Model 1700 / 1750 Rotary Platform Abraser 2Operating Instructions ver. 1.0

p/n 135505

LIMITED WARRANTY

Taber Industries, (“Taber”) warrants that its products are

free from defects in material and workmanship. This

Limited Warranty shall be applicable for a period of one

year from the date of initial shipment of any product. The

terms of this Limited Warranty do not in any way extend

to parts of the product thereof which have a life, under

normal usage, inherently shorter than the one year

previously stated. Taber will, at its option, repair or

replace the defective product if Taber determines it is

defective within the warranty period and if it is returned,

freight prepaid, to Taber. Replacement parts will be

shipped F.O.B. Taber’s plant. Taber is not obligated to

furnish service under this Limited Warranty: a) to repair

damage resulting from attempts by personnel other than

Taber representatives to install, repair, or service the

product; b) to repair damage resulting from improper use

or from connecting the product to incompatible

equipment; or c) if personnel other than Taber

representatives, without Taber’s prior permission, modify

the product.

EXCEPT AS EXPRESSLY SET FORTH HEREIN,

TABER MAKES NO OTHER REPRESENTATIONS,

PROMISES, GUARANTEES OR WARRANTIES,

EXPRESS OR IMPLIED, STATUTORY OR OTHER-

WISE, INCLUDING BUT NOT LIMITED TO, ANY

IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, AND

TABER EXPRESSLY DISCLAIMS ALL WARRANTIES

NOT EXPRESSLY STATED HEREIN. IN THE EVENT

THE PRODUCT IS NOT FREE FROM DEFECTS AS

WARRANTED ABOVE, A CUSTOMER’S SOLE

REMEDY SHALL BE REPAIR OR REPLACEMENT AS

PROVIDED ABOVE. UNDER NO CIRCUMSTANCES

SHALL TABER BE LIABLE FOR ANY INJURIES,

DAMAGE TO OR REPLACEMENT OF OTHER

PRODUCTS OR PROPERTY, COSTS FOR

RECOVERING, REPROGRAMMING, OR REPRODUC-

ING ANY PROGRAM OR DATA USED WITH THE

PRODUCT.

EXCEPT AS EXPRESSLY PROVIDED HEREIN, IN NO

EVENT SHALL TABER BE LIABLE TO ANY

CUSTOMER OR ANY THIRD PARTY FOR ANY

INDIRECT, INCIDENTAL, CONSEQUENTIAL, SPECIAL

OR PUNITIVE DAMAGES OF ANY KIND OR NATURE

ARISING OUT OF OR RELATING TO THIS WARRANTY

OR CONNECTED WITH OR RESULTING FROM THE

MANUFACTURE, SALE, DELIVERY, RESALE,

REPAIR, REPLACEMENT, OR USE OF ANY PRODUCT

OR THE FURNISHING OF ANY SERVICE OR PART

THEREOF, WHETHER SUCH LIABILITY IS BASED IN

CONTRACT, TORT, NEGLIGENCE, STRICT LIABILITY

OR OTHERWISE, EVEN IF WARNED OF THE

POSSIBILITY OF ANY SUCH DAMAGES.

TABER IS NOT RESPONSIBLE FOR THE LOSS OF

ANY DATA UNDER ANY CIRCUMSTANCES AND ANY

SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES THAT MAY RESULT THEREOF.

CLAIMS FOR SHORTAGES

We use extreme care during packaging to eliminate

the possibility of error. If a shipping error is

discovered:

1. Carefully examine the packing materials and

ensure nothing was inadvertently overlooked when

the shipment was unpacked.

2. Notify the company you purchased the product

from and immediately report the shortage.

3. File any claim within 30 days from shipment.

CLAIMS FOR DAMAGES

Claims for loss or damage in transit should be made

promptly and directly to the transportation

company.

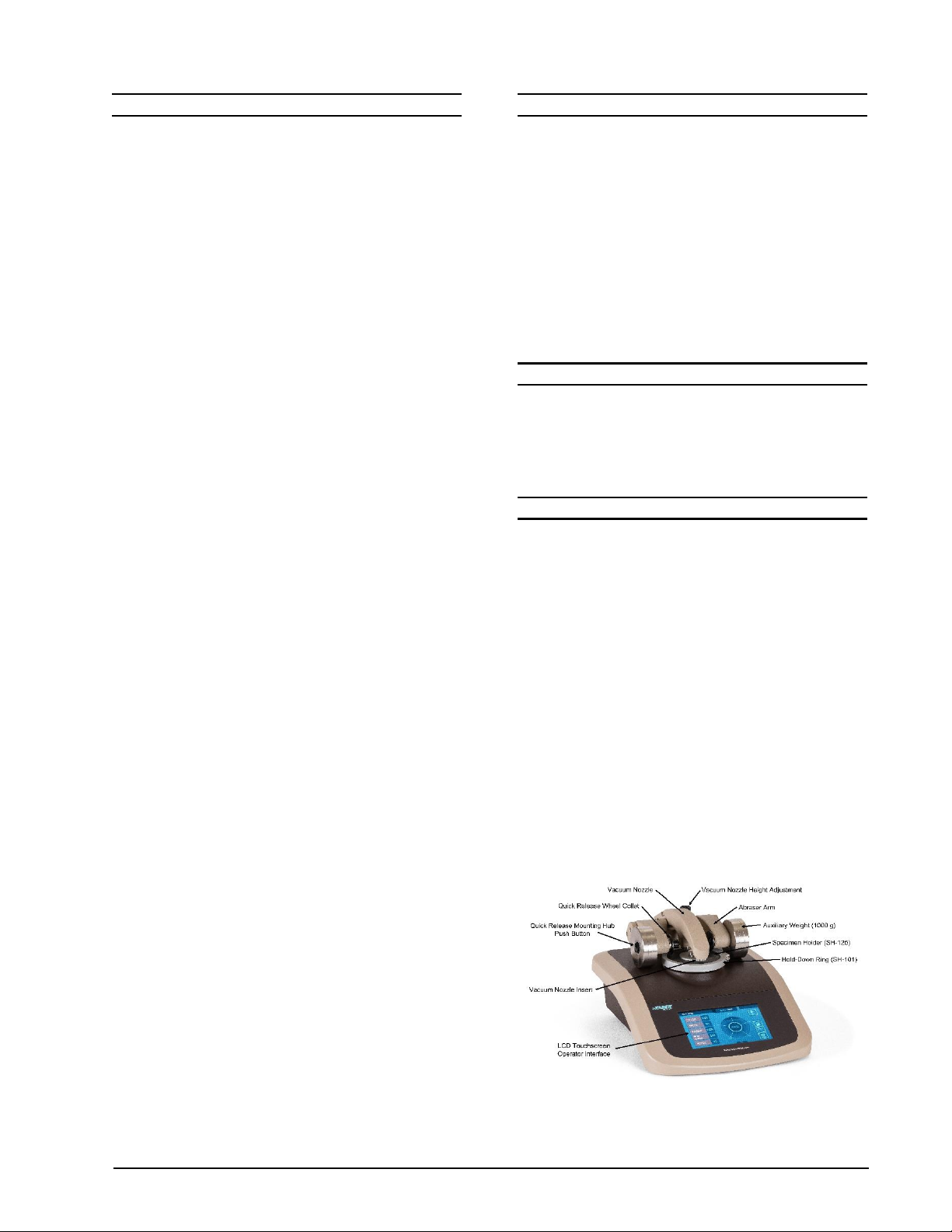

CONTENTS

Contents of the shipping container include the

following:

Model Model

1700 1750

Rotary Platform Abraser

Vacuum System (box 2) 1 1

Vacuum Y-Adaptor & Hose Kit N/A 1

Auxiliary Weights (500 g load) 2 4

Auxiliary Weights (1000 g load) 2 4

Specimen Holder (SH-125)* 1 2

Hold Down Ring (SH-101)* 1 2

Hand Brush (S-12) 1 1

Torx T25 Screwdriver 1 1

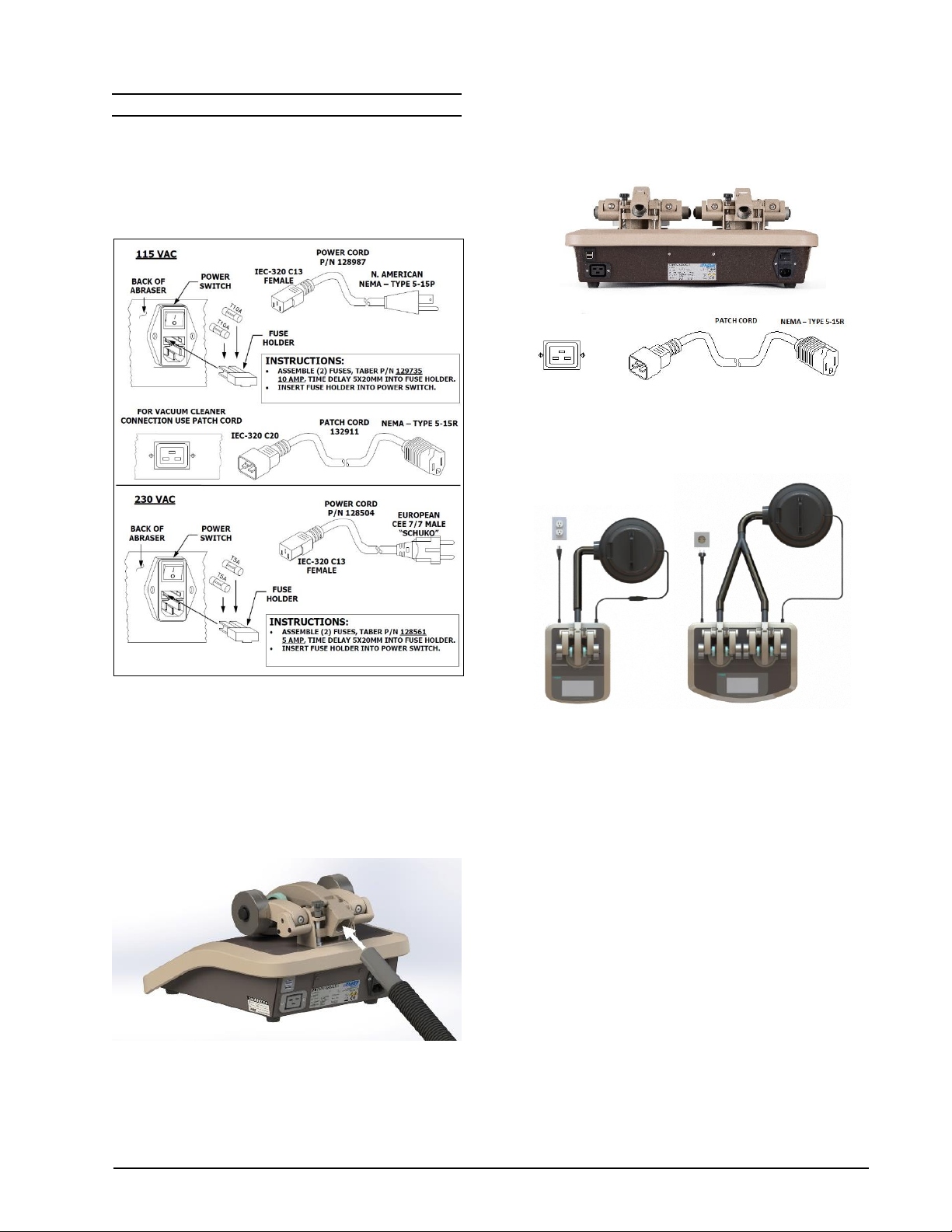

Power Cord Kit 115/230 VAC 1 1

Operating Instructions 1 1

*Mounted on the Abraser