T&C TC36.NGST03.C Assembly instructions

Table of contents

Other T&C Indoor Fireplace manuals

Popular Indoor Fireplace manuals by other brands

Marquis

Marquis KINGSMAN ZCV3622N installation instructions

Superior

Superior VRE4536RS Installation and operation instructions

PERFECTION-SCHWANK

PERFECTION-SCHWANK GFP28MNG OWNER'S OPERATION AND INSTALLATION MANUAL

Vermont Castings

Vermont Castings VLI31DVN Installation and operating instructions

FPI

FPI FP90 Owners & installation manual

Twin-Star International

Twin-Star International Bello ClassicFlame 23DE8202 manual

Stellar Hearth

Stellar Hearth VP-36M Installation and operating manual

HearthStone

HearthStone TUCSON owner's manual

Regency Fireplace Products

Regency Fireplace Products GFI300LNG-R Owners & installation manual

Thermablaster

Thermablaster GLDF18T-VF manual

Majestic

Majestic Designer Installation and operating instructions

FMI

FMI EL36LD installation manual

FMI

FMI (V)GL36PN Owners manual and installation manual

Lennox Hearth Products

Lennox Hearth Products MPE-36R Installation instructions and homeowner's manual

Modern Flames

Modern Flames SPECTRUM SLIMLINE SPS-50B-EU owner's manual

American Hearth

American Hearth ADVD32FP3(0,1,2,3)(N,P)-1 Installation instructions and owner's manual

Heat-N-Glo

Heat-N-Glo ENERGY MASTER EM-415R Installation & operating instructions

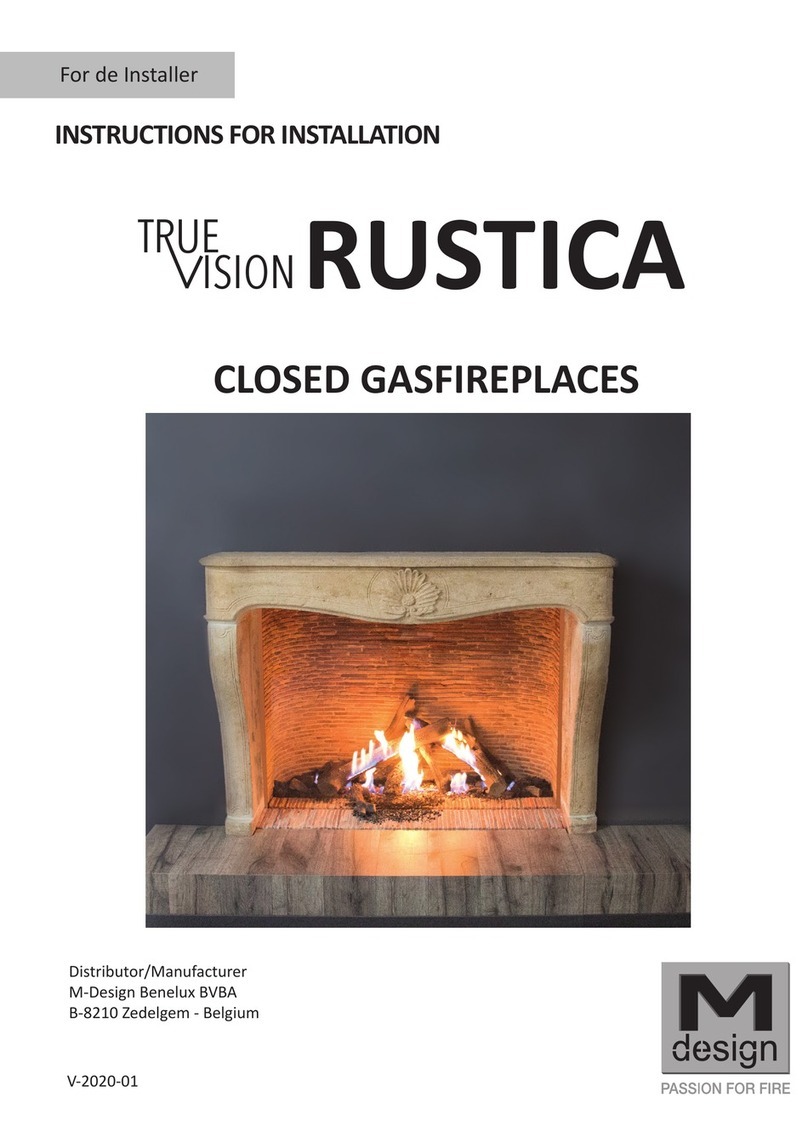

M Design

M Design TRUE VISION RUSTICA M Instructions for installation