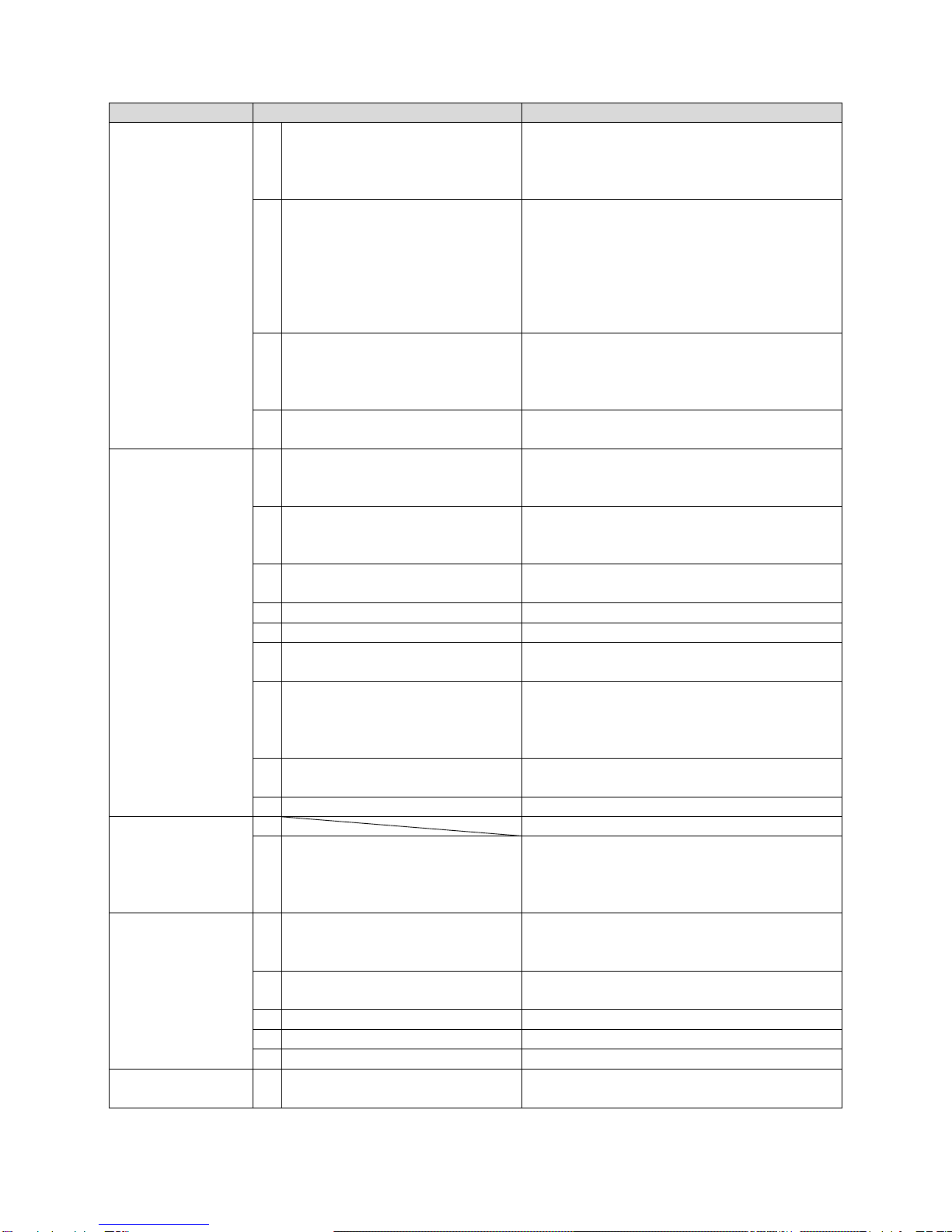

8

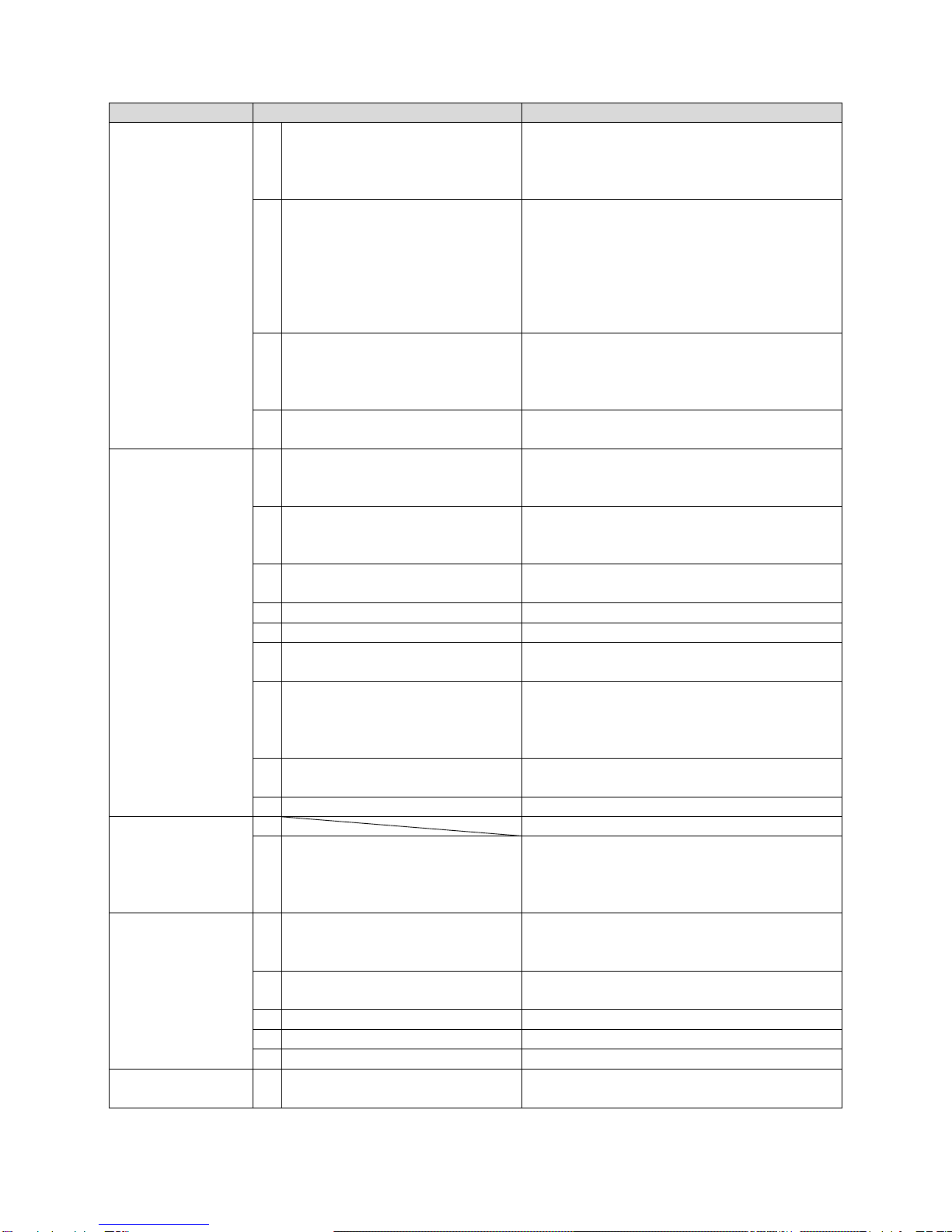

[When you are suspicious of a failure]

Start-up failure

(Start-up disabled,

chattering caused,

etc.)

Ambient temperature is too low.

Have the equipment accustomed to the temperature

of the room, etc. If the start-up instability still persists,

try to start-up with the suction port closed and

continue the warm-up operation for about 5 minutes.

Inadequate power source environment

(Voltage or power degradation due to

use of thin extension cord or too many

loads on one electrical outlet, etc.)

Never use power from an electrical outlet with too

many loads on. Use an extension cord with wire

diameter of 2.0 sq or larger and with length of 10 m

or shorter.

If the start-up instability still persists, try to start-up

with the suction port closed and continue the

warm-up operation for about 5 minutes.

Failure caused by the residual

pressure of the air conditioning system

increasing the internal pressure of the

pump.

Surrender the pump for inspection and repair.

Pump lock or motor failure due to

falling or other strong impact thereon.

Surrender the pump for inspection and repair.

Insufficient degree of

vacuum

Repair the leakage of the piping, etc. of the air

conditioning system and then connect it with the

vacuum pump.

Poor sealing of charge hose or joint

section

Confirm the status of deterioration of the charge hose

or packings, etc. and provide a replacement for any

defective part if any.

Gas ballast valve is opened.

Close the gas ballast valve.

Oil quantity is inappropriate.

Adjust to an appropriate oil level.

Interfusion of foreign material into

pump

Change oil or surrender the pump for inspection and

repair.

Failure caused by the residual

pressure of the air conditioning system

increasing the internal pressure of the

pump.

Surrender the pump for inspection and repair.

Pump or motor failure due to falling or

other strong impact thereon.

Surrender the pump for inspection and repair.

Surrender the pump for inspection and repair.

Oil mist discharged

from exhaust muffler

It is normal when air is being sucked in.

Interfusion of foreign material into

suction valve

Operate for a given length of time and if mist is

discharged intensively even after the object

equipment has reached vacuum status, surrender

the pump for inspection and repair.

Residual pressure of the air

conditioning system increasing the

internal pressure of the pump

Confirm that there is no residual pressure in the air

conditioning system and then connect it with the

vacuum pump.

Exhaust muffler leakage due to falling

sideways

Use and store the equipment in upright position.

Loosening of oil drain screws

Tighten the drain screws further up.

Adjust to an appropriate oil level.

Surrender the pump for inspection and repair.

Abnormal noise/

abnormal odor

Surrender the pump for inspection and repair.

If abnormality persists even after the above has been confirmed, or if any other abnormality has been felt, stop the use

immediately and bring the equipment to the dealer where it was purchased.