tams elektronik KSM-3

Contents

1. Getting started.............................................................................................................4

1.1. Contents of the package.......................................................................................4

1.2. Accessories..........................................................................................................4

1.3. Intended use.......................................................................................................5

1.4. Safety instructions................................................................................................5

1.5. Care....................................................................................................................5

2. Operation overview.......................................................................................................

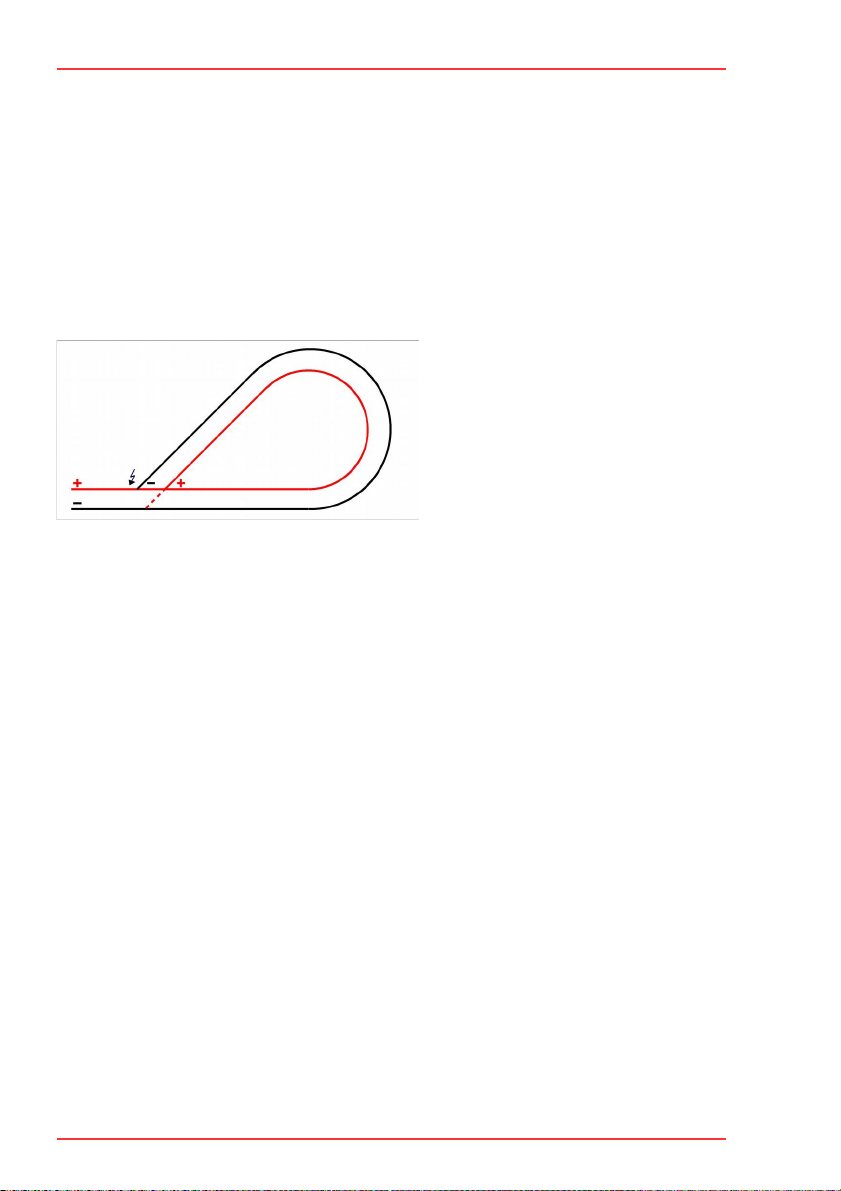

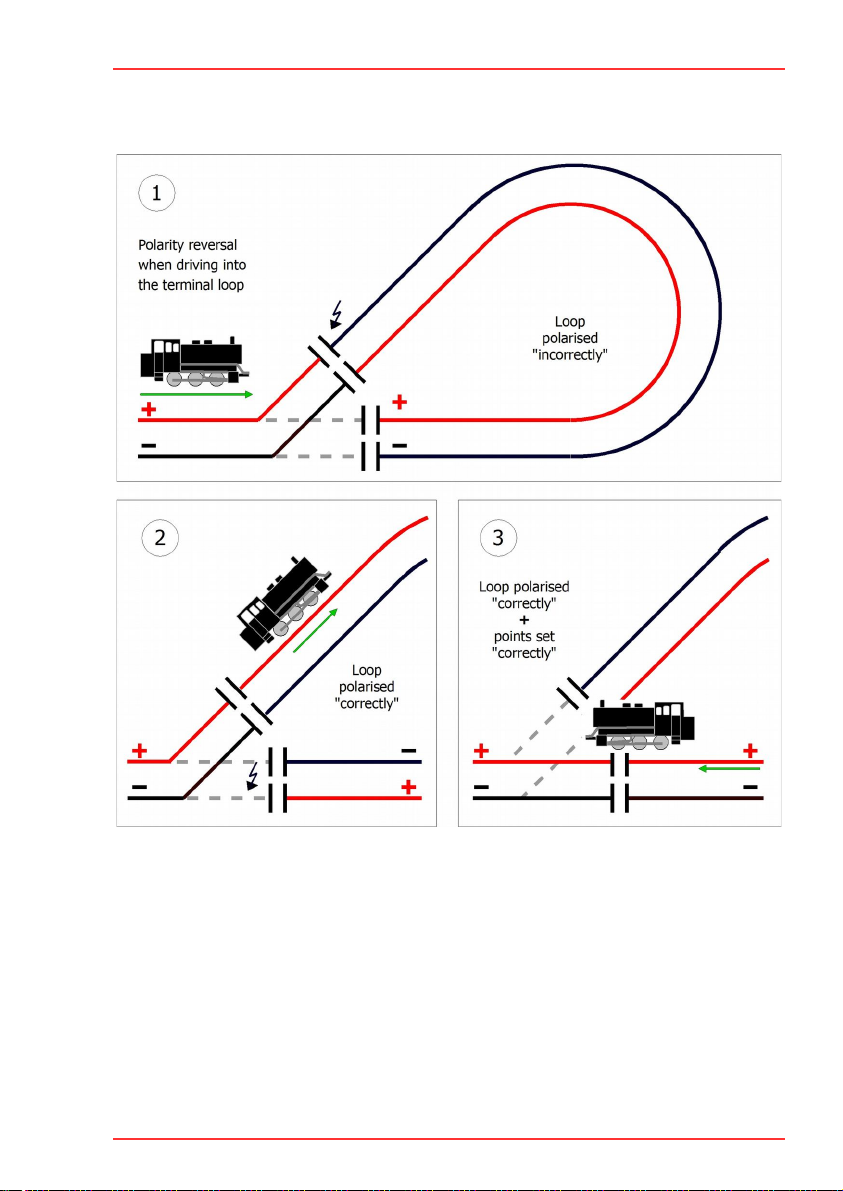

2.1. Loop problems.....................................................................................................

2.2. Mode of operation of the KSM-3............................................................................

2.3. Procedure............................................................................................................7

2.4. Designing a layout with the KSM-3........................................................................8

2.5. Use with a turntable.............................................................................................8

3. Assembling the kit........................................................................................................9

3.1. Safety instructions................................................................................................9

3.2. Soldering properly..............................................................................................10

3.3. Preparation........................................................................................................11

3.4. Assembly diagrams and parts list.........................................................................13

3.5. Assembly...........................................................................................................15

3. . Performing a visual check...................................................................................1

4. Connections KSM-3.....................................................................................................17

4.1. Isolating the terminal loop from the layout...........................................................17

4.2. Connections.......................................................................................................17

4.3. Setting the sensitivity for the polarity reversal......................................................18

4.4. Connecting a turntable........................................................................................19

5. Checklist for troubleshooting and error correction.........................................................20

5.1. Technical Hotline................................................................................................21

5.2. Repairs..............................................................................................................21

. Technical data............................................................................................................22

7. Warranty, EU conformity & WEEE................................................................................24

7.1. Guarantee bond.................................................................................................24

7.2. EU Declaration of Conformity..............................................................................25

7.3. Declarations on the WEEE Directive.....................................................................25

Contents | 3