2

EVERY MACHINE IS THOROUGHLY TESTED BEFORE LEAVING THE FACTORY. EACH MACHINE

IS SUPPLIED WITH A COPY OF THIS MANUAL. OPERATORS OF THIS EQUIPMENT MUST READ AND BE

FAMILIAR WITH THE SAFETY WARNINGS. FAILURE TO OBEY WARNINGS MAY RESULT IN INJURY OR

DEATH. FOLLOW INSTRUCTIONS STRICTLY TO ENSURE LONG SERVICE IN NORMAL OPERATION.

Table of Contents

CONTENTS ................................................................................................................................ PAGE NO.

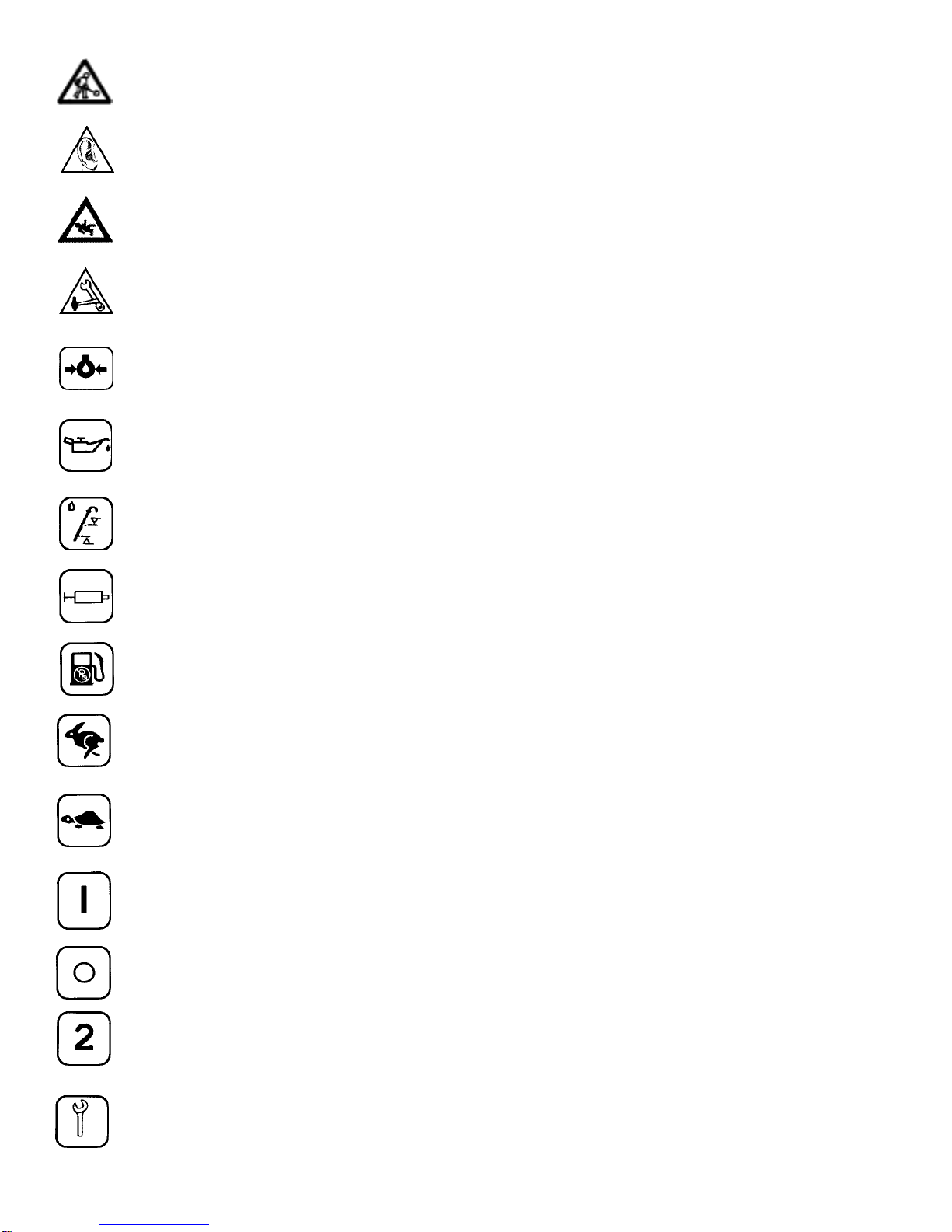

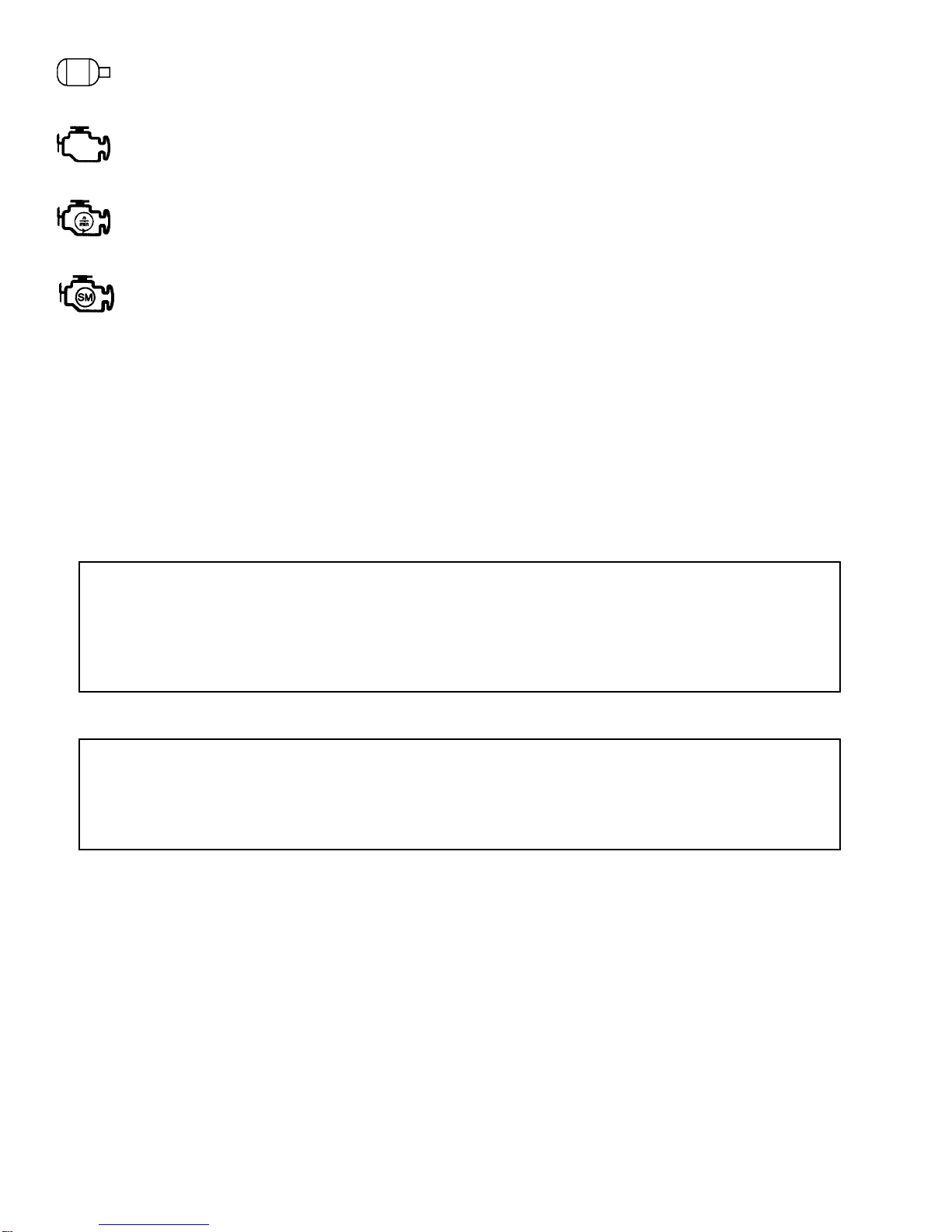

SymbolDefinitions.................................................................................................................................................... 4

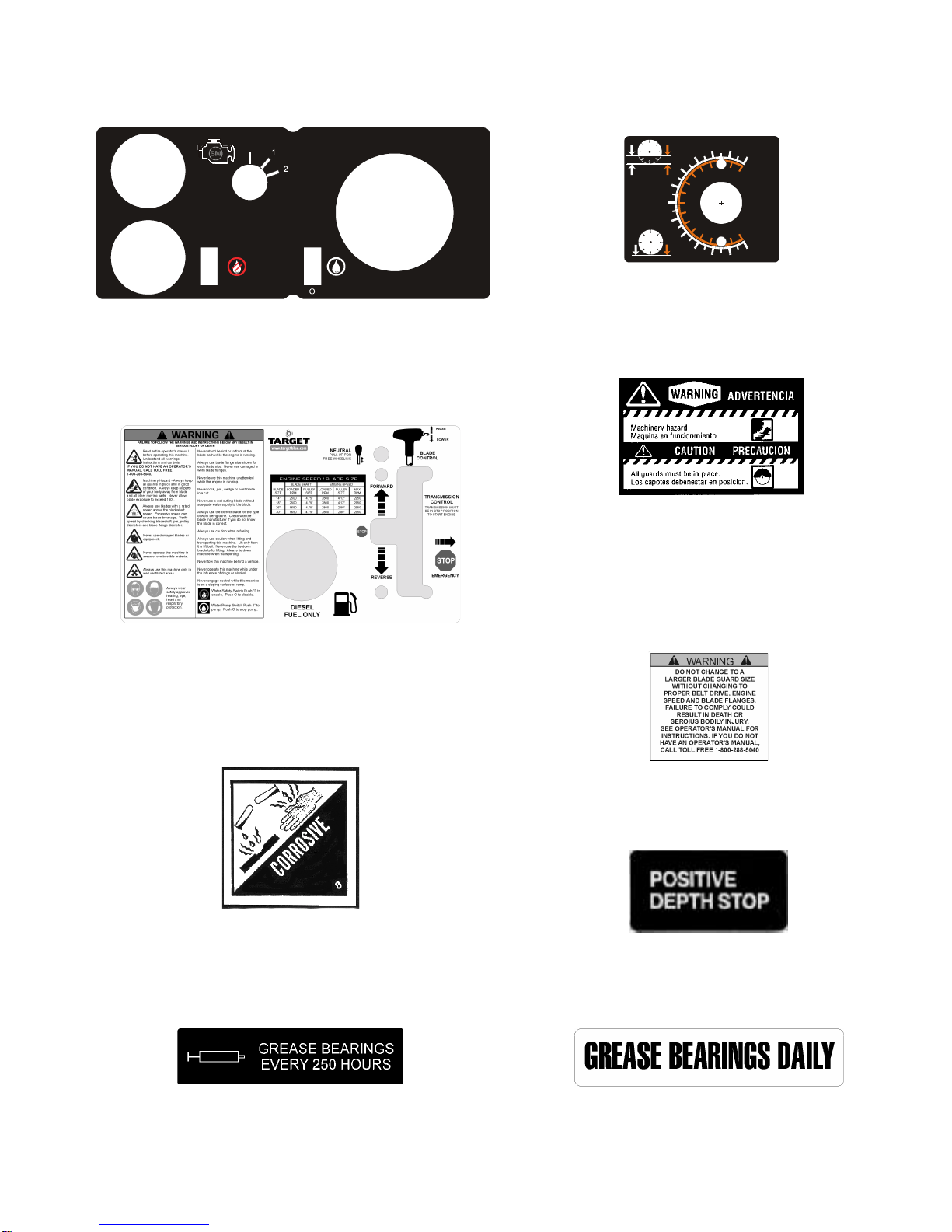

Decal Descriptions And Locations ............................................................................................................................. 9

Saw Dimensions ......................................................................................................................................................11

PRO 65 III Diesel Specifications ............................................................................................................................. 12

PRO 35 III Diesel Specifications ............................................................................................................................. 13

PRO 35 III 20HP Electric Specifications.................................................................................................................. 14

Power Source ........................................................................................................................................................ 15

Special Instructions For Changing Blade Speed On Concrete / Asphalt Saws ........................................................... 16

WARNINGS............................................................................................................................................................ 18

FIGURES

FIG. 1 ..................................................................................................................................................................... 20

FIG. 2 ..................................................................................................................................................................... 21

FIG. 3 ..................................................................................................................................................................... 21

FIG. 4 ..................................................................................................................................................................... 22

FIG. 5 ..................................................................................................................................................................... 28

PreOperation Checklist .......................................................................................................................................... 23

Scheduled Maintenance Quick Reference ............................................................................................................... 23

INSTRUCTIONS

1 Use................................................................................................................................................................ 24

2 Moving The Machine ...................................................................................................................................... 24

3 Transport(BladeRemoved) ............................................................................................................................ 25

4 Check Before Starting.................................................................................................................................... 25

5 Fitting The Blade ............................................................................................................................................ 25

6 StartingTheSaw............................................................................................................................................ 26

7 StoppingTheSaw .......................................................................................................................................... 27

8 Incidents During Sawing ................................................................................................................................ 27

9 Adjustments: Straight Line Sawing ................................................................................................................. 27

10 Maintenance .................................................................................................................................................. 27

11 BladeshaftV-Belt AndJackshaftBeltTension .................................................................................................. 28

12 Hydraulic System ........................................................................................................................................... 30

13 Parking Brake (Optional) ................................................................................................................................ 30

14 ImportantAdvice ............................................................................................................................................ 30

15 Pro 35III Electric saws ................................................................................................................................... 30

16 Accessories................................................................................................................................................... 31

17 MetricHardware ............................................................................................................................................ 32

18 Repairs.......................................................................................................................................................... 32

19 Spare Parts.................................................................................................................................................... 32

PRO 35 III Diesel Blade Size Conversion Chart ....................................................................................................... 34

PRO 65 III Diesel Blade Size Conversion Chart ....................................................................................................... 35

DIAGRAMS

Diagram 1 - Wiring Diagram - PRO 35 III Diesel, 182127........................................................................................ 36

Diagram 2 - Wiring Diagram - PRO 65 III Diesel, 182139........................................................................................ 38

Diagram 3 - Ladder Diagram - PRO 35 III Diesel and PRO 65 III Diesel, 182121 ..................................................... 40

Diagram 4 - Wiring Diagram - PRO 35 III Electric, 182062...................................................................................... 42

Diagram 5 - PRO 35 III Electric Wiring Instructions................................................................................................. 44

Diagram 6 - Ladder Diagram - PRO 35 III Electric, 182068 ..................................................................................... 45