PREVIOUS INSTRUCTIONS............................................................................................. - 4 -

SERIAL NUMBER PLATE............................................................................................. - 5 -

RECEPTION AND IDENTIFICATION OF THE MIXER.................................................... - 6 -

WARRANTY CONDITIONS ......................................................................................... - 7 -

REQUIREMENTS FOR THE OPERATOR ......................................................................- 9 -

SAFETY WARNINGS AND RECOMMENDATIONS.....................................................- 10 -

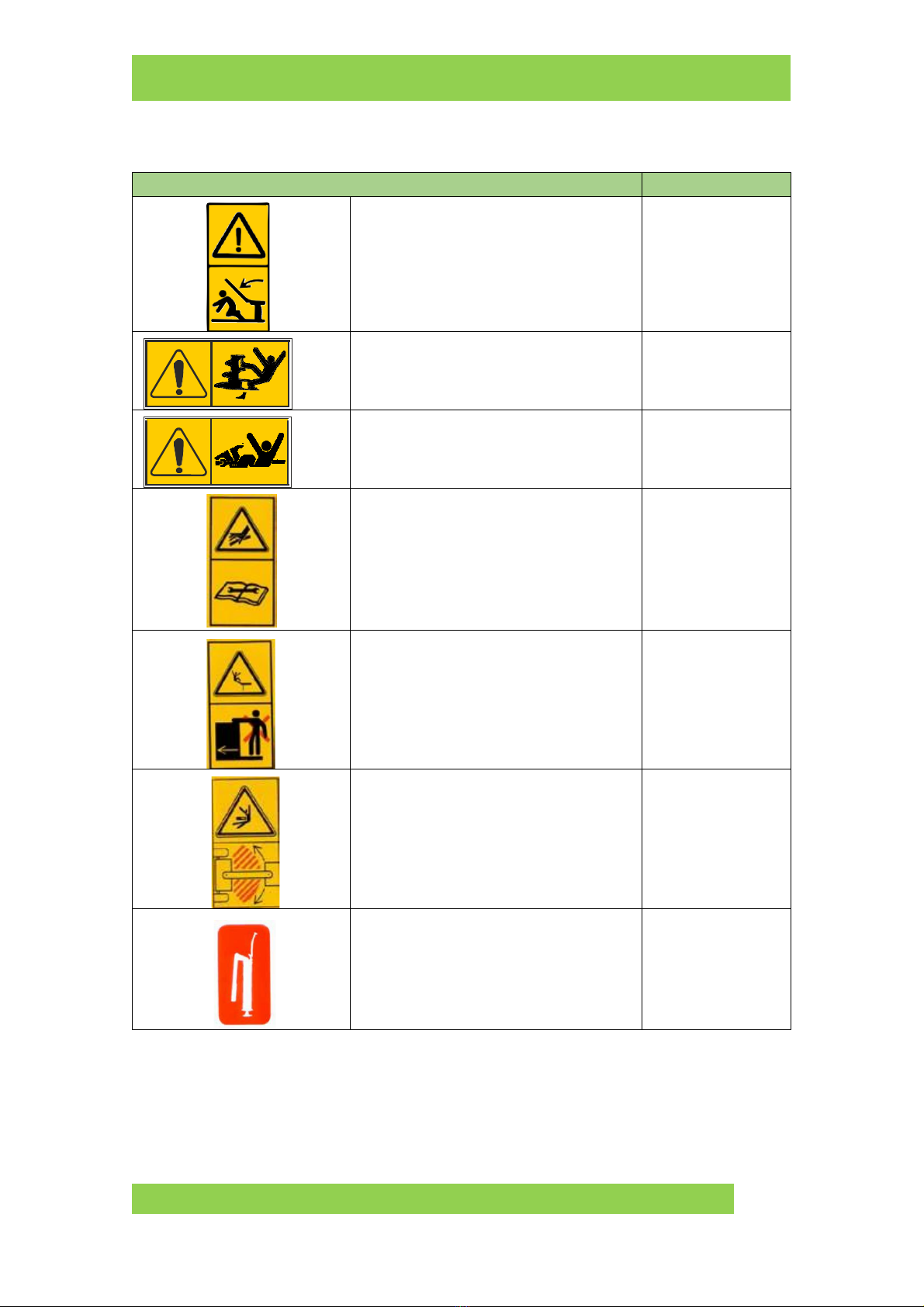

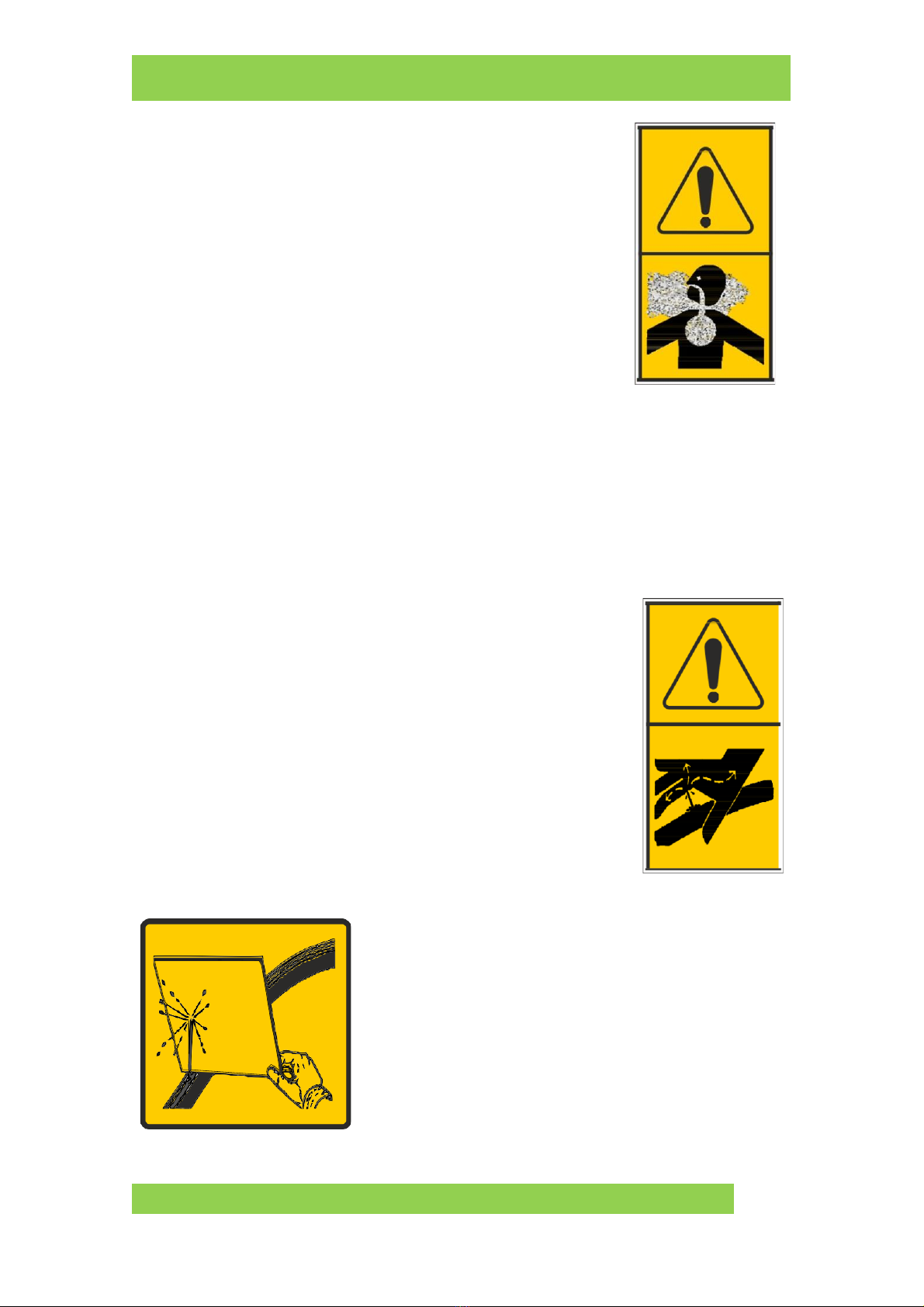

DANGER AND WARNING SIGNS..............................................................................- 11 -

SAFETY STANDARDS AND GUIDELINES...............................................................- 12 -

INSTRUCTIONS AND PRECAUTIONS AT WORK.......................................................- 21 -

MAINTENANCE INSTRUCTIONS ..............................................................................- 22 -

AT THE END OF THE WORK.................................................................................- 23 -

SOLVING PROBLEMS...........................................................................................- 24 -

USE AND CONSERVATION OF THIS MANUAL .........................................................- 25 -

MIXER DESCRIPTION...................................................................................................- 26 -

INTRODUCTION.......................................................................................................- 26 -

USE OF THE MIXER..................................................................................................- 27 -

MAIN PARTS OF THE MIXERS.................................................................................. - 28 -

INSTRUMENTS AND MIXER COMMANDS...................................................................- 34 -

HITCH ......................................................................................................................- 34 -

POWER TAKE OFF AND 2-SPEED GEARBOX............................................................- 35 -

FRONT JACK ............................................................................................................- 37 -

MIXER CONTROLS...................................................................................................- 39 -

LIGHTING AND SIGNALING .....................................................................................- 41 -

PARKING BRAKE......................................................................................................- 42 -

BATTERY (Optional) ................................................................................................- 44 -

WEIGHING SCALE....................................................................................................- 45 -

CONNECTIONS BETWEEN MIXER AND TRACTOR ...................................................- 46 -

USE OF THE MIXER......................................................................................................- 48 -

START UP ................................................................................................................- 49 -

LOADING THE MIXER ..............................................................................................- 53 -