4

2.a Inspect the seal assembly to be sure O-rings are included

on the seal housing cover and the shaft sleeve. On the lock

ring, be sure the lower set screws are tight and upper set

screws are loose. See Figure A5.5.

2.b Prior to installing the shaft sleeve o-ring, lubricate with light

grease then slide complete assembly over head shaft. Seat

and bolt down the assembly against the seal housing, taking

care to be sure that the O-ring of the seal housing cover is in

its groove.

2.c To set seal, first set impeller lateral, then tighten top set of set

screws of the lock ring. Remove paper spacers and keep for

future use.

A5.6: VERTICAL MOTORS

1. Hollow Shaft Motor

1.a Clean threads and face of head shaft projecting above pack-

ing gland thoroughly, then oil threads lightly. Thread coupling

on shaft for half of its length. Stuff a rag into open end of the

shaft coupling.

1.b Remove the top cover from the motor. Unbolt the coupling

(clutch or drive block) from the motor and remove the coupling.

1.c Run a fine flat file over the motor mounting surface of the

head to remove any nicks or burrs. Thoroughly clean face

and register with solvent. Wipe a thin layer of light oil over

the surface. This will help prevent rust and will also facilitate

slight driver shifting during coupling alignment.

1.d Attach the erector sling to the motor lifting lugs. Hoist motor

sufficiently to allow easy access to mounting flange. Remove

nicks and burrs on the mounting flange with a fine flat file and

thoroughly clean with solvent.

1.e If there is sufficient head room to install the head shaft after

placing the motor on the discharge head, prepare the shaft

as described in Step 1.g below, then lower the head shaft

through the motor with the keyway end up. Install the adjust-

ing nut and thread it on 4 or 5 threads, then allow the shaft to

suspend inside the motor.

1.f Hoist motor sufficiently to clear the stand and swing it over

until motor is resting on mounting ring. Properly place conduit

box, align mounting holes and install, but do not tighten cap

screws.

1.g Clean the head shaft thoroughly and dress the threads and

keyway with a 3-cornered file, if necessary. Lift the head shaft

and carefully lower it through the quill or hollow shaft (end

with keyway goes toward the top) and allow shaft to contact

head coupling. Remove the rag in the coupling. Screw the

head shaft into the motor coupling on the head shaft and

tighten.

1.h Make temporary electrical connection to motor, bump starter

to determine correct rotation (counter clockwise as viewed

from above). Install and tighten cap screws to the motor and

discharge head/motor stand. If power is not available, DO

NOT make final drive shaft connections (Steps 1.i and 1.j)

until power is available and correct rotation is determined.

1.i Slide clutch over head shaft, seat against drive plate, install

and tighten bolts.

1.j IMPELLER ADJUSTMENTS: Turn clutch until keyways in

shaft and clutch align; install and seat gib key. Thread head

adjusting nut onto head shaft until it seats against top of the

clutch. Hold the clutch to keep from turning and turn head nut

until the impellers clear the bottom allowing the rotor to turn

freely. Continue to tighten head nut until impellers are elevated

a sufficient distance (about 11⁄2turns) to accommodate pump

hydraulic thrust and associated shaft stretch. Align holes

in head nut with taps in clutch, install and tighten machine

screws. Place top cover on driver and secure.

2. Solid Shaft Motor

2.a Slide the pump hub of the adjustable motor coupling onto the

head shaft and insert the key. Screw the adjuster nut onto the

head shaft.

2.b Attach the erector sling to the motor lifting lugs. Hoist motor

sufficiently to allow easy access to mounting flange. Remove

nicks and burrs on the mounting flange with a fine flat file and

thoroughly clean with solvent.

2.c While the motor is suspended from the erector sling, slide the

motor hub of the adjustable motor coupling onto the motor

shaft. Insert the key into the keyway of the motor hub far

enough up the motor shaft to expose the keeper key seat on

the shaft. Seat the keeper key onto the motor shaft. Pull the

motor hub down over the keeper key.

2.d Bolt the spacer to the motor hub, if applicable.

2.e Hoist motor sufficiently to clear the stand and lower it until the

motor is resting on the discharge head. Properly place the

conduit box, align mounting holes and install cap screws.

2.f IMPELLER ADJUSTMENT: Adjust the adjuster nut until the

clearance between the spacer/adjuster nut and the motor

hub is equal to the impeller adjustment as stated in Section

A5.6, 1.j. Add additional clearance to the above adjustments

to accommodate pump hydraulic thrust and the associated

shaft stretch.

2.g Make temporary electrical connections to motor, bump starter

to determine correct rotation (counter clockwise when viewed

from above). If power is not available, DO NOT make final

drive shaft connections (Step 2.h) until power is avail-

able and correct rotation is determined.

2.h Align holes and taps of the motor hub, pump hub, adjuster

nut, and spacer (if applicable). Install and tighten cap screws.

A5.7: MISCELLANEOUS ASSEMBLIES

1. Discharge Piping

1.a Above and below floor piping should be installed in such a

manner as to eliminate the possibility of the discharge head

being strained. Gate valves, check valves, and other piping

items must not depend upon the pump head for support.

1.b If a flexible joint, such as a dresser coupling, is to be used,

the tie bolts and lugs used to span the flexible joint should

be of sufficient strength to resist the force created by the

discharge pressure at the pump head. None of this force

should be imposed on the head or the foundation bolts. The

tension should be taken carefully on these tie bolts so that

any amount of forward movement induced to the head will

be counteracted during operation so that alignment is main-

tained throughout the operation.

2. Air Release Valve

Install the air release valve on the pump head or just beyond

on the discharge piping. It is suggested that if a throttling valve is

not furnished, a throttling device be used to restrict the discharge

of air to insure that a cushion of air is available in the discharge

head. Placement of the throttling device should be such that the

air release valve is between the discharge head and throttling

valve. Note: Exhausting the air from a head too quickly often

causes breakage.

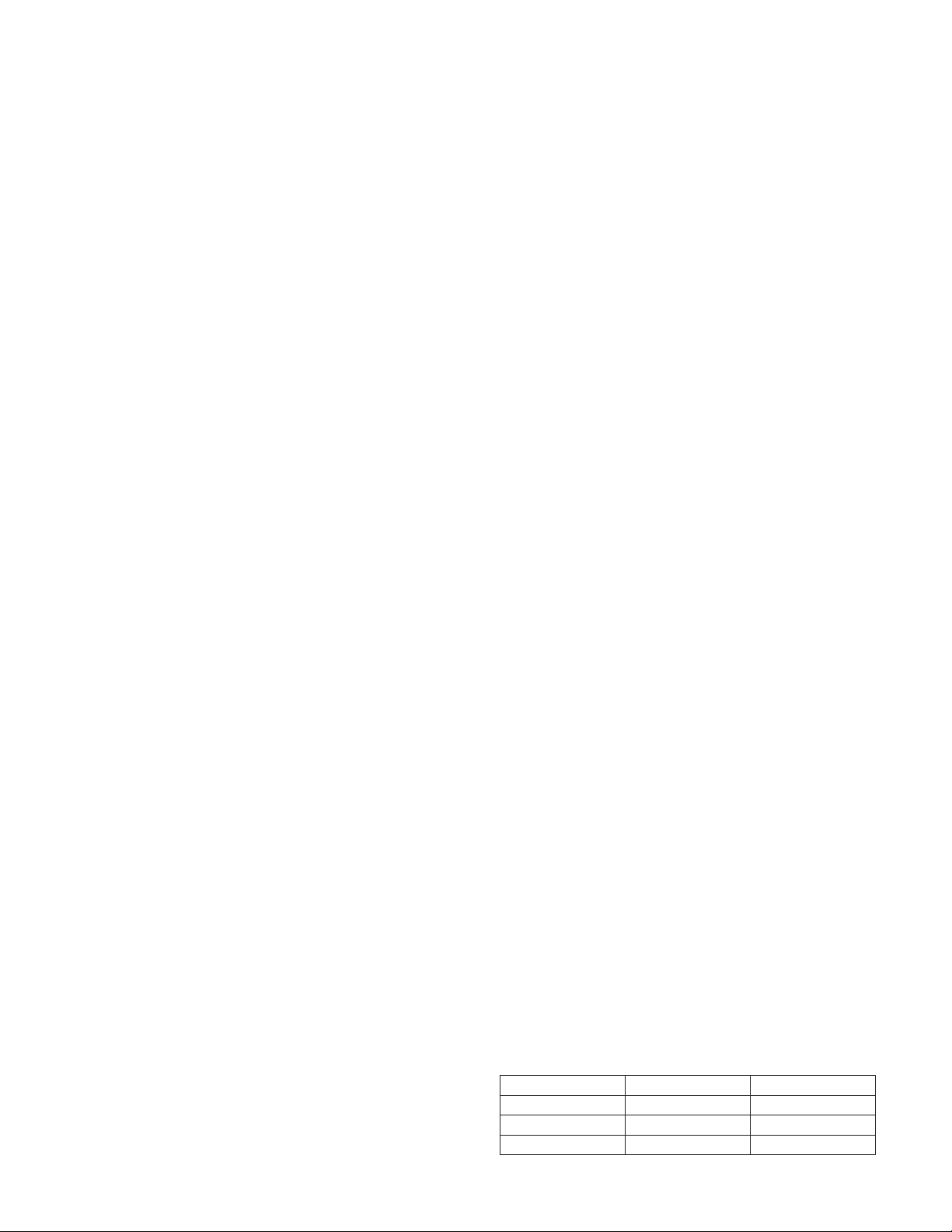

3. Gauges and Miscellaneous Pipe Connections

PRESSURE “L” PORT “U” PORT

0-100 PSI Grease Grease

100-300 PSI Grease Grease

300-450 PSI Bypass Grease