FCS-2 English

Page 21

Summary of operation

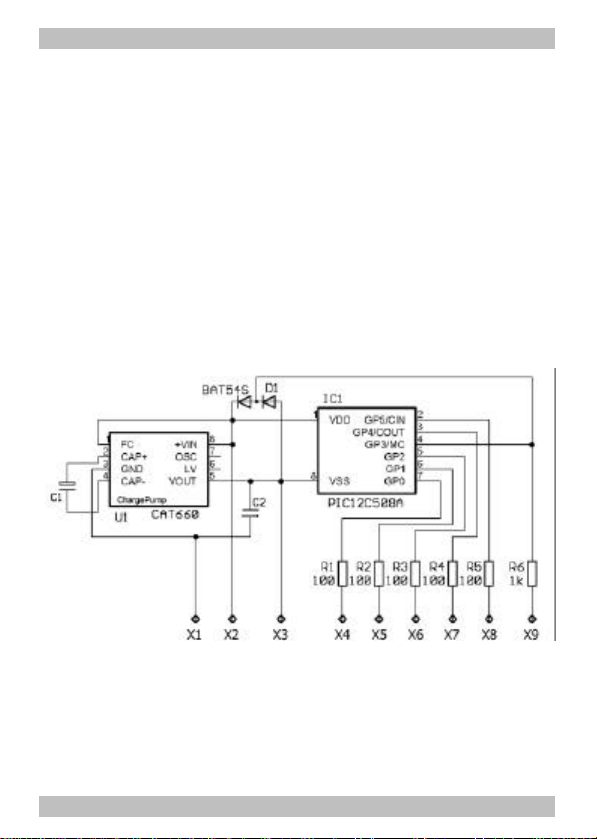

The module is particularly designed for the use in vehicles compatible

to the Faller* car system, that are run with two accumulator batteries. It

has six in- and outputs for the connection of LEDs, motor, reed contacts

and a Dim switch. It is not necessary to use all outputs. The in- and

outputs are controlled from the software stored in the IC.

The voltage of 2,4 V that is provided by the vehicle accumulator batteries,

is doubled by the module. This enables white LEDs to be connected,

which normally need a voltage of more than 2,4 V. Red and yellow LEDs

may be connected directly via series resistors to the accumulator

batteries, provided they are not to be controlled by the software.

Front and back lighting

It is possible to connect two white or yellow LEDs to one output of the

module for the front lighting, and two red LEDs to another output for

the back and stop lights.

Depending on the ambient lighting, the lighting of the vehicle is

switched on and off via a light sensitive switch. The sensitivity of the

light is set via a trimpot.

While breaking and some seconds after stopping, the back lights are

switched brighter, provided that the reed contact existing in the vehicle

is connected to the module.

If the vehicle does not receive the signal to drive on for a longer time,

all lights connected to the module are switched off (current saving

mode).

Driving of the motor

The reed contact existing in the vehicle can be connected to the

module. The module then influences the motor: After a stop it starts

gently and while breaking and some seconds after stopping, the back

lights are switched brighter. If an additional reed contact is mounted,

the vehicle also brakes gently.