IOM Manual – IBC Mixers

Mixers - LBC/HBC 5

1.3. Inspection

On receiving delivery of your IBC Mixer please inspect carefully to confirm that

your mixer has been received un-damaged and to the correct specification. Report any

shortages or damage immediately in writing to the carrier or supplier. Contact details

can be found at the back of this manual.

1.4. Storage

IBC Mixers series LBC, HBC should be stored in an indoor, clean, dry location

with a controlled temperature of 15°C to 40°C until the mixer is ready to be used.

1.5. Description

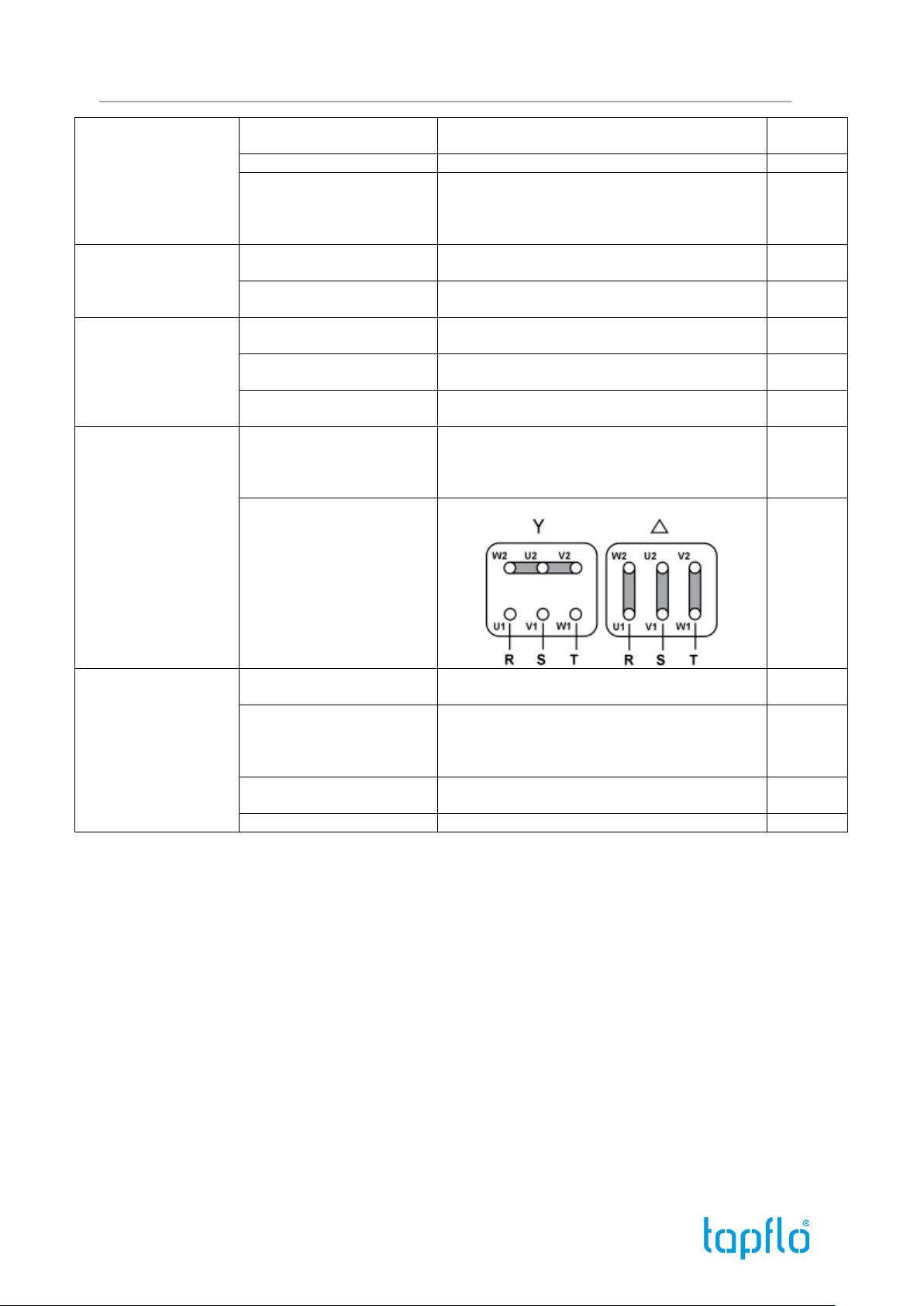

Tapflo IBC Mixers series LBC, HBC are designed for use on Industry standard

Intermediate Bulk Containers (IBC) with a 150mm screw cap and are suitable for most

container types.

The IBC mixers are for use indoors in a safe area only and is fitted with a DOL

starter with overload protection and a safety switch to prevent the mixer operating if the

mixer is not securely mounted on an IBC and a 16 AMP appliance Inlet plug protection

IP44 - splash proof.

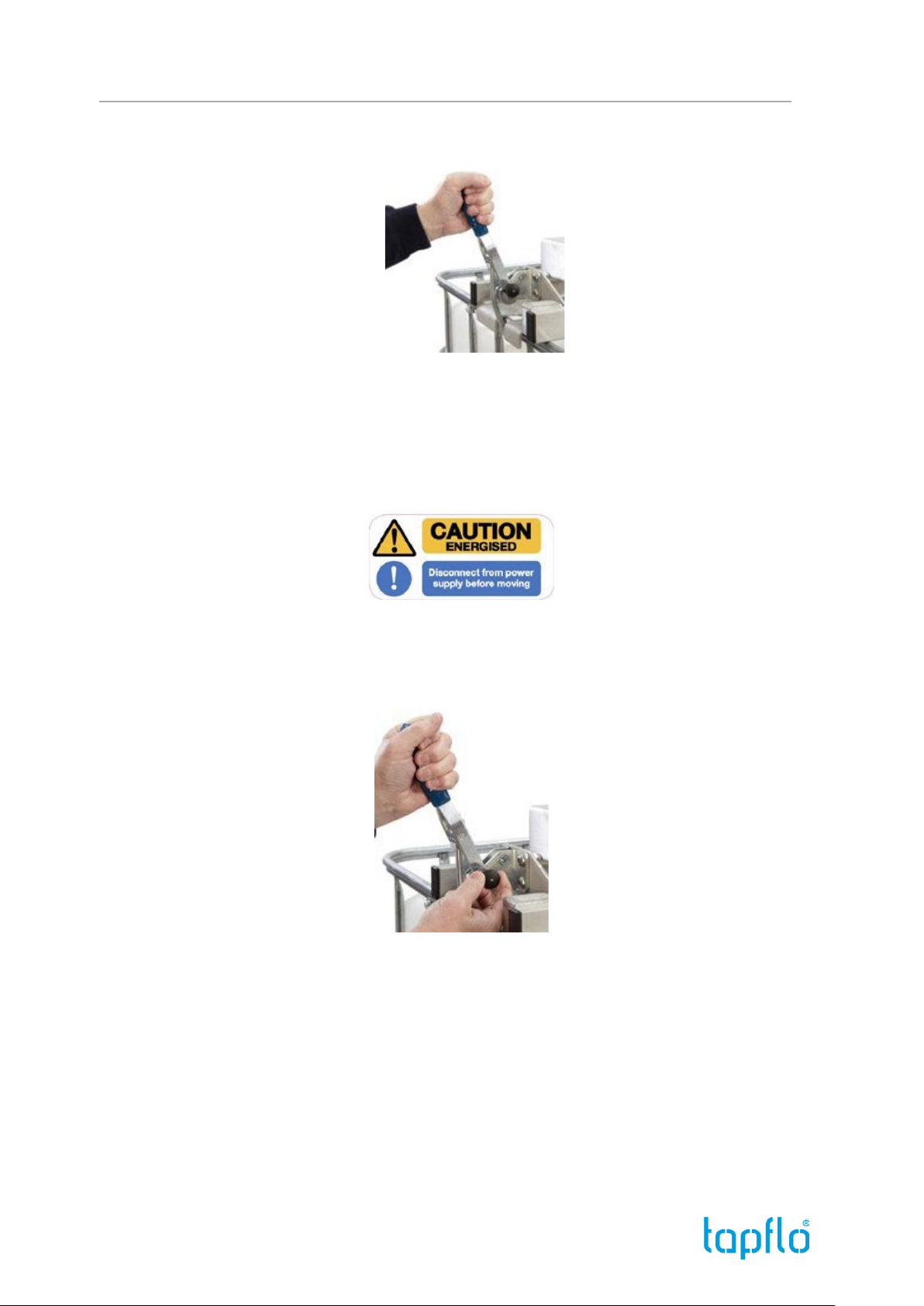

The mixer drive is supported on a lightweight stainless steel bridge which

mounts directly onto the IBC and is held in place with quick action toggle clamps,

standard lifting is an eye bolt for lifting with a hoist or optional fork lift module.

1.6. Safety

The following instructions are important.

• Observe all site safety procedures installing and operating your IBC mixer

• Familiarize yourself with the material being mixed in the IBC and obtain product safety

data sheets, protective clothing and appropriate eye protection before proceeding.

• Use lifting equipment i.e. fork lift or hoist to install the mixer onto an IBC mixer. Mass

in Kg is indicated on the mixer nameplate.

• Mount the mixer securely onto the IBC complete with shaft and impeller before

connecting to the power supply.

• Disconnect from the power supply before moving the mixer or carrying out

maintenance.

• Do not touch any moving / rotating parts.

• Do not touch the motor after use - Hot Surface

WARNING – failure to observe safety instructions could cause severe personal injury.