215649 iii Revision A

Introduction ................................................................................................................................................i

Summary of Changes....................................................................................................................................ii

Chapter 1: Safety ........................................................................................................................................ 1

1.1 Signal Words .........................................................................................................................................1

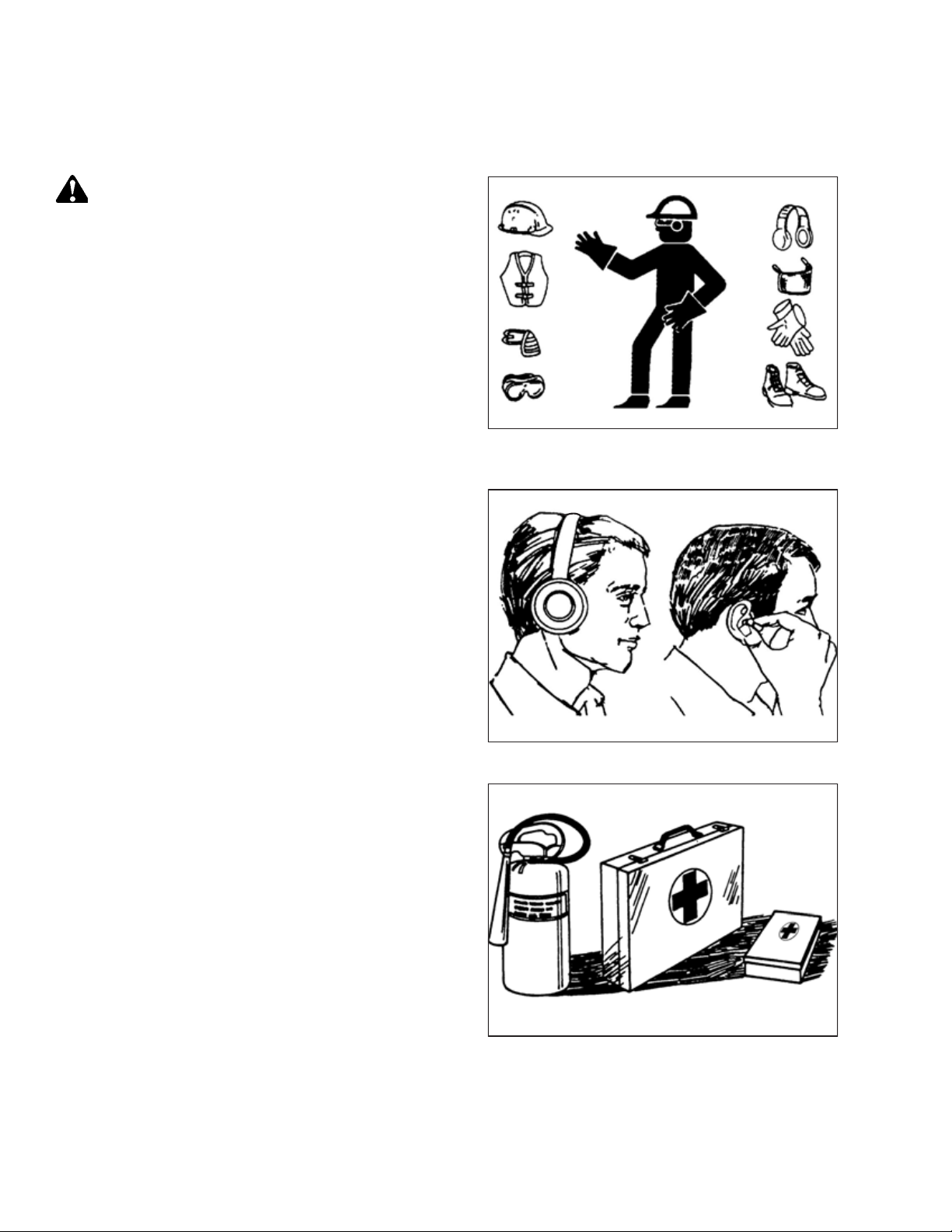

1.2 General Safety .......................................................................................................................................2

1.3 Welding Precaution ................................................................................................................................4

1.4 Safety Signs ...........................................................................................................................................5

Chapter 2: Unloading Header..................................................................................................................... 7

2.1 Unloading Header from Trailer..................................................................................................................7

2.2 Lowering Header to Field Position .............................................................................................................9

2.2.1 Lowering Single-Reel Header............................................................................................................9

2.2.2 Lowering Double-Reel Header ........................................................................................................ 12

2.3 Removing Shipping Supports .................................................................................................................. 16

Chapter 3: Assembling Header................................................................................................................. 19

3.1 Attaching Reel-Lift Cylinders ................................................................................................................... 19

3.2 Positioning Transport Lights ................................................................................................................... 27

3.3 Attaching Cam Arms ............................................................................................................................. 29

3.4 Installing Crop Dividers .......................................................................................................................... 31

3.5 Installing Disc Segments of Outboard Reel Endshields ................................................................................. 33

3.6 Installing Options ................................................................................................................................. 34

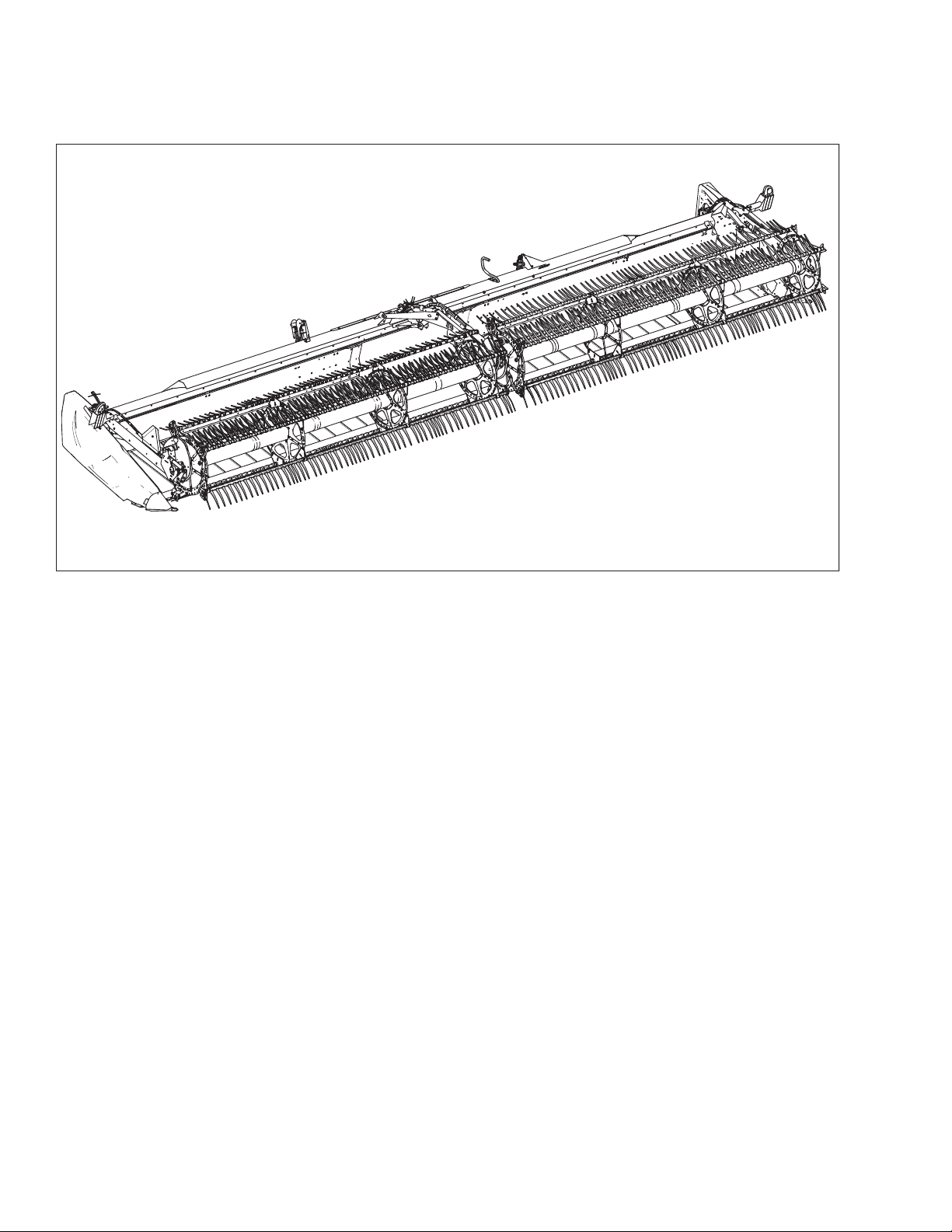

Chapter 4: Attaching Header to Windrower ........................................................................................... 35

4.1 Connecting Center-Link.......................................................................................................................... 37

4.1.1 Mechanical Link........................................................................................................................... 37

4.1.2 Hydraulic Link without Self-Alignment Kit ......................................................................................... 39

4.1.3 Hydraulic Link with Self-Alignment Kit.............................................................................................. 42

4.2 Connecting Hydraulics ........................................................................................................................... 45

4.3 Adding Tire Ballast................................................................................................................................ 49

Chapter 5: Performing Predelivery Checks.............................................................................................. 51

5.1 Checking Tire Pressure –Transport and Stabilizer Wheels............................................................................ 51

5.2 Checking Wheel Bolt Torque –Transport and Stabilizer Wheels .................................................................... 52

5.3 Checking and Adjusting Endshields .......................................................................................................... 53

5.4 Checking Knife Drive Box ....................................................................................................................... 57

5.5 Checking and Adjusting Knife Drive Belt Tension ........................................................................................ 58

5.5.1 Checking and Tensioning Single and Untimed Double-Knife Drive Belts.................................................. 58

5.5.2 Checking and Tensioning Timed Double-Knife Drive Belts.................................................................... 60

5.5.3 Tensioning Timed Knife Drive V-Belts............................................................................................... 64

5.6 Centering Reel ..................................................................................................................................... 65

5.6.1 Centering Double Reel .................................................................................................................. 65

TABLE OF CONTENTS