COLLARING MACHINE

3

S-80

CONTENTS

................................................................... 5

1.1. General .......................................................................................................................... 5

1.2. Symbols for warning and danger used in this manual................................................... 5

1.3. Symbols and warnings used in the TCC-28 machine ..................................................... 6

1.4. Personal protecve equipment for the operator .......................................................... 7

............................................................................................ 7

..............................................................

3.1. Introducon................................................................................................................... 8

3.2. The purpose of the machine ......................................................................................... 8

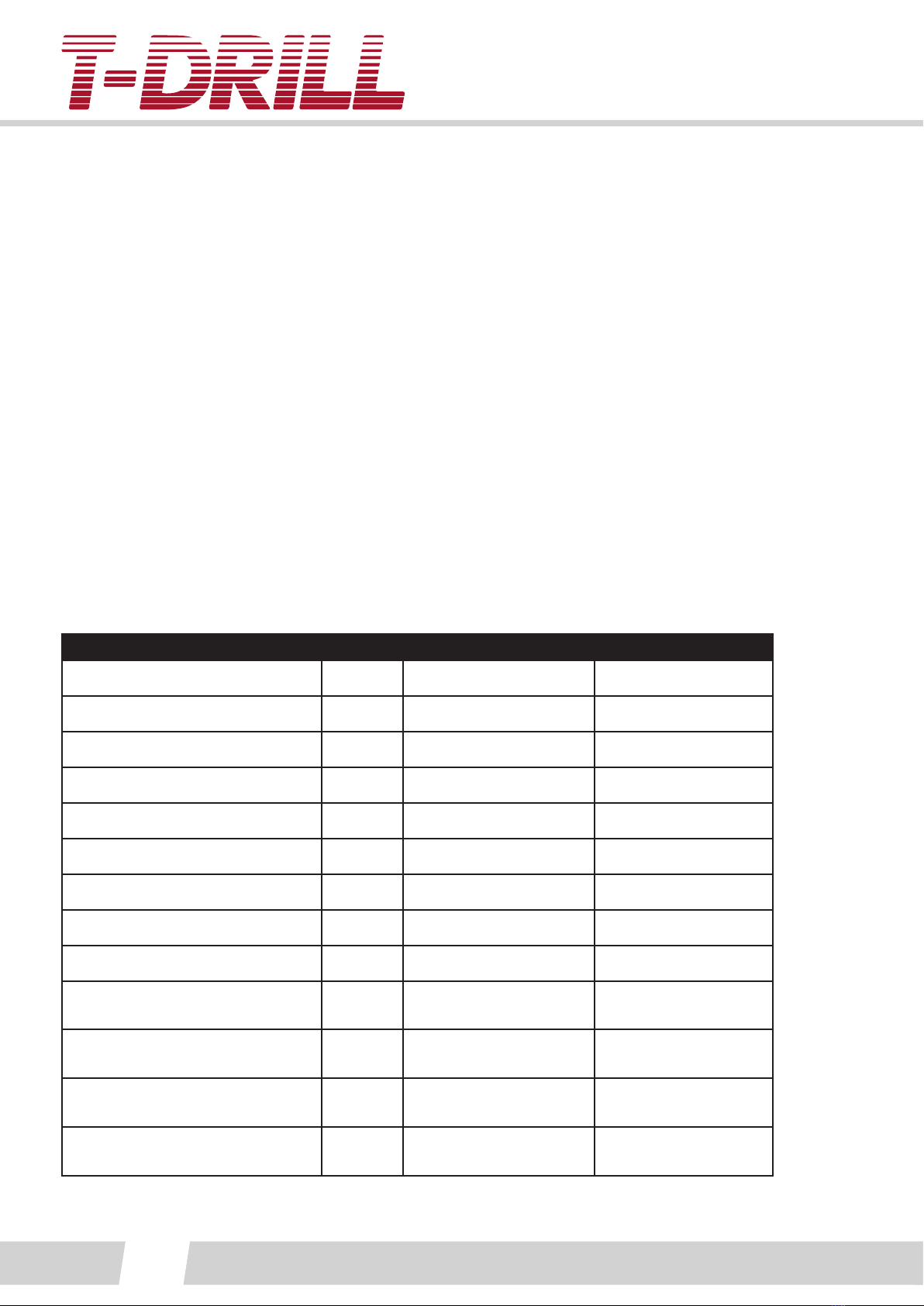

3.3. Technical specicaons ................................................................................................. 8

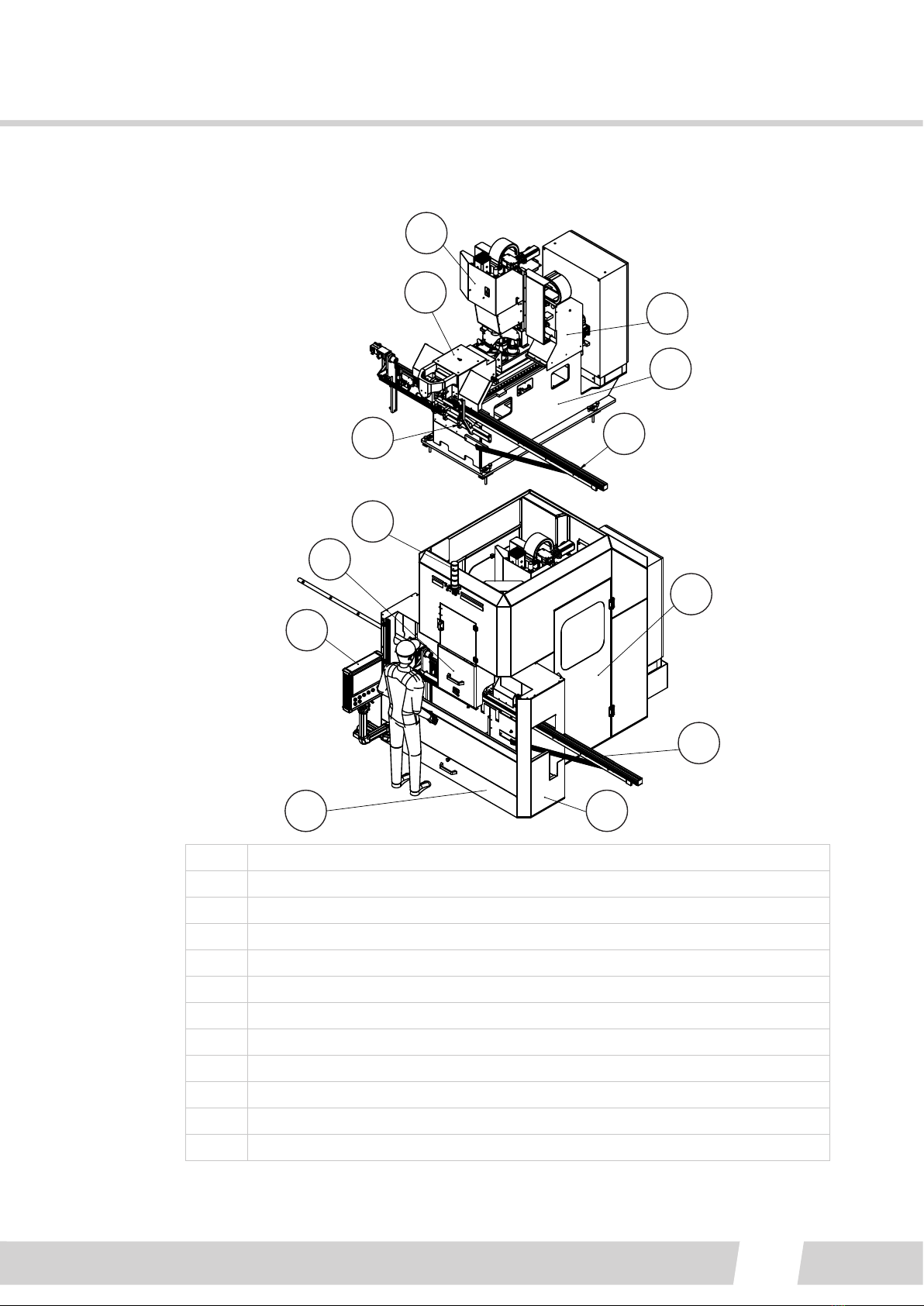

3.4. Main parts of the machine ............................................................................................ 9

3.4.1. Technical features of main parts .......................................................................... 10

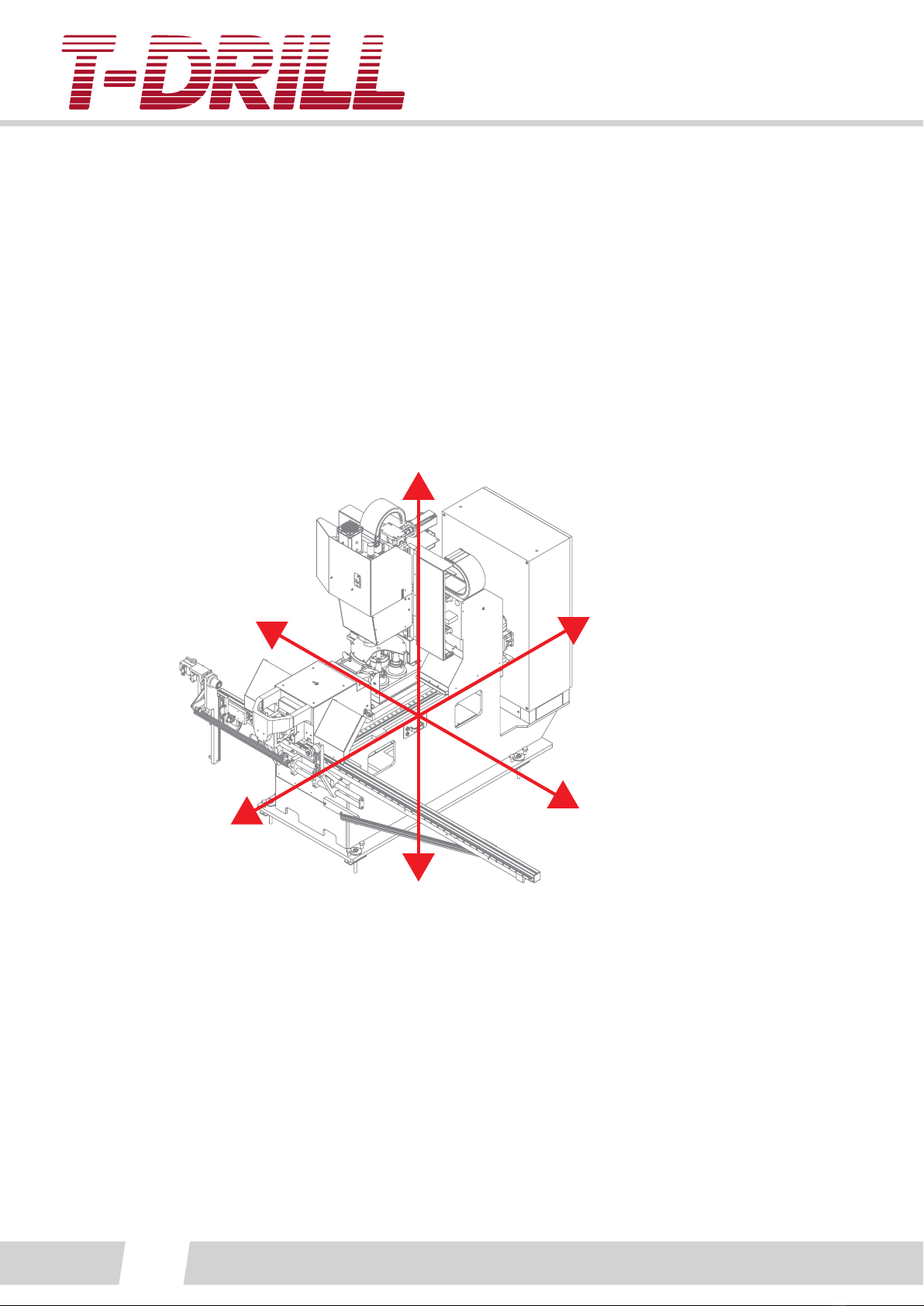

3.5. Axis direcons of the machine ...................................................................................... 10

.................................................................................... 11

4.1. Transport and locaon................................................................................................... 11

4.2. Liing instrucons......................................................................................................... 11

.................................................................................................................... 12

5.1. Ambient condions ....................................................................................................... 12

5.2. Layout of the S-80 Collaring machine............................................................................ 13

5.3. Installaon of the light curtains (oponal equipment).................................................. 15

5.4. Connecon of the machine to the sources of energy ................................................... 16

5.4.1. Connecon to the electricity network .................................................................. 16

5.4.2. Connecon to the compressed air system............................................................ 17

5.5. Start-up checking........................................................................................................... 17

..............................................................

6.1. Descripon of the control devices................................................................................. 18

6.1.1. Main switch.......................................................................................................... 18

6.1.2. Clamp remote control CB3 ................................................................................... 18

6.1.3. Control panel........................................................................................................ 19

6.2. Descripon of the user interface screens...................................................................... 20

6.2.1. Start-up screen ..................................................................................................... 20

6.2.2. Main screen.......................................................................................................... 21

6.2.2.1. Bar charts screen ........................................................................................... 24

6.2.2.2. Menu screen .................................................................................................. 24

6.2.2.2.1. Programs ................................................................................................. 25

6.2.2.2.2. Manual screen.......................................................................................... 27

6.2.2.2.3. Automac screen ..................................................................................... 29

6.2.2.3. Sengs screen ............................................................................................... 30

6.2.2.3.1. Machine sengs ...................................................................................... 31

6.2.2.3.2. Process sengs ........................................................................................ 32

6.2.2.3.3. Tool sengs.............................................................................................. 34

6.2.2.3.4. Tool magazine .......................................................................................... 40

6.2.2.3.5. Posions ................................................................................................... 42

6.2.2.3.6. Servo motors ............................................................................................ 43