Tavistock Axiom SAX2341 Parts list manual

Push Button Control Shower Valve

INSTALLATION & AFTERCARE INSTRUCTIONS

Retain for future reference REF: GEN1FCLICKAR.10.19| V1

This guide covers the installation of:

1 Function Push Button Shower Valve

INTRODUCTION

OPERATING CONDITIONS OF USE AND COMPLIANCE

Thank you for choosing this product. This guide covers the installation and commissioning of

the shower valve - for the installation of the associated shower accessories, please see separate

instructions supplied.

This shower valve must be installed in accordance with the Water Supply (Water Fittings) Regulations

1999. We recommend this product should only be fitted by a qualified plumber.

Before installation the operating conditions of use must be checked. The table below contains

details of the necessary conditions of operation. This valve is suitable for high pressure (BS1111)

operating conditions. Valves cannot operate effectively where a hot or cold pressure system crosses

the boundaries of the two ranges. In addition the maximum ratio of unbalanced hot and cold water

pressures for the valves to operate effectively is 2:1. Hot or cold pressure must be reduced or boosted

so as to work within the required range.

These shower valves are suitable for use with all water supply systems up to a maximum of 5.0 Bar.

Operating pressures above 5.0 Bar will require the installation of pressure reducing valves.

The valve must be installed so that it is readily accessible for commissioning and maintenance. The

valve is supplied with isolation valves on both the hot and cold inlets so as to allow the valve to be

commissioned and tested correctly. The valve is fitted with integral check valve cartridges which

command the water supply, therefore the thermostatic valve is protected against cross-flow due to

unbalanced line pressures as required by the Water Supply (Water Fittings) Regulations 1999.

MAX STATIC BAR 10 BAR

1.0 - 5.0

55 - 65

MAX 25

MAX 44

HIGH PRESSURE BS1111

FLOW PRESSURE (BAR)

HOT & COLD

HOT SUPPLY (OC)

COLD SUPPLY (OC)

MIXED WATER (OC)

WHATS IN THE BOX

Before installation please ensure all components are present. The following illustrations can be used as

a guide and used for reference during installation - illustrations are intended as a guide only, style and

sizes vary depending on system chosen.

Installation Frame

Flexible Hoses

Fixing Spanner

Zip Tie

Tile Guide

Fixing Screws

Isolation Valves

(Assembled to Installation Frame)

Cover Plate

Valve and Housing

Horizontal

Horizontal

Vertical

BEFORE INSTALLATION

Before installation, decide if the valve will be installed horizontally or vertically. Both options are

available with this valve and use similar installation methods. This guide shows horizontal installation for

illustrative purposes.

Most problems associated with the operation of thermostatic shower valves are caused by debris in the

new pipe work getting into the thermostat. These problems are easily avoided by thoroughly flushing

the pipe work BEFORE the valve is fitted. Failure to do so may invalidate your guarantee.

This valve is designed to be installed in stud constructions using timber of a suitable depth as to allow

the full installation frame to fit onto the stud (Figure 1). The centre point between the two studs will be

the final position of the valve. To ensure successful installation, the frame needs to fit correctly between

the two studs without deforming the frame. If necessary use spacers to create the correct fit.

Figure 1

1. Position the installation frame between the two studs or noggins at a suitable height for its final

installation position. The front of the frame and the front of the timber stud should be flush (Figure 3).

Use a spirit level placed on the tiling guide to make sure the installation frame is level both front to back

and left to right. Once level remove the tile guide and keep the fixing screws safe for later steps.

For vertical installations, timber noggins should be installed between studwork to allow for the frame to

be fixed vertically. (Figure 2)

When fitting the installation frame in either orientation, keep the tile guide assembled as this will ensure

that the frame does not warp or bend during installation and also allow a spirit level to be used for

accuracy.

Figure 2

INSTALLATION INSTRUCTIONS

Figure 3

Vertical

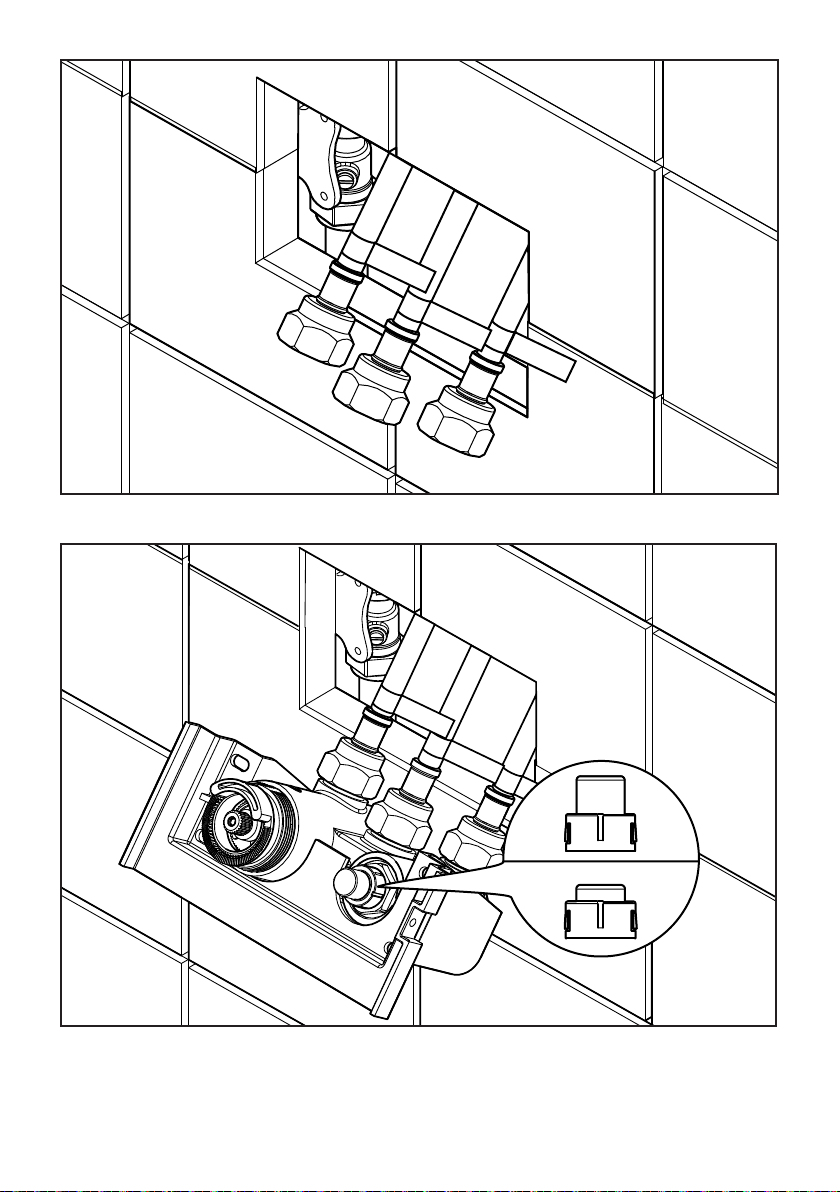

2. Once the frame is installed, remove the plastic tile guide. Install the supply pipework to the isolation

valve and the brass manifolds. The hot water feed should be installed into the left hand manifold and

the cold water feed to the right hand manifold. Ensure the isolation valves are mounted so that they will

be visible and accessible for later stages (Figure 4).

3.With the water inlet supplies installed, install outlet pipework using suitable plumbing fittings. Ensure

that there is enough room to route pipework to the chosen outlet location.

Figure 4

Figure 5

Brass Manifold

Isolation Valve

These fittings are used with flexible hoses to

connect the valve to inlets and outlets

H

H

C

C

4. Connect the flexible hoses to the manifolds - ensure that each hose has a rubber washer inserted at

each end to create a watertight seal. Once connected, label each hose with the corresponding inlet /

outlet - this will help easily identify which hose is which during later installation stages.

5. At this point it is critical that leak tests are performed. Connect the valve body to the flexible hoses

- the hot and cold inlets are marked with red and blue paint on the valve. Turn on the water supply and

test the system for leaks. Push the button for the outlet and check all connections are fully sealed.

HOT COLD OUTLET 1

Figure 6

Figure 7

6. Once satisfied that there are no leaks, turn the water supply off and disconnect the valve from the

flexible hoses. Before installing plasterboard and tiles, use the zip tie provided to tie the ends of the

hoses together to make them easier to access later.

You are now ready to apply the nal nished surface.

7. Reattach the tile guide using the fixing screws. Cut a hole in the plasterboard using the tile guide to

determine position and sizing.

Tip: There are pins in the corners of the tile guide to help mark its position on the plasterboard to use as

a cutting template.

Figure 8

Figure 9

HOT OUTLET 1

COLD

8. Once a hole has been cut in the plasterboard, secure it to the stud. The tile guide should pass

through the hole in the plasterboard. Tile up to the edges of the tile guide to ensure the correct size

access hole. Failure to do so may mean the cover plate does not form a water-tight seal in later

installation stages.

9. Remove the tiling guide, allowing access to the pipework behind the tiled wall. Keep these screws

safe as they will be used to mount the valve. From this position the isolation valves should be visible

and accessible through the access hole.

Figure 10

Figure 11

10. Pull the flexible hoses through the access hole in the wall and remove the zip tie.

11. Working from left to right, using the labels as a guide, connect the hoses to the valve. Ensure the

hose from the hot supply is connected to the inlet marked hot on the valve. Do the same for the cold

supply. Ensuring the outlet button is in the ‘OFF’ position (Figure 13), turn the water supply back on at

the isolation valve. Do not overtighten the hoses as this may damage the rubber washers.

Figure 12

Figure 13

OFF

ON

12. Lift the valve and push the hoses back through the access hole, making sure the hoses do not kink

(Figure 14). Position the valve flat against the tiles and line up the fixing holes with those on the metal

installation frame. Secure the valve to the fixing frame.

Note: Tighten xing screws with a screwdriver to prevent over-tightening. Do not use an electric

driver as this may damage the valve housing or cause it to warp, preventing correct installation. If

the housing ange is not at against the wall surface, the xing screws are too tight.

You are now ready to install the cover plate and valve controls.

13. When secured in place, the fixing nuts of the flexible hoses will be visible above the valve housing.

This will allow the connections to be checked for leaks and for the hoses to be tightened slightly, if

necessary, without removing the entire valve.

Figure 14

Housing Flange

Figure 15

Fixing Nut

Button Spring

Button

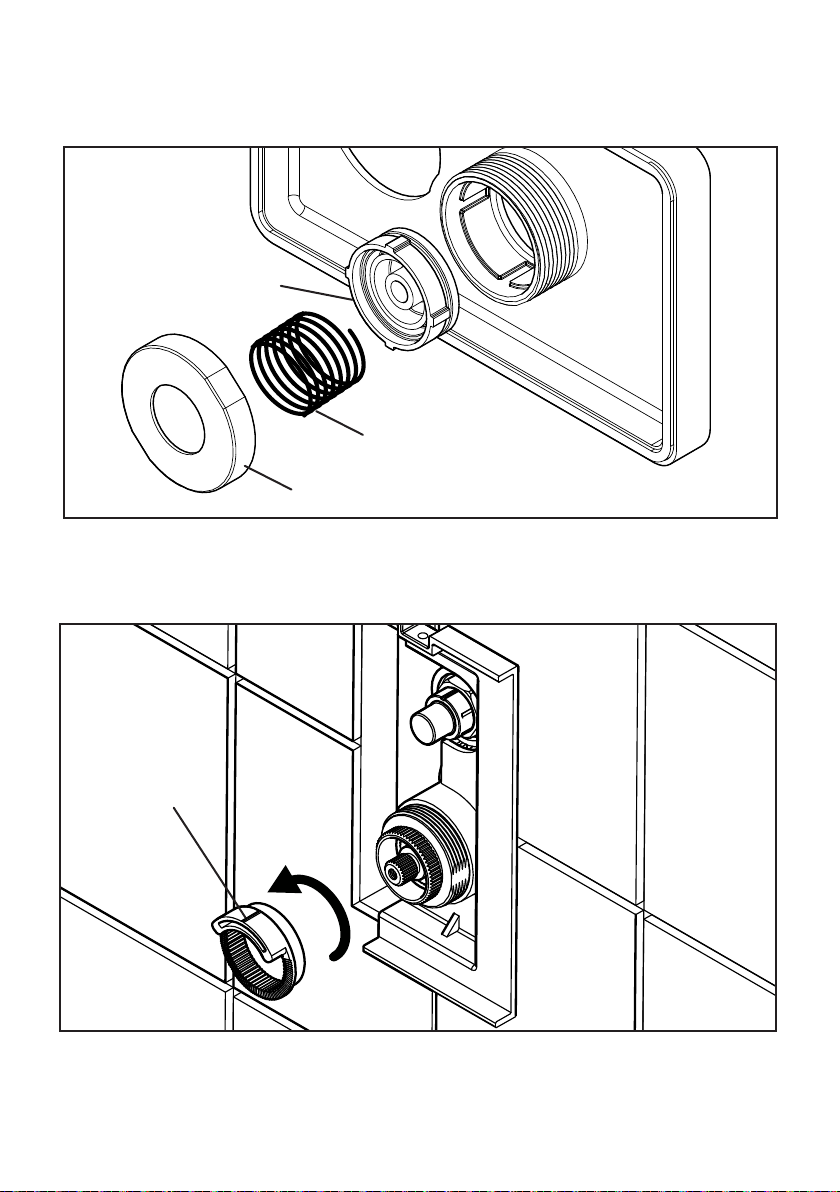

Remove the brass fixing nut from the back of the cover plate, as shown above. This will allow the etched

button and spring to be removed. Rotate the button 90 degrees and reassemble to the cover plate.

(Figure 16). There are four slots which ensure the button is located correctly. With the spring assembled

inside the channel on the back of the button, reassemble the brass fixing nut.

NOTE: For horizontal installations, the cover plate can be tted immediately - proceed to Step 14.

For vertical installation the control button and temperature stop need to be removed and rotated

so that they are in the correct orientation. To do so, follow the below instructions:

The temperature stop ring is installed onto the temperature cartridge fixing nut on the valve. This

prevents the maximum temperature from being exceeded when in use. For vertical installations the

temperature stop ring needs to be removed and rotated 90 degrees as shown (Figure 17)

Figure 16

Temperature

Stop Ring

Figure 17

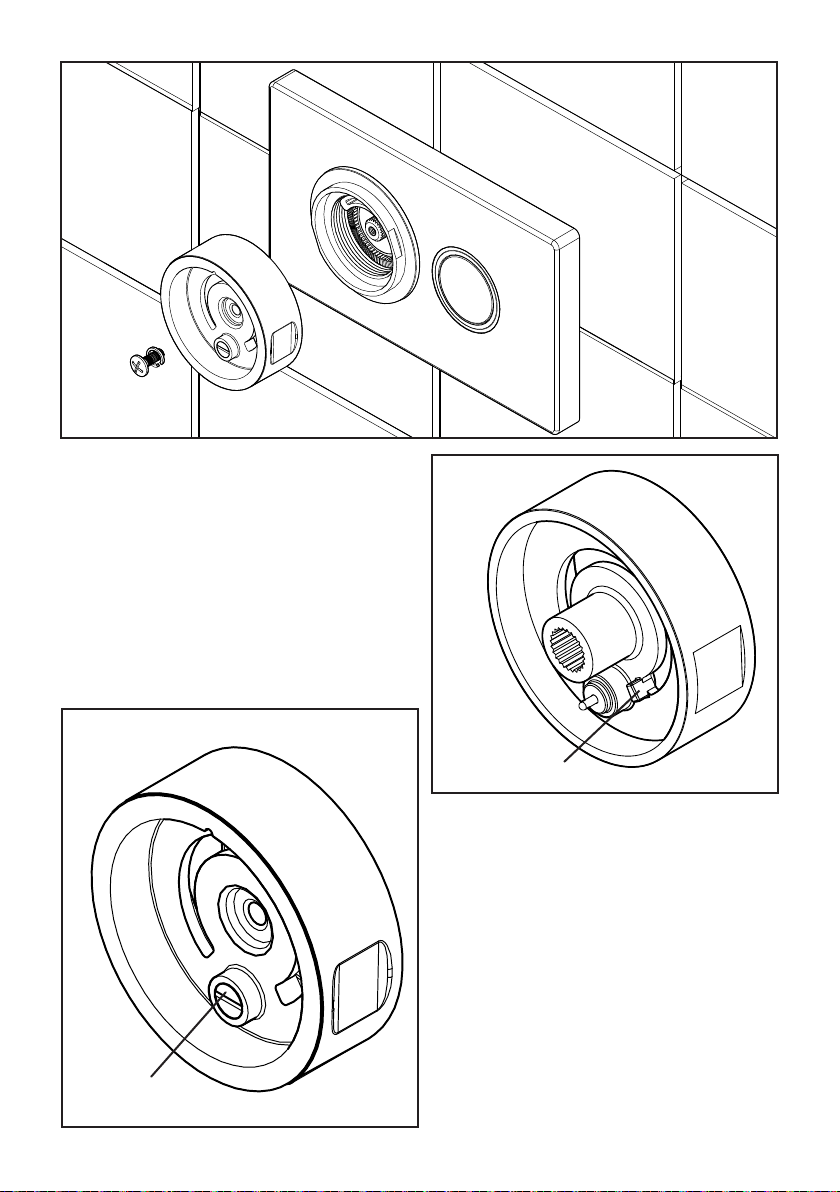

14. Position the cover plate over the valve housing and fix in place with the cover plate fixing nut.

Tighten the plate to the wall with the tool provided making sure not to scratch the cover plate. Make

sure the cover plate is level and that the button is in line with those on the valve. The cover plate is fitted

with an integrated foam seal - it is not necessary to use silicone sealant.

You are now ready to set the maximum temperature of the valve.

15. With all outlet buttons checked for smooth operation, using a thermometer, test the temperature

of the water from the outlets. Rotate the cartridge spindle anti-clockwise to increase the temperature

and clockwise to reduce the temperature until the water from the outlet reaches the maximum

recommended temperature of 44ºC. Leave the cartridge spindle in this position.

Figure 18

Figure 19

16. On the rear of the handle is a handle stop

that sits against the right hand side of the valve

temperature stop ring to prevent the handle

being rotated past the pre-determined maximum

temperature position. Without moving the

temperature spindle, position the handle onto the

cartridge so that it cannot rotate anti-clockwise.

Note: Do NOT remove the temperature stop ring

to make adjustments as this will prevent correct

assembly later.

17. Once installed, the handle should click as it

rotates. This click can be adjusted to give more

feedback when in use.

Rotating the feedback screw clockwise will

make the pin stiffer and the click will be more

noticeable - rotating the screw anti-clockwise will

loosen the pin and soften the click.

Figure 21

Figure 20

Feedback Screw

Handle Stop

18. With the handle installed, the centre dial can be pushed into place. The dial has a tab that fits into

the temperature stop ring via a gap in the handle. To remove the dial for maintenance, line up the notch

in the centre dial with the notch on the handle and use a small screwdriver to separate the two parts.

Installation is now complete.

Figure 22

TESTING AND ANNUAL SERVICING

It is recommended that showers do not exceed 44°C. The valve temperature should never exceed

46°C. After commissioning, carry out the cold failure test to ensure the valve operates at the correct

outlet temperature.

The valve should be tested to ensure correct operation during installation and thereafter at stated

intervals decided by the user but never at greater than 12 monthly intervals. The testing will only require

a normal thermometer with a scale greater than 65°C. The temperature sensitive element of the

thermometer should always be fully inserted into the water flow.

Follow the procedure below:

1. Measure the mixed water temperature.

2. Carry out a cold fail/safe shut-off test by using the mains isolation valve to shut off the water to the

cold supply. Wait 5 seconds, if water is still flowing check that the water temperature is below 44°C.

The flow should stop or reduce to a trickle.

3. Open the cold water isolation valve and measure mixed water temperature. If there is no significant

change from the original settings and fail/safe shut off is functioning the valve is working correctly and

no further service is required. If the outlet temperature has drifted by more than 2°C, or if the fail/safe

function does not work, a full service or re-commissioning is required. We recommend that in these

circumstances you contact a plumber.

TROUBLE SHOOTING

If you require further assistance beyond the guide below, including replacement parts, please contact

customer services using the contact details on the back of this guide.

PROBLEM

After installation, shower only runs Hot or Cold -

there is no mixed water.

Shower will not run hot enough when first

installed.

Cold water is running back through the valve

and into the hot water system.

SOLUTION

Check and clean the check valves located on

the hot and cold inlets on the valve. These may

need to be replaced.

The maximum temperature needs to be

adjusted - see the temperature setting guide in

this manual.

Hot & Cold supplies are plumbed the wrong

way around. Remove the valve from the wall and

check the plumbing connections to the valve.

The valve does not turn on even when the

button is pressed.

The button operation is not smooth and

sometimes scrapes.

In some cases this may be caused by over-

tightening the cover plate during installation

which can cause the buttons to become

partially pressed. Loosening the cover plate

fixing nut slightly should fix this.

Remove the cover plate and reassemble

ensuring that the valve buttons and cover plate

are correctly aligned to avoid interference.

Check you have correctly turned the isolation

valves to the ‘on’ position for both the hot and

cold supplies.

There is no water running to the valve

Customer Services, Brassmill Lane Trading Estate, Bath, BA1 3JF

Tel:01225 303 900

This manual suits for next models

3

Table of contents

Other Tavistock Bathroom Fixture manuals

Popular Bathroom Fixture manuals by other brands

LOOOX

LOOOX PILLAR ROUND user manual

Hans Grohe

Hans Grohe Verso 220 Showerpipe 27237000 Instructions for use/assembly instructions

Kohler

Kohler K-17493 Installation and care guide

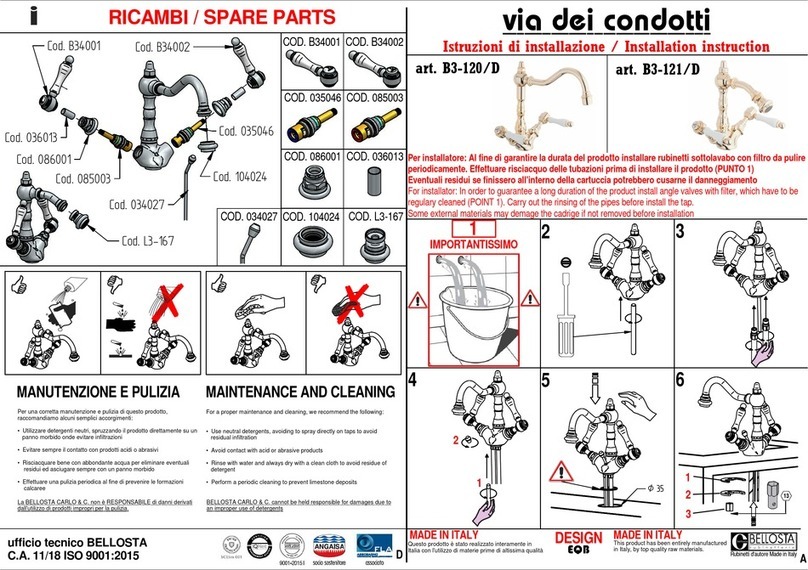

BELLOSTA

BELLOSTA via dei condotti B3-120/D installation instructions

Gessi

Gessi OUTDOOR 63204 manual

WimTec

WimTec SanRec SMART Installation and operating instructions