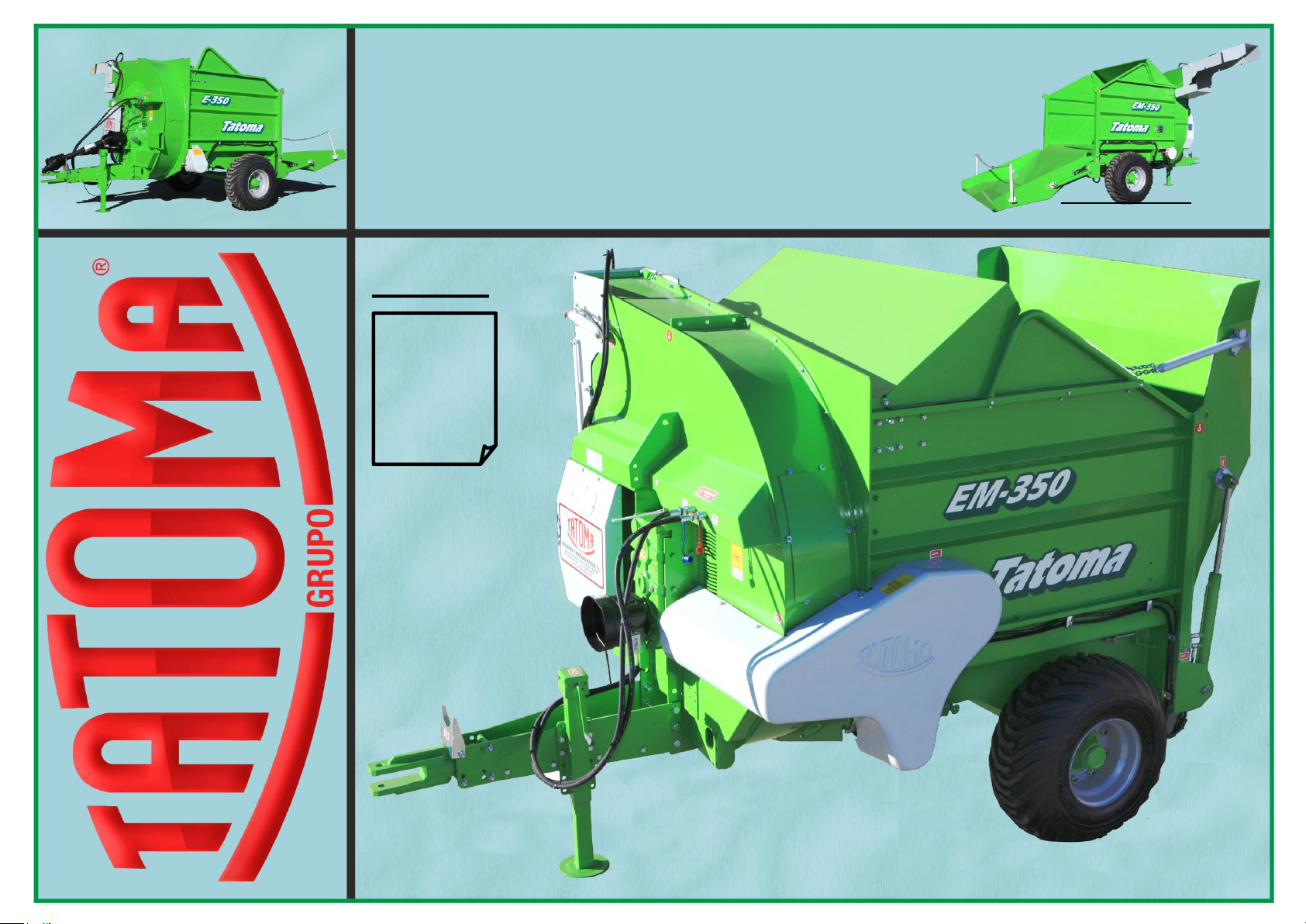

Tatoma E-350 User manual

INSTRUCTION MANUAL

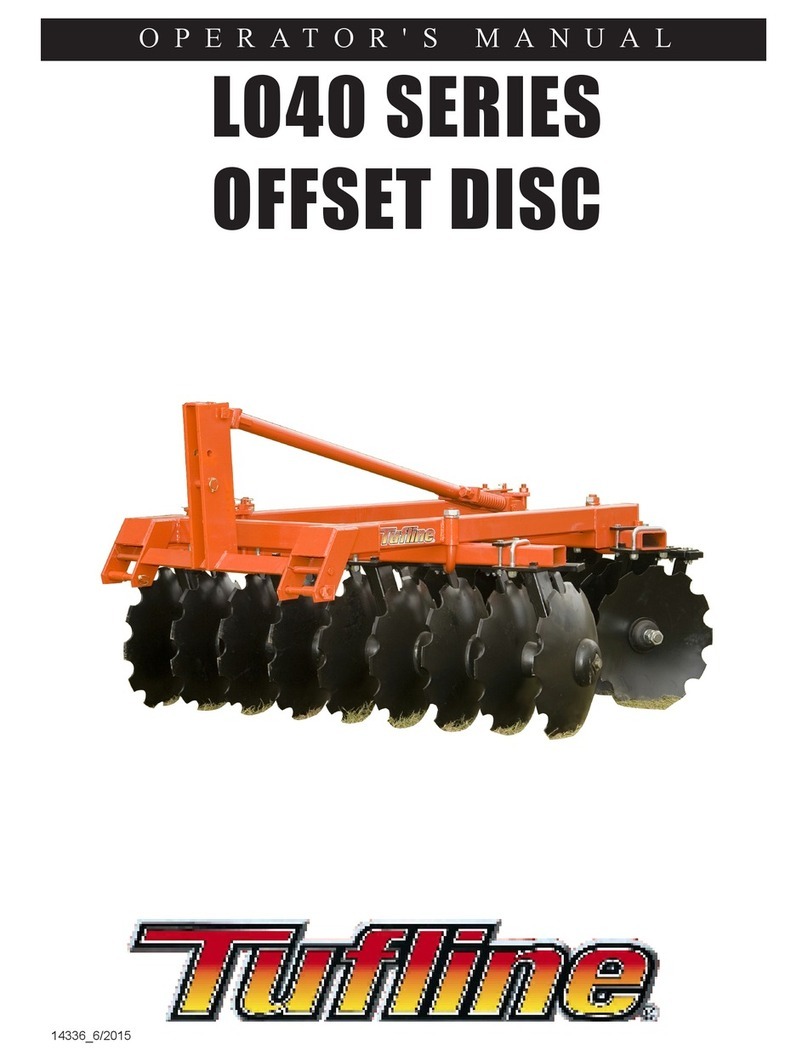

STRAW CHOPPER:

E/EM/D-350 ; E/EM/D-650

350

650

Models:

STRAW CHOPPER

WARNING CAREFULLY READ THE

CONTENTS OF THIS INSTRUCTION

MANUAL ON THE CD BEFORE STARTING

THE MACHINE

STRAW CHOPPER

Congratulations, you have purchased one of the best straw choppers currently available

on the market:

TATOMA designed straw choppers are conceived to make your job easier,

save time and therefore improve the performance, benefits and profitability of your

farm.

With our machines, you can streamline your operations, improving the efficiency of

your work.

Our extensive product range enables us to solve all our customers´ needs.

Thank you for placing your confidence in our products.

STRAW CHOPPER

Page 1

CONTENT

1. INTRODUCTION ______________________________________________________ 2

2. CONFORMITY DECLARATION __________________________________________ 3

3. REGISTRATION PLATE ________________________________________________ 3

4. RECEPTION AND IDENTIFICATION OF STRAW CHOPPER ___________________ 4

5. WARRANTY CONDITIONS ______________________________________________ 5

6. OPERATOR REQUIREMENTS ___________________________________________ 6

7. WARNINGS AND SAFETY REGULATIONS _________________________________ 6

8. MAINTENANCE INSTRUCTIONS _________________________________________ 13

9. USE AND CONSERVATION OF THE INSTRUCTION MANUAL _________________ 16

STRAW CHOPPER

Page 2

1. INTRODUCTION

Congratulations on purchasing your new TATOMA Straw chopper. With

proper use and the correct preventive maintenance your mixer will last for

years.

When you see this

symbol, be alert to the

possibility of personal

injury and carefully read

the message that

accompanies it.

NEVER OPERATE WITHOUT all guards, shields and protection in

place.

KEEP hands, feet and clothing away from moving parts.

Some covers and guards have been removed from the explanatory

details of this manual for illustrative purposes only. However, the equipment

should not be operated in this condition, therefore all protections must be in

place. If a protection element must be removed for repairs, refit it

immediately after the repair and before use.

The warranty appears on the cover of this book along with the

Registration and Inspection Certificate.

For information on ordering replacement parts, see Repair Parts section

in the second part of this book.

The serial number plate is located on the right-side of the tub front.

This number must be recorded in the Registration and Inspection

Certificate to correctly identify your TATOMA mixer.

You are urged to read this manual and follow its instructions carefully.

Your efforts will be rewarded with better performance and service as well as

savings in time and repair costs.

Failure to read the manual, assuming full working knowledge of the

machine or its incorrect handling may to lead to serious injury.

If you do not understand the instructions in this manual please contact

your nearest dealer.

This document supersedes all previous published instructions.

STRAW CHOPPER

Page 3

2. “EC” CONFORMITY DECLARATION

The company

INGENIERIA Y MONTAJES MONZÓN S.L.

Business address:

Polígono industrial Las Paules 53-55

22400 Monzón (Huesca) España

Declares sole responsibility that the towed mixer Models:

E-350, EM-350, D-350

E-650, EM-650, D-650

are manufactured in compliance with the following directives:

- Machine Directive 2006/42/CEE

- Electromagnetic Compatibility Directive 2004/108/CE

The following harmonized technical Standards have been applied:

UNE-EN ISO12100-1, UNE-EN ISO12100-2, EN 294:1992,

UNE EN 1050 and UNE-EN 703:2005

in, Monzon on the ____ day of ___________ of 20____.

P.P. The Management

3. “EC” REGISTRATION PLATE

The following is an illustration of the EC plate. The plate is found on the

right hand side on the frame

STRAW CHOPPER

Page 4

4. RECEPTION AND IDENTIFICATION OF STRAW CHOPPER

Upon receipt of the straw chopper, the owner or personnel in charge

thereof, shall proceed as follows:

-Check that the mixer is supplied with the appropriate instruction

manual.

-Read the instruction manual carefully, paying close attention to the

safety regulations

-Check that the mixer has not been damaged.

-Check that the mixer comes with all accessories and optional items

requested.

After delivery of the mixer and before commissioning, TATOMA qualified

personnel, will instruct the owner or personnel in charge of it on how to

operate it, its maintenance and safety standards to consider for proper use.

It is the sole responsibility of the person in charge of handling the

machine to read and understand this manual and to follow the

recommendations in it.

Warning! If the owner, sells or rents the machine to a third party they must

also provide the instruction manual and instruct the new owner on the

issues previously mentioned.

STRAW CHOPPER

Page 5

5. WARRANTYCONDITIONS .

TATOMA offers a 12 month warranty against defects in workmanship for

its entire range of products. The validity of the guarantee will be susceptible

to the following conditions:

1. Repair costs due to damage

caused to the machine during

transport shall be met by the carrier.

Claims must be made by the person

who contracted the transport service.

2. The period of warranty coverage

begins from the reception date of the

straw chopper.

3. The guarantee will only cover the

free replacement of components that

have left the factory in a defective

state

4. Components that have failed due

to circumstances different from the

previous point will be excluded from

the free replacement guarantee

In the case of replacement of

defective components and/or the

carrying out of repairs by TATOMA

personnel, travel expenses and labour

cost charges will be met by the buyer.

5. Defective components previously

mentioned should be returned to

TATOMA within a period of 15 days

after having been replaced. Otherwise

the warranty will not be processed and

the costs of the replaced parts shall

be met by the buyer of the mixer.

6. The guarantee does not cover

those products subject to wear and

tear due to their position or working

method.

7. Complaints should be sent by fax

to the authorised dealer or directly to

TATOMA depending on procedure

8. TATOMA reserves the right to

check possible claims and assess if

they are covered by the guarantee

9. Failures and / or damage caused

to the mixer in the following cases

involve the immediate cancellation of

the warranty:.

a) Improper maintenance performed

by unqualified personnel

b) Improper use of the mixer, or for

functions other than those specified in

this manual.

c) Use of the mixer by personnel who

have not been trained to handle it.

d) Repairs carried out by non-

authorised personnel.

e) Manipulation or removal of parts of

the mixer by unauthorized personnel.

f) Use of non-original spare parts or

parts not specified by TATOMA.

g) Modification or addition of any

element that could vary the original

design of the mixer.

h) Breach of the safety standards

and recommendations included in this

manual.

i) Towing the mixer using vehicles

unsuitable for this purpose.

j) Exceptional events such as

accidents or weather.

10.TATOMA declines all responsibility

for possible damage caused to people

or objects due to what has been

indicated in the previous section.

11.TATOMA reserves the right to

modify the design and/or

specifications of its products without

prior notice.

12.In the case of any doubts or legal

claims the TATOMA distributor should

be contacted.

STRAW CHOPPER

Page 6

6. OPERATOR REQUIREMENTS

Operating and handling this mixer is limited to competent and

experienced persons. Likewise, anyone operating or working near the

mixer must use common sense.

In order to recognised as a qualified person, he or she must also know

and meet other requirements, such as;

1. Some regulations specify that no one under sixteen (16) years of

age, can handle machinery, and it is your sole responsibility to know

if you are within the scope of these rules.

2. Current OSHA regulations state in part: When initially assigned

and thereafter, at least annually, the employer shall instruct each

employee in the safe operation and maintenance of all equipment

with which the employee will be in contact.

3. Unqualified persons should STAY OUT OF WORK AREA.

4. A person who has not read and understood all operating and

safety instructions is not qualified to operate machinery.

NOT READING THIS MANUAL AND

SAFETY INSTRUCTIONS, WILL RESULT

IN THE INCORRECT USE OF THE

EQUIPMENT

7. WARNINGS AND SAFETY REGULATIONS

TAKE NOTE! This safety alert symbol appearing in this manual is

to bring your attention to the instructions involving your personal

safety and the safety of others. Failure to follow these instructions can

result in injury or death.

Identify, interpret correctly and respect the warning signs placed at

different points of the mixer, and the importance of properly identifying the

information and recommendations contained in this manual, contributes

unambiguously to avoiding accidents that can cause serious damage and

injury to persons.

Therefore, the following section must be read with special attention in

order to identify and interpret quickly and correctly the warning symbols

described as follows

Symbols used in the instructions manual.

WARNING! BE CAREFUL!

YOUR SAFETY IS INVOLVED!

Generally indicates that the instruction that

accompanies it is particularly important

Look carefully at the safety messages accompanying the sign DANGER,

WARNING and CAUTION. Warning messages corresponding to each has

been selected using the following criteria:

STRAW CHOPPER

Page 7

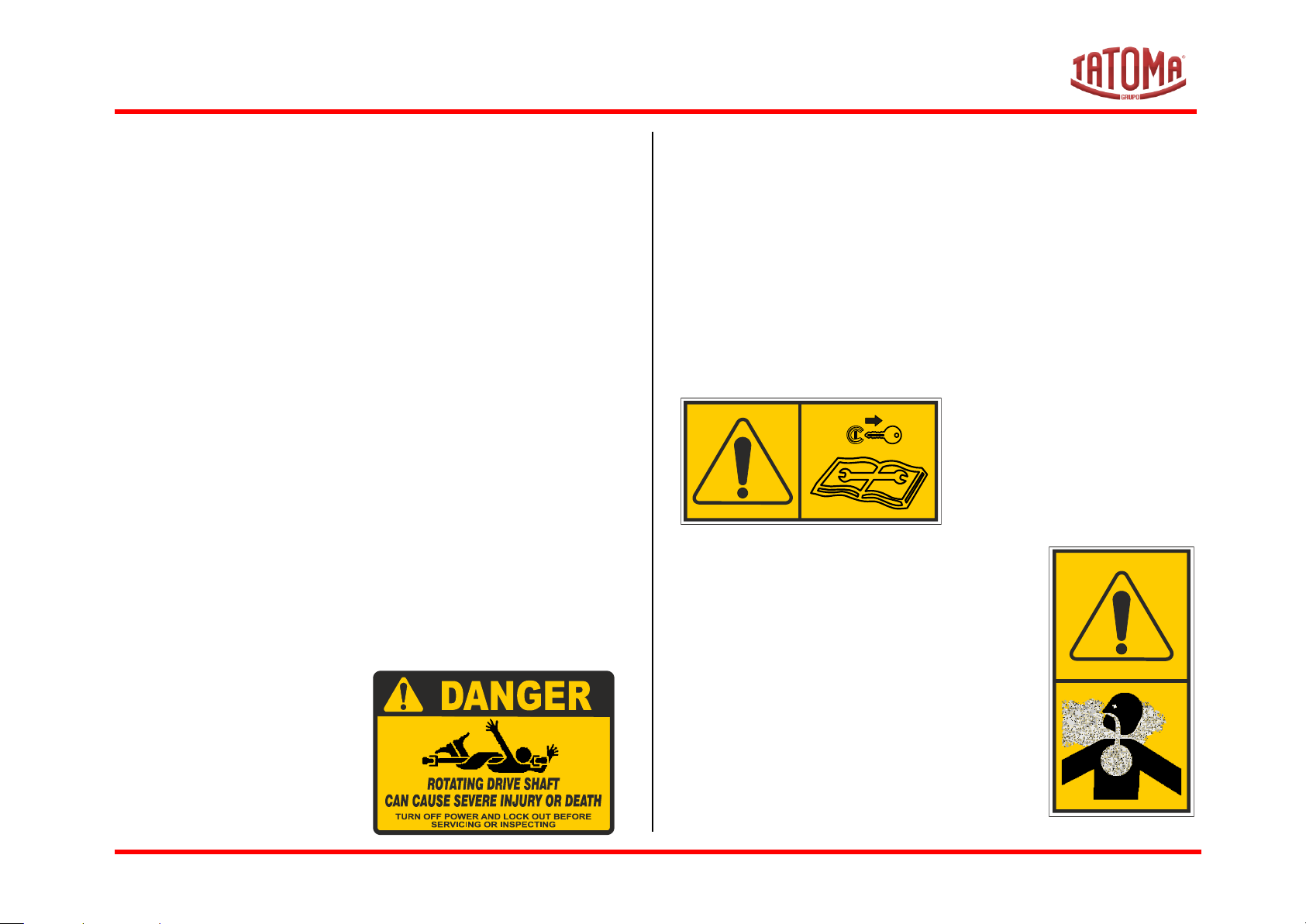

DANGER: Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury. This sign word is limited to the

most extreme situations, for machine components which due to functional

reasons, cannot be monitored.

WARNING: Indicates a potentially hazardous situation which, if not

avoided, will result in death or serious injury, and includes hazards being

exposed when the guards are removed. It can also be used to alert against

unsafe practices.

CAUTION: Indicates a potentially hazardous situation which, if not

avoided, may result in moderate or severe injuries. It can also be used to

alert against unsafe practices.

7.1. WARNING AND DANAGER SIGNS

Safety symbols located on the machines

Location

Attention! Danger, do not

open or remove protective

covers while the engine is in

operation

Side cover.

Forwarding spin to

the reel

Attention! Warning, never

lower the machine loading

system without checking if

there any people or obstacles

in the movement area

Tailgate

Warning! Danger, rotating

cardan shafts can cause

serious injury and death.

Front

Warning! Caution due to fluid

pressure. Consult the

instruction manual before

proceeding with any

maintenance

Front of the

machine

Attention! Danger, do not

climb onto the mixer while it is

running

Front

Warning! Danger, stay out of

the articulation area while the

machine is running

Drawbar

Symbols used in maintenance

Location

Lubrication point

Hitch

Bearings

Rotating shafts

STRAW CHOPPER

Page 8

7.2. SAFETY STANDARDS AND GUIDELINES

Most accidents are caused by human error, so the machine operator

must be careful and methodical and take precautions to avoid the possibility

of injury or death ..

A set of rules are described as follows whose compliance is compulsory

to avoid unnecessary risks that could lead to possible accidents.

Before you start using the mixer:

Carefully study and understand this manual.

Before starting work with the mixer, the owner

or personnel in charge of it should be familiar

with the controls, with their corresponding

duties and must carefully read this instruction

manual.

It is forbidden to perform any operation with the

mixer before having read the instruction manual

and the operator having received relevant

training by TATOMA.

Respect, in addition to the instructions

contained in this manual, the legislation on the

safety regulations and accident prevention.

Do not wear loose clothing that could get

caught in moving parts. Always wear protective clothing and footwear.

Keep the wheel nuts or bolts tightened to the specified torque (220 ft-lb),

and make sure your tires are inflated evenly.

Make a visual inspection beforehand to check for loose bolts, defective

parts or broken welds, and make the necessary repairs. Follow the safety

and maintenance instructions contained in this manual.

Make sure there are no tools on the floor, on the mixer or inside the

mixing tub.

Do not use the unit until you are sure that the area is totally clear,

especially of children and animals.

It is the responsibility of the owner or personnel in charge of the mixer, to

be aware of the lighting and meet the requirements of the local authorities

and roads and to install and maintain in good condition the components of

this equipment and comply with the regulations in force.

All operators involved in using the machine must practice the mixing

operation running on empty and the related operations of loading and

unloading, to become thoroughly familiar with them before using the mixer

when loaded.

Do not rush the learning process and do not take anything for granted, it is

essential that you become familiar with your new mixer before operating it.

Do not attempt to operate this equipment under the influence of

drugs or alcohol.

Preparing the mixer:

Before using the machine, check that all safety devices are in place and in

good condition. If the protection is removed for maintenance or a repair,

reinstall immediately after completing the maintenance or repair.

Damaged guards must be replaced immediately.

The mixer is designed to be towed by a tractor. It is forbidden to use any

other type of vehicle for towing, as the stability positions and visibility on

the different mechanisms of the mixer during use may vary considerably.

When hitching up the tractor to the mixer consider the following:

Make sure there is no one close to the mixer when reversing to bring the

tractor towards the mixer tow bar.

Use the stand to adjust the height of the machine and centre the drawbar

with the tractor, never center it manually. Carry out this operation with the

machine completely horizontal

STRAW CHOPPER

Page 9

By lowering the stand, make sure there is no risk of crushing.

Handle the hitching elements of the mixer and the tractor with work gloves

slowing the engine speed to a minimum.

Once hitched, then connect the cardan to the PTO of the tractor taking the

following precautions:

Check that the mixer has been successfully hitched up.

To prevent transmission damage, set the tractor drawbar to the

recommended setting. The mixer should be approximately level when

connected to the tractor.

Ensure that the tractor PTO has stopped.

Handle the transmission elements with work gloves.

Do not use loose clothing when performing this operation.

Do not pass or jump over the cardan.

Observe the position of the cardan protections and fix them in their

correct location using suitable devices.

After hitching up and connecting to the PTO, the parking brake must be

fully unlocked.

Startng to use the mixer:

Before accessing the tractor cab check the status of the different

mechanisms and protections of the mixer.

Adjust the driver's seat so that access to the controls of the mixer is

carried out with ease.

Adjust the tractor mirrors so as to have good visibility of the mechanisms

of the mixer without their adjustment affecting driving visibility. Help

should be enlisted of another person to perform this operation.

Check for people before putting the mixer in movement. Beware of

onlookers, especially children. Always look around to make sure it is

safe to start the engine and move the unit. If necessary indicate with the

horn or other means that the mixer is going to start moving. This is very

important because with the noise levels of the tractor / mixer and

isolation of the cabins, you may not hear people shouting.

It is forbidden to handle the mixer by several people simultaneously, so

it will only be used by the driver himself.

It Is strictly prohibited to transport people, animals or any objects on the

mixer.

Under no circumstances should the mixer be used to tow other

vehicles, move or push objects or lifting loads. It is forbidden to enter the

mixer through the loading device or that people use it as a system to

reach raised points.

To maneuver check that no people or obstacles are behind the mixer or

close to it, if there is not sufficient visibility enlist the help of others.

Driving with the mixer:

The mixer must be driven in accordance with the ground or road

conditions on which it is driven.

Driving long journeys with the loading system of the mixer in an elevated

position is totally forbidden.

STRAW CHOPPER

Page 10

Keep a safe distance from ditches, canals, ditches, slopes, forrows,

etc.., as the ground can give way and cause the mixer and the tractor to

overturn. ...

Access to the mixer, or proximity to the work area thereof should be

forbidden to any person outside the establishment in which it operates.

When working with the mixer, the operator shall verify at all times that

no one is in the work area. Similarly the operator must also inform

personnel near the work area about the risks involved there.

During loading of the machine the driver should ensure that there is no

one on the silage. When loading directly into the tub from an automatic

the driver should remain inside the vehicle at all times. If the load is

carried with auxiliary vehicles, access to the area should be prohibited to

those working on them. Never exceed the load capacity of the mixer.

Observe the work area and terrain, watch out for holes, rocks or other

obstacles. Always inspect the area before the operation.

Avoid sudden starts and stops. Choose a uniform level as a route during

transport through the fields.

Do not use the mixer near the edge of unlevel ground or terraces. Do

not operate on steep slopes. Operate from top to bottom and not

perpendicular to the slope.

Operate the vehicle at a safe speed. Slow down before turning to

prevent tipping. Avoid sharp turns on steep hills.

Always keep the vehicle running to provide engine braking when going

downhill.

Road transport:

Comply with state and local laws governing highway safety and

movement of farm machinery on public roads.

When driving on public roads with the mixer the rules of the Highway

Code must be observed and respected.

To maneuver or drive with the mixer on the road the loading system

(depending on the model) should be in the transport position.

Use approved accessory lighting, flags and warning devices necessary

to protect operators of other vehicles on the road during day and night

transport.

Avoid overhead , electric and

telephone wires or other obstacles.

Contact with overhead lines could

cause serious injury or death.

STRAW CHOPPER

Page 11

The use of flashing amber lights is acceptable in most areas, however,

some prohibit their use. All highway lighting should be checked and the

requirements of local laws must be followed.

When driving the mixer on the road or motorway below 20 mph (40 kph)

at night or during the day, use flashing lights or rotating amber warnings

and / or of a slow moving vehicle (SMV) with the identification emblem.

Plan your route to avoid heavy traffic. Be a courteous and safe driver.

Always yield to traffic in dangerous situations such as narrow bridges,

intersections, etc.

Observe load ratings and the height of bridges and tunnels. Do not cross

bridges or tunnels rated below the weight or overall height of the tractor-

mixer.

During operation. Elements in Motion:

Do not lean inside the tub, or manipulate the product inside it, when the

mixer is operating.

If it is necessary to access the tub bear in mind that there is a danger of

falling. Access to the tub must be performed exclusively by experienced

personnel, with the chopper at a standstill and with the ignition key

launch in the possession of the person who accesses it.

Before accessing the inside of the tub, as an additional security

measure, disconnect the cardan shaft from the tractor PTO.

It is strictly prohibited to incorporate devices into the mixer, which

provide access to tub with a height above the last step of the staircase.

Operate with extreme caution

when handling the moving parts

of the mixer and make sure

there are no people near these

items before their operation, on

the contrary, the driver of the

mixer should proceed to warn

and evacuate the work area.

Do no open the machine protections when they are running or handle

moving elements such as the unloading belt, etc..

Do not clean, lubricate or adjust the mixer while it is moving

Caution, do not wear loose clothing when approaching the moving parts

of the mixer or the PTO and cardan. Alway check that all guards and

safety protection are in their correct position and in good condition.

As a precaution, recheck the mixer every 100 hours of operation.

Correct any problems and follow the maintenance safety procedures.

Never leave the mixer unattended without supervision.

Maintenance work. High pressure fluids, Welding ...:

It is the responsibility of the owner

and / or operator of the mixer to

ensure it is well maintained. Poor

maintenance is an invitation to

problems and failures.

The area where the maintenance work of the

machine is to be carried out should have

sufficient ventilation. Never do this work with the

vehicle engine running in an enclosed building.

Exhaust gases can cause asphyxiation.

Before working inside the mixer, stop the vehicle

completely, apply the parking brake, disengage

the PTO and power cables, turn off the engine

and remove the ignition key.

Make sure all moving parts of the accessories

have completely stopped before performing any

maintenance.

STRAW CHOPPER

Page 12

Always use a security system to lock the wheels, such as parking

chocks. Never use a jack to support or sustain the machine while

performing such work.

Always use tools and equipment best suited for the type of work done by

hand. Always wear protective gloves and use extreme caution when

making adjustments.

Replace all covers and guards after repairs and before moving the

mixer.

After work, ensure that all tools, parts and equipment that have been

involved in the service are put away separately.

Fluid escaping under pressure

can penetrate the skin and wounds

through small openings and cause

serious injury or death.

Avoid this hazard by relieving

hydraulic pressure before

disconnecting any hydraulic line.

Tighten all connections before

applying pressure.

Never use your hands to

locate hydraulic leaks in

pressurized pipes. Look for

possible leaks with a small

piece of cardboard which

shows the oil and protect

hands and body from high

pressure fluids.

If an accident like this should occur, go to the nearest medical facility

immediately. The fluid injected into the skin must be surgically removed

within a few hours or gangrene may result.

Do not allow grease to accumulate and eliminate any spilled oil

immediately from the ladder and operator platform and other access

areas .Keep access to all areas clean and free of obstructions.

Never replace the original screws with others of less than grade eight

(8.8), unless otherwise specified.

A first aid kit should always be accessible when carrying out

maintenance work on this mixer.

When performing welding work on the mixer avoid current flowing

through the ball bearings or rollers chains directly grounding the item

being welded.

Clean the area before welding and have a fire extinguisher accessible at

all times.

When welding always disconnect , the weighing scale, load cells and the

power supply, preventing current passing through them. Also disconnect

the tractor alternator if the mixer is hooked to the mixer when performing

welding work.

An exploding tire can cause

serious injury. Do not exceed

the recommended tire pressure.

See the Specifications section

of the Instructions to apply the

correct tire pressure.

Replace worn or damaged tires.

corresponding to the fitted tire.

See the Specifications section

of the Instruction´s Manual, to

ascertian the correct tire size.

STRAW CHOPPER

Page 13

Do not weld to the rim with the tyre fitted. Welding can cause an

explosion of the air / gas mix caused by the wheel on catching fire due

to high temperatures.

Preventive and safety labels:

Adhesive labels concerning safety are placed in visible places near the

mechanisms they refer to. Keep the labels clean and visible and replace

them when deteriorated

Identify them correctly and respect the indication on the warning signs at

all times.

The mixer operator must remember the meaning of the labels and the

indications contained in this instruction´s manual.

7.3. INSTRUCTIONS AND PRECAUTIONS ON THE JOB

Loading Instructions:

Visually inspect the mixing system before each load.

Never overload the mixer. The mixing capacity is determined by product

weight. An overloaded mixer will not mix properly, and require more

force, which could damage the unit.

Move the shredders to adjust the length of the cut. Always begins with a

retainer, preferably in the rear, fill the first hole fill and increase until the

cutting length is correct. The shredders at maximum can cause damage

to the quality of the mixture.

Add components to the mixture in the following order:

First load the more fibrous products such as hay, with the tractor PTO at

1000 rpm approximately, continue adding materials in a balanced

fashion finishing with the most fragile towards the end of the load.

Towards the middle of the mixture, and the concentrated ingredients and

the driest are added.

Then load the chopped grass silage and / or other highly moist products.

Finally add the molasses, animal fats and / or other liquid supplements.

Prolong mixing several minutes to homogenize the mixture after adding

the last ingredient. This time will depend on the particular conditions of

each product.

Inspect the mixing operation only from the observation platform of the

machine. For safety, do not allow more than two people onto the

platform at the same time.

If forced to make a stop when loading the mixer, resume mixing as

progresively as possible to avoid escesivas stresses and strains that

may cause any component to break.

Before loading bales, both round and square, remove all kinds of

wrappers, cords and wires.

STRAW CHOPPER

Page 14

8. MAINTENANCE INSTRUCTIONS

WARNING. ALWAYS DISCONNECT PTO and remove keys from the

tractor before adjusting , lubricating or any maintenancein this machine.

THE LACK OF ATTENTION CAN CAUSE SERIOUS PERSONAL INJURY

OR DEATH.

During periodic maintenance work and the repair of the machine parts

requires replacement, these must be genuine factory parts used to

restore equipment, following the specifications of the original parts.

TATOMA does not assume any responsibility for the use of

unauthorized parts and / or accessories that may cause damage as a

result of their use.

If the equipment has been altered in any way from its original design,

TATOMA accepts no responsibility for the warranty or possible injuries.

Lubrication

Disengage the drive and to turn off the power before lubricating the

machine.

Do NOT wear loose clothing which may snag in the moving parts.

Grease the transmission shafts every 8 hours of operation, and the

universal joints.

The machine tanks should be filled with hydraulic oil -04 T SAE 10W.

Service Oil Filter : All filters should be changed 24 hours after start

system up, and after during regular maintenance every 500 hours. Filter

elements should not exceed 10 microns. The liquid level of all the tanks

must be checked daily to ensure that it is correct . Visually inspect

daily for leaks .

Reducer / Multiplier: After the first 500 hours of operation, drain oil

preferably when the box is hot. For an oil change effectively, the unit

should be cleaned with a liquid detergent, preferably recommended by

the lubricant supplier and refill with clean oil. From then on the oil should

be changed every 2000 hours or 12 months, whichever occurs first. Fill

the gearbox with 75W-90 synthetic lubricant.

Recommendation: the oil level should be checked of the gear box to at

least once a month once a month. If after the revision more than 10% of

the Total capacity needs to be added, check for oil leaks .

Temperature of the reducer housing: in normal operation conditions ,

the temperature of the outer casing of the reducer should not exceed

175 ° F (80 ° C ).

STRAW CHOPPER

Page 15

Lubrication table:

8.1. AFTER WORK:

After operation, set the brakes, disconnect all power units, stop the

engine and remove the keys from the ignition.

Store in an area away from human activity.

Do not park the mixer where it may be exposed to animals for long

periods of time. It could damage the equipment and cause injury to

livestock.

Do not allow children to play around the stored unit. Make sure the

machine is parked on a hard, level surface without compromising the

safety devices.

Use the footrest to park the machine horizontally. Remember that this

footstand can only withstand vertical loads.

If necessary place parking chocks on the wheels to prevent the unit from

moving.

COMOPONENT

TYPE OF LUBRICANT

INTERVALS

Unloading belt

Light oil

Brush or spray lightly every 40

hours of operation.

Bearings

Quality grease

Every 8 hours

Transmission

shaft.

PTO.

Quality grease

Every 8 hours.

In each lubrication ensure

cardan shaft comes out freely,

any slip fault can cause damage

to the driveshaft.

Wheel Bearings

Lithium based grease

Every 12 months.

Universal Joints

Quality grease

Every 8 hours

CV Joints

Quality grease

Every 8 hours

Hydrostatic

system

Hydraulic fluid:

T-04SAE10W

Only when the system has been

contaminated.

Reducer

Step up gear

speed

Synthetic Gear Lube

75W -90

After the first 500 hours of

operation, then every 2000

hours or 12 months, whichever

occurs first

Oil Filters

24 hours after the system startup.

Normal maintenance every 500 hours in service.

STRAW CHOPPER

Page 16

8.2. TROUBLESHOOTING:

PROBLEM

POSSIBLE CAUSE

POSSIBLE REMEDY

Machine Vibration

Universal joints misaligned.

Worn bearings

Check and realign.

Machine vibration

Universal joints misaligned.

Worn bearings

Check and realign.

Excessive bearing

failure

Improper lubrication.

See lubrication table .

Contamination.

Check the seal.

Excessive load.

See the information

about the machine load.

Poor quality mix,

not fully mixed

The load has a high

concentration of light

ingredients and rotates

too quickly inside the

hopper.

Extend the shredders

into the hopper, as

described in 5.3

High concentration of long

straw.

Does not tear.

Extend the shredders

towards the inside of the

hopper, as described in

5.3

Straw is added to

the load, but not

mixed.

The mixing action is

unable to cut up the

straw, as the load inside

of the hopper rotates too

quickly.

Extend the shredder

towards the inside of the

hopper, as described in

5.3

Too much power

consumption on

mixing

Shredders

are extend too deeply into

the hopper slowing

rotation.

Extend the shredders

less into the hopper, as

described in 5.3

NOTE:this table does not cover all the problems that may arise . Contact

your dealer for further assistance.

9. USE AND CONSERVATION MANUAL

This manual is intended for users of the mixer, the owner, the personnel in

charge of it and the specialist who performs the maintenance.

The manual serves to indicate the correct handling of the mixer, provide

information about its technical characteristics, training of personnel in charge

of it, maintenance and warning of possible hazards or failures.

This manual should be kept in a safe place for future reference. The

instruction manual must accompany the mixer at all times.

In case of loss or damage, the user can contact TATOMA and request a

new copy of this manual, specifying the serial number, model and year of

manufacture of the mixer, data inscribed on the CE plate.

TATOMA reserves the right to modify the design or specifications without

prior notice.

The user can at any time contact the manufacturer to make any inquiry as

to the correct use of the mixer.

STRAW CHOPPER

Page 17

REMEMBER

Under no circumstances use the mixer for other purposes than those

specified in this manual and for which it was designed, ie, the mixing of

different products for livestock feed.

Your best assurance against accidents is a careful and responsible

operator. If there is any part of this manual or function you do not

understand, contact your dealer or the TATOMA factory.

Warning! In addition to the above, other rules, warnings and statements to

be taken into account when operating the mixer are included throughout the

instruction manual.

Warning! The said standards, as well as the warnings and indications

contained in this instructions manual, should at all times be complementary

with that in force in terms of Health and Safety at Work.

TATOMA declines all responsibility for damage or injury to people or material

damage caused by non compliance of the regulations, warnings and

indications included in this instructions handbook, as well as the non-

compliance of the regulations in force in terms of health and safety in the

work place or the incorrect use of the machine itself.

This manual suits for next models

5

Table of contents

Other Tatoma Farm Equipment manuals