5

All winch protective devices (protective nets, covers, etc.) must be properly

installed, and should never be changed before operation!

Replace a damaged cable or plug immediately.

Use PTOs with a proper transfer power (min. 25 kW) with undamaged

protection! The PTO shaft must be properly protected.

The load capacity of the attachments (e.g.: forestry chain, hook, slider) and

fastening (e.g.: snatch block, load belt) gear must be in accordance with the

traction force of the winch.

Damaged attachments and fastening tools must be replaced immediately!

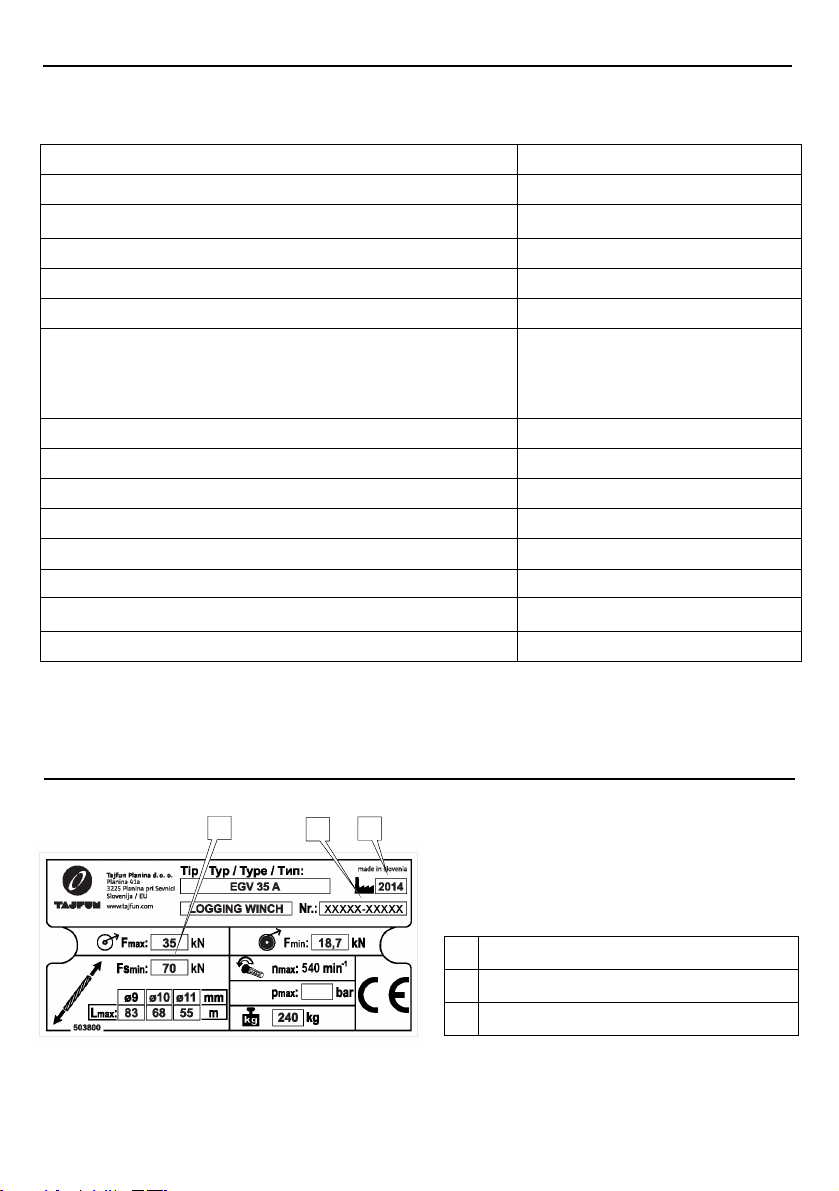

Pulling ropes must be strong enough and in accordance with the data on the

winch type plate and the winch specifications. The minimum wire rope

breaking force must be at least twice as high as the maximum pulling power

of the winch.

A damaged pulling rope must be replaced immediately!

Use pulling ropes of an appropriate length (See section: Technical data)!

Wire rope must always be wound tightly on the drum (See section: Coiling

the wire rope tightly onto the drum).

The drive machine (e.g. tractor) to which the winch is connected must be in

perfect technical condition. We recommend that the machine is adequately

equipped (e.g.: additional cab protection, chassis protection) for forestry

work.

The drive machine must have an adequate tyre tread depth that complies

with the applicable law and traffic regulations. Install snow chains, if

necessary. The use of snow chains on slippery, snowy, or icy terrain is

mandatory.

Use personal protective equipment (protective clothing, gloves, forestry

shoes, helmet)!

Working with the winch is challenging and dangerous, therefore it requires full

concentration and vigilance. For the safe performance of the required work,

observe the following instructions:

Always connect and disconnect the winch on a level and hard surface.

Prior to pulling and during the use of the winch, the operator must ensure

that no people or other objects are present in the working area.

The winch operator must be careful not to fully unwind the pulling rope

under load. There must be enough rope to make at least five more rotations

(except in dangerous situations).

The operator must observe the load at all times during pulling. If the

operator cannot observe the entire pulling path from the seat, the load must

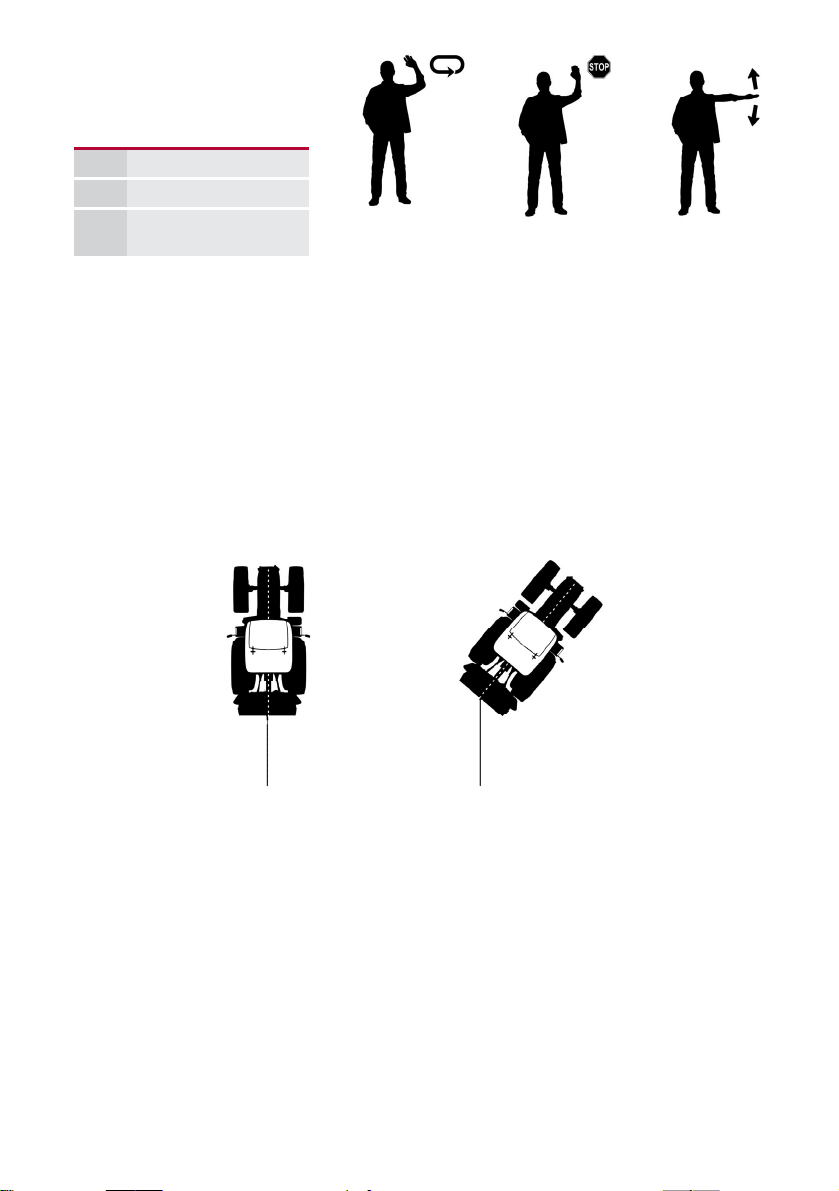

be observed by an assistant with whom the operator is in constant contact.

The assistant communicates with the operator with previously agreed signs

(see picture below).

2.2. SPECIAL SAFETY INSTRUCTIONS .

2.3. INSTRUCTIONS FOR SAFE WORK .