Tasselli PANDA H205 User manual

1

EN

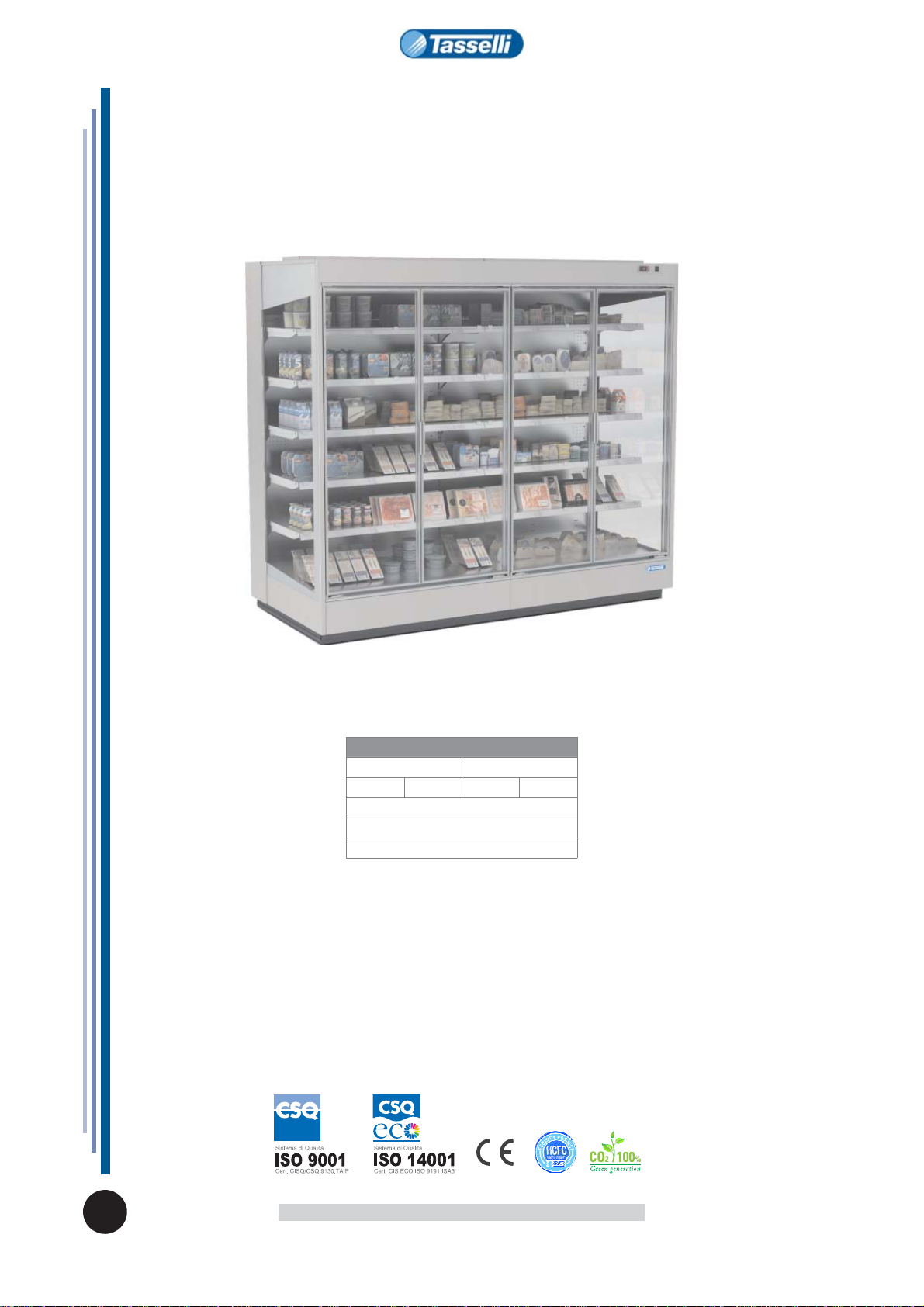

PANDA

USE AND MAINTENANCE MANUAL

428900224237

PANDA

MODELS

H205 H225

P100 P115 P100 P115

L125

L250

L375

ISA S.r.l. Division TASSELLI

Via del Lavoro, 5

06083 Bastia Umbra - Perugia - Italy

Tel. +39 075 80171 - Fax +39 075 8000900

www.isaitaly.com

2

PANDA

USE AND MAINTENANCE MANUAL

428900224237

EN

1. NOTES / IMPORTANT NOTES 4

1.1 INTRODUCTION 5

1.2 MANUFACTURER’S CONTACT DETAILS 5

2. SAFETY 6

2.1 STAFF TRAINING 6

2.2 SAFETY DEVICES APPLIED 6

2.2.1 SAFETY DEVICES PRESENT 6

2.2.2 FIXED GUARDS 6

2.2.3 ISOLATING THE ELECTRICTY SUPPLY 7

2.3 RESIDUAL RISKS 7

2.3.1 RISK OF CONTACT WITH LIVE PARTS 7

2.3.2 FIRE 7

2.3.3 EXPLOSIVE ATMOSPHERE 8

2.3.4 SLIPPING 8

2.3.5 TRIPPING 8

2.3.6 CIRCUIT FAULTS 8

2.3.7 FALLING OBJECTS 8

2.3.8 COOLING 8

2.3.9 FOODSTUFFS SAFETY 9

2.4 WARNING SIGNS (if any) 9

3. DISPOSAL OF WASTE MATERIAL 10

4. INSTALLATION 11

4.1 STORAGE AND UNPACKING 11

4.2 INSTALLATION, POSTIONING AND AMBIENT CONDITIONS 11

4.3 ELECTRICAL CONNECTION 11

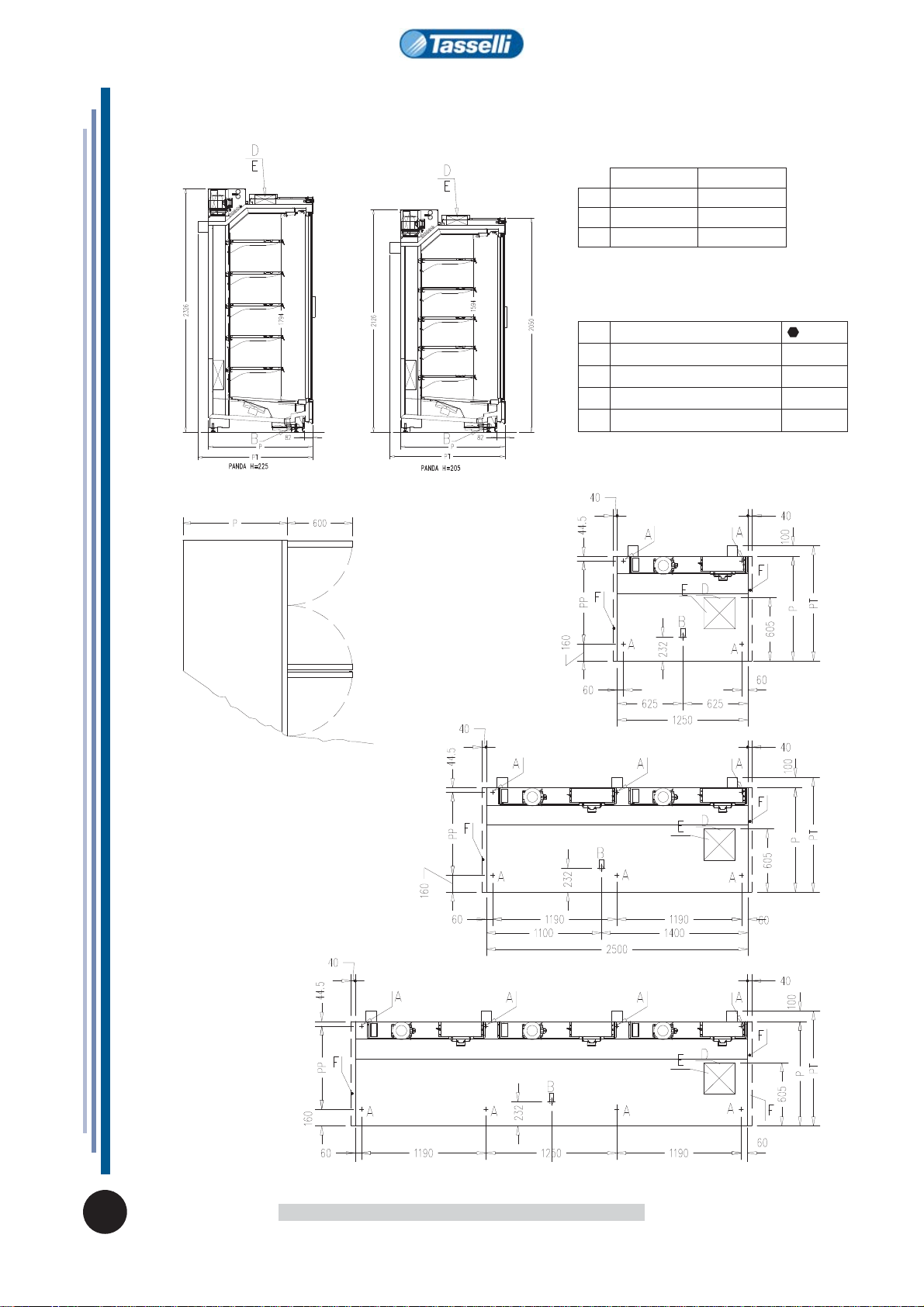

5. TECHNICAL SPECIFICATIONS 12

5.1 INSTALLATION AND LEVELLIG 14

5.2 TECHNICAL PLAN - AIR COOLED 15

5.2 TECHNICAL PLAN - WATER COOLED 16

5.3 LOAD LIMITS 17

5.4 SHELF LOAD LIMITS 17

5.5 CONNECTING THE WATER LINE (WATER COOLED) 18

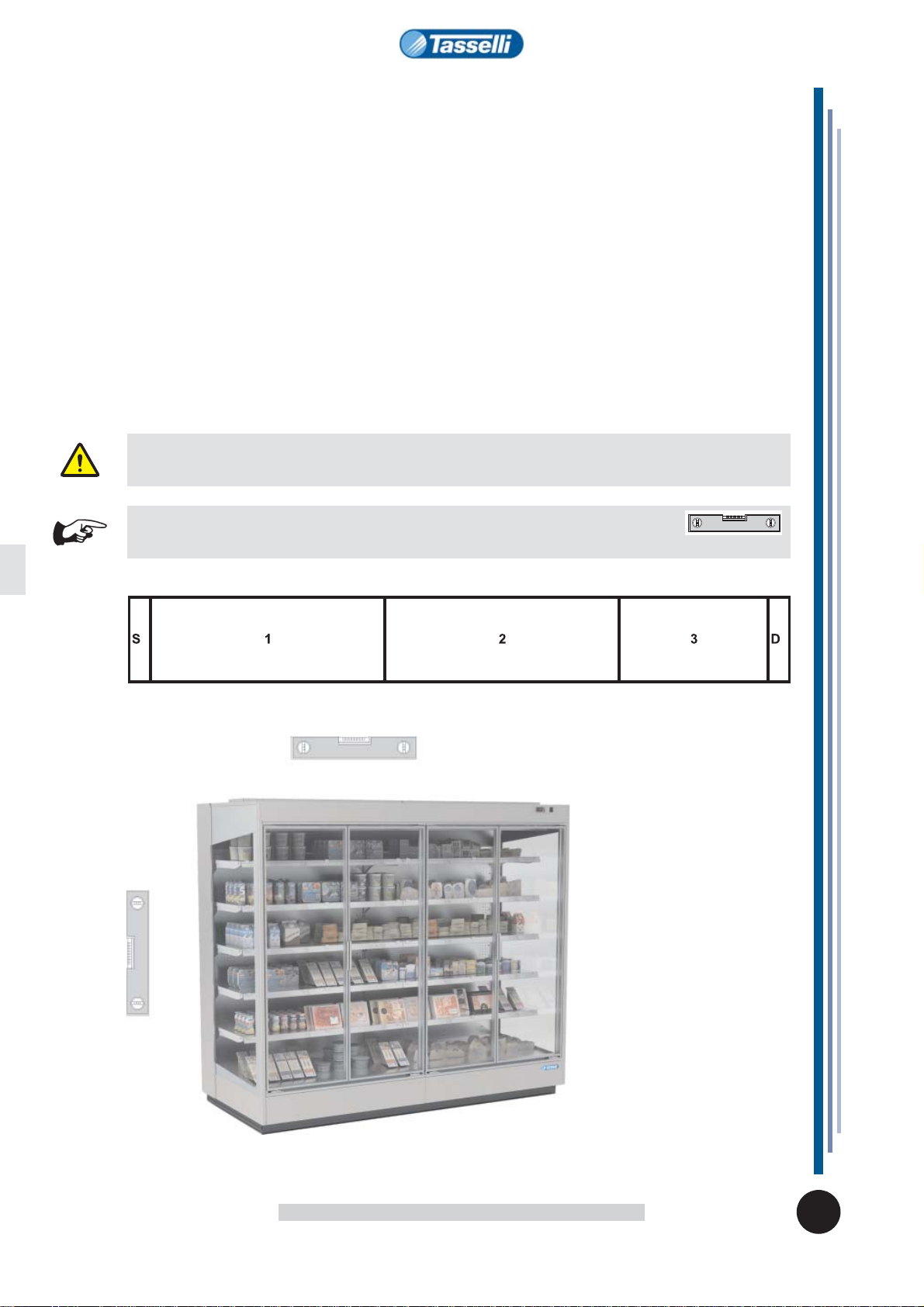

6. DESCRIPTION OF THE APPLIANCE 19

6.1 COMPOSITION 19

6.2 REFRIGERANT R744 19

6.3 IDENTIFICATION 20

7. CONTROL PANEL 21

6. CLEANING 22

8.1 INSIDE THE CABINET 22

8.2 EXTERNAL 22

8.3 CONDENSER (AIR) 22

9. MAINTENANCE 23

10. FAULTS - TECHNICAL AFTER SALES ASSISTANCE 24

11. WARRANTY TERMS AND CONDITIONS 25

3

EN

PANDA

USE AND MAINTENANCE MANUAL

428900224237

The manual contains symbols to attract the reader’s attention and highlight particularly

important aspects. The table below illustrates the meaning of the various symbols used.

Read the instructions manual

Danger: Live electrical parts

Use of protective clothing

Requests for maintenance or operations must

be carried out by qualified staff or technical

after-sales centres.

Attention / Danger

Information

Important information

Operations that must be performed by two

persons.

Visual observation

Condensing unit on board

Notes / Important notes

Remote condensing unit

Attachment 1 DECLARATION OF CONFORMITY 26

Attachment 2 DISCHARGE 27

Attachment 3 DUCTING 28

Attachment 4 BRACKETS 29

Attachment 5 SIDE ASSEMBLY 30

Attachment 6 UNPACKING AND HANDLING 31

Attachment 7 BRACKETS 32

Attachment 8 MIRROR 33

Attachment 9 BASE BOARDS 34

Attachment 10 CHANGE IN SHELVES 35

Attachment 11 HOOKS 36

Attachment 12 SPACER REAR 37

Attachment 13 WIRING DIAGRAM - 412100606200 38

Attachment 14 WIRING DIAGRAM - 412100607200 41

Attachment 15 WIRING DIAGRAM - 412100608100 44

Attachment 16 WIRING DIAGRAM - 412100609100 47

Attachment 17 WIRING DIAGRAM - 412100615100 50

Attachment 18 WIRING DIAGRAM - 412100616000 53

Attachment 19 CONTROL PANEL - IR33 56

Attachment 20 CONTROL PANEL - AK CC 250 58

Attachment 21 CONTROL PANEL - EW 978 59

Attachment 22 CONTROL PANEL - XR 44 CX 62

Attachment 23 CONTROL PANEL - CRD XP 64

4

PANDA

USE AND MAINTENANCE MANUAL

428900224237

EN

1. NOTES / IMPORTANT NOTES

The content of this manual is of technical nature and is owned by ISA S.r.l. divisionTASSELLI

It is forbidden to reproduce, circulate or modify all or part of its content without written

consent. Any infringement will be legally pursued.

The manual and the conformity certificate are an integral part of the equipment and should

always accompany the product in the event of a transfer to a new location or to a new

owner. The user is responsible for the integrity of these documents, for their consultation

and during the whole life cycle of the equipment itself. Keep this manual in a safe place. It

should be available for consultation near the equipment at all times. If lost or destroyed,

you can request a copy of the manual from ISA S.r.l. division TASSELLI by specifying the

exact model, serial number and year of manufacture. The manual reflects the manufacturing

technology at the time of supply. The manufacturer reserves the right to modify its products

in any way it deems necessary, with no obligation to update manuals and machines relating

to previous manufacturing batches.

This appliance is not to be intended as directly usable by a final general user: it is intended

to be installed and incorporated in one or more plants by an installer, who will use suitable

specialised staff for the purpose Before commissioning, it is necessary that the installer

supplies the relative certificate of conformity to the applicable national and international

legislation. The appliance can be used only at this point.

In all cases, this appliance is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities or by persons lacking the necessary experience and

knowledge, unless they are supervised by a person responsible for their safety who has

instructed them on how to use the equipment. Children should be supervised to ensure that

they do not play with the equipment. Always refer to this manual before going ahead with

any operation. Before doing any type of work, disconnect the equipment from the power

supply. Any work on electric and electronic parts or cooling system components should only

be carried out by trained personnel in compliance with current laws.

The Manufacturer cannot be held liable for any injury to persons or animals, or damage to the

product itself in the event of:

• improper use of the equipment or use of the appliance by unqualified or unauthorised

personnel;

• failure to comply with current legislation

• incorrect installation and/or power supply faults

• failure to observe the instructions contained in this Manual

• failure to follow the maintenance programme

• unauthorised modifications

• installation of non-original spare parts in the equipment

• installation and use of the equipment for purposes other than those for which the appliance

was designed and sold

• Tampering with or damage to the power supply cable.

Liability for applying the safety instructions contained in this manual is held by the technical

personnel responsible for the intended use of the equipment, who should ensure that

authorised personnel:

• are qualified to carry out the requested activity;

• Are aware of, and carefully comply with, the instructions contained in this document;

• are aware of, and apply, the general safety standards applicable to the equipment.

Failure to comply with safety standards may result in injury to personnel and damage to the

equipment components and control unit. The user can contact the dealer to request additional

information not contained in this document, or suggest improvements, at any time.

Before the product is delivered to the customer, it is essential that a trained technical

member of staff checks that the appliance is operating correctly in order to achieve

maximum performance.

5

EN

PANDA

USE AND MAINTENANCE MANUAL

428900224237

1.1 Introduction

ISA S.r.l. division TASSELLI employs materials of the best quality and as they enter the

company, we constantly monitor their storage and the use as part of the manufacturing

process to prevent damage, deterioration and failure. All manufacturing elements are

designed and manufactured in order to guarantee reliability and high safety standards.

All appliances are subjected to a strict testing procedure before delivery. However, please

bear in mind that product performance over time depends on correct use and adequate

maintenance. This manual contains the necessary instructions to maintain the appliance's

initial appearance and functions over time.

Note

In order not to compromise functionality and safety of the appliance, the particularly complex installation

and maintenance activities are not documented in this manual and are performed by specialised ISA

s.r.l. division technicians.

The Use and Maintenance manual contains the necessary information for understanding

how the appliance works and how to use it properly, namely: the technical description

of the various operational units, equipment and safety systems, operations, how to use

the instruments and the interpretation of any diagnostics reports, main procedures and

information relating to routine maintenance. For correct use of the appliance, the working

environment should comply with current health and safety standards.

The safety requirements, indications, standards and notes illustrated in the various chapters

of the manual are aimed at establishing a code of conduct and a series of obligations to

be observed when performing the various activities, in order to create safe conditions for

personnel, the equipment and the surrounding environment. The safety standards reported

in this document are intended for trained, authorised personnel responsible for:

- transport

- installation

- operations

- management

- maintenance

- cleaning, putting out of service and disposal that constitute the only methods of use

envisioned for the appliance in question

Attention

Reading this manual, albeit in full, is no substitute for adequate user experience. therefore it should

only be considered a useful reminder of the technical features and the main operations to perform.

Warning

The installers and users must read and understand the instructions contained herein before any

operation on the appliance.

1.2 Manufacturer's contact details

ISA S.r.l. division TASSELLI

Via del Lavoro, 5

06083 - Bastia Umbra - Perugia - Italy

Tel. +39 075 80171

Fax +39 075 8000900

www.isaitaly.com

6

PANDA

USE AND MAINTENANCE MANUAL

428900224237

EN

2. SAFETY

The buyer is responsible for training personnel using the appliance on the risks, safety devices

and general health and safety rules required by the laws of the country where the appliance

is installed.

Users/operators should be aware of the position of all the controls and how they work, as well

as of the features of the appliance.

They should also read this manual in its entirely.

Maintenance work should be conducted by qualified personnel after the appliance has been

prepared adequately.

Danger

Unauthorised tampering or replacement of one or more parts of the appliance, use of accessories

that modify the use of the same and use of spare parts different to those recommended, can become

the cause of injury.

Danger

Before doing any type of work, disconnect the appliance from the power supply.

Any work on electric parts or cooling system components should only be carried out by

trained personnel in compliance with current laws.

2.1 Staff training.

The buyer is responsible for ensuring personnel who will use the appliance and maintenance

technical staff are instructed and trained adequately.

The manufacturer is available for advice, clarifications, etc. so that the operator and technical

staff can use the appliance correctly.

Attention

The appliance is intended for professional use.

2.2 Safety devices applied

The appliance is equipped with the following safety devices:

2.2.1 Safety devices present

Devices whose operation prevents the occurrence of risk situations in operating conditions

(e.g. fuses, pressure switches, protections, magnet circuit breakers, etc.).

2.2.2 Fixed guards

Fixed protective devices consist of fixed perimeter shields, which are used to prevent external

parts from entering the equipment.

Danger

It is prohibited to re-start the appliance following maintenance without having correctly restores the

panels.

Attention

You should check the integrity of fixed panels and corresponding fixings to the frame, focussing in

particular on the protective panels.

7

EN

PANDA

USE AND MAINTENANCE MANUAL

428900224237

2.2.3 Isolating the electricity supply

Before conducting any maintenance work on the equipment or part of it, it is necessary to

section the power supply that powers it.

Danger

Therefore remember, in the event of maintenance operations in which the operator cannot prevent

accidental closure of the circuit by others, to totally disconnect the appliance from the mains electricity.

2.3 Residual risks

During design the manufacturer examined all the areas or parts at risk. Therefore, all

necessary precautions have been taken to prevent risks to persons

and damage to the appliance as mentioned earlier.

Attention

Periodically check that all safety devices are operating correctly.

Do not remove the fixed guards.

Do not introduce objects or tools into the work area.

Although the appliance is fitted with the aforementioned safety devices, there are still some

risks that cannot be eliminated, but reduced via corrective actions by the end user and

correct operational procedures.

Below is a summary of the remaining risks associated with the appliance during:

- Normal operation

- Adjustments and tweaking

- Maintenance

- Cleaning

2.3.1 Risk of contact with live parts

Risk of breaking or damaging the electrical components of the appliance, with a possible

reduction in safety levels, following a short circuit or other events.

Before connecting the electricity supply, make sure there is no ongoing maintenance work.

Attention

Before making the connection, check that the d.c. current in the installation point does not exceed that

indicated on the protections switches present in the electric control board. If this is not the case, the

user must envision the relevant limiting devices.

It is strictly forbidden to conduct any electrical modification, in order to prevent additional unforeseen

hazards and risks.

2.3.2 Fire

Danger

In the event of a fire, immediately disconnect the master switch from the main power supply line and

move as far away as possible from the appliance.

8

PANDA

USE AND MAINTENANCE MANUAL

428900224237

EN

2.3.3 Explosive atmosphere

The equipment must not be located in an area classified as an explosion risk according to

1999/92/EC such as:

Zone 0

An area in which there is a permanent, long-lasting or frequently explosive atmosphere made

up of a mixture of air and flammable substances in the form of gases, fumes or steam.

Zone 1

An area in which the formation of an explosive atmosphere, made up of a mixture of air and

flammable substances in the form of gases, fumes or steam is occasionally probable during

normal activities.

Zone 20

An area in which there is a permanent, long-lasting or frequently explosive atmosphere in the

form of clouds of combustible dust in the air.

Zone 21

An area in which the formation of an explosive atmosphere in the form of clouds of combustible

dust is occasionally probable during normal activities.

2.3.4 Slipping

Any leaks in the areas surrounding the appliance may cause personnel to slip.

Check that there are no leaks and keep these areas clean at all times.

2.3.5 Tripping

Generally untidy deposits of material may constitute a tripping hazard and a total or partial

obstruction of emergency exit routes.

Ensure that operating and transit areas and emergency exit routes are free from obstacles in

compliance with current legislation.

2.3.6 Circuit faults

Owing to potential faults, safety circuits may become less effective, which results in lower

safety levels.

You should check the operational condition of the appliance devices regularly.

2.3.7 Falling objects

Positioning of the cabinet display parts (i.e. counters, rods and hooks), as also product

arrangement inside the cabinet can be the source of potential hazards if not properly

performed.

Follow the positioning instructions described in this Manual before you place products inside

the cabinet, check that the counters are properly fastened, as also the hooks, etc. Do not

exceed the maximum load limit. Do not tilt the shelves.

Do not place any goods and in general, do not load the tank sliding element closing devices

with any load, while open or closed.

2.3.8 Cooling

During different operations to perform on the counter, such as cleaning or loading goods, it is

necessary to handle products and/or counter parts at a low temperature with the risk of "cold

injury" for the operators and/or accidental slipping hazard.

Follow the safety regulations in the place where the cabinet is installed; more specifically, be

sure to always use the right PPE (especially gloves).

9

EN

PANDA

USE AND MAINTENANCE MANUAL

428900224237

2.3.9 Foodstuffs safety

The refrigerator cabinet described herein is meant to be used to display packaged products.

As such, it is not designed for direct contact between the foodstuffs and display surfaces. If

the foodstuffs do accidentally make contact with the surfaces and for a rather long time, the

product may be contaminated.

Follow the guidelines on how to use the cabinet. If a product package breaks, remove it from

the cabinet and clean, if necessary.

2.4 Warning signs (if any)

Depending on the residual risks of various nature, identify the equipment with warning

danger, warning and obligation signs defined in agreement with the Standard relative to the

graphical signs to be used on plants.

The signs are located in clearly visible positions.

Attention

The warning plates present on the appliance must not be removed.

The user is responsible for replacing warning signs that, owing to wear, become unreadable.

10

PANDA

USE AND MAINTENANCE MANUAL

428900224237

EN

3. DISPOSAL OF WASTE MATERIAL

During normal operation, the appliance does not generate any environmental contamination.

At the end of its life cycle, or if it is necessary to proceed to permanent decommissioning, we

recommend following the procedures below:

DISPOSAL (User)

The symbol, applied to either the product or its packaging, indicates that the product should

not be considered as normal domestic waste, but should be taken to a waste collection point

for the recycling of electrical and electronic appliances. The correct disposal of this product

helps to prevent potential negative consequences that might derive from inadequate product

disposal. For detailed information about recycling this product, contact your council, your

local waste collection service or the store where you purchased the product.

PROCEDURE FOR DISPOSAL and RECYCLING AT THE END OF APPLIANCE LIFE SPAN

(Authorised Bodies)

Foreword

During the period of use, the appliance subject of this manual, is an integral part of a

cooling plant, an electric plant and a hydraulic plant (drain lines). At the end of the life cycle,

the appliance must first be completely disconnected from all plants mentioned above, in

compliance with methods and procedures that are the responsibility of the operator of the

plants and whose description lies outside this manual.

Once disconnected, perform the following procedures:

1. Check that the appliance is disconnected from the electric plant (cables disconnected)

and from the cooling plant (piping cut and opened on the input and output sides).

2. Remove the lamps (if installed). These should be disposed of separately.

3. Remove the power units and the electronic cards. These should be disposed of separately.

4. Remove all the independent parts (grids, casings, profiles, etc.) and group them according

to shared features in order to access the heat exchangers, pipes, cables, etc. and be careful

not to damage the cooling circuit.

5. Remove all mobile parts (doors, sliding doors, glass parts, etc.) and group the various

materials according to their features.

6. Disconnect the evaporator, condenser, compressor, pipes and fans. These are made of

copper, aluminium, steel and plastic and should therefore disposed of separately.

7. On removal of all guards and the various components from the frame, separate the different

types of material making up the appliance (plastic, sheet steel, polyurethane, copper, etc)

and collect them separately.

All recyclable materials and waste should be processed and recycled by professionals, in

compliance with the laws in the country in question.

The company responsible for recycling the materials should be registered and certified as a

waste disposal service in accordance with the country in question

Attention

Illegal disposal of the product by the owner will result in administrative sanctions as required by cur-

rent laws.

Disposal of the product should comply with current laws on the disposal of coolant liquids and mineral

oils.

Important

If the crossed wheelie bin sign is not present on the appliance, it means that the disposal of the

product is not the manufacturer's responsibility. In this case, the Regulations regarding the disposal

of waste in force are valid.

Additional information

Further information on the disposal of liquid coolant, oils and other substances is available on the safety

data sheet corresponding to the substance itself.

In order to dispose of foamed assemblies, remember that the polyurethane foams used are CFC, HFC

and HCFC free.

11

EN

PANDA

USE AND MAINTENANCE MANUAL

428900224237

4. INSTALLATION

This manual supplies the information necessary for correct unpacking, procedures for

positioning and connection to mains electricity.

4.1 Storage and unpacking

The appliance, with or without the packaging, should be carefully stored inside warehouses

or in areas away from the elements and direct sunlight, at a temperature between 00and

+40 °C.

The appliance should only be moved by qualified personnel operating forklift trucks, the

power of which should be suited to handling the weight of the product: during this operation

the appliance MUST placed on the special pallet supplied.

For the specifications to follow regarding the lifting truck and for the unpacking operations,

refer to the instructions attached.

All packaging materials are recyclable and should be disposed of in accordance with local

regulations. Please destroy "plastic" bags to prevent them from becoming hazardous to

children (suffocation).

4.2 Installation, positioning and ambient conditions

Attention

Position the appliance away from heat sources (radiators, stoves of all types, etc.) and away from the

effects of continuous currents of air (e.g. caused by fans, air conditioning vents, etc.).

Also avoid exposure to direct sunlight; all of this causes the temperature inside the refrigerated

compartment to rise with negative consequences on operation and energy consumption. Do not use

the appliance outdoors and do not leave it exposed to rain.

4.3 Electrical connection

Attention

Remember that the electric connection of this appliance and its connection as a utility in an entire

electric plant must be performed by a qualified installer, who must produce suitable certification

of compliance. Check that the voltage indicated on the appliance is the same as the value on the

appliance identification label and in the table provided in paragraph 1 of this manual, and check that

the required voltage is suitable.

The plant power supply socket must be fitted with a disconnection device from the mains electricity

(dimensioned to the load and in compliance with Standards in force), which guarantees complete

disconnection in category III (3) over-voltage conditions and therefore protects the circuits against

earth faults, overloads and short circuits.

Do not route the electricity cable in passageways.

Attention

Earthing is necessary and mandatory by law.

Attention

This cabinet is fitted with antisweat heaters, mainly placed in the doorframe, which have been

designed and sized to work under continuous power supply. The use of “on/off economizer” devices

in the upstream lines of the heaters may bring to malfunztions and/or early damages: we therefore

strongly advise not to use them.

12

PANDA

USE AND MAINTENANCE MANUAL

428900224237

EN

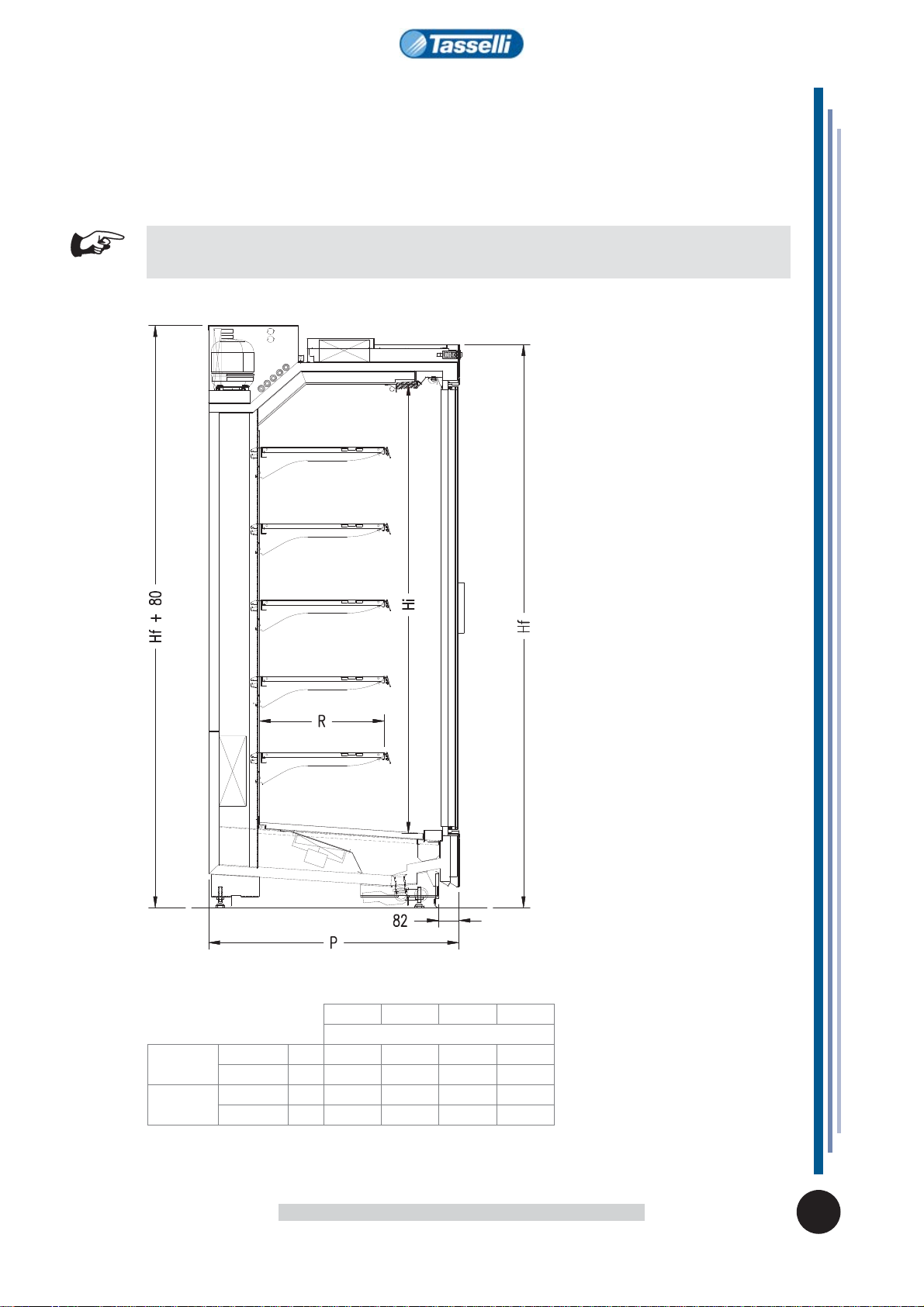

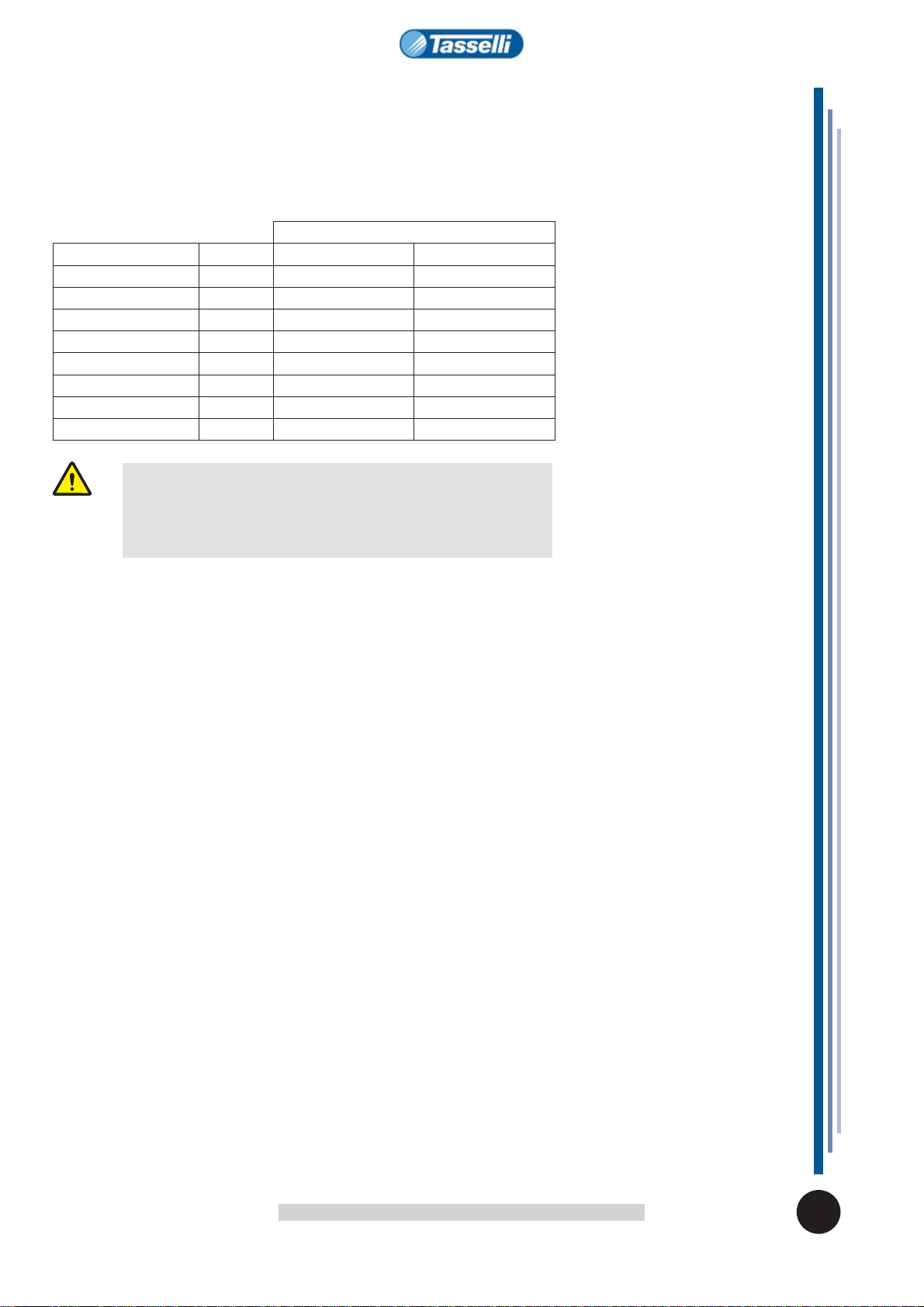

PHfHiRmax

mm

P100 H205 mm 1000 2050 1590 500

H225 mm 1000 2250 1790 500

P115 H205 mm 1145 2050 1590 600

H225 mm 1145 2250 1790 600

5. TECHNICAL SPECIFICATIONS

This appliance is exclusively intended to display and sell cheeses, milk products and/or

fresh pre-packed products.

The manufacturer is not liable for injury to persons or damage to property or the appliance

itself caused by the displaying of products other than those described above.

Uses not allowed:

- Food preservation.

- Displaying and/or preserving non-food products (chemicals, pharmaceuticals, etc...).

13

EN

PANDA

USE AND MAINTENANCE MANUAL

428900224237

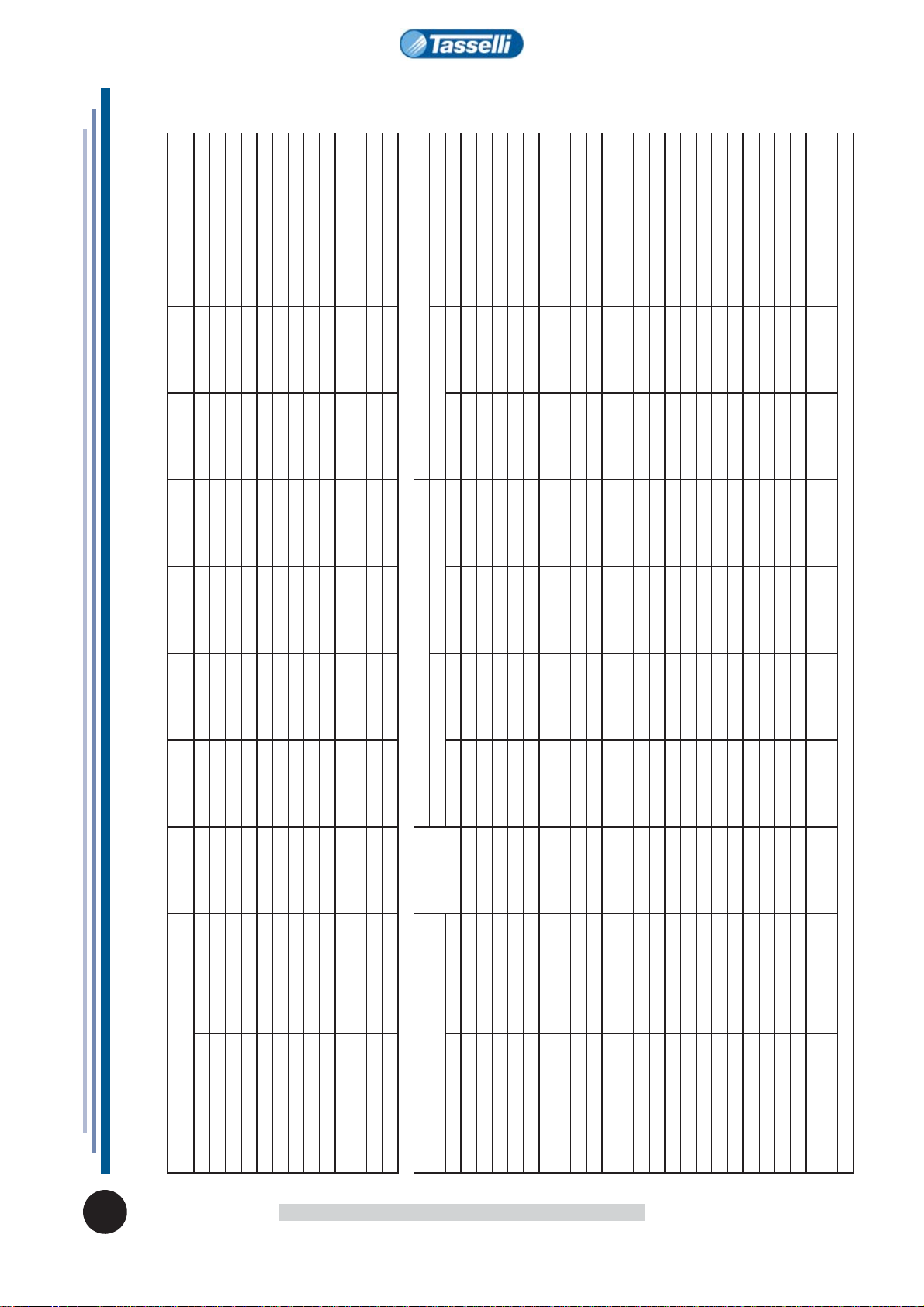

5. TECHNICAL SPECIFICATINS

TECHNICAL SPECIFICATIONS Dimensions

(PxH) Length

(without ends) Thickness

back TDA (Total

Display Area) Net weight

(without ends) Climatic Class Environmental

conditions Performance Defrost

equipment shelves mm mm mm m2 Kg - °C / % -

PANDA 100/205 125 5x500 1000 x 2050 1250 40 1,65 348 3 25° / 60 M1/M2/H off-cycle

PANDA 100/205 250 5x500 1000 x 2050 2500 40 3,31 597 3 25° / 60 M1/M2/H off-cycle

PANDA 100/205 375 5x500 1000 x 2050 3750 40 4,96 861 3 25° / 60 M1/M2/H off-cycle

PANDA 100/225 125 6x500 1000 x 2250 1250 40 1,84 373 3 25° / 60 M1/M2/H off-cycle

PANDA 100/225 250 6x500 1000 x 2250 2500 40 3,69 640 3 25° / 60 M1/M2/H off-cycle

PANDA 100/225 375 6x500 1000 x 2250 3750 40 5,53 919 3 25° / 60 M1/M2/H off-cycle

PANDA 115/205 125 5x600 1145 x 2050 1250 40 1,71 361 3 25° / 60 M1/M2/H off-cycle

PANDA 115/205 250 5x600 1145 x 2050 2500 40 3,42 622 3 25° / 60 M1/M2/H off-cycle

PANDA 115/205 375 5x600 1145 x 2050 3750 40 5,13 899 3 25° / 60 M1/M2/H off-cycle

PANDA 115/225 125 6x600 1145 x 2250 1250 40 1,90 386 3 25° / 60 M1/M2/H off-cycle

PANDA 115/225 250 6x600 1145 x 2250 2500 40 3,80 665 3 25° / 60 M1/M2/H off-cycle

PANDA 115/225 375 6x600 1145 x 2250 3750 40 5,70 957 3 25° / 60 M1/M2/H off-cycle

TECHNICAL SPECIFICATIONS Power supply

[V / ph / Hz]

electrical power standard [W] electrical power defrosting [W]

(LED light) light LED Philips light LED standard light LED Philips light LED standard

banco colour/number light (#) version ARIA version H2O version ARIA version H2O version ARIA version H2O version ARIA version H2O

PANDA 100 - 115 125 R 1L 230~ / 1N / 50 700 450 691 441 50 50 41 41

PANDA 100 - 115 125 R 1L 5R 230~ / 1N / 50 750 500 736 486 100 100 86 86

PANDA 100 - 115 125 R 1L 6R - 1L 5R 1S 230~ / 1N / 50 760 510 745 495 110 110 95 95

PANDA 100 - 115 125 R 1L 6R 1S 230~ / 1N / 50 770 520 754 504 120 120 104 104

PANDA 100 - 115 125 W 1L 230~ / 1N / 50 711 461 691 441 61 61 41 41

PANDA 100 - 115 125 W 1L 5R 230~ / 1N / 50 791 541 716 466 141 141 66 66

PANDA 100 - 115 125 W 1L 6R - 1L 5R 1S 230~ / 1N / 50 807 557 721 471 157 157 71 71

PANDA 100 - 115 125 W 1L 6R 1S 230~ / 1N / 50 823 573 726 476 173 173 76 76

PANDA 100 - 115 250 R 1L 230~ / 1N / 50 1386 886 1368 868 86 86 68 68

PANDA 100 - 115 250 R 1L 5R 230~ / 1N / 50 1486 986 1458 958 186 186 158 158

PANDA 100 - 115 250 R 1L 6R - 1L 5R 1S 230~ / 1N / 50 1506 1006 1476 976 206 206 176 176

PANDA 100 - 115 250 R 1L 6R 1S 230~ / 1N / 50 1526 1026 1494 994 226 226 194 194

PANDA 100 - 115 250 W 1L 230~ / 1N / 50 1408 908 1368 868 108 108 68 68

PANDA 100 - 115 250 W 1L 5R 230~ / 1N / 50 1568 1068 1418 918 268 268 118 118

PANDA 100 - 115 250 W 1L 6R - 1L 5R 1S 230~ / 1N / 50 1600 1100 1428 928 300 300 128 128

PANDA 100 - 115 250 W 1L 6R 1S 230~ / 1N / 50 1632 1132 1438 938 332 332 138 138

PANDA 100 - 115 375 R 1L 230~ / 1N / 50 2086 1336 2059 1309 136 136 109 109

PANDA 100 - 115 375 R 1L 5R 230~ / 1N / 50 2236 1486 2194 1444 286 286 244 244

PANDA 100 - 115 375 R 1L 6R - 1L 5R 1S 230~ / 1N / 50 2266 1516 2221 1471 316 316 271 271

PANDA 100 - 115 375 R 1L 6R 1S 230~ / 1N / 50 2296 1546 2248 1498 346 346 298 298

PANDA 100 - 115 375 W 1L 230~ / 1N / 50 2119 1369 2059 1309 169 169 109 109

PANDA 100 - 115 375 W 1L 5R 230~ / 1N / 50 2359 1609 2134 1384 409 409 184 184

PANDA 100 - 115 375 W 1L 6R - 1L 5R 1S 230~ / 1N / 50 2407 1657 2149 1399 457 457 199 199

PANDA 100 - 115 375 W 1L 6R 1S 230~ / 1N / 50 2455 1705 2164 1414 505 505 214 214

(#): L = luce fronte - canopy light, S = luce soffitto - ceiling light , R = luce ripiano - shelf light; R = rosata - meat colour; W = bianca - white

14

PANDA

USE AND MAINTENANCE MANUAL

428900224237

EN

5.1 Installation and Levelling

The installation of the apparatus involves the formation of channels as that described in

figure, typically consisting of one or more counters and from the shoulders of the ends.

If the channel were to be installed against walls, the minimum distances of:

• 100 mm / 300 mm posterior versions respectively for water / air; to meet this distance for

versions air is advisable to mount the rear spacer as shown in the annex to this manual.

• 500 mm between the back and side walls.

Once unpacked and placed in the ground equipment, approach and level them taking them at

the same height.

Channeling then adjoining equipment (1-2 and 2-3) by following the instructions laid down in

annex.

If they were not already pre-assembled, mount the shoulders S and D according to the

instructions attached.

Once installation is complete, ensure stability and leveling using the adjustable feet (all of

which must touch the ground).

Warning:

It is absolutely necessary after placement level l’ equipment to the floor.

Warning:

E’ assolutamente necessario dopo il posizionamento livellare l’ apparecchiatura a pavimento.

15

EN

PANDA

USE AND MAINTENANCE MANUAL

428900224237

5.2 Technical plan - AIR cooled

P100 P115

P1000 mm 1145 mm

PT 1100 mm 1245 mm

PP 795.5 mm 940.5 mm

ACabinet feet 32 mm

BDrain pipe Ø 40 mm

DTerminal box

EControl board

FStandard endwall (optional)

16

PANDA

USE AND MAINTENANCE MANUAL

428900224237

EN

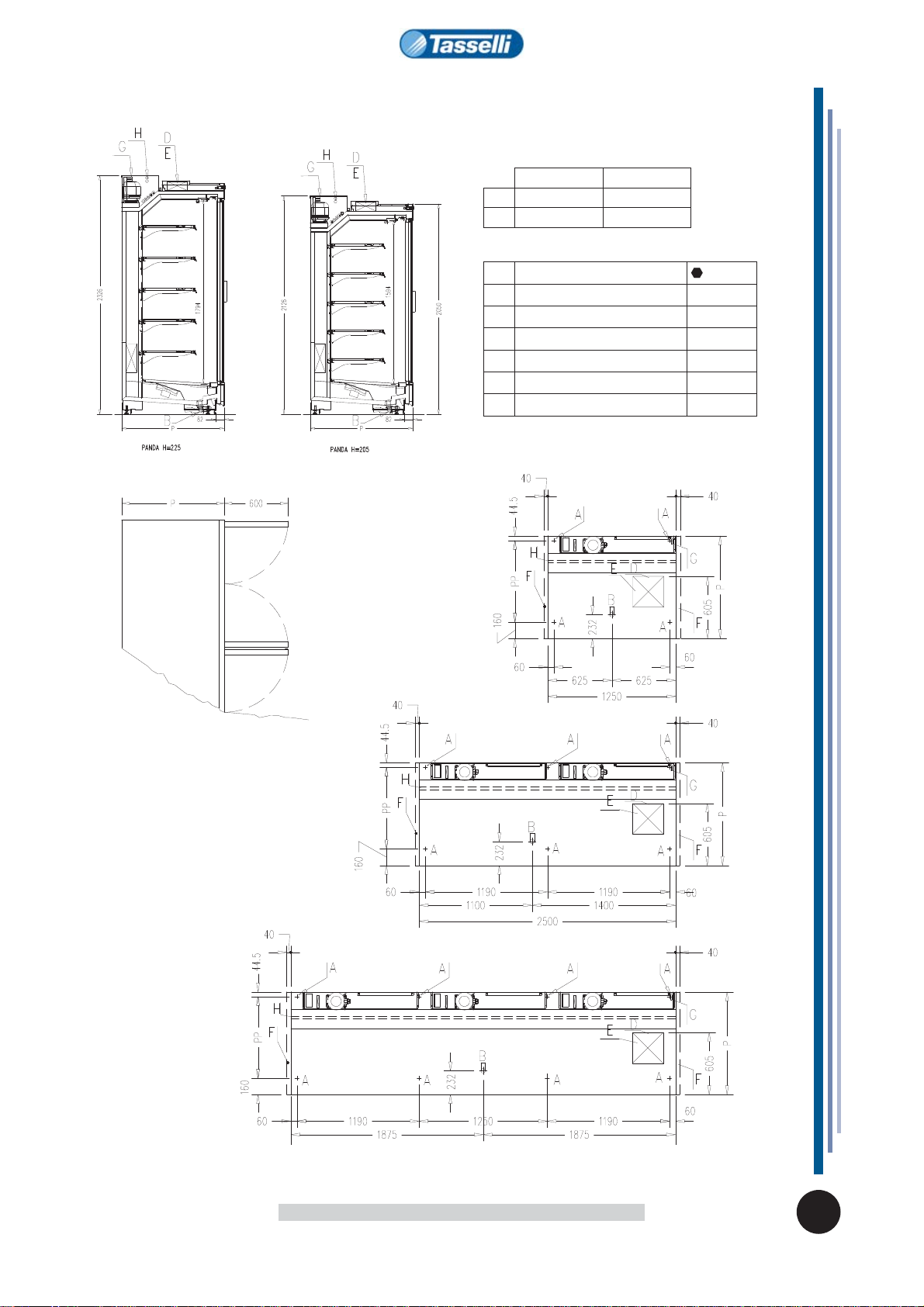

5.2 Technical plan - WATER cooled

P100 P115

P1000 mm 1145 mm

PP 795.5 mm 940.5 mm

ACabinet feet 32 mm

BDrain pipe Ø 40 mm

DTerminal box

EControl board

FStandard endwall (optional)

GH20 IN / H20 OUT 1/2” F

HPiping H20

17

EN

PANDA

USE AND MAINTENANCE MANUAL

428900224237

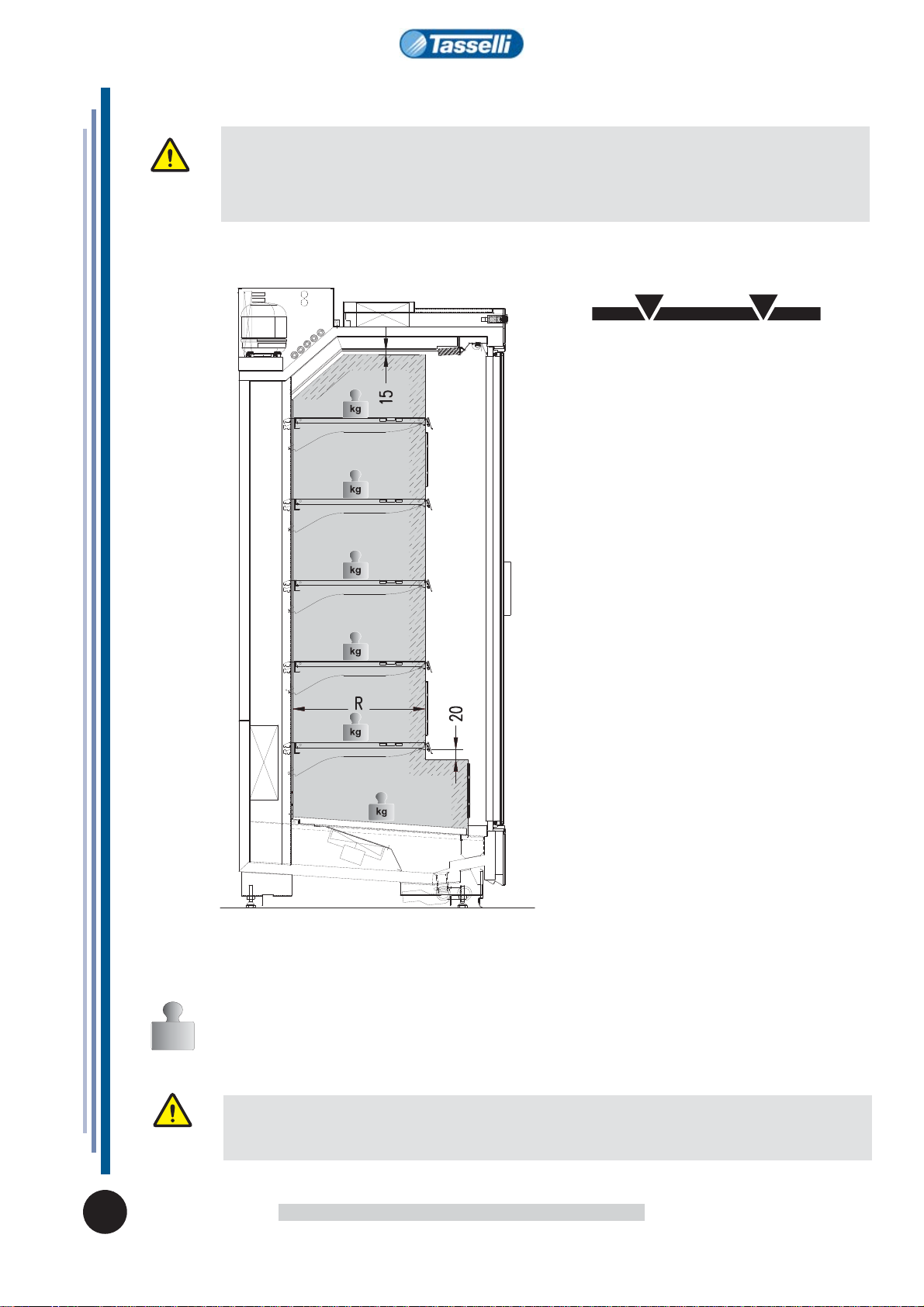

5.3 Load limits

Attention

It is fundamental not to exceed the load limits indicated in order not to alter the correct air circulation

and thus prevent a high product temperature.

The limits indicated refer to a static and evenly distributed load. Therefore dynamic overloads due to

violent loading operations are excluded, which must be prevented foe safety reasons.

5.4 Shelf load limits (max)

Shelves: 165 Kg/m2

Bottom plates: 165 Kg/m2

The maximum number of shelves is that represented in the silhouette shown in the manual

Attention

It is absolutely necessary to respect the weight limits indicated for each shelf in order to prevent the

deformation or breakage of the shelves themselves.

kg

18

PANDA

USE AND MAINTENANCE MANUAL

428900224237

EN

Panda water cooled condensation

version - chilled water air-cooled water

Tin (min/max) [°C] 5 / 15 25 / 35

Toutdoor (min/max) [°C] n/a 20 / 30

Tin (nominal) [°C] 13 33

Tout (nominal) [°C] 20 40

Flow rate L=125 [m3/h] 0,1 0,1

Flow rate L=250 [m3/h] 0,2 0,2

Flow rate L=375 [m3/h] 0,3 0,3

Pressure drop bar 0,5 0,5

5.5 Connecting the water line (water cooled)

If provided in the condensation water, the device provides for the connection to an external line with

water at Pmax <4 bar.

The following table shows the data required for the sizing of the line and the external cooling system.

Attention

The unit on board equipment is not equipped with a control

system of the water freezing.

In the case of water-cooled chiller is equipped to ensure that the

controls anti-freeze.

19

EN

PANDA

USE AND MAINTENANCE MANUAL

428900224237

The appliance is made up from:

• an external support structure.

• insulation in ecological polyurethane.

• an internal support structure.

• internal display sheets.

• an electric plant that refers to a connection terminal board to the electric plant.

• a control board.

• a condensing unit to R744 (CO2) which, in the case of versions to water, is connected to a circulation

system and cooling water.

• a system for collecting condensation water that ends on a drain connection to the hydraulic.

BEQUIPMENT

QCONTROL BOARD

UC CONDENSING UNIT

1ELECTRICAL CONNECTION

2NETWORK CONNECTION (optional)

3DRAIN CONNECTION

4CONNECTION

CONDENSATION WATER

(solo versioni H2O)

6.2 Refrigerant R744 (CO2)

The refrigerant R744 (CO2) is a gas that is compatible with the environment.

Pay close attention during transport, installation and that the destruction not to damage the refrigerant pipelines.

IN THE EVENT OF DAMAGE:

Keep away from the flame or ignition sources. Properly ventilate the premises for a few minutes. Turn the unit off,

pull the plug. Inform customer support service.

WARNING

The refrigerant system is High Pressure.

Do not tamper with the system, but call a

specialised and qualified technician before disassembly.

Maintenance must be performed exclusively by

qualified staff.

6. DESCRIPTION OF THE APPLIANCE

To ensure the operator's safety, appliance devices should be kept in constant working order. Regarding

this, the manual has the purpose of illustrating use and maintenance of the appliance and the operator

has the responsibility and the duty to respect it scrupulously.

6.1 Composition

Once the appliance is installed, it is an integral part of the electric plant, a cooling plant and a hydraulic

plant and can be schematized according to the following layout.

20

PANDA

USE AND MAINTENANCE MANUAL

428900224237

EN

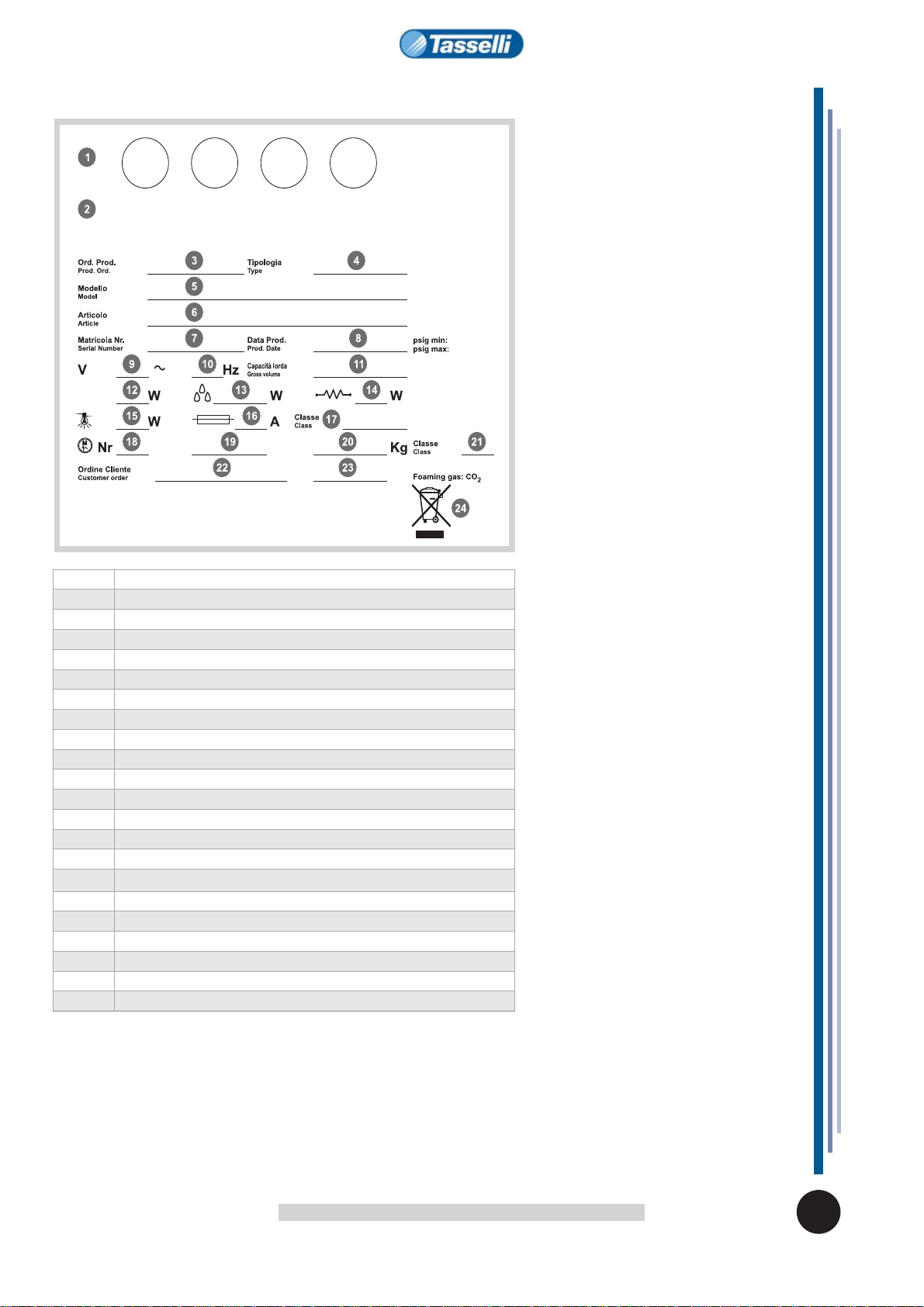

1 Symbols of Compliance

2 Identification of the Company Product Manager

3 Production Order

4 Type

5 Model Name

6 Article

7 Serial Number

8 Production Date

9 - 10 Power supply - Voltage and Frequency

11 Gross Capacity

12 Absorption at Rated Capacity

13 Absorption during Defrosting

14 Absorption of Heating Elements

15 Lamp Power

16 Fuse Value

17 Climate Class

18 Number of Motors

19 Type of Coolant

20 Amount of Coolant

21 Safety Class

22 - 23 Customer order

24 WEEE Mark

6.3 Identification

This manual suits for next models

6

Table of contents