3

EVERY MACHINE IS THOROUGHLYTESTED BEFORE LEAVING THE FACTORY. EACH MACHINE IS

SUPPLIED WITH ACOPY OF THIS MANUAL. OPERATORS OF THIS EQUIPMENT MUST READAND BE

FAMILIAR WITH THE SAFETY WARNINGS. FAILURE TO OBEY WARNINGS MAY RESULT IN INJURYOR

DEATH. FOLLOW INSTRUCTIONS STRICTLY TO ENSURE LONG SERVICE IN NORMAL OPERATION.

CONTENTS

SymbolDefinitions .....................................................................................................4 - 6

DecalDescriptions andLocations..............................................................................7 - 9

Safety Warnings - DOs & DO NOTs ..........................................................................10 - 11

Reference Figure 1 ....................................................................................................12

Instructions:

1. Features ........................................................................................................13

2. Benefits .........................................................................................................13

3. Machine Set-Up Procedures..........................................................................13-14

4. OperatingProcedures ...................................................................................14-15

5. ManualThermal Overload..............................................................................15

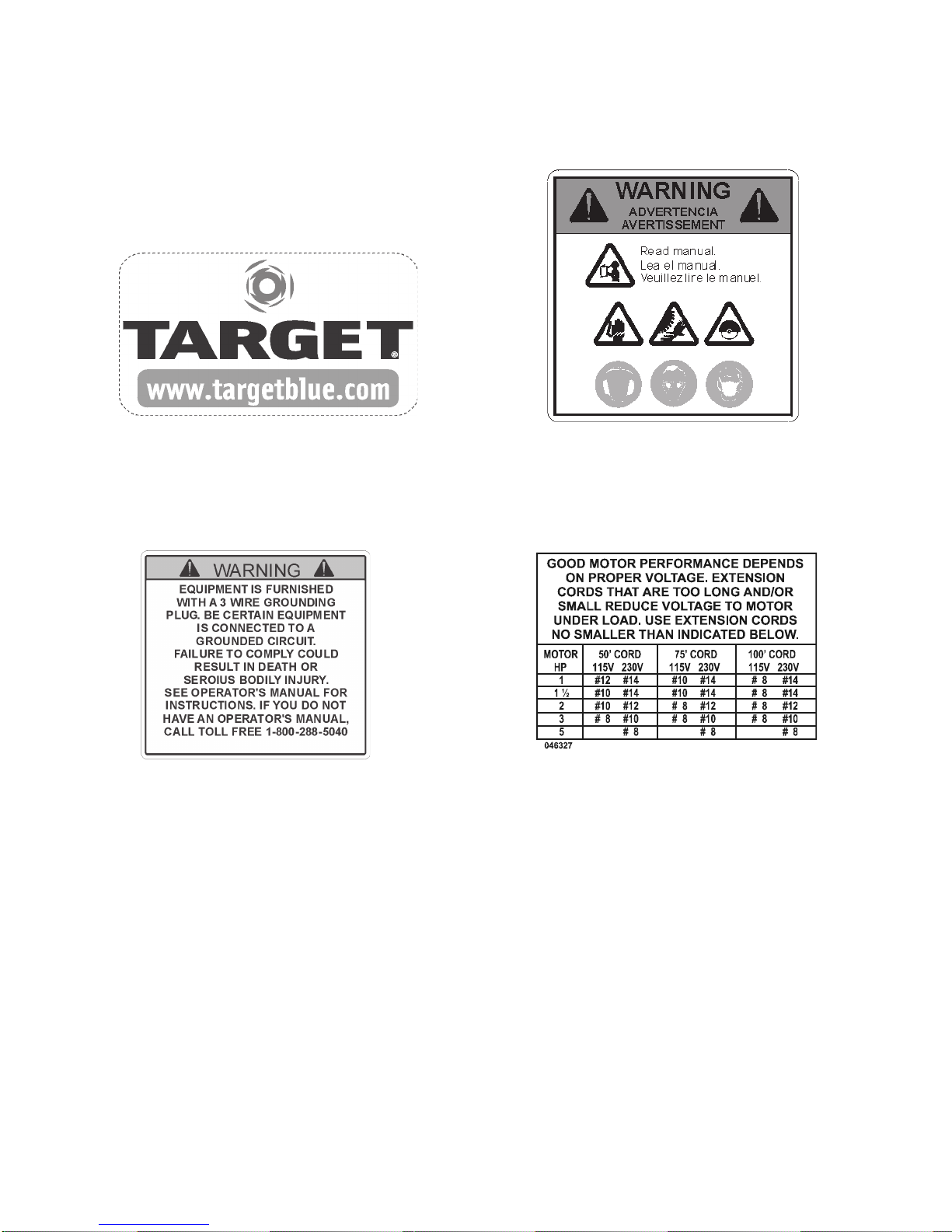

6. ExtensionCords ............................................................................................15

7. AlignmentProcedures....................................................................................15-16

8. Profile Wheel Set-Up ..................................................................................... 16

9. Maintenance ..................................................................................................16

10.Water Pump, Trouble Shooting Procedure..................................................... 16

11. Repairs ..........................................................................................................17

12.Spare Parts ...................................................................................................17

13.Accessories ...................................................................................................17

Diagrams and Spare Parts ........................................................................................28-29

WiringDiagrams ........................................................................................................30-32

Warranty ....................................................................................................................33

ANTES DE SALIR DE NUESTRA FÁBRICA, CADAMÁQUINAES SOMETIDAAPUREBAS DETENIDAS. CADA

MÁQUINA DE CORTE ES ENTREGADA CON UNA CIPIA DE ESTE MANUAL. LOS OPERARIOS DE ESTOS

EQUIPOS DEBEN LEER YFAMILIARIZARSE CON LAS INSTRUCCIONES DE SEGURIDAD. ELNO PRESTAR

ATENCIÓNAESTASADVERTENCIASPUEDE OCASIONAR GRAVESLESIONE. SIGAESTRICAMENTE NUES-

TRAS INSTRUCCIONES Y SU MÁQUINA LE VA A PRESTAR LARGOS AÑOS DE SERVICIO EN CONDICIO-

NES NORMALES DE UTILIZACIÓN.

CONTENIDO

DefiniciónDe LosSimbolos .......................................................................................4 - 6

DescripciónDe CalcamoniasY Ubicaciones.............................................................7 - 9

AdvertenciasDe SeguridadHACER& NOHACER....................................................18-19

Figura 1 De Referencia..............................................................................................20

Instrucciones:

1. Caracteristica...............................................................................................21

2. Beneficio ......................................................................................................21

3. Instalacíon De La Cortadora ........................................................................22-23

4. InstruccionesDe Operación .........................................................................23

5. Protector Térmico - Rearmado Manual ........................................................24

6. CablesDe Extensión ....................................................................................24

7. Procedimientos deAlineacion .......................................................................24

8. Armado y Uso de la Rueda Perfiladora ........................................................25

9. InstruccionesDe Mantenimiento...................................................................25

10. EnCaso De Problemas Con La Bomba DeAgua ..........................................25

11. Reparaciones ...............................................................................................26

12. Piezas DeRecambio ....................................................................................26

13. Accesorios ...................................................................................................27

Diagrame y Piezas De Recambio ..............................................................................28-29

Diagrame De Cablado Eléctrico.................................................................................30-32

Garantia.....................................................................................................................33