--

(?4;

4.0 HEADALIGNMENTWITH TANDBERG

TESTTAPES,MODEL

6041X

4.1Playback

Head

Set the recorder for stereo playback and connect a

VTVM to eachone of the phono outputs.

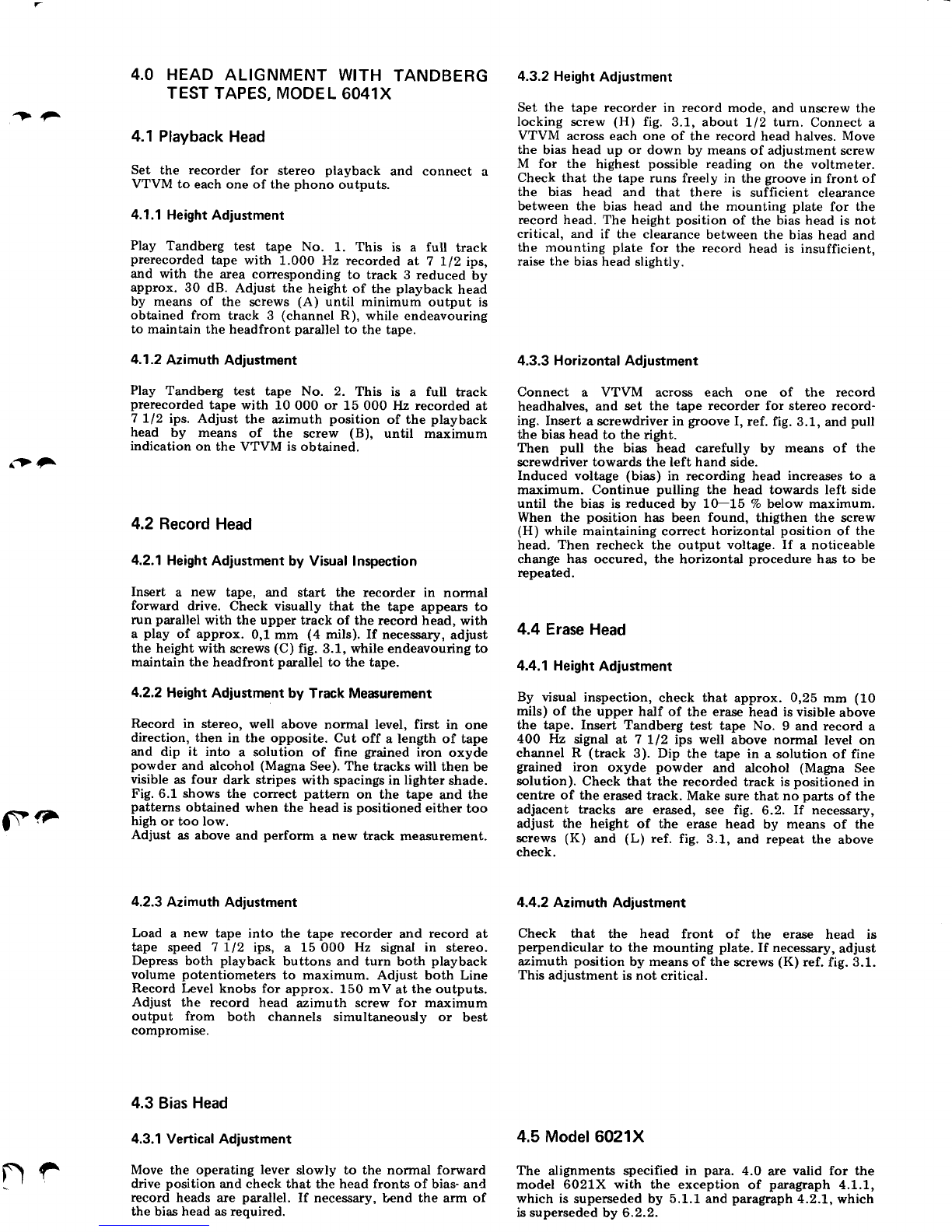

4.1.1 HeightAdiustment

Play Tandberg test tape No. 1. This is a full track

prerecorded tape with 1.000 Hz recorded at 7 ll2 ips,

and with the area corresponding to track 3 reduced by

approx. 30 dB. Adjust the height of the playback head

by means of the screws (A) until minimum output is

obtained from track 3 (channel R), while endeavourlng

to maintain the headfront parallel to the tape.

4.1.2 Azlmuth Adjustment

Play Tandberg test tape No. 2. This is a full track

prerecorded tape with 10 000 or 15 000 Hz recorded at

7 tl2 ips. Adjust the azimuth position of the playback

head by means of the screw (B), until maximum

indication on the VTVM is obtained.

4.2 Record Head

4.2.1 Height Adiustment by Visual Inspection

Insert a new tape, and start the recorder in normal

forward drive. Check visually that the tape appears to

run parallel with the upper track of the record head, with

a play of approx. 0,1 mm (4 mils). If necessary,

adjust

the height with screws

(C) fig. 3.1, while endeavouring to

maintain the headfront parallel to the tape.

4.2.2Heighl Adiustment by Track Meaurement

Record in stereo, well above normal level, first in one

direction, then in the opposite. Cut off a length of tape

and dip it into a solution of fine grained iron oxyde

powder and alcohol (Magna See). The tracks will then be

visible as four dark stripes with spacingsin lighter shade.

Fig.6.1 shows the correct pattern on the tape and the

patterns obtained when the head is positioned either too

high or too low.

Adjust as above and perform a new track measurement.

4.2.3 Azimuth Adiustment

Load a new tape into the tape recorder and record at

tape speed 7 Ll2 ips, a 15 000 Hz signal in stereo.

Depress

both playback buttons and turn both playback

volume potentiometers to maximum. Adjust both Line

Record l,evel knobs for approx. 150 mV at the outputs.

Adjust the record head azimuth screw for maximum

output from both channels simultaneously or best

compromise.

4.3

Bias

Head

4.3.1 Vertical Adiustment

Move the operating lever slowly to the normal forward

drive position and check that the head fronts of bias-and

record heads are parallel. If necessary, bend the arm of

the biasheadasrequired.

4.3.2 HeightAdjustment

Set the tape recorder in record mode, and unscrew the

locking screw (H) fig. 3.1, about 1/2 turn. Connect a

VTVM acrosseach one of the record head halves.Move

the bias head up or down by means

of adjustment screw

M for the highest possible reading on the voltmeter.

Check that the tape runs freely in the groovein front of

the bias head and that there is sufficient clearance

between the bias head and the mounting plate for the

record head. The height position of the bias head is not

critical, and if the clearance between the bias head and

the mounting plate for the record head is insufficient,

raisethe biashead slightly.

4.3.3 Horizontal Adjustment

Connect a VTVM across each one of the record

headhalves, and set the tape recorder for stereo record-

ing. Insert a screwdriver in groove I, ref. fig. 3.1, and pull

the bias head to the right.

Then pull the bias head carefully by means of the

screwdriver towards the left hand side.

Induced voltage (bias) in recording head increasesto a

maximum. Continue pulling the head towards left side

until the bias is reduced by 10-15 7o

below maximum.

When the position has been found, thigthen the screw

(H) while maintaining correct horizontal position of the

head. Then recheck the output voltage. If a noticeable

change has occured, the horizontal procedure has to be

repeated.

4.4EraseHead

4.4.1 Height Adjustment

By visual inspection, check that approx. 0,25 mm (10

mils) of the upper half of the erasehead isvisible above

the tape. Insert Tandberg test tape No. 9 and record a

4OO Hz signal at 7 Ll2 ips well above normal level on

channel R (track 3). Dip the tape in a solution of fine

grained iron oxyde powder and alcohol (Magna See

solution). Check that the recorded track is positioned in

centre of the erasedtrack. Make surethat no parts of the

adjacent tracks are erased, see fig. 6.2. If necessary,

adjust the height of the erase head by means of the

screws (K) and (L) ref. fig. 3.1, and repeat the above

check.

4.4.2 Azimuth Adlustment

Check that the head front of the erase head is

perpendicular to the mounting plate. If necessar5r,

adjust

azimuth position by meansof the screws

(K) ref. fig. 3.1.

This adjustment is not critical.

4.5Model6021X

The alignments specified in para. 4.0 are valid for the

model 6021X with the exception of paragraph 4.1.1,

which is supensededby 5.1.1 and paragraph4.2.1, which

issuperseded

by 6.2.2.

$'rF

D{^