SUGGESTION: For soft materials, it is recom-

mended to test within 3 seconds after lowering the

scratch pins onto the specimen surface.

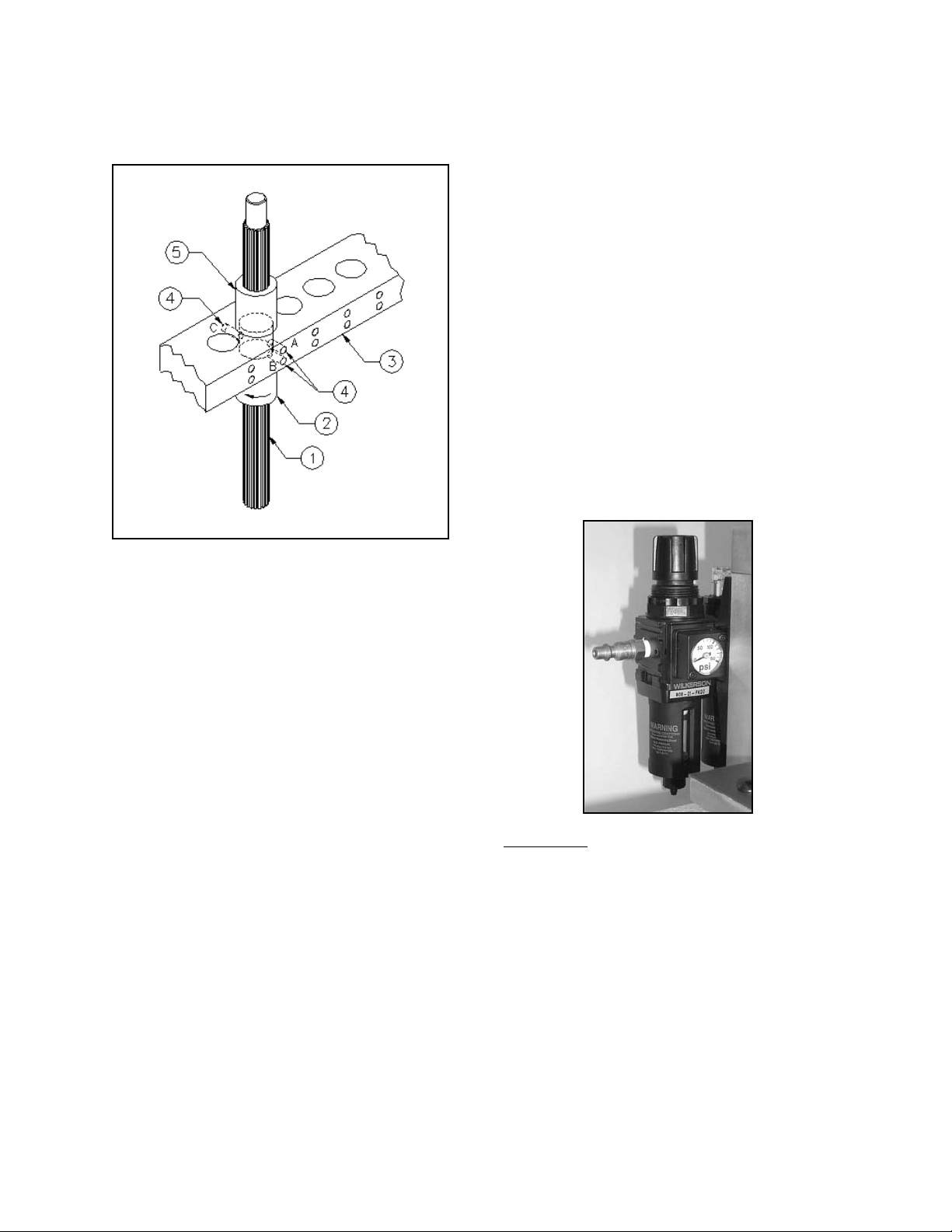

•Mark the direction of movement of the

scratching device on the panels, taking care

not to mark the surface just tested.

•To remove the specimen, raise the spline-

shaft fingers using the handle and release the

clamping.

•Evaluate the extent of the damage on the

sample.

Speed Adjustment

Prior to conducting any tests, you will need to

adjust the speed of the platform. A sliding veloc-

ity of approximately 100mm per second (± 10) is

normally recommended.

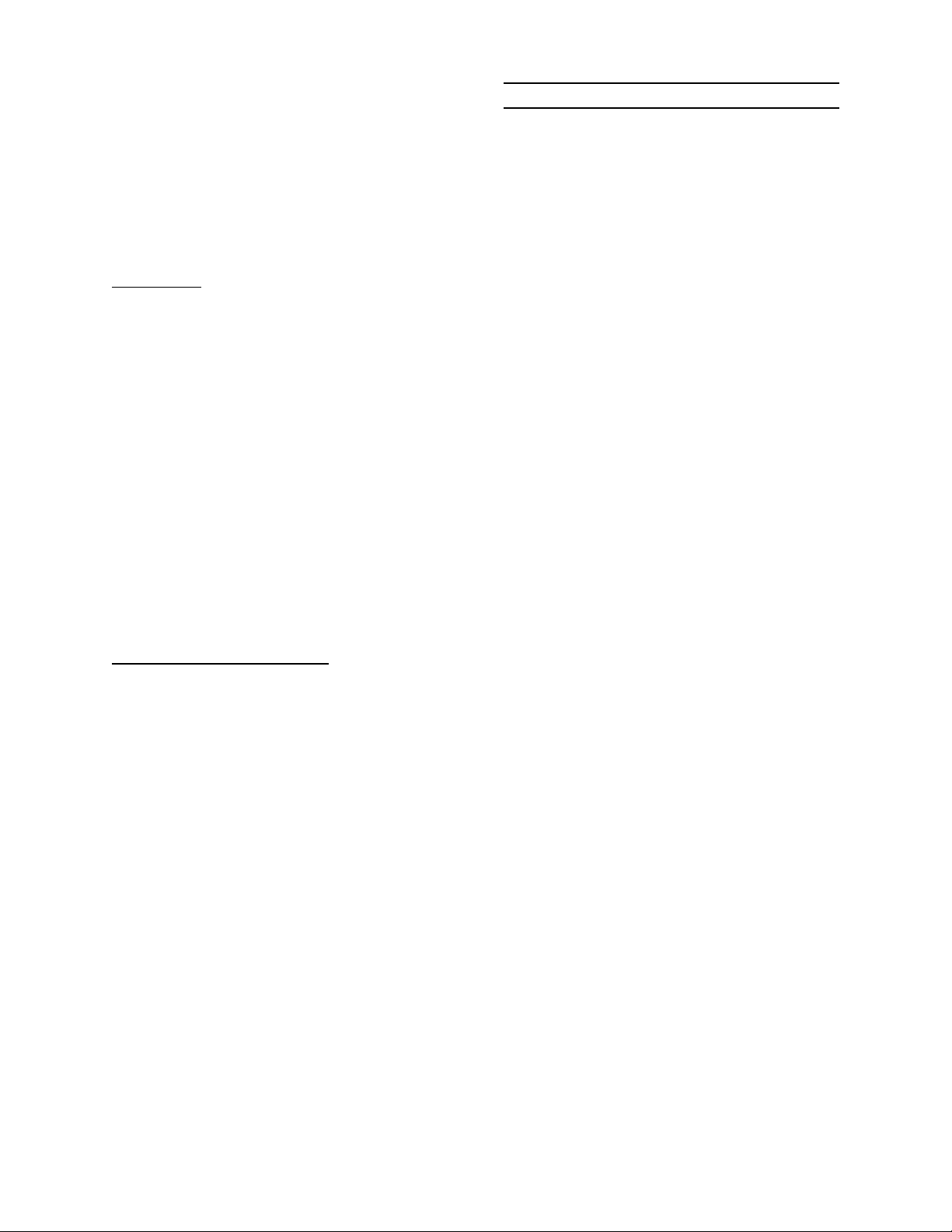

•Turn the knob on the air regulator/lubricator to

an air pressure between 80 - 100 psi. To

increase air pressure, turn the knob clockwise

(to decrease turn counterclockwise).

•Using the handle, raise the 'fingers' to the

upright position.

•Press the red button to reset the electronic timer.

•Actuate the moveable platform by turning the

control knob in the direction the table will trav-

el. The number displayed on the timer, indi-

cates the time in seconds it takes the platform

to travel 100mm.

•To adjust platform speed, turn the flow control

valves found on the right hand side of the

instrument. Turning the valve counter-clock-

wise will increase the speed, while turning it

clockwise will decrease the speed. If you are

testing in both directions, ensure the platform

travels at the same rate. The valve toward

the front of the instrument controls the speed

when the platform is moving to the left. The

valve toward the back, controls the speed

when the platform is moving to the right.

•After adjusting the flow control valve, lock in

place by tightening the lock thumbnut.

•Lower the scratch (mar) tips onto a ‘dummy’ test

specimen, and verify the speed adjustment.

To calculate the platform speed, divide 100mm

by the time shown on the display

XWARNING: It is possible for the speed of

the platform to exceed the capacity of the

automatic Start/Stop of the electronic timer.

Should this occur, disconnect the timer and

operate electronic timer by hand using the

Green button to Start and Stop.

Weight Adjustment

If you are not following a test method that indi-

cates which weights are required, start with 3N,

5N, 7N, 10N, and 15N. Loads can be increased

or decreased accordingly.

CALCULATION OF RESULTS

Depending on the type of material under evalua-

tion, the visual appearance of a scratch normally

involves changes in surface topography, color, or

brightness. Three methods are normally used:

Method A - Visual Evaluation:

Using a controlled light source, hold the sample

such that the scratch lines are in a horizontal posi-

tion to the observer. The scratch line caused by

the highest weight should be at the upper position.

Rotate the sample, so the angle of observation

changes. The observer should be checking each

scratch line individually, and noting the point at

which the scratch lines emerge at the clearest vis-

ibility. Do not use the starting and ending point of

the scratch lines (approx. 10mm) in this evaluation.

Examine all scratch lines and rate according to a

Rating Scale 1 to 5 (1 = no scratch line at all; 5 =

severe scratch line). For plastic materials, indi-

cate if the line exhibits signs of whitening.

Report the tip diameter, stylus loading level, and

Rating Number for each line on the surface of the

sample.

SUGGESTION: A lightbooth with North Sky

Daylight (D65) has been recommend as a lighting

source for automotive specifications.

4 710 Operating Instructions ver 1.1