6

Motor Protection

See the motor nameplate for electrical connection/wiring

diagram.

Taco pumps must be used with the proper size and type of

motor starter to ensure protection against damage from low

voltage, phase failure, current imbalances, and overloads.

The overload should be sized to trip at the full-load current

rating of the motor.

OPERATION

Priming

Hazardous pressure. Do not run the pump

with the discharge valve closed; the water in the pump may

boil, causing risk of explosion and steam burns to anyone

nearby.

Hazardous voltage. Disconnect all power to

the pump before servicing or working on the pump. Make

sure that the power is locked out and that the pump cannot

be accidentally started.

NOTICE: Under no circumstances should the pump be

operated without flow through the pump. Never operate

the pump dry.

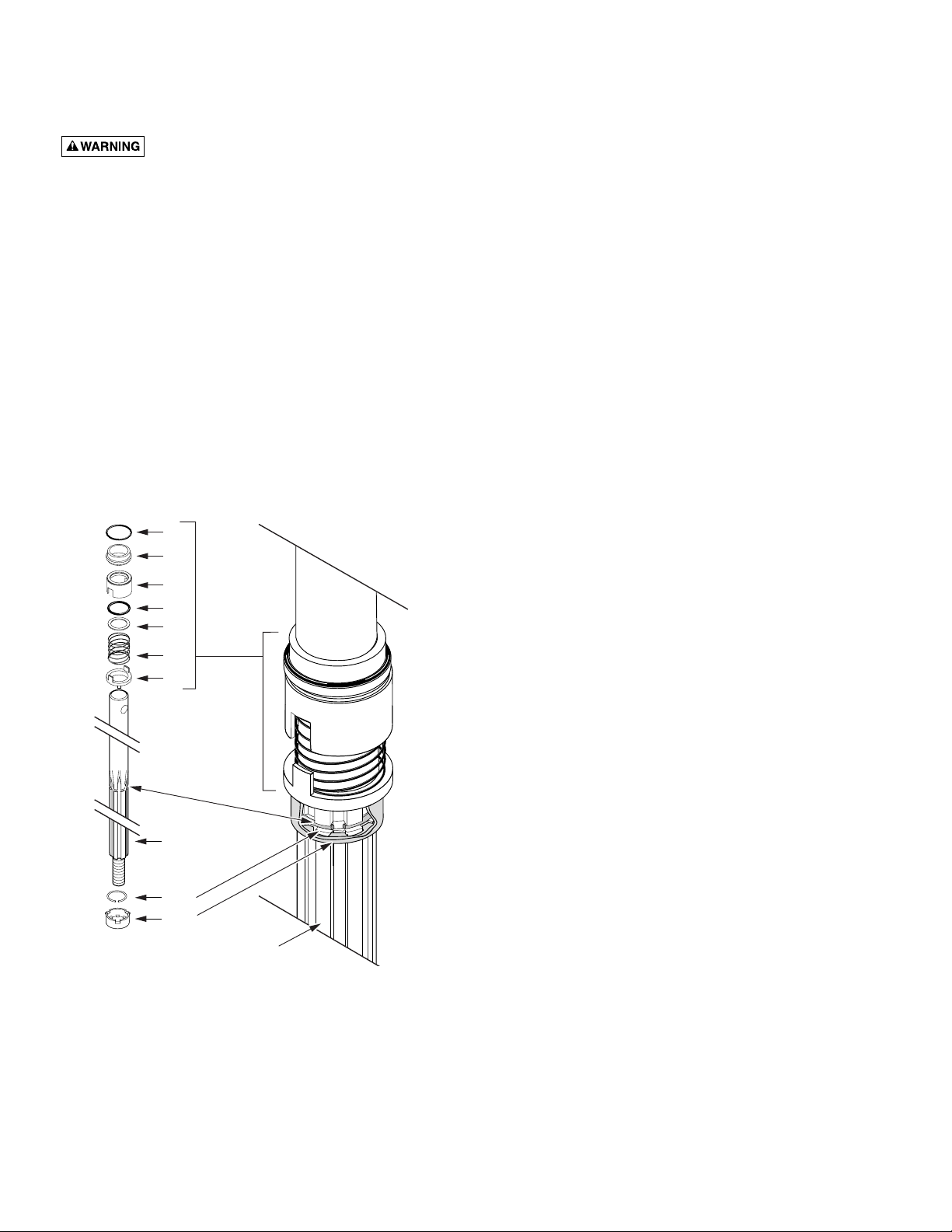

Operation of closed systems or open systems with the

liquid level above the pump priming plug:

1. Close the discharge isolating valve and loosen the

needle valve in the vented priming plug in the pump

head (Figure 7). Do not remove the needle valve.

Risk of water damage and injury. Watch the

direction of the priming plug and make sure that the liquid

escaping from it does not injure persons nearby or damage

the motor or other components. In hot water installations,

pay particular attention to the risk of injury from scalding

hot water.

2. Slowly open the isolation valve in the suction pipe until

a steady stream of liquid runs out the vent in the priming

port.

3. Tighten the needle valve to 25 inch-pounds torque.

Completely open isolation valves.

NOTICE: Please turn to “Starting”, Page 7, before proceeding

any further.

Operation of open systems with the liquid level below the

top of the pump:

NOTICE: The suction pipe requires a check valve or

isolation valve.

1. Close the discharge isolation valve.

2. Remove the vented priming plug.

3. Pour liquid through the priming port until the suction

pipe and the pump are completely filled with liquid.

4. Replace the vented priming plug and tighten it securely.

5. Repeat steps 1-4 until the pump is primed.

NOTICE: Please turn to “Starting”, Page 7, before proceeding

any further.

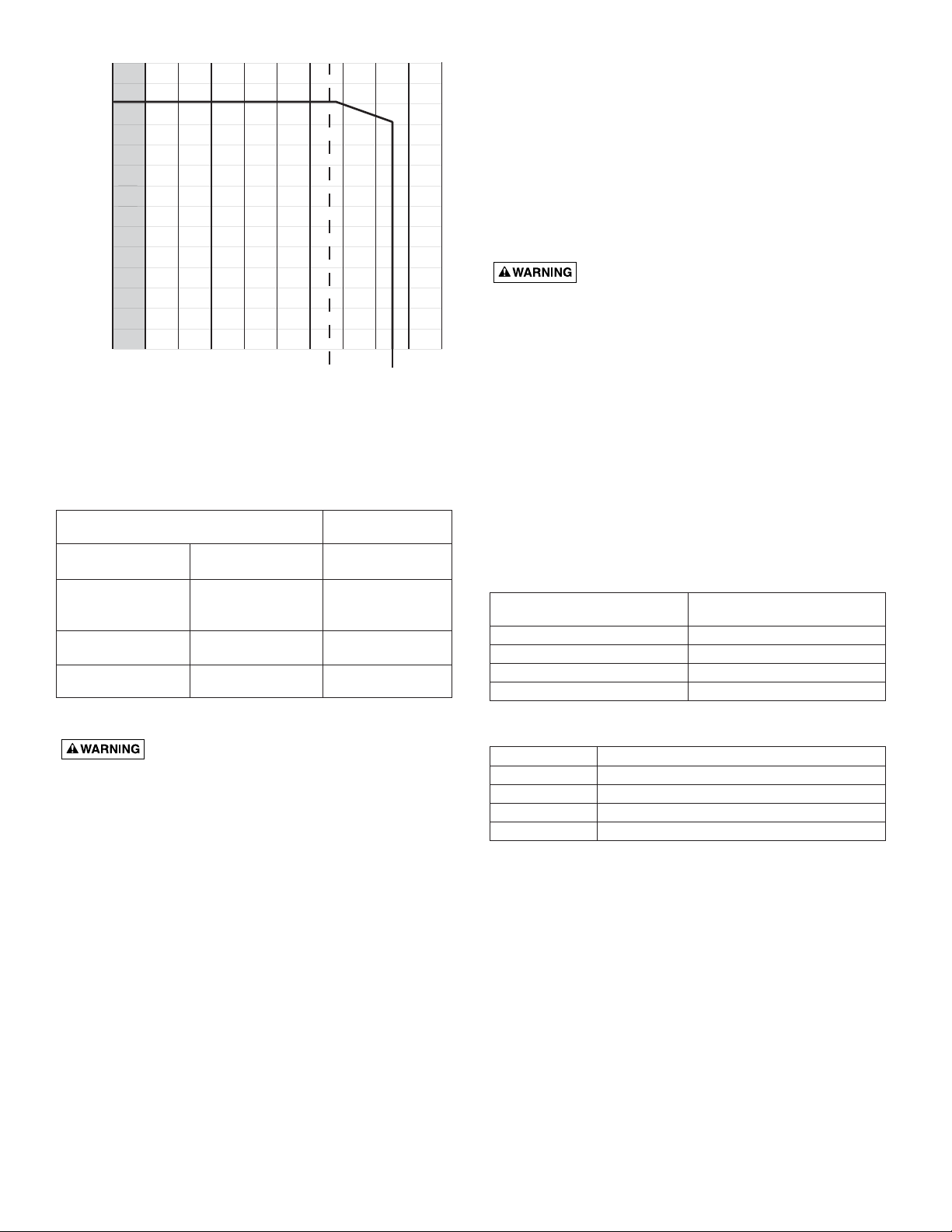

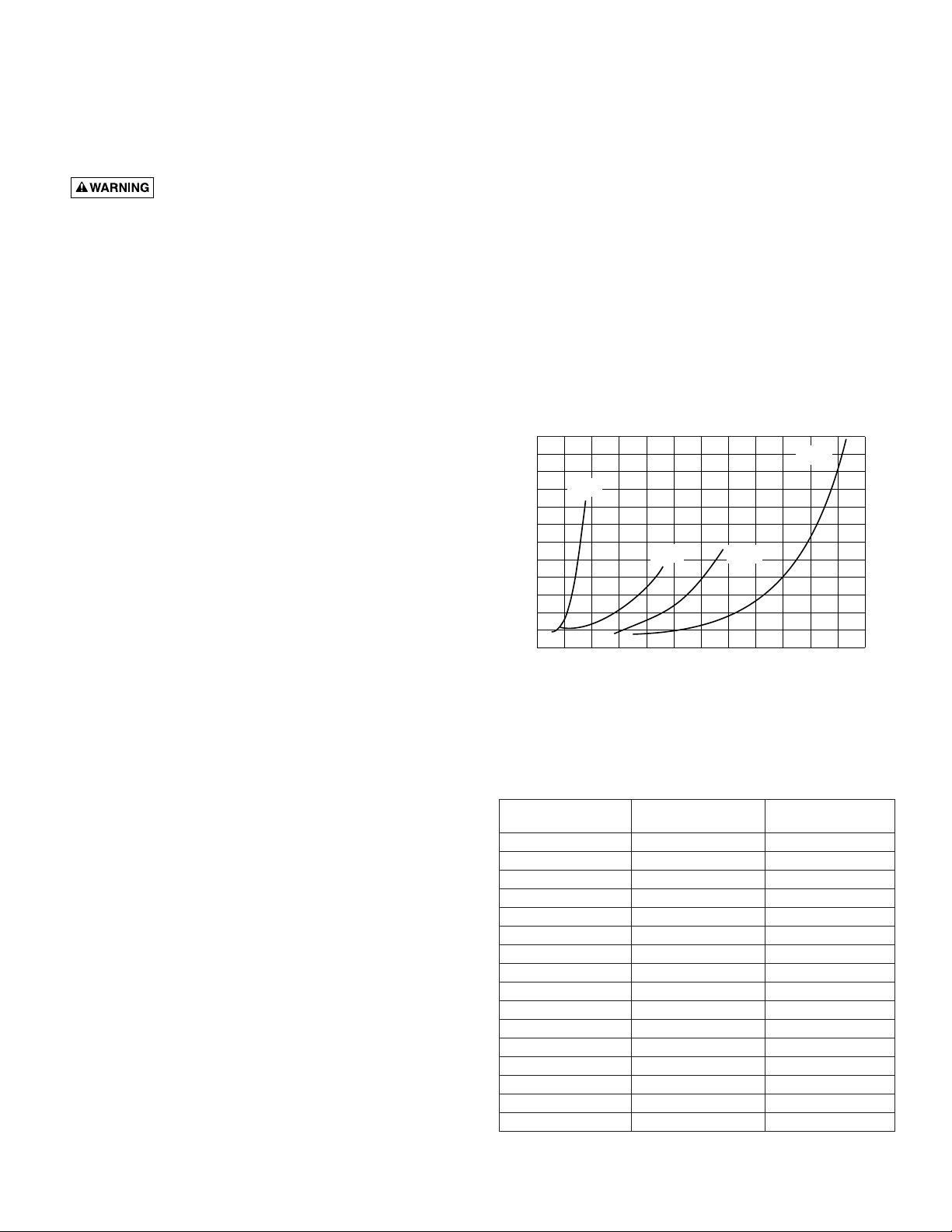

No-Flow Operation

This pump must not operate at no flow. To prevent no-flow

operation, install a bypass orifice, sized to allow the

minimum rate of flow to pass the pump at all times (see

Table III). Taco recommends a 3-inch long nipple-style

orifice, which will compensate for erosion and ensure the

correct minimum flow for extended time periods. Inspect

the orifice and bypass loop periodically to make sure that it

is not obstructed, eroded, or leaking and that the correct

minimum flow is maintained. See Table V to select the

correct orifice size for your installation.

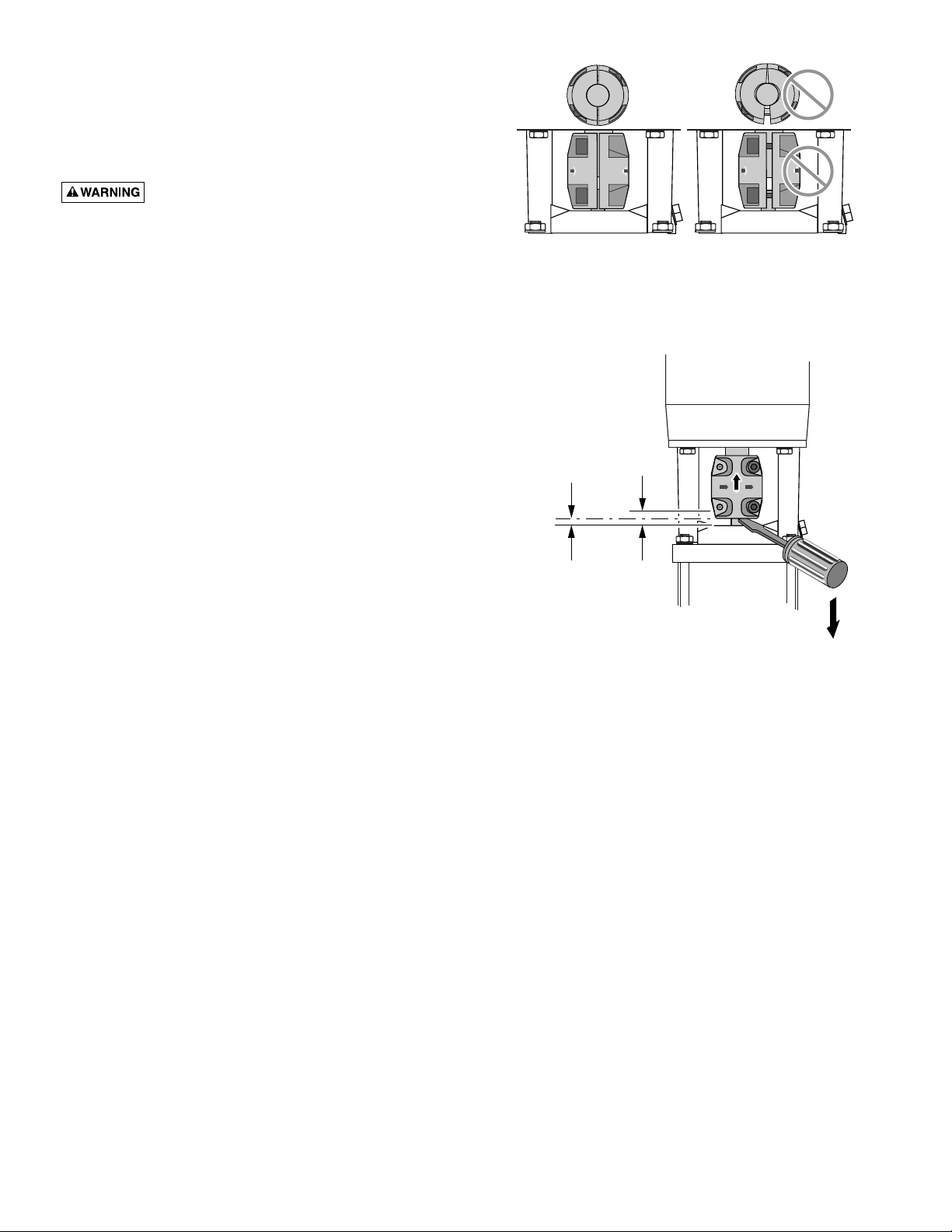

Checking Direction of Rotation

NOTICE: Do not disconnect the motor from the shaft to

check the direction of rotation. If you remove the coupling,

then you must adjust the shaft position when you reinstall

it. This must be done before starting the pump.

Arrows on the pump head show the correct direction of

rotation. When seen from the motor fan, the pump should

rotate

counterclockwise

()

.

For pump motors without a

fan remove one of the coupling guards and look at the

coupling to determine the direction of rotation. Turn off the

pump and replace coupling guard.

NOTICE: Do not check the direction of rotation until the

pump has been filled with liquid. See “Priming”, at left and

above.

1. Switch power off.

2. Remove the coupling guard and rotate the pump shaft to

be certain it can turn freely. Replace the coupling guard.

3. Verify that the electrical connections are in accordance

with the wiring diagram on the motor.

4. If the fan is visible, turn on and off to verify rotation.