4

B5: Thermal Shock

Taco GT pumps are not designed to withstand rapid changes in

temperature. Where a pump is handling hot liquids, the liquid

should be introduced slowly allowing the pump to gradually

increase in temperature.

B6: Thermal Hazards

Pumps handling hot liquid in excess of 154°F present a hazard to

personnel if the hot surface of the pump casing or associated

pipework is touched. The installer is responsible for warnings and

means of protection.

B7: Materials Compatibility

The materials of construction of this pump have been selected by

agreement between the manufacturer and the buyer, to be com-

patible with the pumped liquid as specified. The installer is

responsible for ensuring that the liquid actually handled on site is

as specified. Should there be any doubt, the installer is to seek

advice before proceeding.

B8: Controlling Solids

Where solids may be present, a strainer may be fitted to the

pump suction line to prevent entry into the pump impeller, pre-

venting possible damage to the impeller. A regular schedule

should be established to check and clean the strainer. A blocked

strainer will cause the pump to cavitate resulting in damage to the

impeller.

B9: Dry Running

The pump must never be allowed to run dry. Possible seizure of

the internal close clearances, and failure of the mechanical seal

may result. The operator should regularly check that the pump

suction source is adequate. In some installations, it may be pru-

dent to fit a level device or other means of automatic protection

to prevent the pump from dry running.

B10: Automatic Operation

Pumps operating on an automatic control system must not be

allowed to run at zero flow or flow below 30% of the peak effi-

ciency flowrate. Interlocks should be fitted appropriate to the

system. The pump should not be started more than 10 times per

hour, as damage to the shaft coupling and driver may result.

Installation of a pressure tank or timers on the electrical control

should be considered as required to reduce the frequency of

starts.

B11: Protection from Freezing

Where the pumpset may be exposed to cold weather, ensure that

the pump and associated pipework is lagged or trace heated to

prevent frost damage.

C: MAINTENANCE

C1: Electrical Supply Isolation

For pumps driven by electric motor, always isolate the electrical

power supply before working on the pump. Affix a notice on the

electrical isolator to inform others that work is being carried out

on the installation. If possible lock closed the supply isolator.

C2: Lubrication

The pump bearings are provided with grease fittings. Apply a high

quality bearing grease (Shell Alvania or equal) every 2000 hours,

or every six months, whichever comes first. Grease containing

dust and particles will quickly destroy the bearings. Only use

fresh grease from a sealed grease gun.

C3: Mechanical Seal

The mechanical seal is a wearing item. Life of a seal depends on

the erosive properties of the pumped liquid, and the temperature

and pressure of operation. The seal is self-adjusting, and requires

no periodic maintenance.

C4: Strainer

If a strainer is fitted to the suction pipe before the pump, period-

ically check and clean the strainer element. A blocked or leaking

strainer will cause cavitation damage to the impeller.

C5: Free Rotation

The pump should rotate freely by hand. Having isolated the

power supply, remove one of the guards and rotate the shaft by

hand to check freedom of rotation. Replace all guards prior to

operating the pump.

C6: Flooding

If the pump is accidentally subjected to flooding, on no account

operate the pump until it is thoroughly dry and checked. If water

has entered the pump’s bearing housing, it is likely that the bear-

ings will need to be cleaned or replaced. For pumps driven by an

electric motor, check that the motor fan is cleared of debris and

is free to rotate.

Inspect the pump shaft for debris.

D: DISASSEMBLY

D1: Special Tools

No special tools are required for disassembly of the pump set. In

preparation for disassembly, the pump should be allowed to cool

to ambient temperature before commencing any work. Close the

suction and discharge valves and drain the pump of liquid by

releasing the casing drain plug. If the pump is driven by an elec-

tric motor, ensure the power supply is isolated.

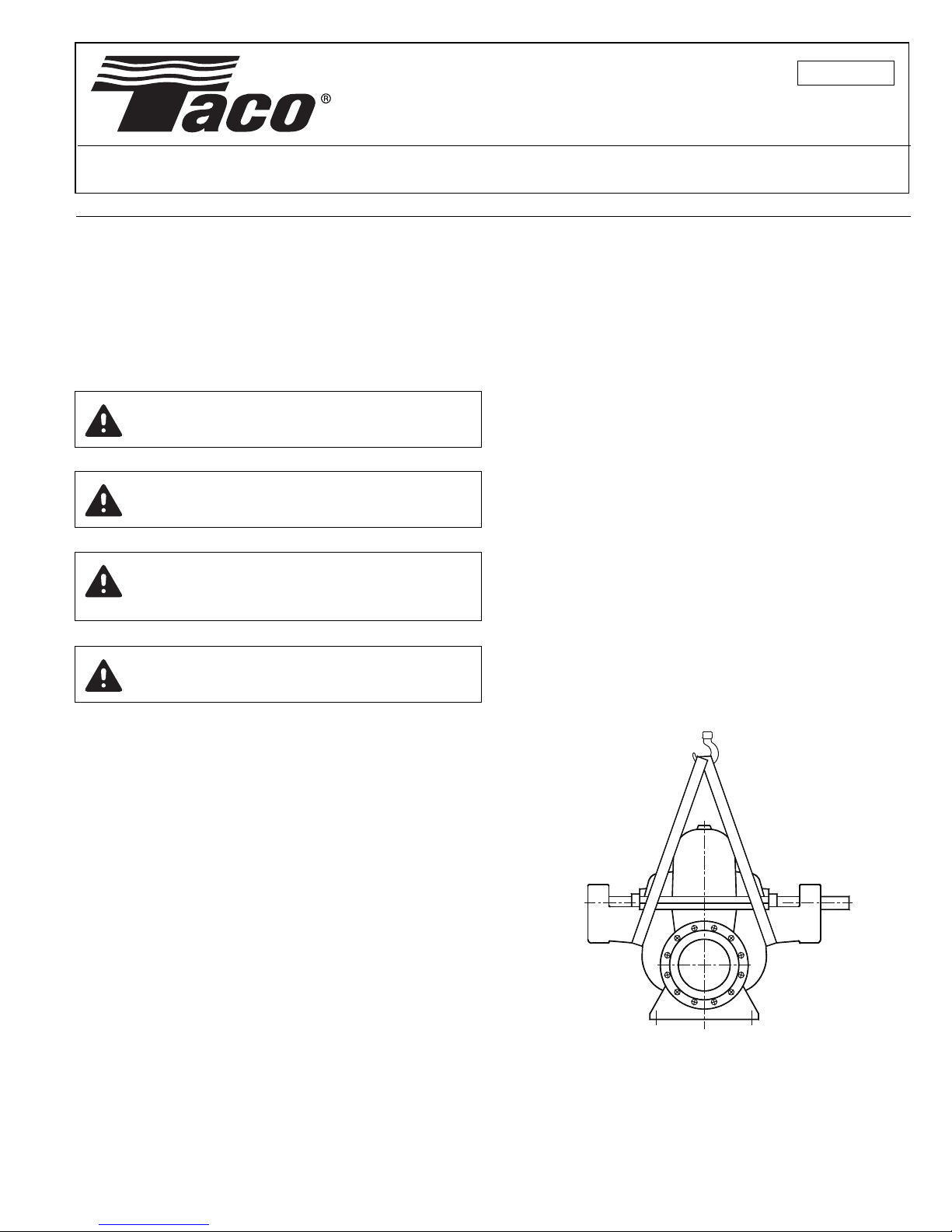

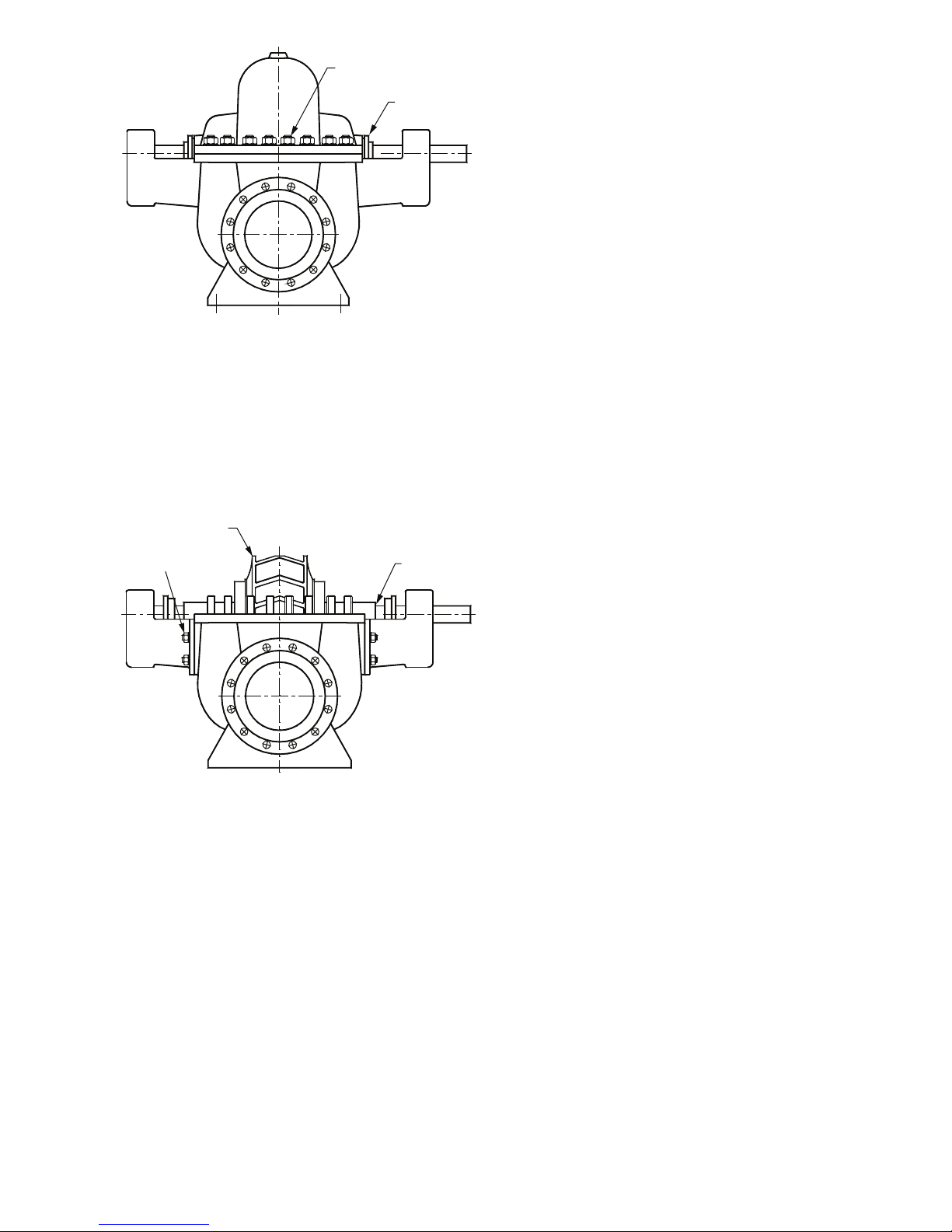

D2: Removing the Casing Top Half

Access to the pump internals is provided by a removable casing

top half. Before proceeding with removal, ensure that gasket

material of the correct thickness is available, as the gasket should

be replaced.

1) With the coupling guard removed, disconnect the drive cou-

pling between pump and driver.

2) Withdraw the two glands (for packed gland pumps) or

mechanical seal glandplates, if fitted, by removal of their

retaining nuts. Slide the glands or glandplates along the shaft

toward each bearing. (See Figure 7.)

3) Remove all the nuts on the casing split flange.

4) Using the jacking bolts provided, the casing top half may now

be separated and raised by 1-2 mm.

5) Using suitable lifting tackle, the top half casing may now be

lifted away. The pump internals may now be inspected.