2

EVERY MACHI E IS THOROUGHLY TESTED BEFORE LEAVI G THE FACTORY. EACH MACHI E IS SUP-

PLIED WITH A COPY OF THIS MA UAL. OPERATORS OF THIS EQUIPME T MUST READ A D BE FAMIL-

IAR WITH THE SAFETY WAR I GS. FAILURE TO OBEY WAR I GS MAY RESULT I I JURY OR DEATH.

FOLLOW I STRUCTIO S STRICTLY TO E SURE LO G SERVICE I ORMAL OPERATIO .

CONTENTS

Symbol Definitions ............................................................................................................................................ 3 - 6

Hearing Hazard Warnings ................................................................................................................................ 6

Decal Descriptions and Locations .................................................................................................................... 7

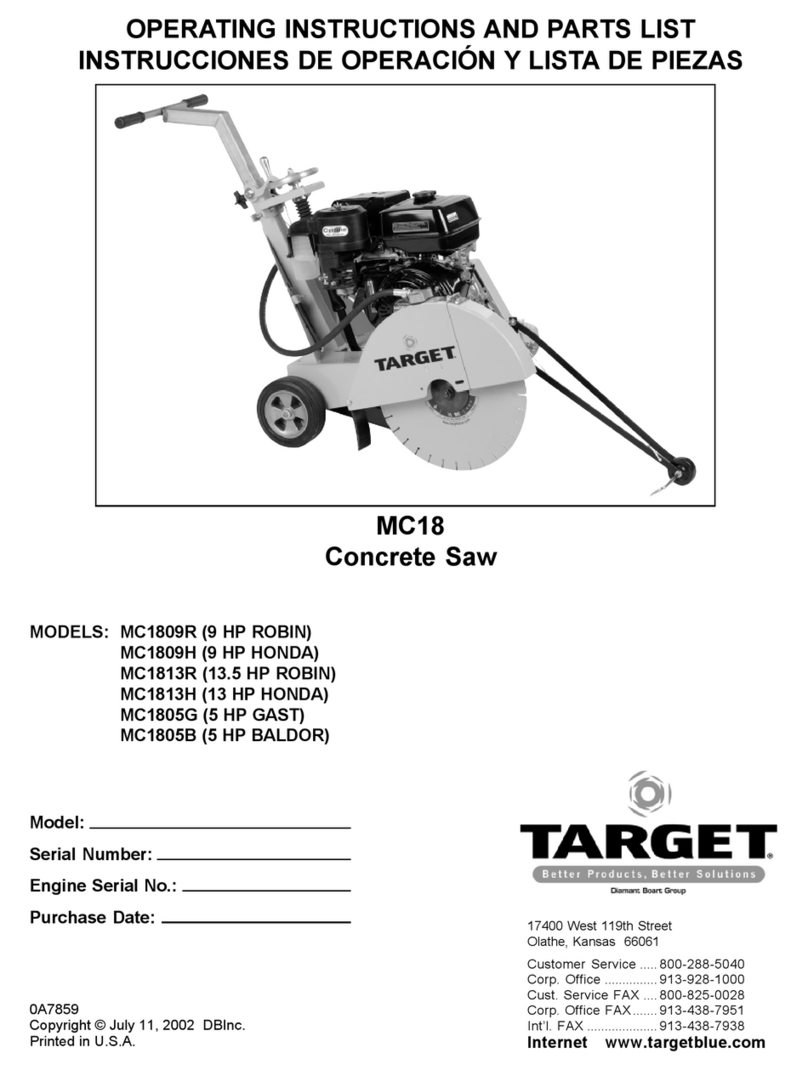

Specifications & Po er Sources ....................................................................................................................... 8

Sa Dimensions ............................................................................................................................................... 9

Safety Warnings - Do's and Do Not's ............................................................................................................... 10 - 11

Reference Figures: 1 - 12 ................................................................................................................................. 12 - 14

Pre Operation Checklist .................................................................................................................................... 15

Instructions:

1-Features ..................................................................................................................... ............... 16

2-Assembly .................................................................................................................................. 16 - 17

3-Check Before Operating ........................................................................................................... 17 - 18

4-Fitting the Blade ........................................................................................................................ 18

5-Operating Instructions ............................................................................................................... 18 - 19

6-Incidents During Operation ....................................................................................................... 20

7-Maintenance .................................................................................................................. ........... 20 - 21

8-V-Belt Tension ........................................................................................................................... 21

9-Important Advice ....................................................................................................................... 21 - 22

10 - Accessories................................................................................................................. .............. 22

11 -Repairs ..................................................................................................................... ................. 22

12 - Spare Parts ................................................................................................................. .............. 22

Diagrams and Spare Parts ................................................................................................................................ 40 - 47

Wiring Diagrams ................................................................................................................ ............................... 48 - 49

A TES DE COME ZAR: Lea y compren a to as las a vertencias e instrucciones antes e operar la máquina

que se escribe en este manual. ¡LAS ADVERTE CIAS Y PRECAUCIO ES DE ESTE MA UAL DEBE SER

COMPRE DIDAS Y CUMPLIDAS! SI O SE OBEDECE LAS ADVERTE CIAS, SE PUEDE PRODUCIR

SERIAS LESIO ES O LA MUERTE. ES SU RESPO SABILIDAD el asegurarse que las personas que usen

esta máquina hayan leí o este manual.

CONTENIDO

Definición de Símbolos ..................................................................................................................................... 3 - 6

Advertencias Auditivas de Peligro .................................................................................................................... 6

Calcomanís - Descripciones y Ubicaciones ..................................................................................................... 7

Especificiones y Fuentes de Energía ............................................................................................................... 24

Dimensiones de la Sierra.................................................................................................................................. 25

Advertencias de Seguridad - Los SI y Los NO ................................................................................................. 26 - 27

Ilustraciones de Referencia: 1 - 12 .................................................................................................................. 28 - 30

Pre-Operation Checklist .................................................................................................................................... 31

Instrucciones:

1-Usos ......................................................................................................................... ................. 32

2-Armado ....................................................................................................................... .............. 32 - 33

3-Verifique Antes De Operar ........................................................................................................ 34

4-Colocación De La Hoja ............................................................................................................. 34 - 35

5-Instrucciones De Operación ..................................................................................................... 35 - 36

6-IIncidentes Durante La Operación ............................................................................................ 36 - 37

7-Mantenimiento .......................................................................................................................... 37 - 38

8-Tensión De La Cinta En V ......................................................................................................... 38

9-Consejo Importante................................................................................................................... 38 - 39

10 - Accesorios ................................................................................................................................ 39

11 -Reparaciones ............................................................................................................................ 39

12 - Piezas De Repuesto ................................................................................................................. 39

Diagramas y Lista de Piezas ............................................................................................................................ 40 - 47

Diagramas de Cableado ................................................................................................................................... 48 - 49