IOM manual Active pulsation dampeners 7

1.5.1. Protection

In the interest of health and safety it is essential to wear protective clothing and safety goggles

when operating, and/or working in the vicinity of Tapo dampeners.

1.5.2. Explosion hazardous environments – ATEX

Static electricity may occur in the pump under operation, which may cause explosion

and injury. Special conductive pulsation dampeners DTX are available for such applications.

Follow below instructions and local/national rules for safe use.

ATEX (directive 94/9/EC) classication of Tapo DTX dampeners:

ATEX II 2 GD IIB cT4

Equipment group II – all other explosive areas than mines;

Category group 2 – high level of protection (can be used in zone 1);

Atmosphere G– gas; D– dust;

Explosion group IIB – such as ethylene;

Type of protection c– constructional safety;

Temperature class T4 – in the event of a malfunction, the maximum temperature of a surface that

may be exposed to gas T4 = 135 °C.

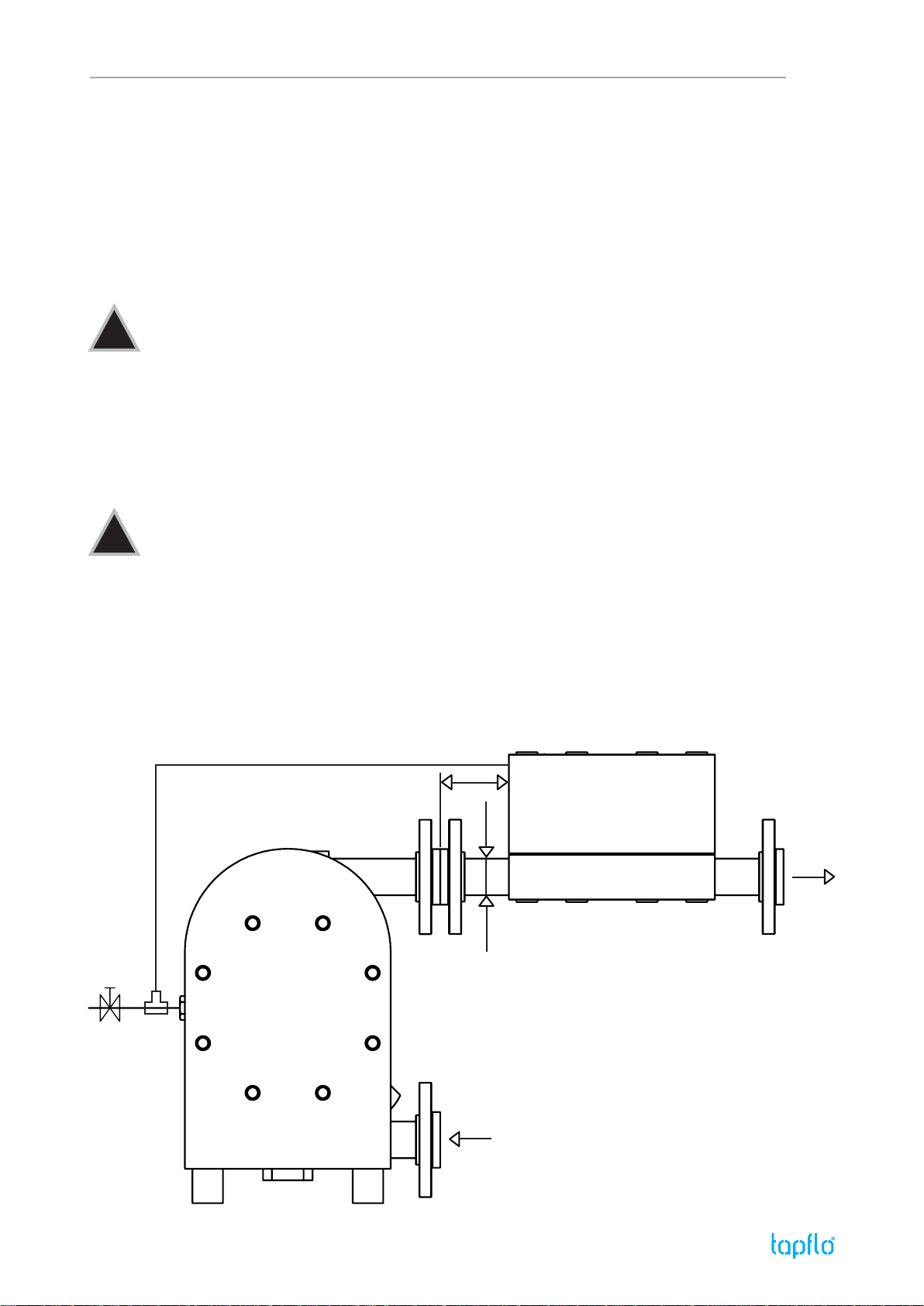

Earth connection of dampener and other equipment

Connect a suitable earth wire to the stainless steel earth connection that is placed on the inside

of one of the pump housings. Connect the other end of the earth wire to earth and also make sure

that other equipment like hoses/pipes/containers etc. are properly earthed/connected.

1.5.3. Air pressure

The maximum air pressure for Tapo dampeners is 14 bar. Higher air pressure than 14 bar can

damage the dampener and may cause injury to personnel in vicinity of the dampener.

Please make sure that supply air to the dampener must have the same ow and pressure as the

pump that dampener is installed with.

1.5.4. Noise level

At tests, the noise level from a Tapo dampener has not exceeded 70 dB(A).

1.5.5. Temperature hazards

Raised temperature can cause damage to the dampener and/or piping and may also be hazar-

dous for personnel in the vicinity of the dampener/piping. Avoid quick temperature changes and

do not exceed the maximum temperature specied when the dampener was ordered.

1. INSTALLATION & SAFETY

STOP

STOP

STOP