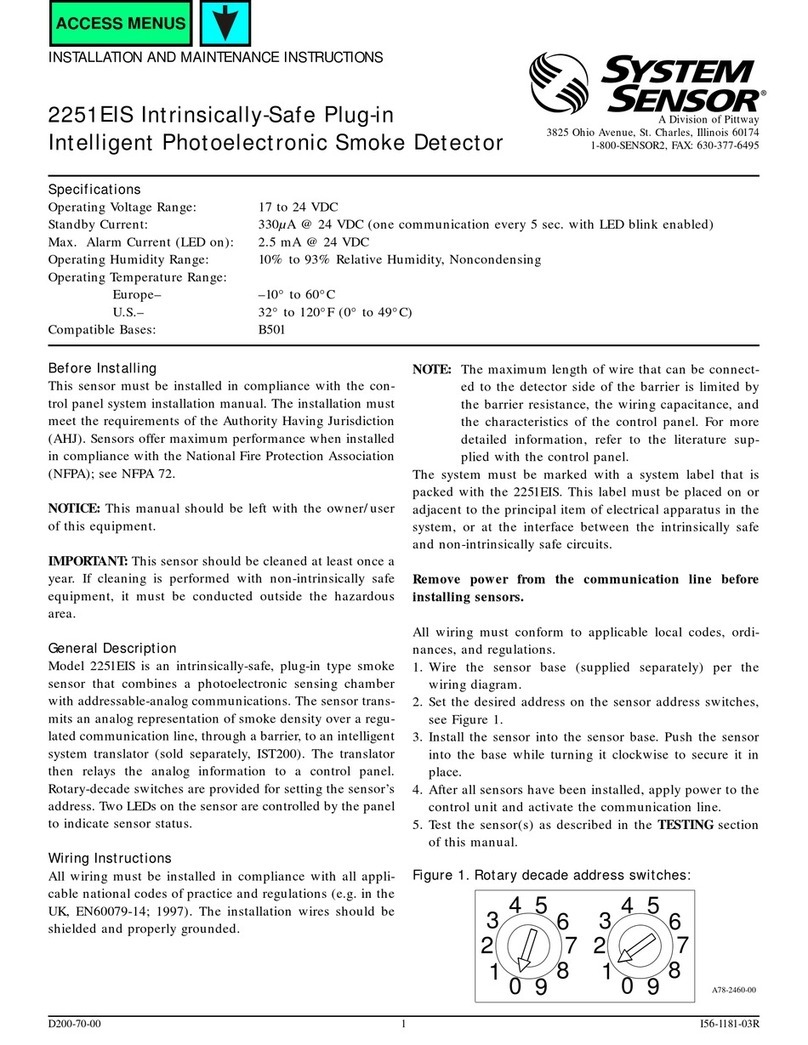

System Sensor 2251EIS User manual

System Sensor

System Sensor B402B User manual

System Sensor

System Sensor 2100S User manual

System Sensor

System Sensor 6500R User manual

System Sensor

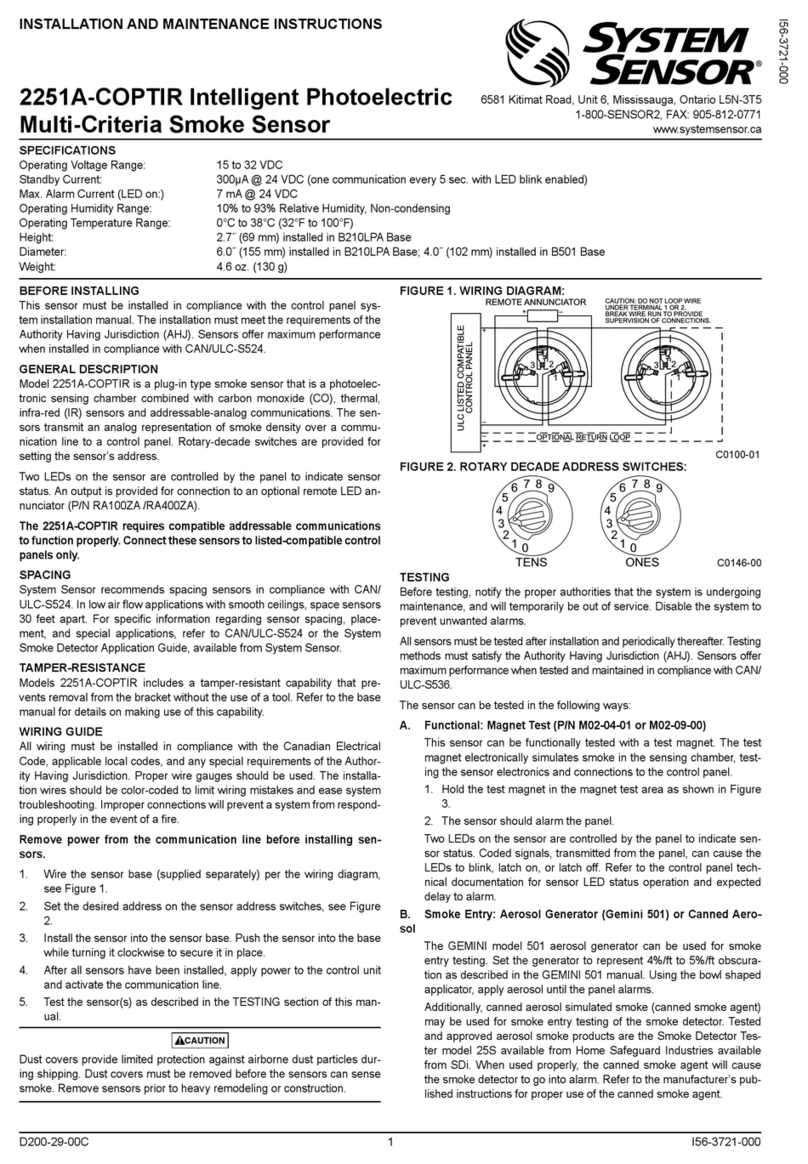

System Sensor 2251A-COPTIR User manual

System Sensor

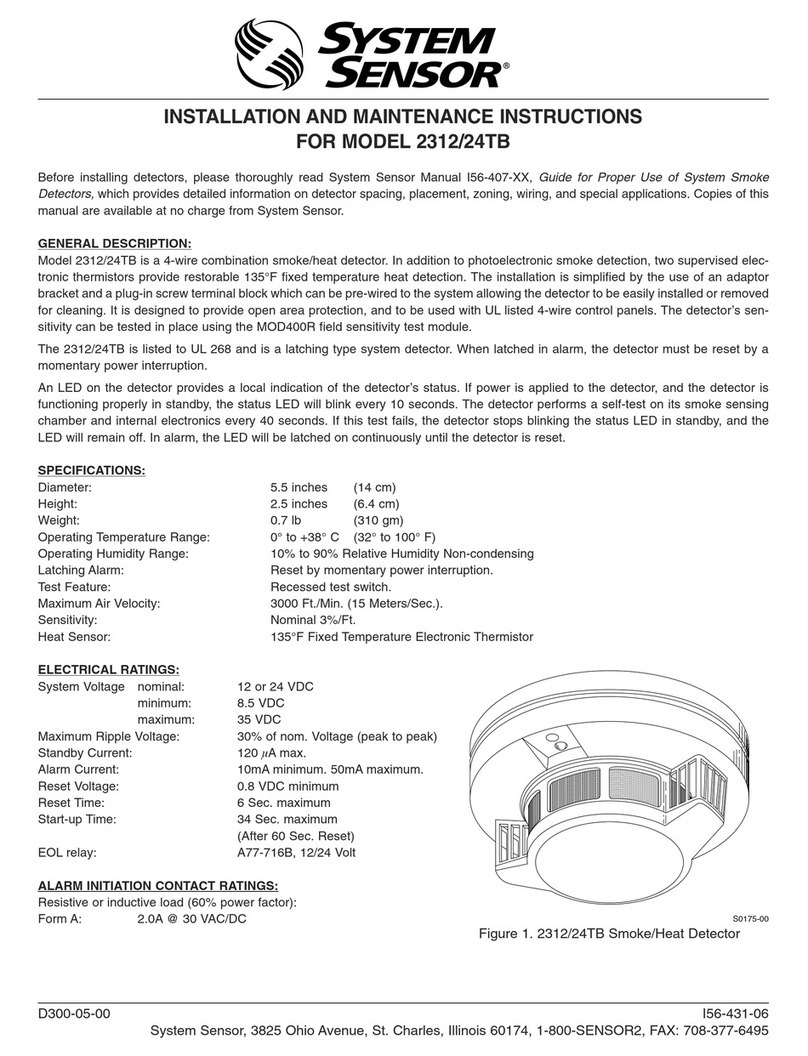

System Sensor 2312/24TB User manual

System Sensor

System Sensor 2351B User manual

System Sensor

System Sensor Innovair Flex D2E User manual

System Sensor

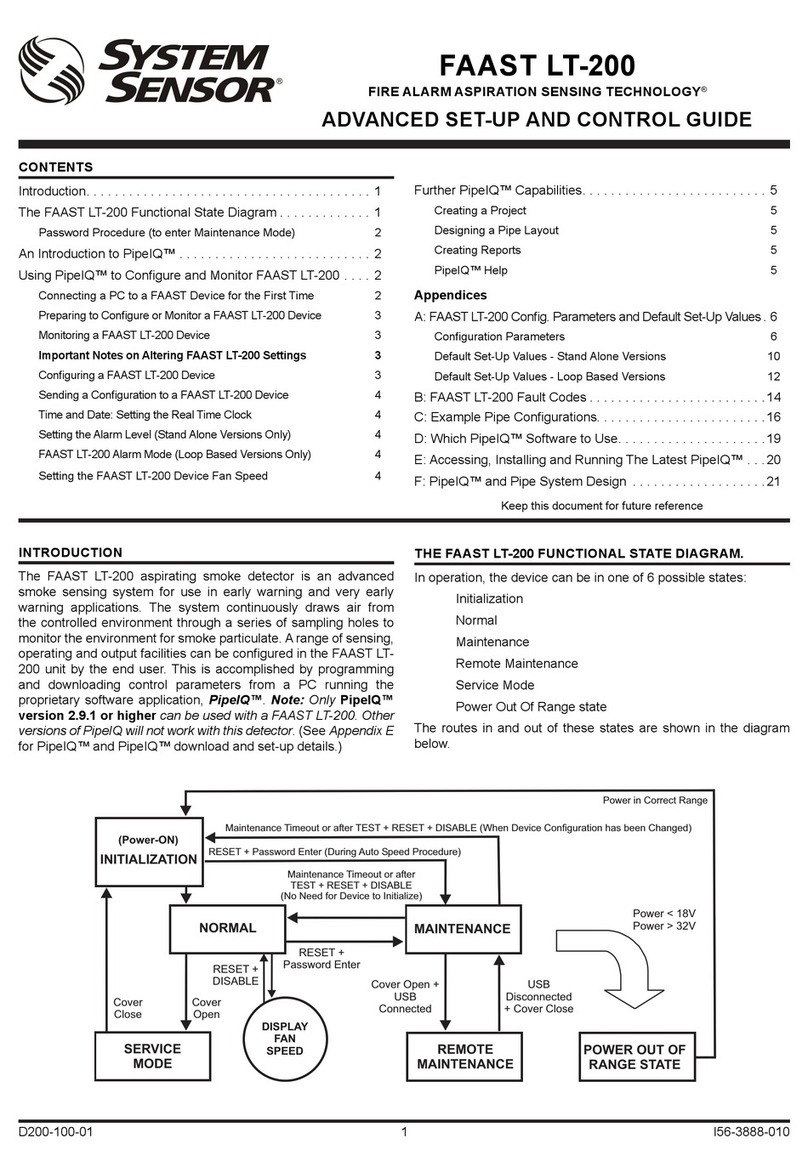

System Sensor FAAST LT-200 User manual

System Sensor

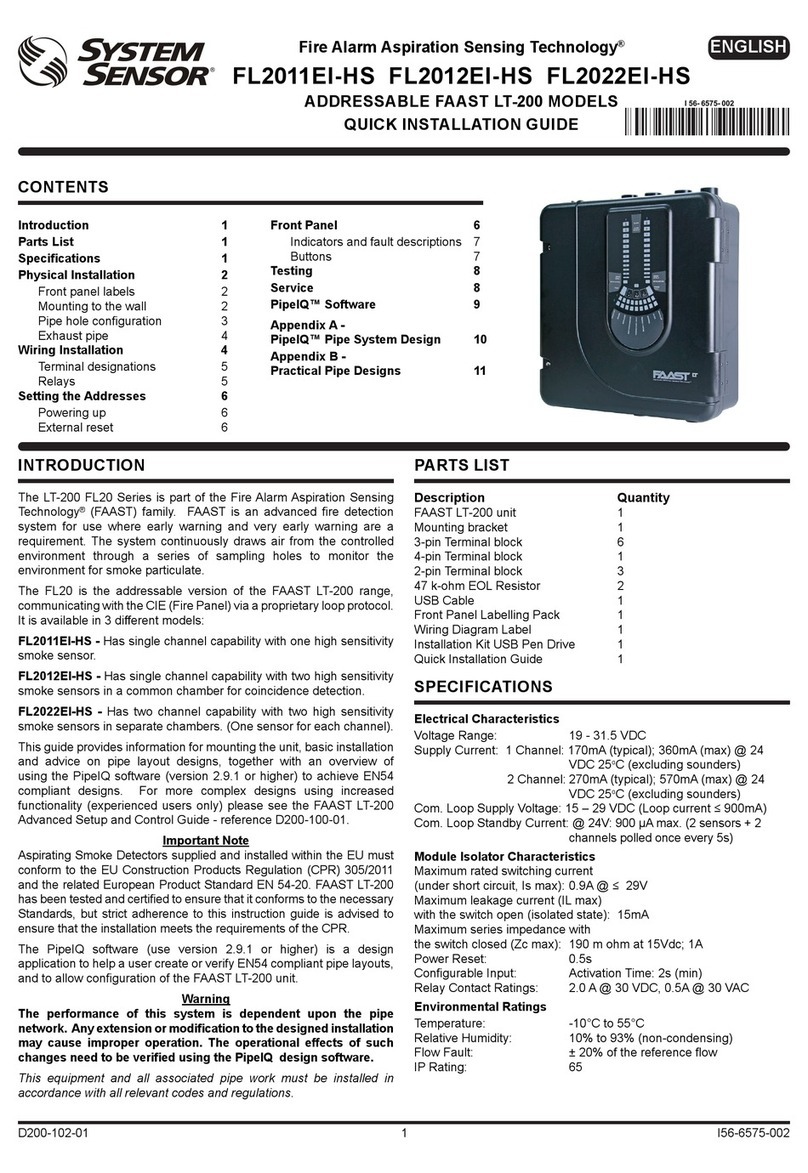

System Sensor FAAST LT-200 FL20 Series User manual

Popular Smoke Alarm manuals by other brands

Family Gard

Family Gard FG225 user manual

Regin

Regin SDD-S65 instruction manual

Aparton

Aparton ASD-10 Instructions for use

Greystone

Greystone DSD120 Installation and maintenance instructions

LST

LST ÜMS-55000-841 Specification sheet

Radal Technology

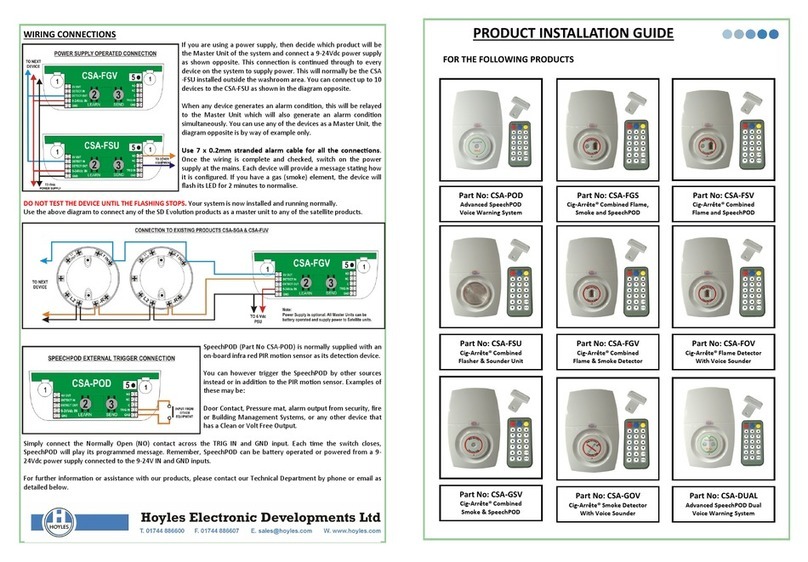

Radal Technology Cig-Arrête CSA-POD Product installation guide