Tatoma EMV-8 User manual

INSTRUCTION MANUAL

TOWED VERTICAL MIXERS

MODELS:

EMV-8, EMV-9, EMV-10, EMV-12

EMV-14, EMV-17

EMV-14.5B, EMV-16B, EMV-18B

EMV-20B, EMV-22B, EMV-24B

EMV-26B, EMV-17BB, EMV-20BB

EMV-8P, EMV-9P, EMV-10P

EMV-12P, EMV-14P

VERSION:

FEBRUARY 2006

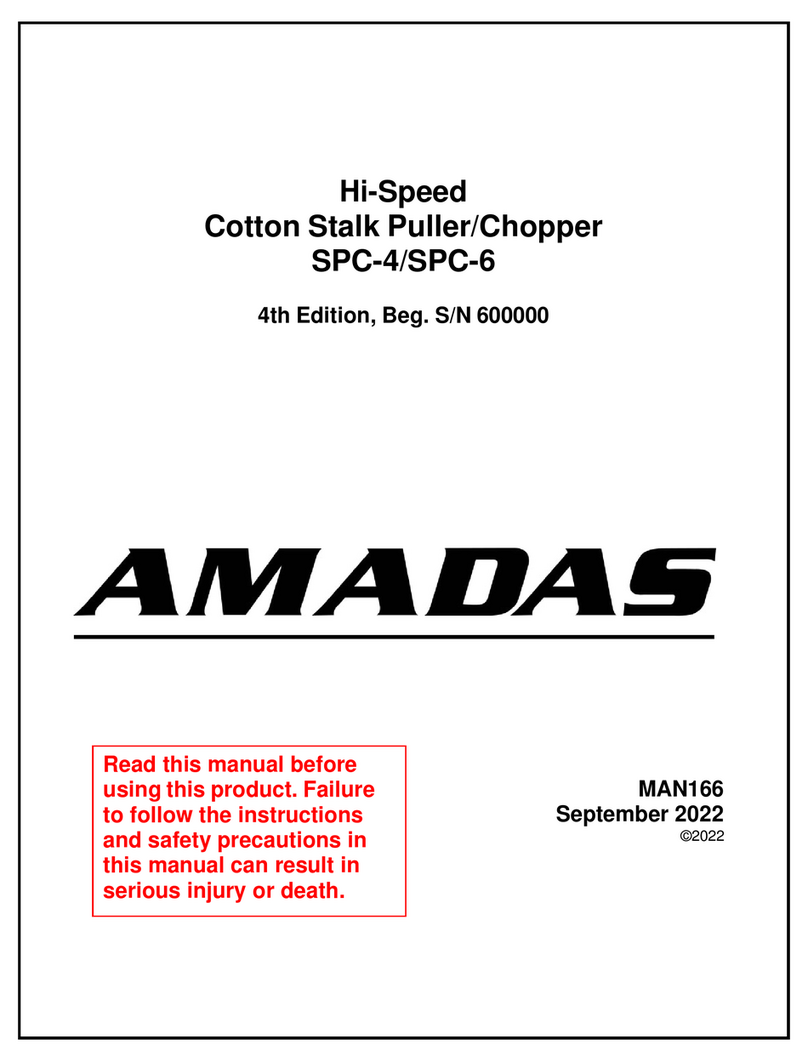

VERTICAL TOWED MIXER

Warning! Carefully read the instruction manual before using the

machine.

VERTICAL TOWED MIXER

VERTICAL TOWED MIXER

VERTICAL TOWED MIXER

VERTICAL TOWED MIXER

CONTENTS

1. CONFORMITY DECLARATION 2

2. REGISTRATION PLATE 2

3. RECEPTION OF THE MIXER 3

4. GUARANTEE CONDITIONS 4

5. SAFETY WARNINGS AND RECOMMENDATIONS 5

6. USE AND CONSERVATION OF THE INSTRUCTIONS HANDBOOK 10

7. INSTRUCTIONS HANDBOOK 11

VERSION:

FEBRUARY 2006

Page 1

TOWED VERTICAL MIXER

1. “EC” CONFORMITY DECLARATION

The company

INGENIERIA Y MONTAJES MONZÓN S.L.

Business address:

Polígono industrial Las Paules 53-55

22400 Monzón (Huesca) España

Declares sole responsibility that the towed mixer Models

EMV-8, EMV-10, EMV-12, EMV-14, EMV-17,

EMV-14.5B,EMV-16B,EMV-18B,EMV-20B,EMV-22B,EMV-24B,

EMV-26B,EMV-17BB,EMV-20BB.

EMV-9P,EMV-10P,EMV-12P,EMV-14P.

are manufactured in compliance with the following directives:

- Machine Directive 98/37/CEE

- Electromagnetic Compatibility Directive 89/336/CEE

The following harmonized technical Standards have been applied:

UNE-EN ISO12100-1, UNE-EN ISO12100-2, EN 294:1992,

UNE EN 1050 and UNE-EN 703:2005

in, Monzon on the ____ day of ___________ of 20____.

P.P. The Management

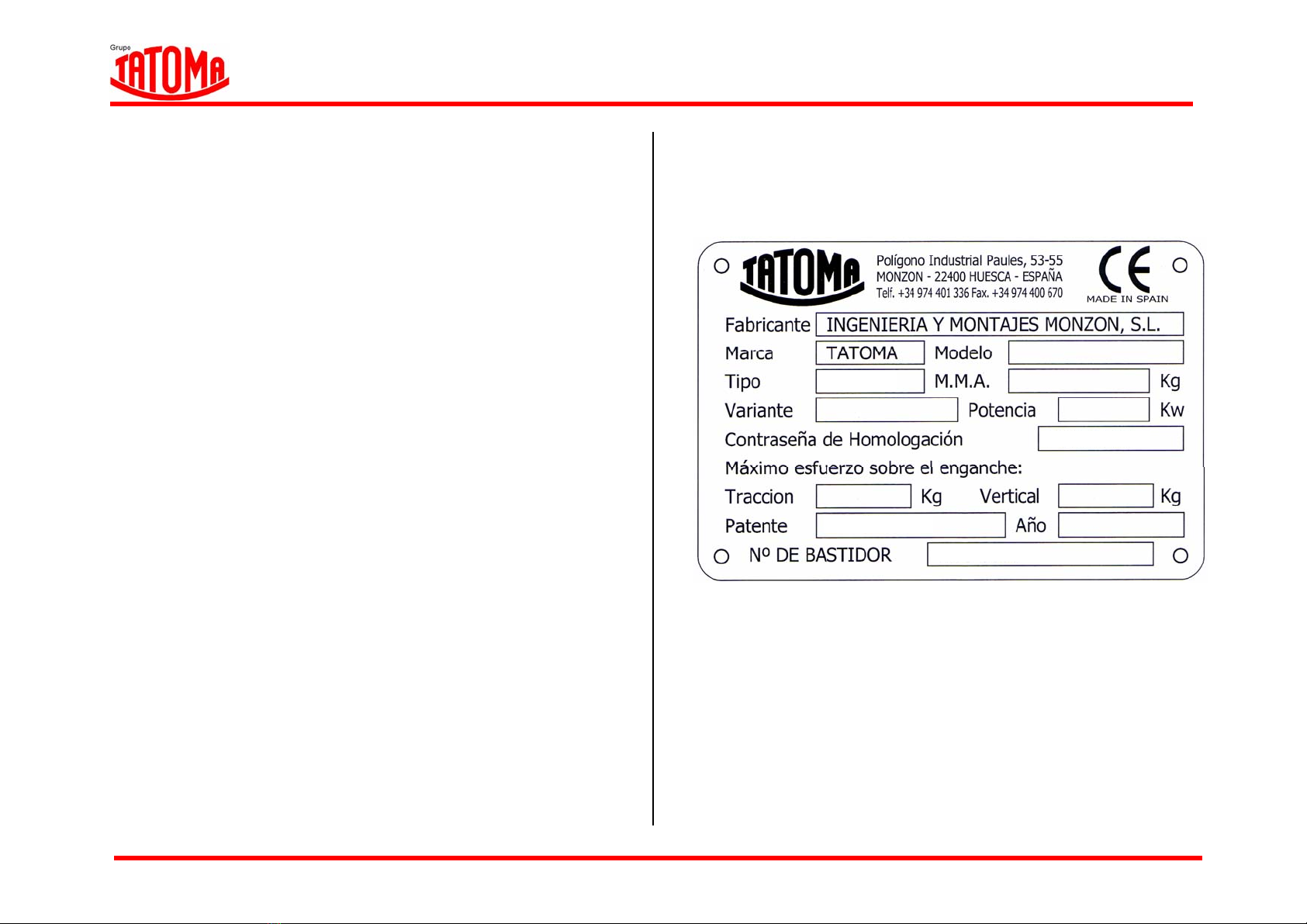

2. “EC” REGISTRATION PLATE

The following is an illustration of the EC plate. The plate is found on the

right hand side on the frame

Page 2

VERTICAL TOWED MIXER

3. RECEPTION OF THE MIXER

Upon reception of the mixer, the owner or the personnel in charge of it

should proceed in the following manner:

-Check that the mixer is supplied with the corresponding instructions

manual.

-Read the instruction manual carefully, paying careful attention to the

safety regulations.

-Check that the mixer is not faulty and has no flaws.

-Check that the mixer is delivered with all the accessories and

optional elements requested.

Once the mixer has been delivered and before being put into service

qualified personnel from TATOMA will instruct the owner or the personnel in

charge of the machine on its use, maintenance, and the safety regulations

to be taken into consideration for its correct use

Warning! Should the owner, hire or sell the mixer to a third party, he

should also hand over the instructions manual dealing with the

aforementioned information to the new owner.

Page 3

TOWED VERTICAL MIXER

GUARANTEE CONDITIONS.

TATOMA Offers for the complete range of its products, a six-month

guarantee for all factory defects. The validity of the guarantee will be

susceptible to the following conditions:

1. Repairs to damage caused to the

mixer during transport will be the

responsibility of the transport

company. Complaints should be

processed by whoever has contracted

the transport service.

2. Warranty coverage will begin on

the reception date of the mixer.

3. The guarantee will only cover the

free replacement of components that

have left the factory in a defective

state.

4. Components that have failed due

to circumstance different from the

previous point will be excluded from

the free replacement guarantee.

5. In the case of replacement of

defective components and the

carrying out of repairs by TATOMA

personnel, travel expenses and labour

cost charges will be met by the buyer.

6. Defective components should be

returned to TATOMA within a fifteen

day period, once they have been

replaced. On the contrary the

guarantee will not be processed and

the cost of the components to be

substituted will be at the buyer’s

expense.

7. The guarantee does not cover

those products that due to their

position or method of working are

subject to wear and tear.

8. Complaints should be sent by fax

to the authorised dealer or directly to

TATOMA depending on procedure.

9. TATOMA reserves the right to

check possible claims and assess if

they are covered by the guarantee.

10. Breakdowns and or defects

caused to the mixer in the following

cases will mean cancelling the

guarantee immediately:

a) Inadequate maintenance or

maintenance carried out by non-

qualified personnel.

b) Inadequate use of the mixer or

for uses that are different to those

specified in the manual.

c) Use of the mixer by those who

have not been instructed in the use of

the same.

d) Repairs carried out by non-

authorised personnel.

e) Manipulation or taking apart of

the machine by unauthorised

personnel.

f) Use of non-original spare parts or

those not specified by TATOMA

g) Modification of addition of any

element that would vary the original

design of the mixer.

h) Non-compliance of the safety

regulations and the recommendations

included in this instructions hand

book.

i) Towing the mixer with vehicles

that are not appropriate for the task.

j) Exceptional reasons such as

accidents or weather

11. TATOMA declines responsibility

for all possible damage caused

persons or objects in any of the cases

indicated in the previous section.

12. TATOMA reserves the right to

modify the design or the specifications

of their products without prior warning.

13. In the case of doubt or dispute

please contact the nearest authorised

distributor

Page 4

VERTICAL TOWED MIXER

4. SAFETY WARNINGS AND RECOMMENDATIONS

4.1. INFORMATION ON ACOUSTICS AND VIBRATIONS

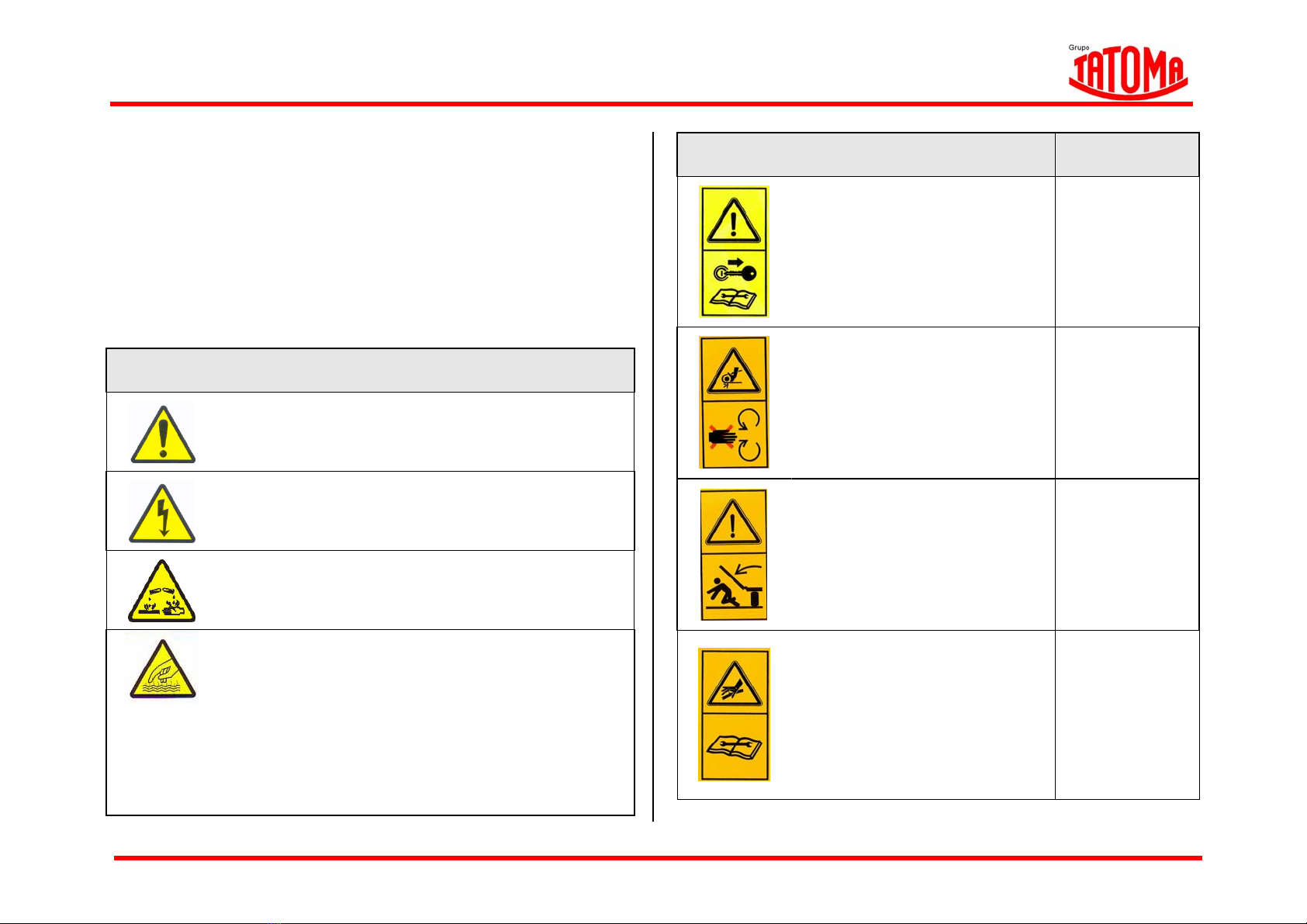

Identify, interpret correctly and respect the warning signs located on

different parts of the mixer, as well as identifying the importance that the

indicators and recommendations included in this handbook play on

contributing unequivocally to avoiding accidents that could cause damage

and serious injury.

Therefore, these instructions should be read paying special attention to

the section dealing with rapid identification and correct interpretation of the

following warning signals.

Symbols used in the instructions handbook

Generally indicates that the instructions that accompany it

are of special importance.

Indicates that the instructions that accompany it refer to

possible risks or dangers of electrocution.

Indicates that the instructions that accompany it refer to

Possible risk of burns produced by corrosive liquids.

Indicates, that the instructions that accompany it makes

reference to possible danger burns caused by high

Temperature liquids.

Safety symbols situated on the machine Location

Warning! Stop the machine the tractor

engine and carefully check the

instructions manual before proceeding

with any maintenance or repair

operation.

Front part of the

mixer alongside the

hydraulic controls.

Warning! Do not open or remove the

protection covers while the engine is

working.

Side of mixer,

alongside the

unloading belt.

Back of the mixer on

the sides.

Warning! Never lower the unloading belt

or the mixer loading system without first

checking if anyone or any obstacle is

within its working area.

Front part of the

machine that can be

seen by the tractor

driver

Mixer side, alongside

the unloading belt.

Warning! Danger due to high pressure

fluids. Check instructions handbook

before starting to carry out any

maintenance operations.

On the hydraulic oil

tank.

Beside the hydraulic

distributors

Page 5

TOWED VERTICAL MIXER

Safety symbols situated on the machine Location

Warning! Do no climb up on the mixer

nor on the stairs while this is in motion

Front part of the

mixer, alongside the

tub access ladder

Warning! Stay out of the articulation area

while the machine is working

Front end of the

mixer and on the

front and side parts

of the same.

Symbols used in maintenance location

Greasing point Distributed around

the mixer at each

greasing point

4.2. SAFETY REGULATIONS.

A set of rules are described as follows whose compliance is compulsory

to avoid possible accidents.

•Before starting work with the mixer, the owner or the person in

charge of it should become familiar with its controls and the

corresponding functions and should carefully read this instructions

handbook.

•It is expressly forbidden to carry out any operation on the mixer

without the trailer operator having first received the corresponding

training by TATOMA.

•The mixer has been designed to be trailed using a tractor. It is

expressly forbidden to use any other type of vehicle for towing, as the

stability conditions of the various mixer mechanisms could vary

considerably during use.

•To hook up between the tractor and the mixer please bear the

following in mind:

Check that no-one is near the mixer when manoeuvring

backwards to bring the tractor to the mixer.

Handle the hooking up items of the mixer with heavy duty work

gloves.

•Once hooking up has been carried out, the following precautions

should be taken when proceeding with the cardan connection to the

PTO of the tractor:

Check that the mixer has been correctly hooked up.

Ensure that the PTO is stopped.

Manipulate the transmission elements with heavy duty gloves.

Do not use loose clothes when carrying out the operation.

Do not step or jump over the PTO.

Follow the cardan protection positions and fix their position

using a suitable device.

•Once the hook-up is finalised and the coupling of the PTO, the

parking brake should be completely released.

•Before using the mixer:

Before accessing the tractor cab check the state of the

different mixer protection and mechanisms.

Adjust the driver’s seat so that the mixer control access can be

carried out comfortably.

Page 6

VERTICAL TOWED MIXER

Adjust the rear view mirrors so that the mixer mechanisms can

be easily seen, without their adjustment. The help of another

person should be obtained for this operation.

•Check the presence of others before moving the mixer. If necessary

use the horn or other mechanism to indicate that the mixer is about to

move.

•The mixer should be driven in accordance with the conditions of the

land or the road on which it is to be driven.

•It is expressly forbidden for various persons to manage the mixer at

the same time, and must be used only by the driver.

•It is expressly forbidden to transport people, animals or any other

object on the mixer.

•Under no circumstances should the mixer be used to tow other

vehicles, move or push objects or raise loads. It is expressly

forbidden to access the mixer through the loading device or its use as

a system to reach high up objects.

•It is forbidden to travel long trips with the mixer loading system in an

elevated position.

•When driving the mixer on the public highway, the Highway Code

should be observed at all times.

•To manoeuvre or move the vehicle on the road the loading system (in

accordance with the model) should be in the resting position.

•To carry out manoeuvres check that that there are no obstacles

behind the mixer or near it, should there not be enough visibility ask

others for help.

•Keep a safe distance from, furrows, channels, banks and ditches,

etc., as the ground could give way and cause the mixer to roll and a

consequence the tractor too.

•All access to the mixer or to the working area around the same is

forbidden to those outside of farm area where the machine is being

used.

•When working with the mixer the operator should check at all times

that no one is inside the working area.

•The machine operator should inform those near the working area of

the possible dangers.

•During loading of the machine the driver should check that nobody is

on top of the silage. Should the machine be loaded directly into the

tub from the silo the driver should remain throughout the entire

operation inside the cabin? If loading is done with additional vehicles

the access of people to the working area must be prohibited.

•Work with extreme care when manipulating the moveable elements

of the mixer and check that nobody is near the elements before

starting them up, if anyone is present they should be warned and

asked to leave the area.

•Do not lean over into the tub, or manipulate the product in the inside

of the tub when the mixer is working.

•If it is necessary to access the tub bear in mind that the risk of a fall is

present at all times. Access to the tub should only be attempted by

the most experiences personnel, and with the mixer totally stopped

and the ignition key in the hand of the person who is going to access

the mixer.

•Before accessing the interior of the tub, as an additional safety

measure the cardan should be disconnected from the PTO of the

tractor.

•It is expressly forbidden to incorporate devices into the mixer that

permit access to the tub and are higher than the last step of the

access steps.

•Do not open the protection of the mixer mechanisms when they are

working, nor manipulate the mixer when it is not working, nor

manipulate the moving elements, loading, unloading belt, etc.

•Warning, do not use loose clothes when nearing the moving parts of

the mixer or the PTO and cardan. Check at all times that the guard

rails and safety protection and in the correct position and in good

order.

Page 7

TOWED VERTICAL MIXER

•Adhesive labels concerning safety are placed in visible places near to

the mechanisms they refer to. Keep the labels clean and visible and

replace them when deteriorated.

•Identify them correctly and respect the indication on the warning

signs at all times.

•The mixer operator should remember the meaning of the labels as

well as the instructions indicated throughout the instruction

handbook.

•Under no conditions should the mixer be used for other purposes

rather than those indicated in this user handbook and for which it has

been designed, i.e. mixing different products for animal feeding.

Warning! In addition to the previous instructions, other instructions,

warnings and indications are included throughout the manual that should be

taken into consideration when handling the mixer.

Warning! The stated rules as well as the warnings and indications

contained in this instruction handbook, should be complemented at all times

with the compliance of the laws in force on Health and Safety at Work.

TATOMA declines all responsibility for damage or injury to people or

material damage caused by non compliance of the regulations,

warnings and indications included in this instructions handbook, as

well as the non-compliance of the regulations in force in terms of

health and safety in the work place or the incorrect use of the machine

itself.

5. USE AND MAINTENANCE OF THE INSTRUCTIONS HANDBOOK

This instructions manual is aimed at the mixer user, the owner, those in

charge of the machine and the technicians who carry out maintenance.

The instructions manual, serves to indicate the correct usage of the mixer,

knowledge of its technical characteristics, personnel training, maintenance

and indication of warnings about possible dangers or breakdowns.

The manual should be kept in a safe place for future reference. The

instructions manual should accompany the mixer at all times.

Should it be lost or become deteriorated, the user should contact

TATOMA to order a new copy of the manual, quoting the serial number and

the year of manufacture of the mixer, and the information that is inscribed on

the EC registration plate

The manufacturer reserves the right to modify the product without prior

warning.

The manufacturer can be contacted at any time by the user to resolve any

queries that the user may have with regards to the correct use of the mixer.

Page 8

VERTICAL TOWED MIXER

Page 9

TOWED VERTICAL MIXER

7. INSTRUCTIONS HANDBOOK

Page 10

VERTICAL TOWED MIXER

INSTRUCTIONS MANUAL: CONTENTS

1. DESCRIPTION OF THE MIXER 13

1.1.INTRODUCTION 13

1.2.USING THE MIXER 13

1.3.MAIN PARTS OF THE MIXER 13

2. MIXER CONTROLS AND INSTRUMENTS 20

2.1.HOOKING UP 20

2.2.PTA 20

2.3.FOOT REST 21

2.4.MIXER CONTROLS 22

2.5.ILLUMINATION AND SIGNALLING 24

2.6.PARKING BRAKE 25

2.7.CHOCKS 25

2.8.BATTERY 26

2.9.WEIGHING SCALE 26

3. HANDLING THE MIXER 28

3.1.STARTING UP28

3.2.LOADING THE MIXER 30

3.3.FUNCTIONING AND USE OF THE BEATERS 32

3.4.PREPARATION OF THE MIX 32

3.5.DISTRIBUTION OF THE MIX 33

3.6.STOPPING THE MIXER 34

3.7.LOAD TESTS 35

3.8.ACCESS TO THE TUB 35

3.9.PARKING THE MIXER 36

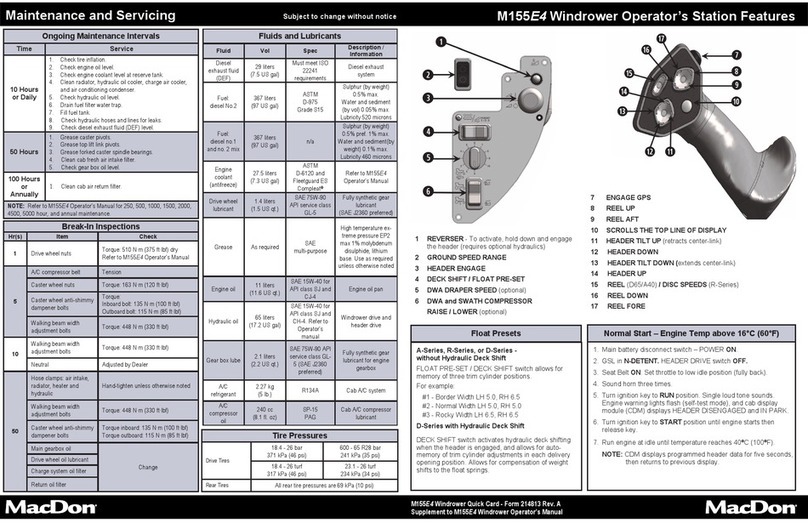

4. MIXER MAINTENANCE 37

4.1.GENERAL POINTERS FOR MAINTENANCE 37

4.2.MAINTENANCE OPERATIONS 37

4.3.CHECKING LEVELS 39

4.4.GREASING 40

4.5.FILTERS 43

4.6.WHEELS AND TYRES 43

4.7.BATTERY 44

4.8.LOADING AND MIXING SYSTEM 45

4.9.UNLOADING BELT 46

4.10. HYDRAULIC SYSTEM 47

4.11. ELECTRICAL SYSTEM 47

4.12. STOPPING THE MIXER FOR A PROLONGED TIME 49

5. TECHNICAL CHARACTERISTICS 50

6. OPTIONAL EQUIPMENT 53

7. OPERATING IRREGULARITIES 54

Page 11

TOWED VERTICAL MIXER

1. MIXER DESCRIPTION

1.1. INTRODUCTION

TATOMA designs its mixers thinking of how to facilitate your daily work,

save you time and, accordingly, improve performance and the benefits of

use.

With our mixers, you can ration the way you feed your herd improving

the efficiency of your work.

The breadth of our range of products allows us to solve any query.

To assure that the mixer is operated correctly, it is recommended to

designate a person in charge, who has previous experience driving tractors

or other farm machinery. This will also facilitate the instruction period.

Attention! Technical data and characteristics of the trademark or model, of

the different marketing materials or other components of the mixers cited in

this manual are indicative. TATOMA reserves the right to modify the design

or specifications without prior notice.

1.2. USING THE MIXER

The towed mixer has been designed specifically to perform the following

operations only:

-Chop silage (depending on the model)

-Load loose silage:

By hand (depending on the model)

Using the appropriate machine

From an automatic silo

-Mix silage with other feeds or compliments

-Dose the mix previously cited

It is strictly prohibited to carry out operations other than those

specified here. Doing so could run the risk of physically putting

the driver and people near the mixer in danger, and it could

cause major breakdowns to the mixer.

Carrying out operations different from those specified will

result in the immediate loss of the warranty.

The previous operations should be carried out by one single

person. When other machines are used with the mixer (loading

the mixer), the operation of these shall be coordinated by one

single person.

While performing the previous operations, the presence of

unauthorised persons in the mixer working area shall be

avoided at all times.

1.3. MAIN PARTS OF THE MIXER

The mixer system, incorporated in the machinery described in this

manual, is a vertical type, with one or two conical augers incorporated in the

inside of the cone shaped tub, with an open ended opening at the top.

The tub has several circular metal sections (operated manually or

hydraulically, hydraulic shredder option), which allow the degree of

shredding of the products that form the mix to be controlled.

The mixing principle is based on the movement of the product by the

auger, which turns and lifts the components of the mix upward. Then, these

fall by gravity around the edges of the tub and down to the bottom of the

auger. Accordingly, the components and the mix are in continual motion.

Page 12

TOWED VERTICAL MIXER

Using this system a homogeneous mix is obtained in minutes.

Two towed vertical mixer models are available:

•The simple vertical auger mixer, which has one auger in the

centre of the tub.

•The dual vertical auger mixer, which is equipped with two augers

in the inside of the tub. This mixer model is called the DUPLO,

and from this point forward, it will be referred to by its name.

The towed vertical mixers do not have a loading system. Thus,

appropriate auxiliary equipment must be used when loading or the mixers

can be loaded from automatic silos.

In general, using the mixer permits the silage to be conserved

maintaining all of its energetic properties without any deterioration at all until

the moment of distribution.

Furthermore, both types of mixers are equipped with an electronic scale,

which allows the quantity of products that are mixed into the ration,

determined by a nutritionist or veterinarian, to be controlled at all times.

TATOMA designed mixers are built simple and made with highly resistant

steels. The machine components experience minimal wear and require little

maintenance.

The figures on the following pages show the main components of the

types of towed vertical mixers described previously.

Below, descriptions of the main components on the different mixer

models are given.

Mixer System: The system is made of highly resistant materials that

are capable of operating continually and correctly for several years. In

general, these elements have been designed such that parts, which

are prone to wear, are easy to repair and replace. It is made up of the

following components:

Tub (11/30): The products comprising the mix are held inside the

tub. Tub capacity depends on the model.

Auger (12/32): Consists of a vertical conical auger positioned in

the centre of the tub. The auger is controlled by a hydraulic motor

and a planetary gear reducer providing the efficiency needed to

perform its job.

The auger is equipped with treated and tempered blades for

shredding the product. Because they are submitted to wear, the

blades are interchangeable.

Circular Metal Sections (10/29): The purpose of these sections is

to retain the product close to the outer edge of the tub, so the

blades come in direct contact with it, increasing the degree of

shredding the components. They are manually operated, or the

sections can be operated by hydraulic cylinders (hydraulic

shredder option), in which case they are covered with a

detachable protective plate.

Page 13

TOWED VERTICAL MIXER

Page 14

UMixer Components

1. Electronic scale 5.- Trailer footrest 9. Unloading belt 13. Side unloading door

2. Remote control 6. Tub access ladder 10. Shredders 14. Parking brake

3. Control block 7. Hydraulic circuit 11. Tub 15. Power takeoff

4. Hitch 8. Unloading door 12. Auger

Interior detail of the tub

1

2

3

4

5 6 7 9 10

8 11

12

10

10

Side unloading door detail

13

14 15

Figure 1.1: Towed mixer

TOWED VERTICAL MIXER

Page 15

UMixer Components: self loading shovel

16. Mobile upper shovel

17. Loading shovel fixed track

18. Hydraulic drive cylinders

Components not indicated are the same as those used on the simple auger

mixer.

(See previous figure.)

View of Auto loading Shovel Lowered

Figure 1.2: Self Loading Shovel

16

17

18

This manual suits for next models

19

Table of contents

Other Tatoma Farm Equipment manuals

Popular Farm Equipment manuals by other brands

John Shearer

John Shearer CONNOR SHEA 8000 Series Operator's Manual / Parts Catalogue

Powerfix Profi

Powerfix Profi 68920 operating instructions

Hurricane

Hurricane 3-PT-Swinger manual

HMF

HMF SH2630 instruction manual

agromaster

agromaster BUFALO 1856 Operator's manual

enorossi

enorossi HAY TOP 300 Use and maintenance manual