2

■Floor surface

○Ensure that the material or finishing of the floor surface is waterproof or has a waterproof coating applied.

○This product weighs There are maximum 55㎏. Please refer to the sufficient reinforcement work on the installation floor portion.

○Always ensure that the floor surface is horizontally level.

○Ensure that the floor surface is smooth and free from bumps around the attachment areas.

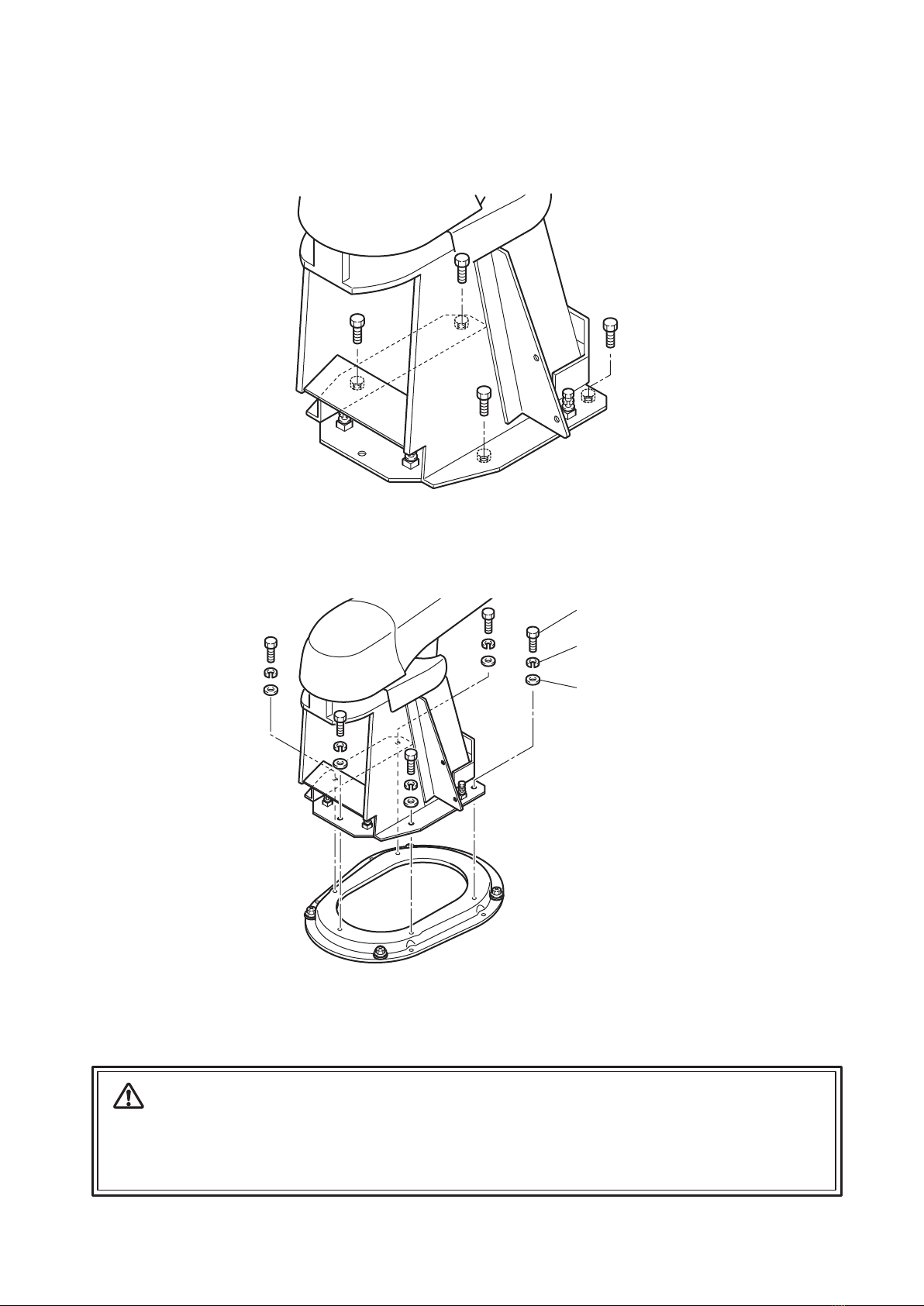

○Pipe risers

○If the floor surface is tiled, cracks may occur when fastening the bolts during installation of the RS SWING main body.

If this looks likely to happen, use the main body attachment diagram and template as a reference and change the material

of the attachment area that is in contact with the floor to another such as plywood or mortar.

○The following levels of strength are required for the floor surface.

○Be sure to take the necessary precautions to prepare for and prevent possible water leakage.

○Use waterproof flooring materials.

○When installing the product on the 2nd floor or higher, be sure to observe waterproofing (waterproofing works,

installing a pan made of stainless panel, etc. or installing water leakage sensor.).

○Be sure to cover an opening of raised plumbing and a connection of pipes by caulking material, etc.

■Request measures to prevent water leakage under the floor and downstairs

Hot water / water supply

Drainage

Rc 1/2"; pipe risers from floor; rise dimensions: hot water 50 mm; water 50 mm

VU40/VP40; pipe risers from floor; rise dimensions: 60 mm

Wooden floor

Mortar floor Mortar thickness of 50 mm or more

Special floor (stone finish) A foundation with levels of strength listed above around the installation areas is required.

Plywood thickness of 30 mm or more (two 15 mm sheets joined together)

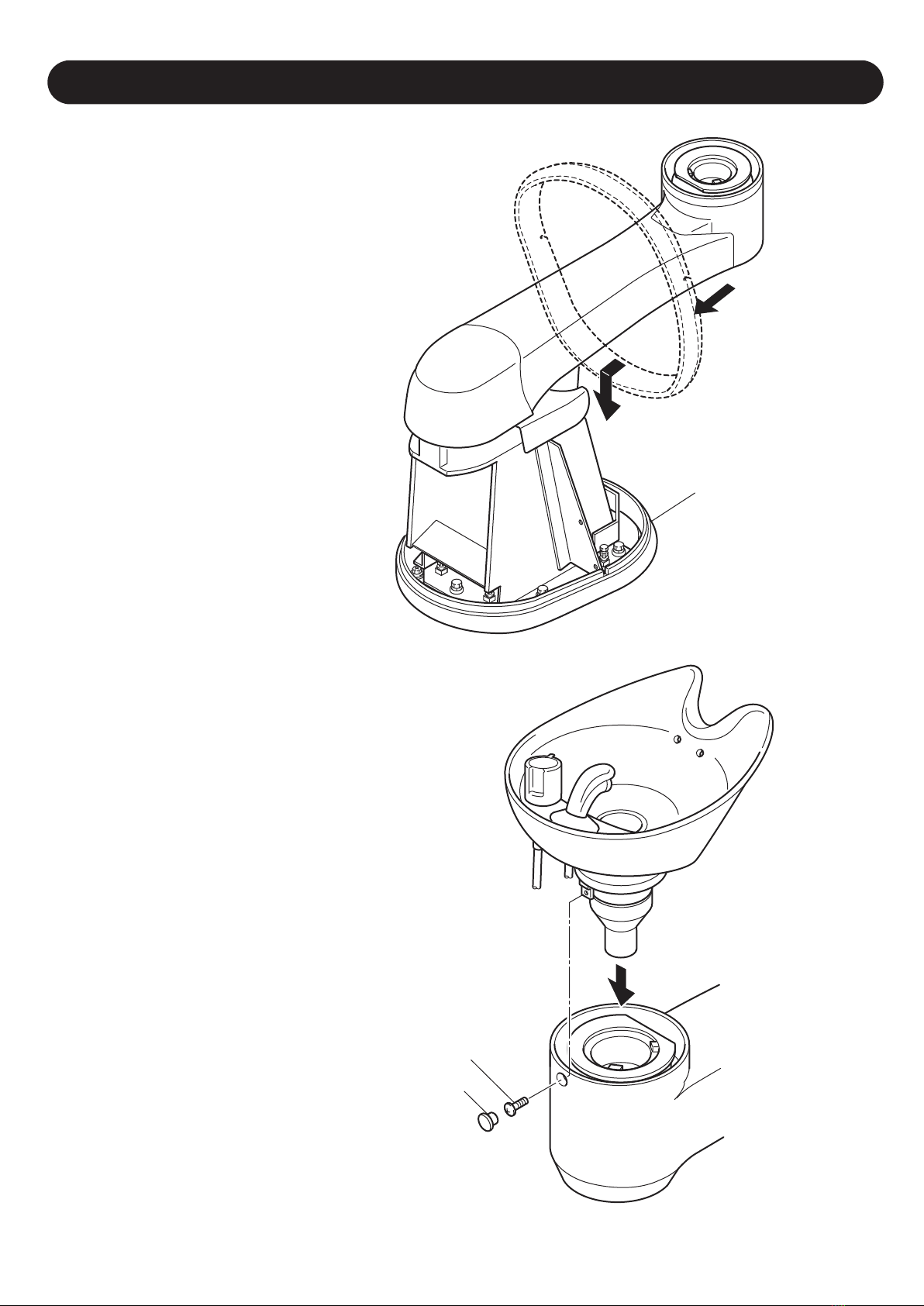

■Installation of pipes

The following are important points to adhere during the installation of pipes. Read through

the details carefully and ensure that the pipes are installed correctly.

○This product is designed for indoor installation. Always install this product indoors.

■”Precautions during installation of pipes”

○Do not use pipes made of materials that may introduce rust for the water supply pipe. In general, VP pipes or other materials

specified by regulations in that particular region, are recommended for installation.

○In general, Type L deoxidized copper pipes are recommended for hot water pipes.

○In general, the same diameter and same pressure is recommended for hot water pipes and water supply pipes.

○Always use a reamer to deburr the ends of cut pipes.

○Avoid using inverted U-shaped pipes (siphon) as these can cause air to become trapped.

○Always connect hot water and water supply pipes after removing all contaminants such as dirt, sand and oil.

Failure to follow this instruction may cause problem.

○Ensure that the drain pipe is installed at a gradient of 1/50 for a diameter of φ75 or less, or 1/100 for a diameter of φ75

or more.

○Do not connect the hot water and water supply pipes in reverse.

Connecting pipes in reverse will mean the temperature of water cannot be controlled properly by the water faucet,

which can cause problems including burns.

○Ensure that the hot water pipe from boiler is only run over a short distance so as to minimize resistance.

Longer pipe can cause fluctuations in temperature and poor hot water delivery.

○Boiler pipes

・ In general, the same diameter and same pressure is recommended for main hot water pipe and main water supply pipe.

・ Ask professional to install boiler.

○Product comes with hair catchers installed. Handle it with care.

○Always wrap pipes with lagging material after installation is complete.

○After connecting the pipes and executing water flow test, clean the filters and showerhead.

Before installation