TASKING iSYSTEM NXP S32K344 User manual

NXP S32K344 Emulation Adapter

User Manual

V1.4, June 2023

isystem.com/start

General safety instructions

Please read the following safety precautions carefully before putting this device to use to avoid

any personal injuries, damage to the instrument, or to the target system. Use this instrument

only for its intended purpose as specified by this manual to prevent potential hazards.

Use included power cord and power supply

The enclosed power supply has been approved for use by iSYSTEM. Please contact iSYSTEM if

you need to consider an alternative power.

Use grounding wire

Prior to applying power to either the BlueBox or the target, connect the device and the target

system together with the included grounding wire. This is to avoid potential damage caused by

any voltage difference between the device and the target system.

Use proper overvoltage protection

Ensure proper protection to avoid exposing the BlueBox device or the operator to overvoltage

surges (e.g. caused by thunderstorm, mains power).

Do not operate without cover

Do not operate the device with cover removed.

Avoid circuit and wire exposure

Do not touch exposed components or wires when the device is powered.

Do not operate with suspected damage

If you suspect damage may have occurred, the BlueBox device must be inspected by qualified

service personnel before further operation.

Do not operate the device outside its rated supply voltage or environmental range

Consult with iSYSTEM before using equipment outside of the parameters provided in this

manual.

This symbol is used within the manual to highlight further safety notices.

Contents

NXP S32K344 ...................................................................................................................................... 4

Package content ................................................................................................................................ 5

Options .................................................................................................................................................... 6

Target adaptation ................................................................................................................................... 6

Measurement board ............................................................................................................................... 7

Operation ............................................................................................................................................... 8

How to connect ........................................................................................................................................ 8

Configuration ............................................................................................................................................ 8

Connectors .............................................................................................................................................. 11

Standalone Operation .......................................................................................................................... 12

Mechanical information ............................................................................................................. 14

Emulation Adapter ................................................................................................................................ 14

Solder parts ............................................................................................................................................. 14

Extenders ................................................................................................................................................ 15

Assembly ............................................................................................................................................. 16

QFP Fixed ................................................................................................................................................ 16

MaxQFP Fixed ........................................................................................................................................ 16

Accessories ......................................................................................................................................... 19

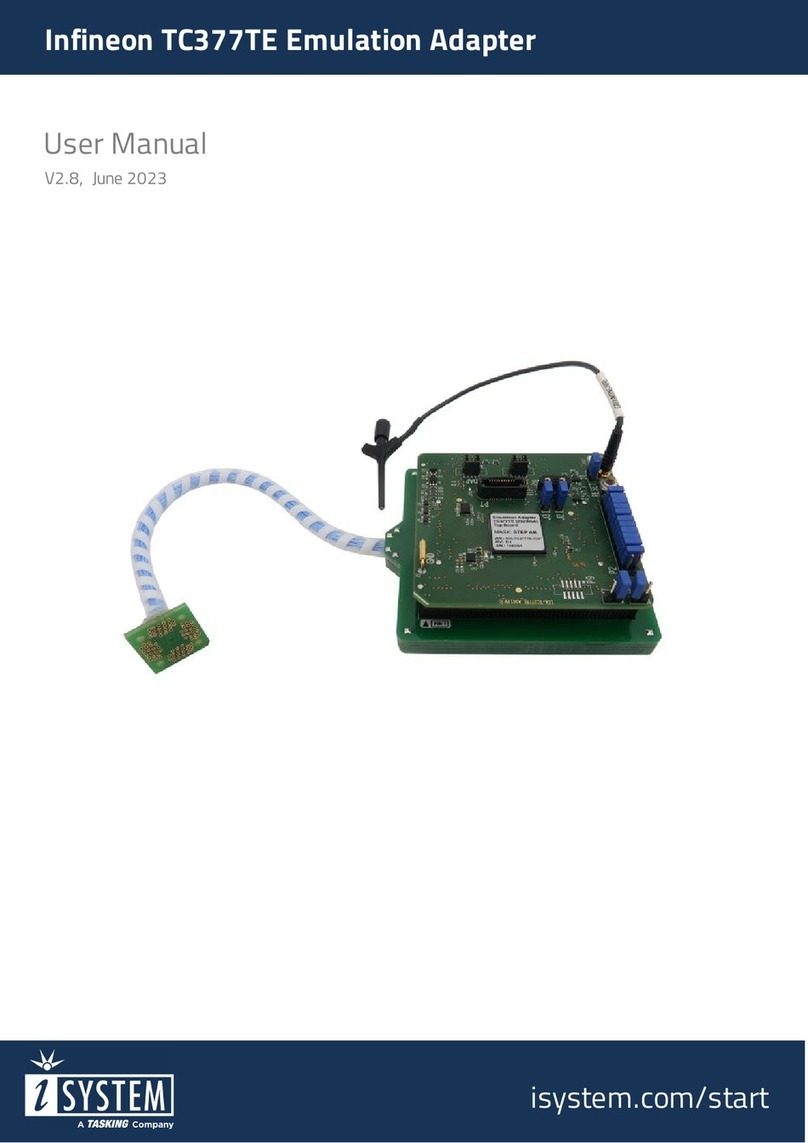

NXP S32K344

NXP S32K344 Emulation Adapter is based on the 257-pin S32K344 superset device and provides

full trace capabilities for the:

·

48-pin

·

100-pin

·

172-pin

NXP S32K344 / 342 / 341 / 324 / 322 / 314 / 312 / 311 microcontroller, where the trace port is not

available or lacks the full trace capability.

The Emulation Adapter might differ in some peripherals from the target device; therefore, the

device datasheet should be checked.

Emulation Adapter supports the following debug and trace interfaces:

·

JTAG or SWD debug interface;

·

HTM/ETM/ITM trace to trace Cortex-M7 program execution; Trace data is connected to the ARM

CoreSight 20 and ARM Mictor 38-pin connector provided on the Emulation Adapter;

·

ETF trace to trace Cortex-M7 program execution; Trace data is stored in up to 2 kB of dedicated

RAM memory and read out through JTAG or SWD;

·

Serial wire viewer (SWV) and printf() style debugging through a Single Wire Output (SWO) “trace”

pin on Cortex-M7.

The Emulation Adapter can also be used as a standalone device for microcontroller evaluation

purposes or for development and testing of an embedded application ahead of target board

availability.

More information about our products on www.isystem.com or via sales@isystem.com.

Package content

NXP S32K344 Emulation Adapter is delivered with all the components required for a standalone

operation. Target adaptation parts for the Target board adaptation must be ordered separately.

NXP S32K344

Emulation Adapter

Power supply package

Power converter

Power adapter

Ordering code:

IEA-S32K344

Ordering code:

IEA-PS

Ordering code:

IT9V-PS

GND Wire

Crystal

Ordering code:

BB-WIRE

Crystal 16 MHz

Options

Target adaptation

The Emulation Adapter adaptation to a specific target microcontroller pincount and package is

done via a Conversion board and a Solder part. Sometimes also an optional Extender is available.

Conversion boards connect between the Emulation Adapter and the matching Solder part, which is

being soldered on the embedded target side. Available Conversion boards, Solder parts and

optional Extenders are listed in the table below.

Package (Pitch)

Conversion board

(Ordering code)

Type

Extender

(Ordering code)

Solder part

(Ordering code)

QFP48 (0.5 mm)

IEA-S32K344-311F48TQ

Fixed

/

IA48TQ-SOLDER

HDQFP100 (0.5 mm)

IEA-S32K344-312F100M

IA100MQFP-EXTENDER

IA100MQFP-SOLDER

IEA-S32K344-342F100M

HDQFP172 (0.5 mm)

IEA-S32K344-312F172M

IA172MQFP-EXTENDER

IA172MQFP-SOLDER

IEA-S32K344-344F172M

QFP Fixed Adaptation

This adaptation is delivered with a slot screw, which can be optionally used to achieve a more solid

and stable fixing of the Conversion board and the Solder part.

Conversion board

Solder part

HDQFP Fixed Adaptation

Conversion board

Extender (optional)

Solder part

Measurement board (optional)

The Measurement board connects between the Emulation Adapter and the Conversion board.

Embedded targets often do not have access to all the MCU pins / connected signals to connect with

measurement equipment (oscilloscope, logic analyzer), its use provides easy access to all MCU

pins. It is delivered together with an Layout board (chip signals are clearly marked), which is placed

over the Measurement board.

Measurement board

Layout board example for the Measurement

board

Ordering code:

IAMS32K344

Operation

How to connect?

·

How to connect Emulation Adapter (video) - short link: isystem.com/ea-intro

·

How to connect iSYSTEM Hardware (video) - short link: isystem.com/connect-hardware

Configuration

DIP1: Target reset configuration

DIP switch DIP1 connects the Emulation Adapter reset line and the target reset line and is on

(position next to the white dot) by default. The Emulation Adapter also features a Reset push button

(SW1).

If having problems establishing the initial debug session with the Emulation Adapter, adjust the DIP

switch DIP1 to the off position (position away from the white dot) and try again.

DIP2: Clock source configuration

DIP switch DIP2 selects a clock source for the emulation device.

When the switch is in position next to the white dot (default setting), it selects the crystal circuit

oscillator from the target.

When the crystal circuit of the emulation adapter is to be used instead of the target board's crystal

circuit, adjust the switch in the position away from the white dot. In this case, the Q1 socket on the

Emulation Adapter must also be populated with an adequate crystal.

The Emulation Adapter may not operate when your target board’s crystal circuit is used as the

clock source. A typical design guideline is that the crystal should be as close as possible to

the microcontroller. The crystal on your target board might not oscillate in conjunction with

the Emulation Adapter when the clock lines (XTAL, EXTAL) between the crystal and the

emulation device on the Emulation Adapter become too long, thus affecting the impedance of

the crystal circuit.

Separately packed 16 MHz crystal can be used as a 16 MHz external clock (XOSC) source to

the emulation device. If a different clock frequency is required, insert an adequate crystal into

the Q1 socket and replace C1 (default 22pF populated) and C2 (default 22pF populated)

accordingly. Crystal socket Q1 is by default not populated (NP).

Crystal socket Q1 schematics below:

Trace port

The superset microcontroller device being used on the Emulation Adapter features Slow and Fast

trace signals. Slow trace signals are connected to ARM Mictor 38 and ARM CoreSight 20 target

connectors provided by the Emulation Adapter. Fast trace signals share microcontroller I/O ports

with other peripheral functionalities, and for this reason, they are connected towards the target for

the user to use them according to their target application configuration and usage.

List of used microcontroller ports:

·

TRACECLK - PTG6

·

TRACEDATA[0] - PTG7

·

TRACEDATA[1] - PTG15

·

TRACEDATA[2] - PTG16

·

TRACEDATA[3] - PTF31

·

TRACEDATA[4] - PTG17

·

TRACEDATA[5] - PTF28

·

TRACEDATA[6] - PTG18

·

TRACEDATA[7] - PTG19

·

TRACEDATA[8] - PTG20

·

TRACEDATA[9] - PTG21

·

TRACEDATA[10] - PTG22

·

TRACEDATA[11] - PTG23

·

TRACEDATA[12] - PTG24

·

TRACEDATA[13] - PTG25

·

TRACEDATA[14] - PTG26

·

TRACEDATA[15] - PTG27

winIDEA configuration

By running the New Workspace Configuration Wizard, the correct emulation adapter trace port will

be configured. In the Wizard, select iSYSTEM S32K344 Emulation Adapter.

P2: Power supply configuration

The power supply of the Emulation Adapter is configured via the unshrouded 26-pin 2.54 mm

header (P2).

Signal direction

Signal

Pin

Pin

Signal

Signal direction

Target board

TVDD_HV_A

1

2

VDD_HV_A

Emulation device

Target board

TVDD_HV_B

3

4

VDD_HV_B

Emulation device

Not Connected

TVREFH

5

6

VREFH

Not Connected

Not Connected

NC

7

8

NC

Not Connected

Not Connected

NC

9

10

NC

Not Connected

Not Connected

NC

11

12

NC

Not Connected

Not Connected

NC

13

14

NC

Not Connected

Not Connected

NC

15

16

NC

Not Connected

Not Connected

NC

17

18

NC

Not Connected

Not Connected

NC

19

20

NC

Not Connected

Ground

GND

21

22

GND

Ground

Ground

GND

23

24

GND

Ground

Ground

GND

25

26

KEY

P2 Signal description

Signal Direction is described from the BlueBox perspective.

By default, all jumpers are set to connect your target power supply to the microcontroller on the

Emulation Adapter. Note that only pins 1-2, 3-4 and 5-6 of the P2 connector must be bridged with

jumpers, but for the convenience and ease of use, all jumpers are set. Pin 26 is the Key pin

preventing incorrect connection of the IEA-PS Power converter when being used and plugged in.

If, for some reason, a power supply is not provided from the target side (e.g., a standalone

operation), all jumpers must be removed and, depending on the application, 3V3 or 5V must be

applied to the following pins:

·

P2 pin 2 - VDD_HV_A

·

P2 pin 4 - VDD_HV_B

·

P2 pin 6 - VREFH

An enclosed Power supply package (Power converter and Power adapter) provides these voltages

by simply plugging in the Power converter to the P2 header row.

LED D1 indicates if the Emulation Adapter is powered.

Refer to the microcontroller documentation for more details on VDD_HV_A, VDD_HV_B and VREFH

signals.

J28: VREFH limiting circuit

The Emulation adapter holds a limiting circuit to prevent VREFH exceeding VDD_HV_A. By default,

the limiting circuit is enabled by J28 in position 2-3 (default). In case the user would like to bypass

the limiting circuit, the J28 jumper should be set to 1-2.

J30: 1V5 power

1V5 can be generated on the Emulation Adapter or provided from the target board. By default, 1V5

is generated on the Emulation Adapter by J30 in the position 2-3 (default). In case the user would

like to provide it from the target board, the J30 jumper should be set to 1-2.

J31: VDD_HV_B power

In case the target device does not provide VDD_HV_B, voltage to the mentioned rail should be

provided via VDD_HV_A. This can be achieved by enabling J31. By default, J31 is disabled. In

standalone mode, J31 should be disabled.

J4 and J5:GND connection points

In case a good ground connection is required, connection points bridge J4 and pin J5 provide easy

access to the Emulation Adapter's GND potential.

Connectors

P1

The following pinout is valid on the target side for the ARM Mictor 38-pin connector:

Signal

Direction

Signal Description

Signal

Pin

Pin

Signal

Signal Description

Signal

Direction

Not Connected

NC

1

2

NC

Not Connected

Not Connected

NC

3

4

NC

Not Connected

Ground

GND

5

6

TRACECLK

Trace Clock

I

Not Connected

NC

7

8

NC

Not Connected

O

Reset

nRESET

9

10

NC

Not Connected

I/I

JTAG/SWD

TDO/SWO

11

12

VDD_HV_A

Reference Voltage

I

Not Connected

NC

13

14

NC

Not Connected

O/O

JTAG/SWD

TCK/SWDCLK

15

16

TRACEDATA[7]

Trace Data

I

O/IO

JTAG/SWD

TMS/SWDIO

17

18

TRACEDATA[6]

Trace Data

I

O

JTAG

TDI

19

20

TRACEDATA[5]

Trace Data

I

O

JTAG

nTRST

21

22

TRACEDATA[4]

Trace Data

I

I

Trace Data

TRACEDATA[15]

23

24

TRACEDATA[3]

Trace Data

I

I

Trace Data

TRACEDATA[14]

25

26

TRACEDATA[2]

Trace Data

I

I

Trace Data

TRACEDATA[13]

27

28

TRACEDATA[1]

Trace Data

I

I

Trace Data

TRACEDATA[12]

29

30

GND

Ground

I

I

Trace Data

TRACEDATA[11]

31

32

GND

Ground

I

I

Trace Data

TRACEDATA[10]

33

34

VDD_HV_A

Reference Voltage

I

I

Trace Data

TRACEDATA[9]

35

36

NC

Not Connected

I

Trace Data

TRACEDATA[8]

37

38

TRACEDATA[0]

Trace Data

I

ARM Mictor 38-pin connector pinout

Blue colored signals are trace signals.

Signal Direction is described from the BlueBox perspective.

Be aware that debug and trace signals from the Emulation adapter superset device are not

connected to the target board. They are exposed only to the connectors on the Emulation

adapter.

P7: ARM CoreSight 20 connector

The following pinout is valid on the target side for the ARM CoreSight 20-pin connector:

Signal

Direction

Signal Description

Signal

Pin

Pin

Signal

Signal Description

Signal

Direction

I

Reference Voltage

VDD_HV_A

1

2

TMS/SWDIO

JTAG/SWD

O/IO

Ground

GND

3

4

TCK/SWDCLK

JTAG/SWD

O/O

Ground

GND

5

6

TDO/SWO

JTAG/SWD

O

Not Connected

NC

7

8

TDI

JTAG

Ground

GND

9

10

nRESET

Reset

O

Ground

GND

11

12

TRACECLK

Reference Voltage

I

Ground

GND

13

14

TRACEDATA[0]

Not Connected

Ground

GND

15

16

TRACEDATA[1]

Trace Data

I

Ground

GND

17

18

TRACEDATA[2]

Trace Data

I

Ground

GND

19

20

TRACEDATA[3]

Trace Data

I

ARM CoreSight 20-pin connector pinout

Blue colored signals are trace signals.

Signal Direction is described from the BlueBox perspective.

Be aware that debug and trace signals from the Emulation adapter superset device are not

connected to the target board. They are exposed only to the connectors on the Emulation

adapter.

P3–P6: Emulation device pinout

Connectors P3, P4, P5 and P6 on the bottom side of the Emulation Adapter expose all emulation

device signals toward the Conversion board, through which the Emulation Adapter adapts to

different pin count packages.

Standalone operation

The Emulation Adapter is delivered with all the components required for a Standalone operation.

Power supply

Use the enclosed IEA-PS Emulation Adapter Power converter and adapter.

A Power supply package, which is delivered with the Emulation Adapter, is required when:

·

The Emulation Adapter is used as a standalone device .

·

The target board doesn’t provide an accurate supply voltage.

·

The target board doesn’t provide sufficient current for the Emulation Adapter operation.

The Power converter can supply either 3.3 V or 5 V. The array of jumpers J0–J9 selects 3.3 V or 5 V

voltage on the P3 connector, which connects to the Emulation Adapter.

Signal

Pin

Pin

Signal

NC

1

2

J0

NC

3

4

J1

NC

5

6

J2

NC

7

8

J3

NC

9

10

J4

NC

11

12

J5

NC

13

14

J6

NC

15

16

J7

NC

17

18

J8

NC

19

20

J9

GND

21

22

GND

GND

23

24

GND

GND

25

26

KEY

P3 connector and J0–J9 jumper correlation table

For example, when J2 is in the 3V3 position, it supplies 3.3 V to pin 6 of the P3 connector. When J2

is in the 5V position, it supplies 5 V to pin 6 of the P3 connector pin.

Be careful not to supply 5 V to the microcontroller power supply pin, which has declared a

maximum voltage 3.3 V! Refer to the microcontroller documentation for detailed information

on power supply.

P3 connector on the Power Supply board

External power supply requirements:

Min Voltage

Max Voltage

Min Power

8 V

12 V

5 W

Clock source

If the target’s crystal circuit microcontroller oscillator (if available) is not an adequate clock source,

insert the appropriate crystal into the Q1 socket, replace the default 22pF C1 and C2 capacitors

when necessary, and DIP switch DIP2 to position away from the white dot.

Mechanical information

Emulation Adapter

Side view of the Emulation adapter complete setup - QFP Fixed Adaptation

Top view of the Emulation

Adapter

Top view of the Conversion board

Ordering code

Unit (mm)

M

N

P

R

S

T

V

IEA.S32K344

70

70

32.6

36.4

47.5

IEA-S32K344-xxxxx

70

70

Solder parts

QFP

Solder part Solder pad view

Top view of the Solder part

In the case of soldering the Solder part manually, it’s highly recommended to prolong the solder pad

E on the outer side (e.g., for 1.5–2 mm) during the PCB design. Note that without this modification,

it’s very difficult to solder the Solder part manually.

Recommended PCB footprint dimensions:

Ordering code

Unit (mm)

A

B

C

D

E

K

L

IA48TQ-SOLDER

9

1.005

10

10

1.75

12

12

Assembly

QFP Fixed

Watch out that the pin 1 position and alignment of all pins. Avoid disassembling and

reassembling the hardware setup too frequently.

1. Solder the Solder part [B] on the target PCB [A] to get a BA setup.

Use the Surface Mount Technology (SMT) to solder the Solder parts to the target instead of

the original microcontroller. iSYSTEM provides this soldering service on request.

2. Assemble the in order: Emulation Adapter [E], optional Measurement board [D], the Conversion

board [C], together to get an E(D)C setup.

3. Assemble the E(D)C setup with the BA setup by connecting the Conversion board of the E(D)C

setup to the Solder part of the BA setup.

Slot screw

The Slot screw (30mm) is used to fix the Conversion board to the Solder part. The setup becomes

mechanically more robust.Screw the Conversion board to the Solder part first, before the Emulation

Adapter is attached on top and watch out not to break out the Solder part, e.g., if you accidentally

hit the Emulation Adapter from the side.

HDQFP Fixed

1. Solder the Solder part Bon the Target A.

2. (optional, recommended) Connect Extender Cto the Solder part B.

The Extender protects from damaging the Solder part if the Emulation Adapter setup is frequently assembled and disassembled. Be

careful and gentle during this procedure because all parts of the setup are extremely sensitive, and pins can easily bend or even break

in the worst-case scenario.

More Extenders can be stacked to gain height between the Emulation Adapter and the Target, if surrounding components so high that

they prevent connecting the Emulation Adapter. Keep the number of Extenders C at minimum since every Extender degrades the signal

integrity of the electrical signals.

3. Assemble in order: Emulation Adapter F, optional Measurement board E, Conversion board D.

4. Connect Conversion board Dto:

·

Solder part or

·

Extender

Accessories

Ordering Code

Description

IC5700

iC5700 BlueBox On-Chip Analyzer

IC5000

iC5000 BlueBox On-Chip Analyzer

IC57031

IOM6 Hub (3 x FNet & FBridge)

IC57040

IOM6 CAN/LIN

IC57041

IOM6 ADIO

Debug Adapters

Listed Debug Adapters provide tracing functionality for the Emulation Adapter.

Ordering Code

Description

IC50118-2

20-pin 1.27mm CoreSight Debug Adapter

IC50115

38-pin Mictor ARM Parallel 16-bit Debug Adapter

More information about our products on www.isystem.com or via sales@isystem.com.

www.isystem.com

Visit our website for:

·

Support - isystem.com/support

·

Tutorials - isystem.com/getting-started

·

Knowledge Base - kb.isystem.com

Table of contents

Other TASKING Adapter manuals

TASKING

TASKING iSYSTEM Cypress CYT2BL Instructions for use

TASKING

TASKING iSYSTEM Infineon TC397XE Instructions for use

TASKING

TASKING iSystem Cypress CYT2B9 Instructions for use

TASKING

TASKING iSYSTEM Infineon TC234LF Instructions for use

TASKING

TASKING iSYSTEM IC50130 User manual

TASKING

TASKING iSYSTEM NXP S32K148 Instructions for use

TASKING

TASKING iSYSTEM Infineon TC397XE User manual

TASKING

TASKING iSYSTEM Aurora MPC5 Series User manual

TASKING

TASKING iSYSTEM Infineon TC377TE User manual

TASKING

TASKING iSYSTEM Infineon TC377TE User manual