Lipco HSA 10 User manual

Instructions

Hydraulic shaker HSA 10

2 - 28

220018-00-EN BA HSA 10 / 28.09.2019

1. Introduction

Dear Customer,

We thank you for having chosen a LIPCO hydraulic shaker HAS 10.

We hope that you will be happy with your choice.

In order that your LIPCO hydraulic shaker HAS 10 will serve you well

for many years, we ask you to pay close attention to the operating

instruction, which you will find in this manual. This will help you to pre-

vent breakdowns and accidents resulting from non-observance of the

operating instructions, for which our company will not accept respon-

sibility.

This Instruction and Maintenance Manual is to be considered as an

integral part of the machine itself and therefore it must always accom-

pany the machine when it is sold, even in the event of its sale to third

parties.

If you keep this manual in a safe place and in good condition, you -

and whoever must use the machine - will always be able to have a

complete reference on hand.

Note:

The illustrations, descriptions and specifications in this manual are not

binding. LIPCO reserves the right to make modifications without no-

tice.

Instructions

Hydraulic shaker HSA 10

3 - 28

220018-00-EN BA HSA 10 / 28.09.2019

2. Content Page

1. Introduction 2

2. Content 3

3. Designated use 4

4. Warning signs attached to the machine 5

5. General safety regulations 6

6. Accident prevention 7

7. Technical details –standard equipment 9

8. Technical details –special equipment 9

9. Technical data 10

10. Attachment to tractor 12

11. Attachment of the universal joint shaft 14

12. Operating HSA 10 16

13. Driving on public roads. 19

14. Lubrication chart 21

15. Maintenance 22

16. Machine storage 24

17. Machine disposal after end of lifetime 24

18. Notices 25

19. Warranty 26

20. EC declaration of conformity 27

Instructions

Hydraulic shaker HSA 10

4 - 28

220018-00-EN BA HSA 10 / 28.09.2019

3. Designated use

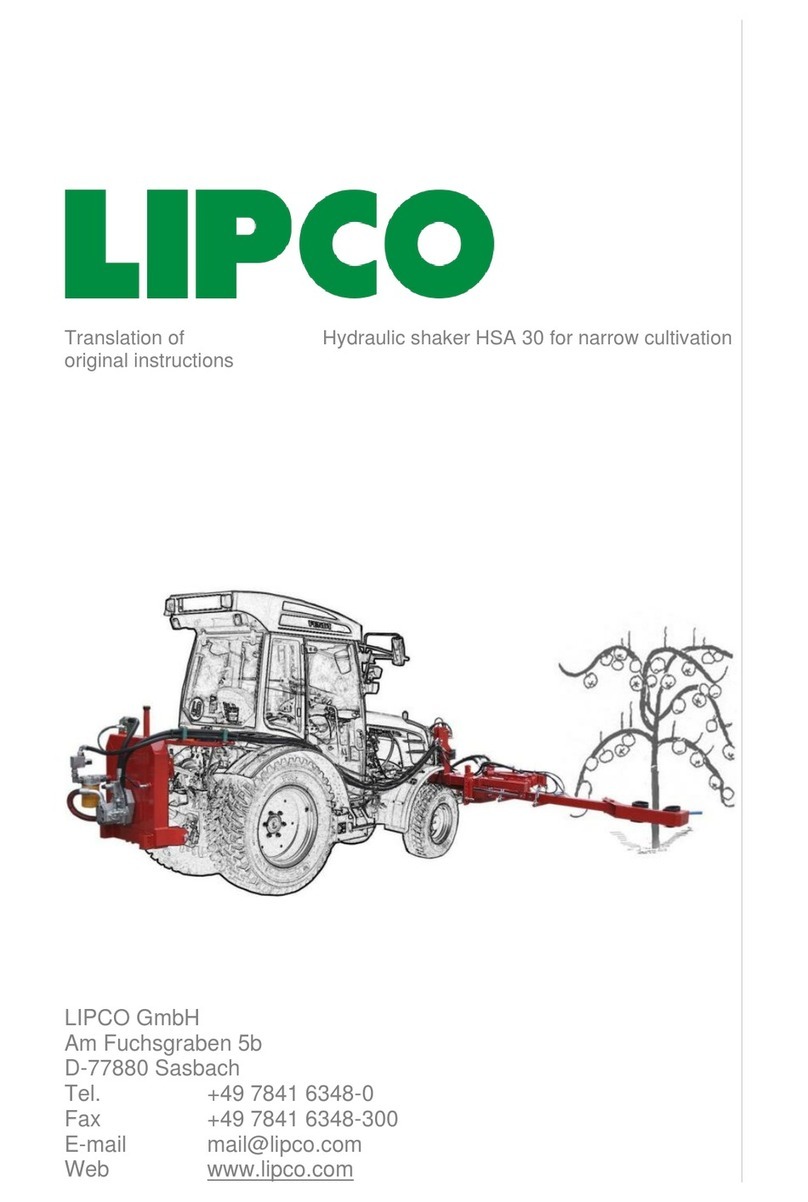

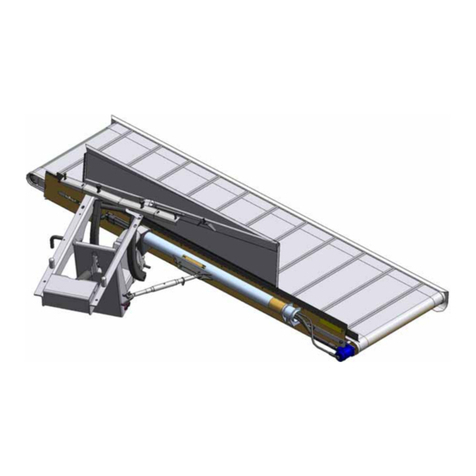

The LIPCO hydraulic shaker HSA 10, when connected to a tractor, is

designed for hydraulic shaking of fruit and other crop trees.

Any other use for purposes other than those described here is not ac-

cording the designated use. Do not held the manufacturer liable for

damage resulting from such use; the risk for such use lies entirely with

the user.

Operating the unit within the limits of its designated use also means

following the instructions for operation, transport and maintenance de-

scribed by the manufacturer.

Persons who are familiar with the unit and informed about possible

risks must carry out any work, maintenance and repair on the LIPCO

hydraulic shaker HSA 10.

Please observe the relevant accident prevention regulations as well

as the other generally recognized maintenance, safety, industrial med-

icine and road traffic rules and instructions.

The manufacturer cannot held liable for damage resulting from unau-

thorized modifications of the LIPCO hydraulic shaker HSA 30.

•Note for use on public roads

Before driving on public roads and paths, make sure that the com-

bination of tractor and LIPCO hydraulic shaker HSA 10 or other

combined equipment complies with the applicable traffic regula-

tions (maximum gross weight, maximum axle loads, lights, warn-

ing signs, etc.). It may be necessary to transport the LIPCO hy-

draulic shaker HSA 30 on a flatbed truck.

•Note

The LIPCO hydraulic shaker HSA 10 is also referred to in this op-

erating manual only as HAS 10.

Instructions

Hydraulic shaker HSA 10

5 - 28

220018-00-EN BA HSA 10 / 28.09.2019

4. Warning signs attached to the machine

Before starting operation, the personnel must have

read the operating and safety instructions and must

observe them.

For maintenance and repair work, switch off the engine

and pull the key.

When operating the hydraulic lift, stay outside the lift-

ing range of the three-point suspension.

Do not exceed the prescribed speed (540 rpm) when

operating the unit!

Never reach between the rotating universal joint shaft.

Instructions

Hydraulic shaker HSA 10

6 - 28

220018-00-EN BA HSA 10 / 28.09.2019

5. General safety regulations

The operation of any machine, which is controlled by means of hy-

draulic or mechanical movements is associated with certain risks.

For this, please follow the safety regulations below:

•To get the maximum benefit with the HAS 10, it must be always in

perfect condition. Maintenance or repair work may only be per-

formed by trained personal.

•Spare parts must at least comply with the specified, technical re-

quirements, defined by LIPCO.

•This is only guaranteed by using LIPCO original spare parts!

•Note:

When attaching the HSA 10 to the tractor, no persons are allowed

to stay between tractor and HAS 10!

Moving the tractor towards HAS 10, may knock the machine,

which is still sitting on his supports.

•Secure the unit carefully before lying down beneath the unit for

repair or control purposes!

No persons or additional material are allowed on HAS 10 during

operation or during driving on public roads!

•In case of loss of hydraulic oil, it is strongly recommended to stop

the work immediately and to repair the damage first.

•Before each use, make sure that on tractor and HAS 10, joint shaft

protection and other safety devices are properly installed and fully

functional. Replace any damaged or missing component carefully

before operating the machine!

•Prior to maintenance or repair operations, make sure that the ma-

chine is switched off!

•The operator is responsible for compliance with applicable acci-

dent prevention regulations, in addition to the generally recog-

nized safety, occupational health and traffic safety regulations!

Instructions

Hydraulic shaker HSA 10

7 - 28

220018-00-EN BA HSA 10 / 28.09.2019

6. Accident prevention

Most accidents that occur during work, maintenance or transport of a

machine are due to non-observance of the most elementary rules of

accident prevention.

Therefore, it is important that all persons involved with use of the ma-

chine are aware of it and comply with following rules:

•Before starting any operation, read the instruction manual and

note safety information!

•Before each use, check tractor / machine 3-point linkage, chains,

suspension of shaking arm as well as hydraulic hoses and oper-

ating elements that they are in properly condition.

•Switch-off PTO drive and tractor prior to any repair, maintenance

or cleaning operation!

•Driving on public road, shaker unit must be in adequate safe po-

sition!

•Drive slowly with shaking unit in working position!

•Operate the shaking head only, when the tractor is standing still!

•Never climb on the machine during any operation!

•Never remove any safety protection!

Note:

•Never enter working area during PTO drive shift in operation.

Accident risk in case of contact with PTO drive shaft.

For your personal safety, never wear loose clothing like scarves…

•Prior to any operation, check PTO dive shaft length / overlapping.

Possibly a length adjustment will be required.

•Operate the machine only at the specified speed (max. 540 rpm)!

Instructions

Hydraulic shaker HSA 10

8 - 28

220018-00-EN BA HSA 10 / 28.09.2019

•Operate machine only with PTO drive unit fully protected, i.e. uni-

versal joint shaft completely covered and additional protection on

tractor and HAS 10. Make sure that the universal joint shaft con-

nections are securely locked!

•Attach the safety chain to avoid turning of PTO drive shaft protec-

tion during operation!

•The operator is responsible for compliance with applicable acci-

dent prevention regulations, in addition to the generally recog-

nized safety, occupational health and traffic safety regulations!

•Note:

Because of the maximum allowable additional tractor load, please

refer to adequate information, given by tractor manufacturer!

Lifting the HAS 10 with tractor’s 3-point linkage will increase trac-

tor’s axle load!

•Note:

Check especially the instructions of the tractor manufacturer about

the maximum allowable slope angle with attached machines /

load.

This concerns driving parallel to the slope or downslope.

Any operation not adapted to local conditions can cause serious

personal injuries or material damages because of tilting of the

combination of tractor + HAS 10.

Instructions

Hydraulic shaker HSA 10

9 - 28

220018-00-EN BA HSA 10 / 28.09.2019

7. Technical details –standard equipment

Technical description:

•Frame with double-coat paint RAL 3002 (red)

•Parking supports

•Shaking pole can pivot to left and right

•Adjustable suspensions of shaking pole (from 1 to 4 suspension

points)

•Monoblock 4 x double-action for horizontal, vertical adjustment

and gripper for clamping

•Pressure control valve with manometer for infinitely variable ad-

justment of the contact pressure on the gripper jaws

•Shaking is started electrically

•Hydraulic upper guide rod (fitting length depends on tractor)

•Universal joint shaft

Please indicate gripper size (large or small) with purchasing or-

der.

Standard version is available with 2 or 3 telescoping arms.

Please note price difference.

8. Technical details –special equipment

•Axle, wheels included 195 R-14C

•Shunting aid (not approved for road use)

•Turning mechanism

•Hydraulic overrun brake

•Backfitting of the hydraulic overrun brake

•Proper hydraulic

•Cover for telescope

•Electrical operation including 4 function control box and 4 m ca-

ble

•Wireless control including 4 function control box

•Lighting kit 12V (road traffic act), detachable, with magnet panel

Instructions

Hydraulic shaker HSA 10

10 - 28

220018-00-EN BA HSA 10 / 28.09.2019

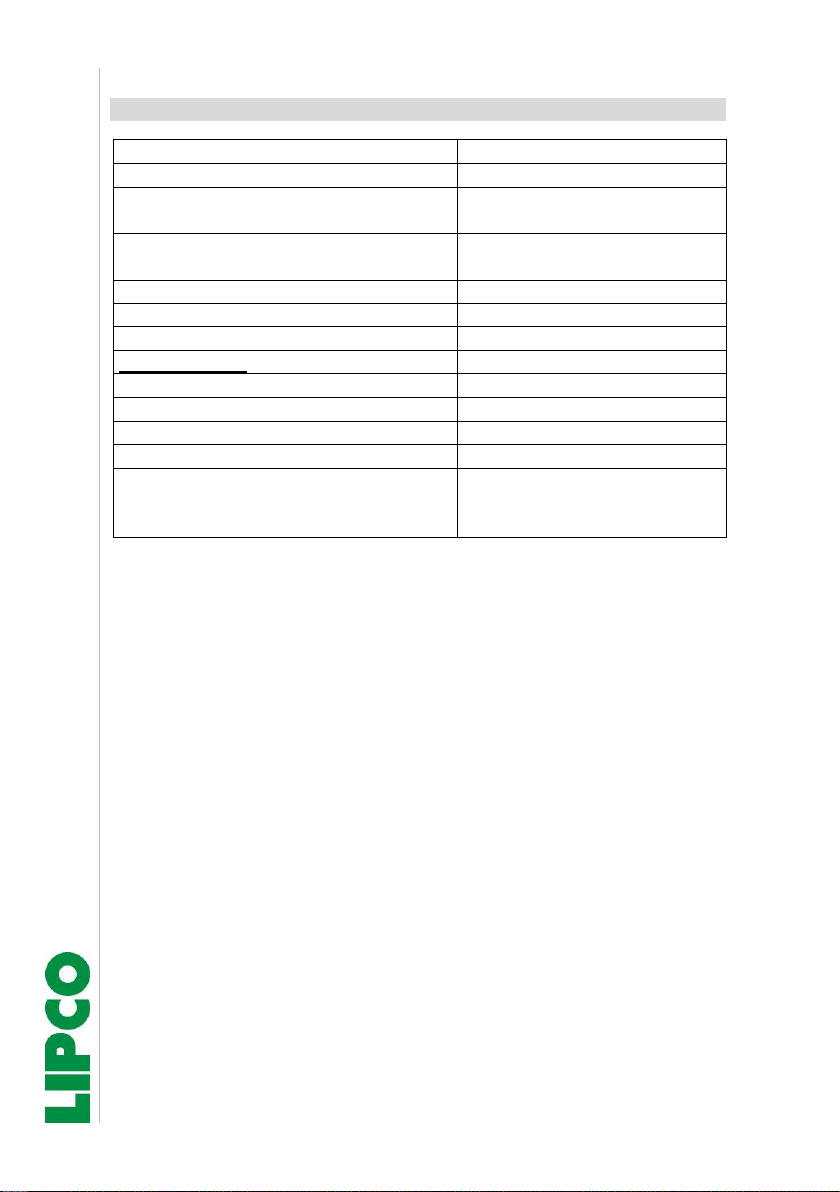

9. Technical data

Trunk diameter (small gripper)

0,1 m bis 0,43 m

Trunk diameter (large gripper)

0,1 m bis 0,55 m

Range on back side

5,60m with 2 cylinders, each

cylinder 1000mm stroke

Optional version

6,60m with 3 cylinders, each

cylinder 1000mm stroke

Hydraulic swivel range

35 °

Manual swivel range

180 °

Set-up values:

Gripper pressure adjustable

0 - 180 bar

Hydraulic pump

110 l

Maximum allowable pressure

150 bar

Switching on shaking operation

Standard –via PTO sahft

Special edition:

electric operation via sole-

noid valve

Instructions

Hydraulic shaker HSA 10

11 - 28

220018-00-EN BA HSA 10 / 28.09.2019

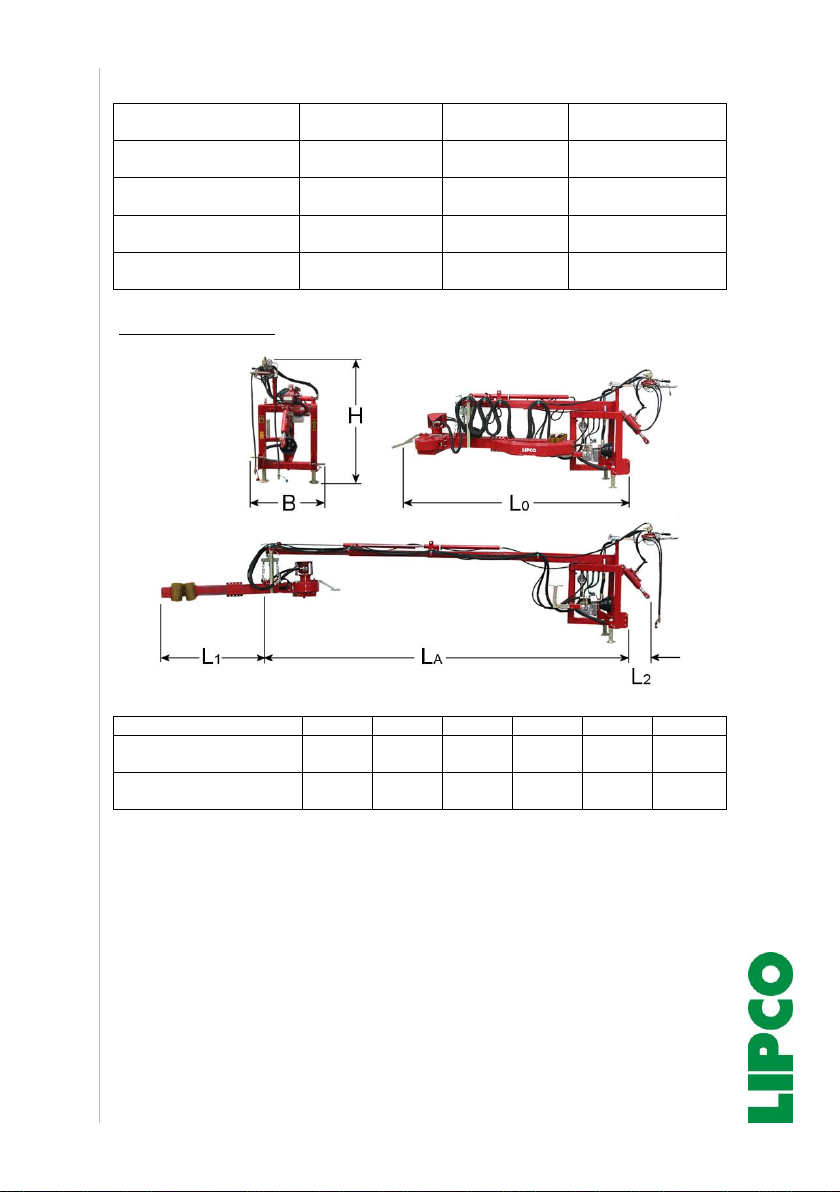

Version

Weight

(kg)

required

power (kW)

Gripper design

HSA 10 with 2 telesco-

pic arms

640

32

0,1 –0,43 m

660

32

0,1 –0,55 m

HSA 10 with 3 telesco-

pic arms

780

32

0,1 –0,43 m

800

32

0,1 –0,55 m

Main dimensions:

L1

L2

LA

L0

H

B

HSA 10 with 2 telescopic

arms

1450

500

4400

3360

1710

1000

HSA 10 with 3 telescopic

arms

1450

500

5400

3540

1710

1000

Instructions

Hydraulic shaker HSA 10

12 - 28

220018-00-EN BA HSA 10 / 28.09.2019

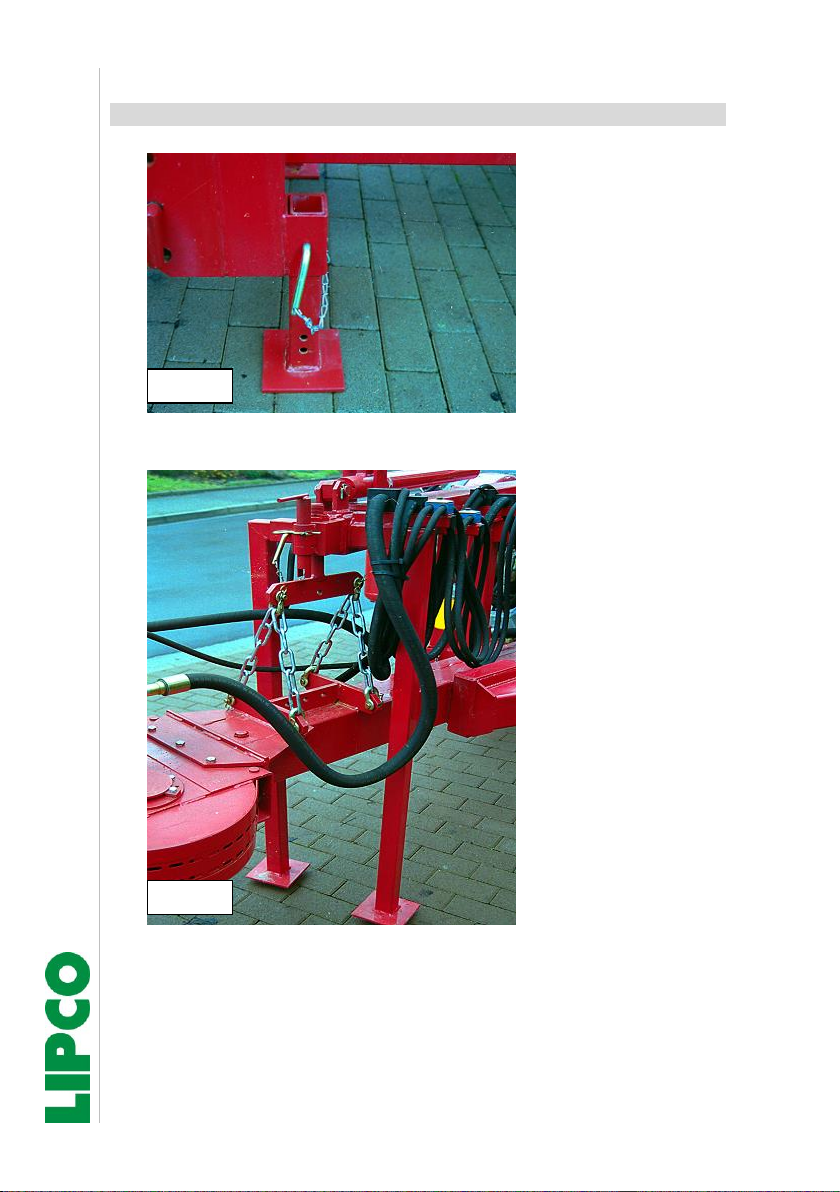

10. Attachment to tractor

•Approach cautiously with the tractor to the back side of HAS 10.

Position lower link.

•Insert mounting bolts through the suspension of the lower link and

secure with linch pin. Tighten lower link.

•Fasten upper link with upper link pin.

•Lift HAS 10 with tractor and move / secure all supports in upper

position.

•Store supports in suitable location for later re-use.

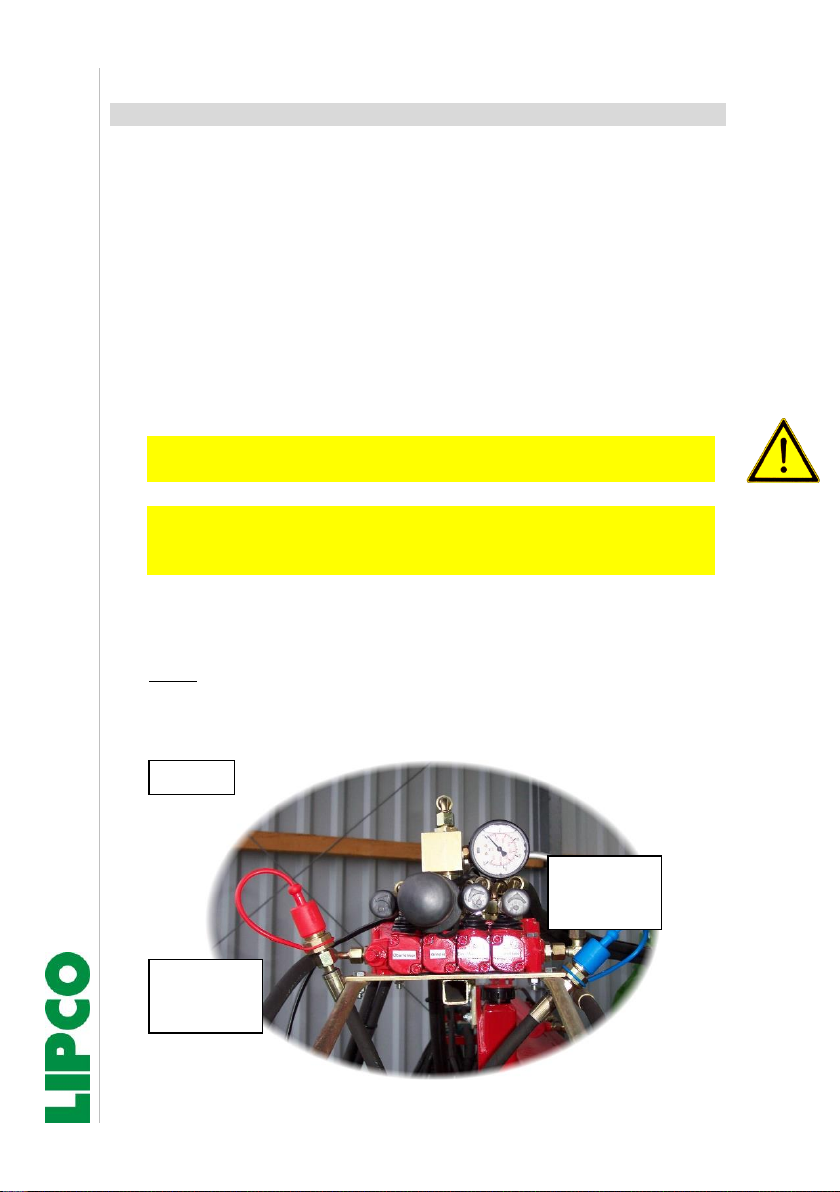

Note !

Lower links of the tractor may only be plugged be-

tween the mounting brackets of the HSA.

Note !

When connecting the hydraulic lines to the tractor,

make sure that the pressure- and return line (pres-

sure-less) are properly connected. (see Fig. 1)

•Prior to connecting the hydraulic hoses, clean the coupling ele-

ments on tractor- and machine side properly.

•Note:

Any dirt within the hydraulic circuit will damage the sealing of hy-

draulic valves and hydraulic motor.

Fig. 1

Return line

blue protec-

tive cap

Pressure side

red protective

cap

Instructions

Hydraulic shaker HSA 10

13 - 28

220018-00-EN BA HSA 10 / 28.09.2019

Note:

Depending on category (CAT 1 / CAT 2) of tractor

reductions will be required for upper link.

Instructions

Hydraulic shaker HSA 10

14 - 28

220018-00-EN BA HSA 10 / 28.09.2019

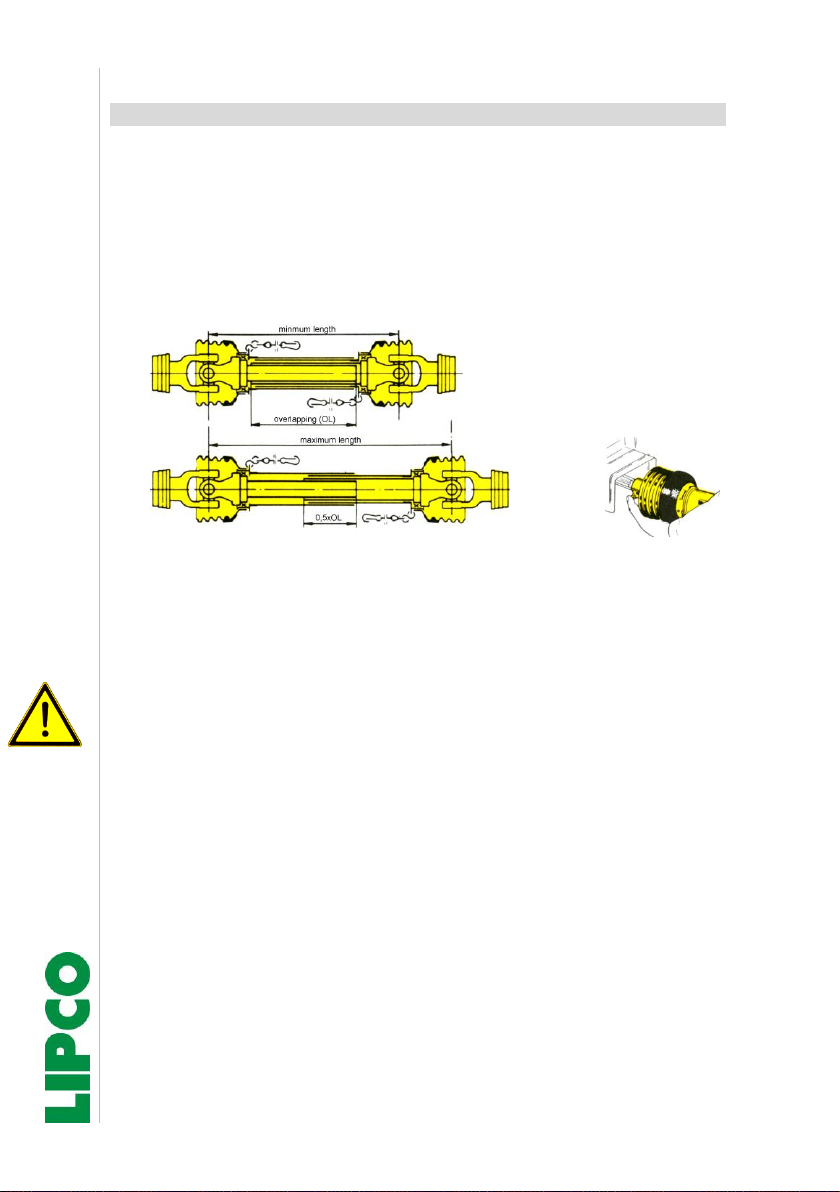

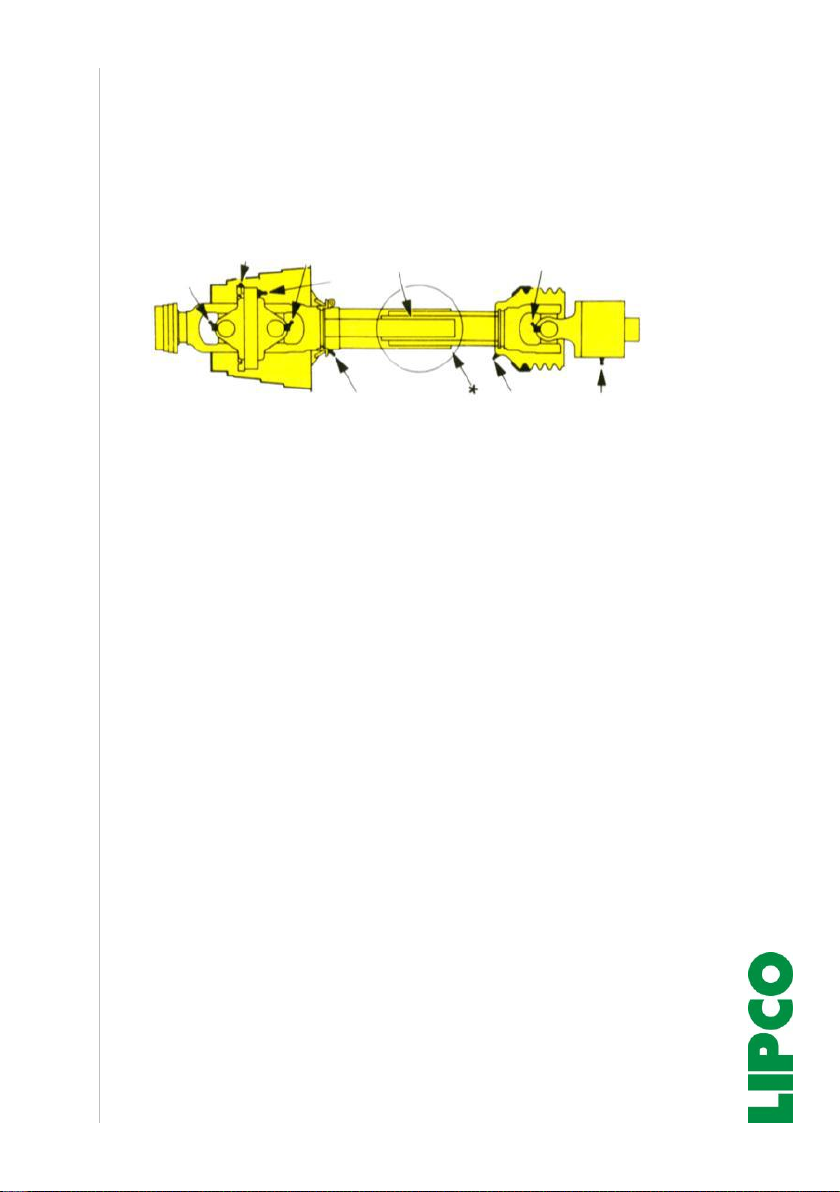

11. Attachment of the universal joint shaft

•Prior to connecting or detaching the universal joint shaft, always

make sure to switch off the power take-off shaft and motor and to

remove the ignition key!

•Press pin and push the universal joint shaft onto the power take-

off shaft until the pin locks into place! (Fig. 2)

Fig. 3

Fig. 2

•After connecting HAS 10 to the tractor, check the length of the

universal joint shaft.

•Note!

Aim for maximum overlap. Minimum overlapping is 0.5xOL = 50%

of maximum overlapping OL. (See Fig. 3)

•When connecting to a different tractor, check the length again!

•When the machine is not in use, locate the universal joint shaft in

the support provided for this purpose.

•When connecting the universal joint shaft to the machine, make

sure that the protective cover covers completely the universal joint

shaft guard in all operating positions!

•For your personal safety, replace damaged or worn protective de-

vices immediately.

Instructions

Hydraulic shaker HSA 10

15 - 28

220018-00-EN BA HSA 10 / 28.09.2019

•Prior to any operation, lubricate universal joint shaft, then following

every 8 hours during operation. Check also free movement!

•During winter season, lubricate protection tubes to avoid freezing.

Locations see lubrication chart. (Fig. 4)

Fig. 4

•Connect safety chains for the universal joint shaft guard so that a

enough swiveling area for the universal joint shaft is possible in all

operating positions. Do not use safety chains for suspending the

universal joint shaft!

•For your personal safety, replace worn or damaged safety parts

immediately.

•Connecting the universal joint shaft to the tractor, check, that the

protection hood on both sides is covering both ends of the univer-

sal joint shaft completely.

•If HAS 10 is not in use, then locate the universal joint shaft in the

adequate hook.

Instructions

Hydraulic shaker HSA 10

16 - 28

220018-00-EN BA HSA 10 / 28.09.2019

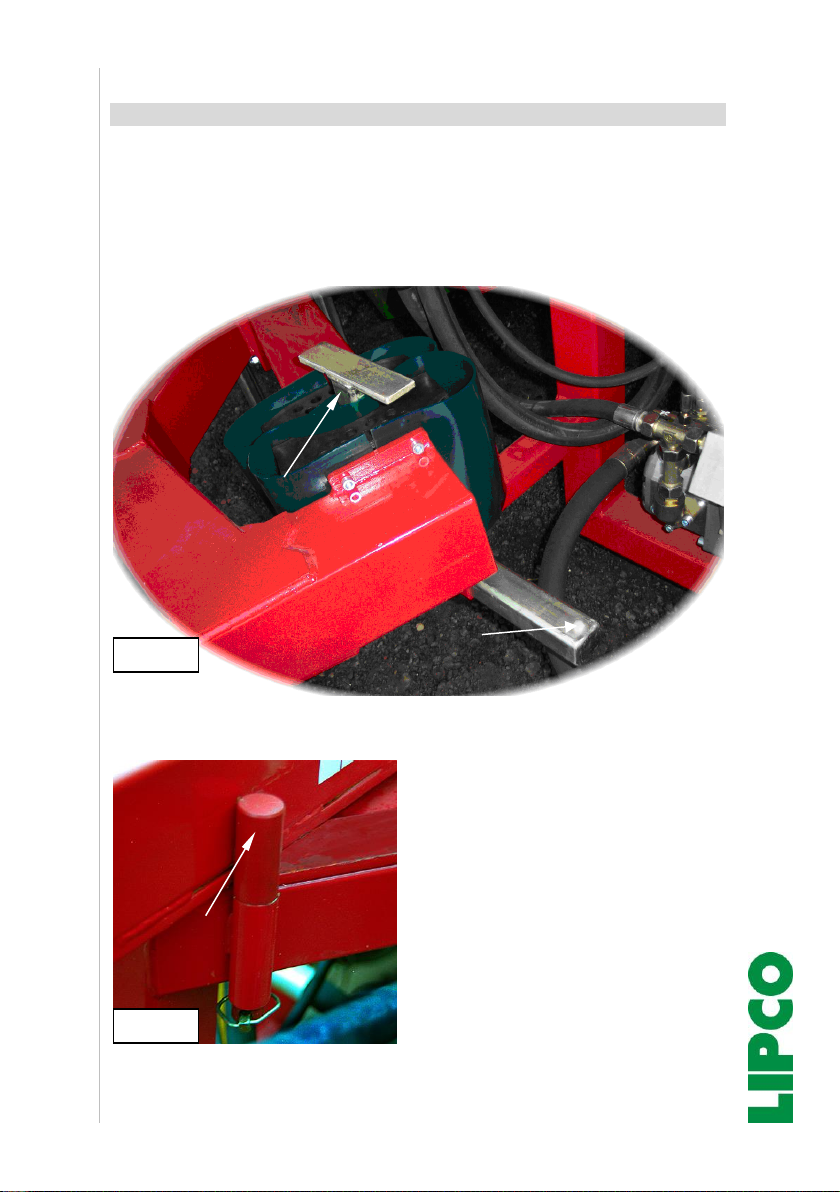

12. Operating HSA 10

•Lift shaker using

tractor hydraulics;

push up the front

parking supports

(Fig. 5) to highest

position and secure

them!

•Remove rear sup-

ports. (Fig. 6)

Fig. 5

Fig. 6

Instructions

Hydraulic shaker HSA 10

17 - 28

220018-00-EN BA HSA 10 / 28.09.2019

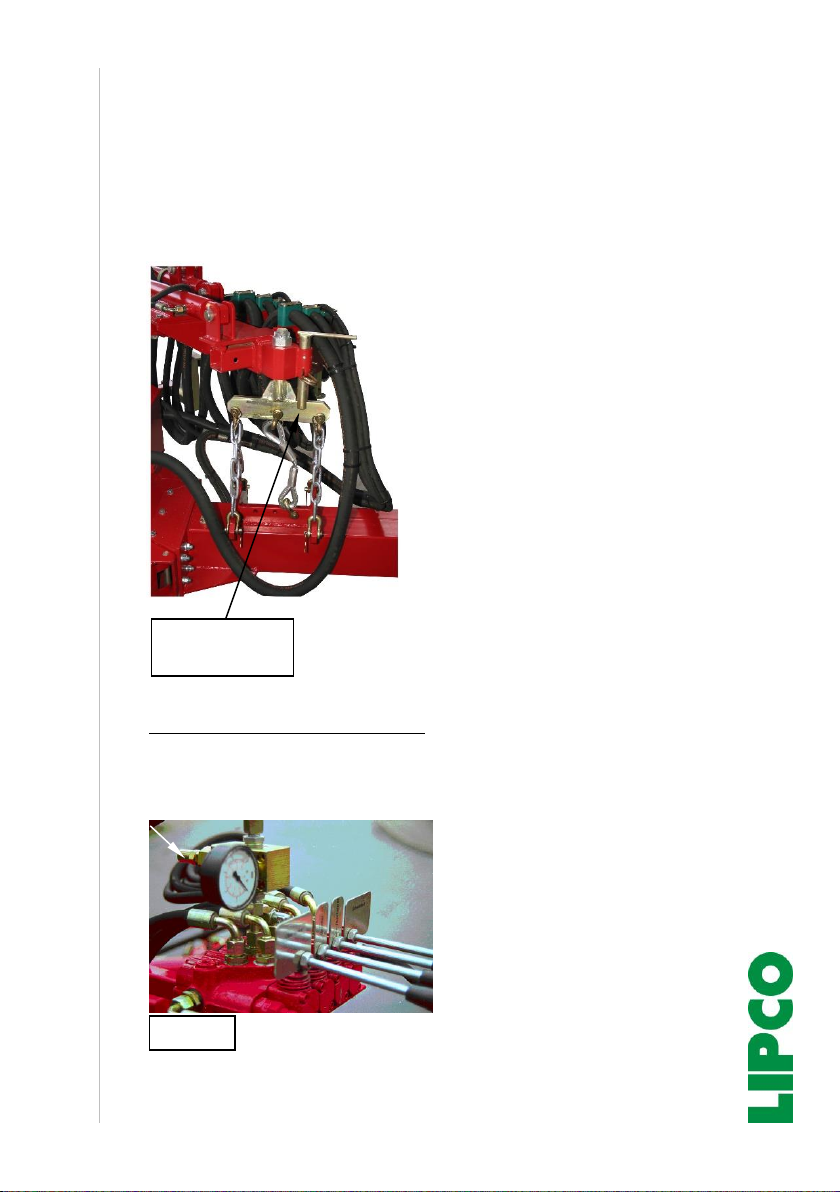

•Set the hydraulic control lever on the tractor to "Pressure".

•Remove transport safety pin.

•On control block of shaker:

Push “Open gripper”

turn the shaker bar manually

by 180° and lock the safety

bolt. The shaker is now ready

for use.

•Move the gripper up to approx.

1.5 m to the trunk and stop.

•Actuate the "Extend" control

lever until the gripper is at the

same level as the trunk.

•Then carefully turn left until the

trunk is in the centre of the grip-

per

•“Close gripper”. Start the

shaking process by switching

on the PTO shaft. Hold control

lever (“Close gripper”) in po-

sition.

•Changing the gripper pressure:

The gripper pressure is factory set to 130 bar. Depending on the

sensitivity of the tree, the pressure can be increased by adjusting

the pressure relief valve (Fig. 7).

Fig. 7

One-man-

handling

Instructions

Hydraulic shaker HSA 10

18 - 28

220018-00-EN BA HSA 10 / 28.09.2019

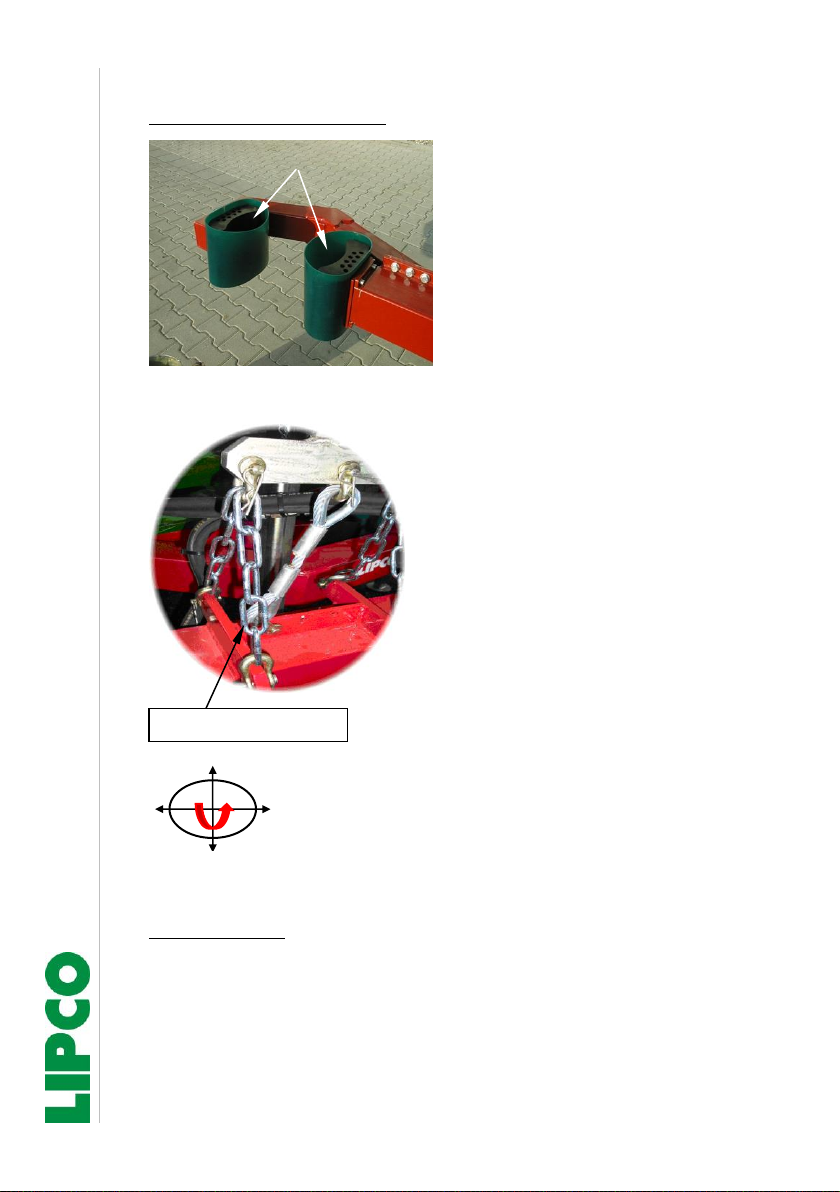

Notes for shaking process:

•In order to avoid damage to

the bark, the shaking rod

must always be placed at

approx. 90° to the trunk or

branch.

•When using the HAS 10, it

is also necessary to lubri-

cate several times a day be-

tween the rubber jaws and

the green rubber band with

a food-safe grease (Vase-

line or milking grease).

•When shaking branches,

the 4 support chains are un-

hooked so that the shaking

rod is held by the wire rope

alone.

•Only short shaking periods:

If the fruits fall badly, repeat

this if necessary or shake

the tree crosswise by swiv-

elling the shaking rod.

•Special edition:

The shaking process is started via an electric on-off valve. For this

special edition, hold control lever (“Close gripper”) also in posi-

tion.

Lubication

Support chains

Shaking directions

Instructions

Hydraulic shaker HSA 10

19 - 28

220018-00-EN BA HSA 10 / 28.09.2019

13. Driving on public roads.

When transporting the device on public roads, the shaking rod must

always be fixed in the transport bracket (Fig. 8). The transport locking

bolt (Fig. 9) must also be fitted. All chains must always be hooked in

during transport on public roads.

•The transport bracket is

equipped with a polyamide

screw with a predetermined

breaking point. If the square

tube (transport lock) is pulled

out by incorrect operation,

only the fixed polyamide

screw will be damaged.

•No other screws may be used

as replacements. Only use

the original screw recom-

mended by LIPCO!

Fig. 9

Transport locking

pin

Fig. 8

Transport bracket

Polyamid screw

Instructions

Hydraulic shaker HSA 10

20 - 28

220018-00-EN BA HSA 10 / 28.09.2019

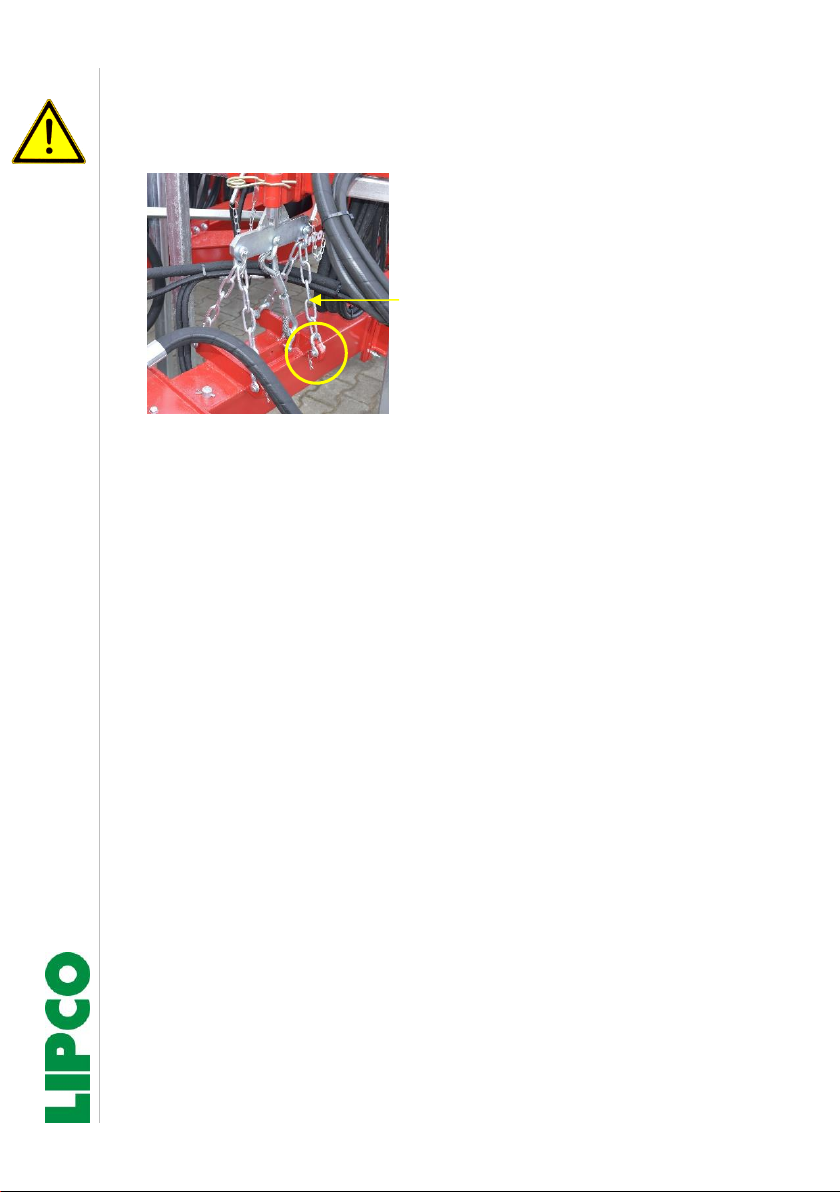

During driving on public roads, all 4 safety chains must always be

hooked in and secured.

Safety chains 4x

Safety pins 6x

Fig. 10

Table of contents

Other Lipco Farm Equipment manuals