TAVRIDA ELECTRIC ISM Shell_2 Series Instructions for use

ISM Shell_2 Series

Vacuum Circuit Breaker

15kV, ...29kA, ...2000A

Applications Manual MAN5002239

Revision 4

2

3

Safety rst

· Check whether the installation position (distances, spatial separation, and the

surroundings) is suitable for the switching devices.

· Installation, operation and maintenance shall only be carried out by trained and

experienced personnel who are familiar with the equipment and the electrical

safety requirements.

· During installation, commissioning, operation and maintenance of the equipment

the relevant legal regulations, accident prevention regulations and the connecting

conditions of the electric utilities shall be followed.

· Take note that during operation of the vacuum circuit breakers certain parts are

subject to dangerous voltage. Mechanical parts, also remote-controlled, can move

quickly. Failure to comply may result in death, severe personal injury or damage

to equipment.

· Pay attention to the hazard statements located throughout this manual.

· The operating conditions of the vacuum circuit breakers shall comply with

the technical data specied in this manual.

· Personnel installing, operating and maintaining the equipment shall be familiar

with this manual and its contents.

For special congurations please contact TAVRIDA ELECTRIC NA.

The following installation and operating Instructions contain information necessary

for the methods of use, installation, commissioning and operation. It is absolutely

necessary for the proper use of the vacuum circuit breakers to read the Installation

and Operating Instructions carefully before starting and to adhere to the instructions

and the relevant regulations.

4

1

2

3

4

Table of Contents

1. Introduction

• Applicability ....................................................................................................................................................................................................8

• Hazard Statements.......................................................................................................................................................................................8

• Safety Instructions........................................................................................................................................................................................8

• Denitions.........................................................................................................................................................................................................9

• General ...............................................................................................................................................................................................................9

• Design and Method of Operation: ISM and CM ..................................................................................................................... 10

2. Receiving, Handling and Storage

• Packing ........................................................................................................................................................................................................... 14

• Transport ....................................................................................................................................................................................................... 15

• Unpacking, Receiving Inspection..................................................................................................................................................... 15

• Rating Plates, Warranty Seals .............................................................................................................................................................. 16

• Storage............................................................................................................................................................................................................. 18

3. Installation

• General, Preparation ................................................................................................................................................................................ 20

• Installation of the ISM.............................................................................................................................................................................. 20

• Minimum Clearances due to Rated Insulation Voltage........................................................................................................ 22

• Minimum Clearances due to Electromagnetic Inuences.................................................................................................. 23

• Coordination of Minimum Clearances .......................................................................................................................................... 23

• Heating ............................................................................................................................................................................................................ 23

• Protective Grounding.............................................................................................................................................................................. 23

• Interlocking ................................................................................................................................................................................................... 24

• Main Contacts Position Indicator...................................................................................................................................................... 26

• Secondary Connections of the ISM ................................................................................................................................................. 29

• CM connections.......................................................................................................................................................................................... 30

• CM_16 Series Factory Programmable Options......................................................................................................................... 32

• Installation of the CM .............................................................................................................................................................................. 34

• Installation of Secondary Cables between ISM and CM...................................................................................................... 35

4. Switching and Control Functions

• Charging of the Capacitors................................................................................................................................................................... 38

• Ready-LED and Ready-Relay Output .............................................................................................................................................. 38

• Malfunction-LED and Malfunction-Relay Output.................................................................................................................... 38

• Switching the ISM On and O via the Dry Contact ............................................................................................................... 38

• Inputs of the CM......................................................................................................................................................................................... 38

• Electrical Closing Lock-Out................................................................................................................................................................... 38

• ISM Forced Trip by an Undervoltage Relay (Optional - CM_1501 Series)................................................................... 39

• Output to Magnetic Actuator and Input for ISM Position Indication........................................................................... 39

• Operations Counter.................................................................................................................................................................................. 39

• Antipumping Duty.................................................................................................................................................................................... 40

• Blocking Duty............................................................................................................................................................................................... 40

• Combined Blocking ................................................................................................................................................................................. 40

• and Antipumping Duty .......................................................................................................................................................................... 40

• Output to Magnetic Actuator and Input for ISM Position Indication........................................................................... 40

5. Commissioning, Maintenance

5

5

6

7

8

9

10

11

12

• General............................................................................................................................................................................................................. 42

• Commissioning Primary Part............................................................................................................................................................... 42

• Commissioning Secondary Part ........................................................................................................................................................ 42

• Maintenance................................................................................................................................................................................................. 43

• Non-Conformity.......................................................................................................................................................................................... 43

6. Signalling

• LED Indicators and Dry Contacts ...................................................................................................................................................... 46

• Malfunction Indication Table .............................................................................................................................................................. 47

7. Special Applications: Fast Switching

• Fast Transfer Switching ........................................................................................................................................................................... 50

• Arc Flash Mitigation.................................................................................................................................................................................. 51

8. Product Line

• Indoor switching modules (ISM)....................................................................................................................................................... 54

• Control modules (CM15 Series) ......................................................................................................................................................... 54

• Control modules (CM16 Series) ......................................................................................................................................................... 54

9. Dimensions and Weights

• Dimensions and Weights of the ISM ............................................................................................................................................... 56

• Dimensions and Weights of the CM................................................................................................................................................ 59

• Dimensions of the Position Indicator............................................................................................................................................. 60

• Dimensions of Mating Part for Interlocking Shaft................................................................................................................... 60

10. Circuit Diagrams

• ISM15_Shell_2 with CM_1501_01.................................................................................................................................................... 63

• ISM15_Shell_2 with CM_16_1............................................................................................................................................................ 64

11. Technical Data

• Indoor Switching Modules (ISM)....................................................................................................................................................... 67

• Control Modules......................................................................................................................................................................................... 68

12. Regulations and Ambient Conditions

• Regulations.................................................................................................................................................................................................... 73

13. Legal Information

• Warranty.......................................................................................................................................................................................................... 75

• Quality Regulations .................................................................................................................................................................................. 75

• Complaints and .......................................................................................................................................................................................... 75

• Transport Damage..................................................................................................................................................................................... 75

• Environmental Friendliness.................................................................................................................................................................. 76

• Non-Conformity Report......................................................................................................................................................................... 76

• Liability............................................................................................................................................................................................................. 76

• Copyright........................................................................................................................................................................................................ 76

6

1THIS PAGE INTENTIONALLY LEFT BLANK

7

Introduction 1

8

Applicability

This Technical Manual applies to a range of Indoor Circuit Breakers (ISM) manufactured by Tavrida Electric.

The following products are covered by this manual:

ISM15_Shell_2(150)

ISM15_Shell_2(210)

ISM15_Shell_2(275)

The model number is shown on the equipment rating plates. If your equipment does not correspond to this number then

this manual is not applicable. Please contact your nearest Tavrida Electric oce.

Every care has been taken in preparation of this manual. However, please note that not all the details or variations

in the equipment or process being described can be covered. Neither is it expected to address all contingencies

associated with the installation and operation of this equipment. For any further information please contact your nearest

Tavrida Electric oce.

Hazard Statements

This manual contains three types of hazard statements, as follows:

DANGER: Indicates an imminently hazardous situation that, if not avoided, will result in death or serious

injury.

WARNING: Indicates a potentially hazardous situation that, if not avoided, could result in death or serious

injury.

CAUTION: Indicates a potentially hazardous situation that, if not avoided, could result in personal injury

or equipment damage.

Safety Instructions

General hazard statements applying to this equipment are described in this section. Statements relating to specic tasks or

procedures are located throughout this manual.

DANGER: Contact with hazardous voltage will cause death or severe personal injury. Contact with Recloser

or Control Cubicle terminals should only be undertaken when equipment is isolated from

applicable sources of voltage.

WARNING: This equipment is not intended to protect human life. Follow all locally approved safety

procedures when installing or operating this equipment. Failure to comply may result in death

or severe personaly injury.

WARNING: Before working with equipment descriped in this manual carefully read and understand the

contents of this manual. Improper handling, installation, operation or maintenance can result

in death, severe personal injury or demage to equipment.

WARNING: Power distribution equipment must be properly selected for the intended operation. It must be

installed, used and understand all relevant safety procedures. Failure to comply can result in

death, personal injury or equipment damage.

1

9

Denitions

The following abbreviations are used in this operating manual:

AR Automatic reclosing

CM Control module

CO Close open cycle

ISM Indoor switching module

LED Light emitting diode

MCB Miniature circuit breaker

Make time

The make time is the time period from the energising of the closing circuit to the time when the current begins to

ow in the rst pole.

Closing time

The closing time is the time period from the energising of the closing circuit to the time when all three poles make

contact.

Pre-arcing time

Interval of time between the initiation of current ow in the rst pole during a closing operation and the instant

when the contacts touch in all poles for three-phase conditions or the instant when the contacts touch in the

arcing pole for single-phase conditions.

Opening time

The opening time is the time period from energising of the closing circuit up to the time when all the switching

poles are separated.

Break time

The break time is the time period from the energising of the closing circuit up to the time when the arcs of all the

poles are extinguished.

Open-close time (during AR)

Interval of time between the instant when the arcing contacts have separated in all poles and the instant when the

contacts touch in the rst pole during a reclosing cycle.

Dead time (during AR)

Interval of time between nal arc extinction in all poles in the opening operation and the rst reestablishment of

current in any pole in the subsequent closing operation.

NC Normally closed contact

NO Normally open contact

PCD Pole center distance

SCADA Supervisory control and data aquisition

VCB Vacuum circuit breaker

VI Vacuum interrupter

General

In comparison to conventional circuit breakers, the Tavrida Electric vacuum circuit

breakers comprise of two components:

· The ISM (Figure 1)

· The CM for controlling the ISM and monitoring both modules (Figure 2)

Both modules must only be operated together and are meant for indoor

installations only. The possibility to choose ISM and CM separately allows any type

of switchgear to be easily equipped with regard to its primary and auxiliary circuits.

Figure 1

Figure 2

1

10

Compact design

Tavrida Electric develops and produces all vital parts of the circuit breakers themselves. The result of intensive

inhouse fundamental and material research are extremely compact vacuum interrupter and magnetic actuators.

Optimal selection of all components makes these the most compact and light weight vacuum circuit breaker in

the world.

Long life

Contact erosion is minimised by use of axial magnetic eld. All the switching elements are assembled axially and

symmetrically in one straight line. This means that all the mechanical movements are exclusively direct and linear.

30 000 operating cycles can be achieved with rated current without replacing or adjusting any components.

Maintenance free

The ISM is maintenance-free over the expected life of at least 25 years.

Highest availability

In addition to minimising the number of failure-critical components, the Tavrida Electric circuit breaker monitors

its status continuously. In the unlikely event that a fault occurs it is indicated and can be rectied before an unsuc-

cessful switching attempt is made. This leads to higher availability of the electric power supply system.

Design and Method of Operation: ISM and CM

The ISM vacuum circuit breaker uses three single-coil magnetic actuators, one per pole. The three actuators are

mounted in a steel frame and mechanically linked by a synchronizing shaft (Figure 3).

1. Support insulator

2. Upper terminal

3. Vacuum interrupter

4. Movable contact with bellows

5. Lower terminal

6. Pulling insulator

7. Actuator stator

8. Opening and contact pressure springs

9. Actuator coil

10. Actuator armature

11. Synchronizing shaft

12. Auxiliary contacts

13. Interlocking shaft

14. Main contacts position indicator link

15. Frame

16. Fixing points

Figure 3

View into the ISM

Indoor Switching Module (ISM)

1

2

3

4

6

7

10

13

5

14

15

12

11

16

8

9

1

1. Terminals

2. LED indicators

3. Fastening holes

4.

Grounding stud

Control Module (CM)

3

2

1

Figure 4

Control Module

11

Closing

In the open position the contacts are kept open by the force of the opening springs. To close the contacts

the coils of the magnetic actuators are excited by a current impulse of the close capacitors of the CM. As a

result the contacts close. At the same time the opening springs are compressed. In the closed position the

contacts are kept closed by means of the magnetic force only. The ISM maintains the closed position

without mechanical latching also in case of a failure of the auxiliary power supply (Figure 5).

Opening

To open the contacts a current impulse in the reverse polarity derived from the opening capacitors of the

CM is injected in the coils of the magnetic actuators releasing the magnetic holding force. The compressed

opening springs and contact pressure springs open the contacts (Figure 5).

Manual-Emergency-Tripping

The ISM can be tripped mechanically without auxiliary power supply (emergency trip). It may be opened

manually by means of interlocking shaft rotating counter-clockwise. The interlocking cam of interlocking

shaft act on the armature, when then starts to move (refer to chapter“Installation/Primary part/

Interlocking”, page 24). As the air gap increases, the opening springs and contact pressure springs

overcome any magnetic holding force and the module opens.

Manual Closing

The ISM can only be closed electrically via the CM. In the case of a failure of auxiliary power supply the

contacts can be closed using an alternative auxiliary power supply such as a battery. Mechanical closing is

not possible and leads to the destruction of the ISM.

Position main

contacts

Actuator coil

current

Anchor travel

Anchor velocity

Open

Closed

Open

Closed

0

0

0

Close command CM (dry contact)

Close impuls to ISM-coils

Start anchor movement

ISM main contacts closed

Stop anchor movement

Switch o actuator

current for close operation

Trip command CM

(dry contact)

Trip impuls to ISM-coils

ISM main contacts open

Open position kept by

opening springs

0 20 40 60 80 100 120 140 160

Time (ms)

Figure 5

Typical oscillograms of ISM operation

1

12

1THIS PAGE INTENTIONALLY LEFT BLANK

13

Receiving, Handling and

Storage

2

14

Packing

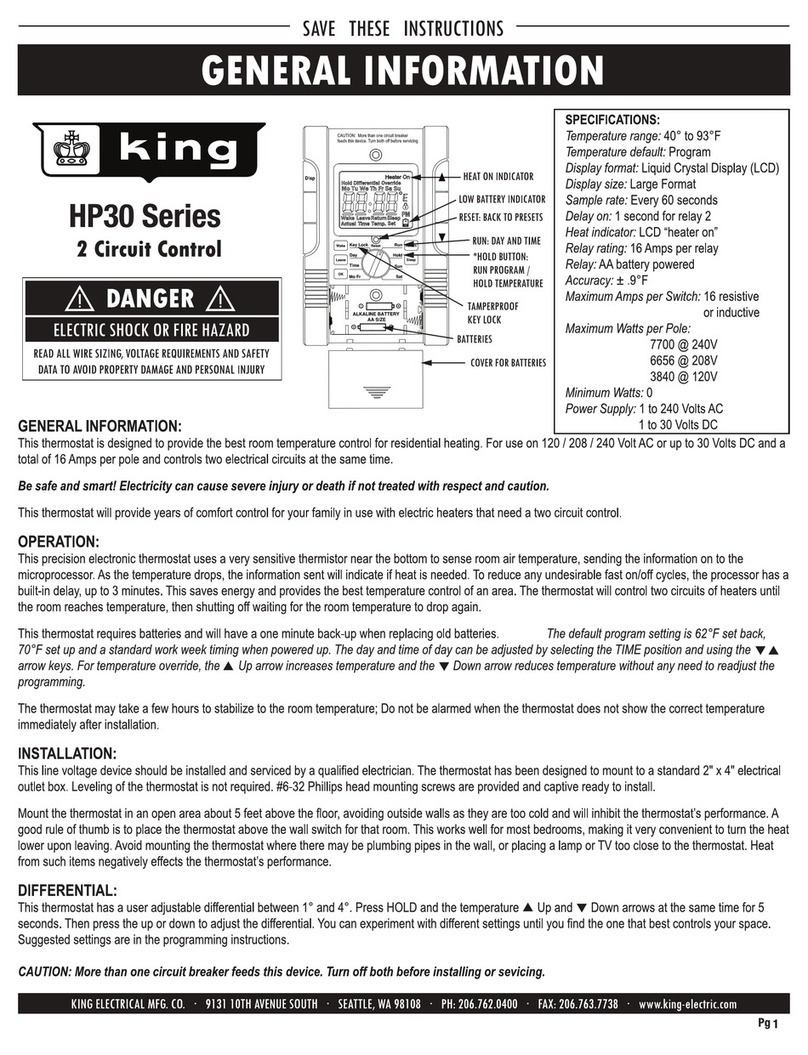

The following information are provided on the ISM packing cartons (Figure 8):

· Handling symbols for transport and storage of the delivery unit (Figure 6)

· Label 1 for manufacturers´ and product information (Figure 7)

· Label 2 for logistics data (Figure 9)

35522

Figure 6

Handling symbols

Figure 7

Label 1 for manufacturers´

and product information

Figure 8

ISM carton package

Figure 9

Label 2 Logistics data

3 421 1. This side up

2. Fragile

3. Protect from rain

4.

Max. weight on

the delivery unit

5. Serial number

5

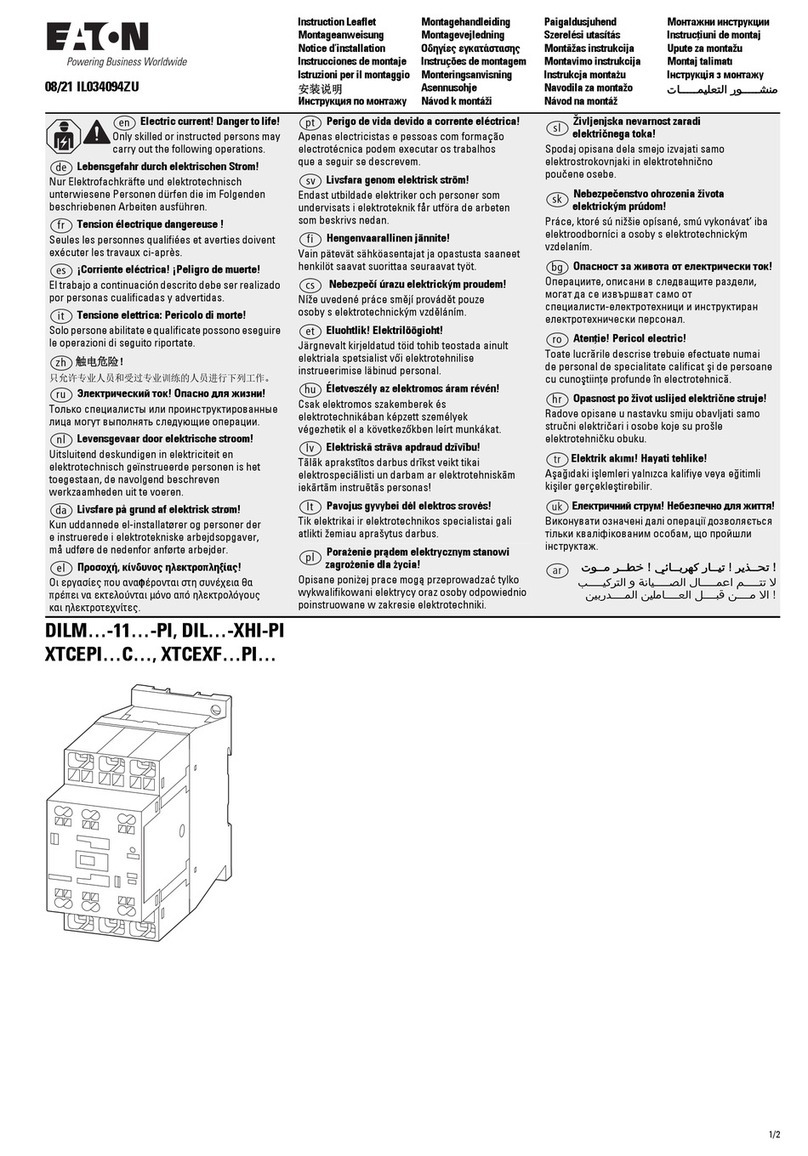

A label with the following information is xed on each CM carton package (Figure 10).

1 2

3

4

5

6

1. Manufacturer

2. Product name

3. Type of device

4.

Serial number

5. Product code

6.

Carton package for

CM/TEL…-12-01A

(265x220x55 mm)

A CM carton package must not have a weight of more than 30 kg applied to it.

Figure 10

CM carton package and label

17.10.2006

Mark: TEG-C-000111

Place of delivery:

Consignee:Address

Address

Address

Address

Address

Phone:

Contact person

P/O Number: Customer reference

Article: Article description

Serial Number:

TAVRIDA ELECTRIC AG, Wetterkreuz 3, 91058 Erlangen, Germany,Phone: 0049-9131-972079-0

Consignee:

35522

2

15

Transport

ISM and CM shall be transported in the original packing only. The packed goods shall be handled in accordance with

the handling symbols. Loading procedures for ISM packing units shall be carried out only with fork lifts or cranes.

If possible the ISM packing unit shall be placed on a palette. Lifting gear must not be attached to the support

insulators. During transportation the ISM and CM must not be hit or dropped.

Unpacking, Receiving Inspection

Before unpacking, please check the carton for damage and dampness. Removal of the products from the original

packing must be carried out with due care. Every ISM and every CM shall be subject to a completeness control.

Scope of delivery for the ISM:

ISM Screwdriver Operating manual Routine test certicate

1x

Main contacts position indicator.

Length of exible link is 1,0 m.

AXCA. 305449.002

Figure 11

Insulating caps optional

6x

AXCA . 757559.014, for contact arms with 50mm

diameter, lenght of the insulation cap is 176 mm

6x AXCA . 757559.015 for contact arms with 74 mm

diameter

6x

AXCA . 757559.016 for contact arms with 50 mm

diameter, lenght of the insulation cap is 203 mm

2

16

2

Scope of delivery for the CM:

CM Screwdriver Routine test certicate

Figure 12

The devices should be checked visually for:

· Mechanical damage, scratches, discolouration, corrosion

· Damage to the seals (Figure 17, Figure 18)

Any transport damage must be reported immediately to the carrier in writing.

Cases of damage must be photographically documented.

Rating Plates, Warranty Seals

Please check that the rating plates of the delivered devices correspond to the data of the order. The rating plate

for the ISM contains the following information (Figure 13):

1. Manufacturer

2. Type of device

3. Rated maximum voltage

4.

Rated impulse withstand voltage

5. Rated dielectric withstand voltage

6.

Rated frequency

7. Single capacitor bank breaking

current

8.

Cable charging breaking current

9. Year manufactured

1

2

3

4

5

6

9

10

Figure 13

Rating plate

7

8

11

12

13

14

15

16

17

18

10.

Rated operating sequence

11. Applicable ANSI stan-

dards

12. Rated continuous current

13. Rated short circuit current

14. DC component percen-

tage

15. Rated short time current

16. Interrupting time

17.

Pole centre distance

18. Weight

17

2

The rating plates for the CM1501 series contain the following information (Figure 14):

Breaker Control Module

Model CM_16_1(60)

Power Supply Input

19-72

25 W for 10s (charging)

5 W steady state

Input must be

protected by a two pole

miniature circuit breaker

rated: 4A, type B or C

Fault / Ready Relays

Max 240 16A

See circuit breaker

applications manual for

detailed information and

DC load break capacity.

Operating Conditions

-40C to +55C ambient

IP40 degree of protection

Operating Duty

O-0.3s-CO-10s-CO-10s

Conforms to

UL STD 508

Certied to

CAN/CSA-22.2 No.

142-M1987

Tavrida Electric North America

1105 Cliveden Ave, Delta, BC, Canada

1-866-551-8362

Made in Russia

4000068

1

2

3

4

5

4

6

7

8

9

1. Model type

2. Auxiliary power supply min / max

3. Power consumption

4.

Warning notes

5. Output contact maximum voltage / current

The rating plate for the CM16 series contain the following information (Figure 15):

1

2

3

4

5

6

7

8

9

The CM_16 has an additional label for factory programmable settings (Figure 16); see page 32 for detailed

information on the settings functions.

1

2

1. Settings

2. QR code (scannable settings code)

3. Applicable breaker type

3

6.

Operating conditions

7. Operating duty cycle

8.

NRTL listing / conformance mark

9. Contact information

Figure 14

Figure 15

Figure 16

18

3

Arrangement of the labels (Figures 16, 17):

3 1 2

ISM

1. Rating plate

2. Serial number

3. Seal

CM

1.

Seal

2. Serial Number, date of manufacturing

3.

Product code

Figure 17

Labelling ISM

Figure 18

Labelling of the CM_16

The manufacturer accepts no warranty for a device if the seal is broken or has been removed.

Storage

Should immediate installation not be possible, the ISM and CM shall be stored in the original packing under the

following conditions:

· The ISM is switched o.

· Dessicants must be placed in the packing.

· Storage must be dry, well ventilated and the room temperature should be between - 40°C and + 40°C

(IEC694/ DIN VDE 0670 Part 1000).

· If several ISM are stacked a maximum of two layers is permitted.

· If several CM are stacked a maximum of 10 vertical layers is permitted.

If CM are stored longer than one year, the built-in capacitors shall be charged according to the following procedure before

putting into operation:

· Switch On auxiliary power supply to CM for 20 seconds.

· Switch O auxiliary power supply to CM for one minute.

· Repeat the described switching on and o procedure two times.

· Switch On auxiliary power supply to CM for at least 8 hours.

2

3

1

19

Installation 3

20

Primary part

General, Preparation

The following regulations must be adhered to during installation, commissioning and operation:

· IEC 60694/DIN VDE 0101, General specication for high-voltage switchgear and control gear standards.

· VDE 0105, Operation of electrical installations.

· DIN VDE 0141, Ground systems for electrical power installations with nominal voltages above 1 kV.

· All rules for accident prevention applicable in the respective countries.

The wearing of gloves for handling the parts during installation

is recommended.

Insulating material surfaces must be cleaned with clean and

dry rags. The contact surfaces of connections must be cleaned

before installation. If the contacts have become oxidized

during transport or storage then the following sequence must

be followed:

· Clean contact surfaces with a rough, dry cloth.

· With hard oxidation, clean with a hard plastic sponge,

the upper layer must not be removed.

For ISM xing and terminal connections steel bolts according

to EN ISO 898 class 8.8 (800 N/mm²), nuts according to EN

ISO 890 class 8 (880 N/mm²), washers to DIN 125 and conical

spring washers to DIN 6796 shall be used.

ISMmountingandconnectionshallbemadewithdynamometic

wrench only.

Installation of the ISM

In any switchgear application, the ISM shall be installed with

the actuator drive axis vertical (Figure 16). ISM may be

installed in position“actuator up”, as well“actuator down”

(for all types).

The ISM shall be installed at the place designated for it on a

suciently stable frame. In order to prevent bending loads

at the support insulators the poles must be xed as shown in

gure 20. The torque of all xing points shall not exceed the

values stated in gure 20.

Vertical installation

position of the ISM (draw out type)

Vertical installation

position of the ISM (draw out type)

Figure 19

3

This manual suits for next models

8

Table of contents

Other TAVRIDA ELECTRIC Circuit Breaker manuals

Popular Circuit Breaker manuals by other brands

Westinghouse

Westinghouse DB-75 manual

FEDERAL PIONEER

FEDERAL PIONEER H-3 INSTRUCTIONS FOR THE CARE AND MAINTENANCE

GE

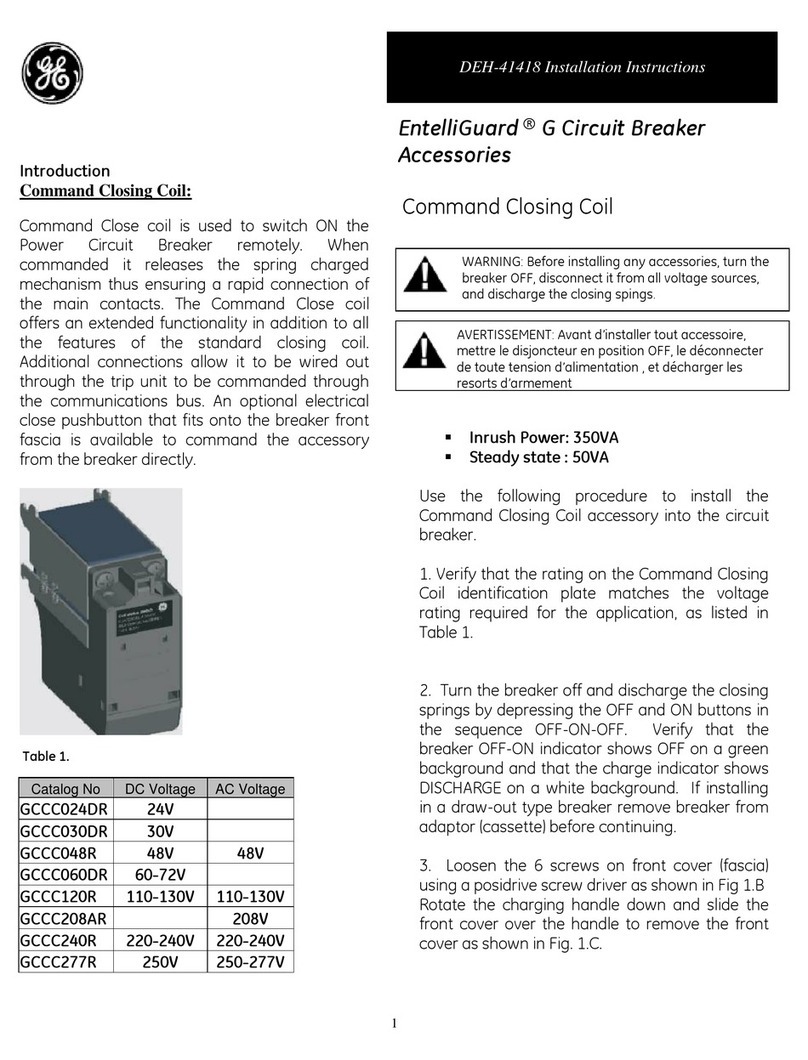

GE GCCC024DR installation instructions

ABB

ABB DEH41820 Installer's instructions

ABB

ABB HPA 12kV Instruction for Installation, Service and Maintenance

Eaton

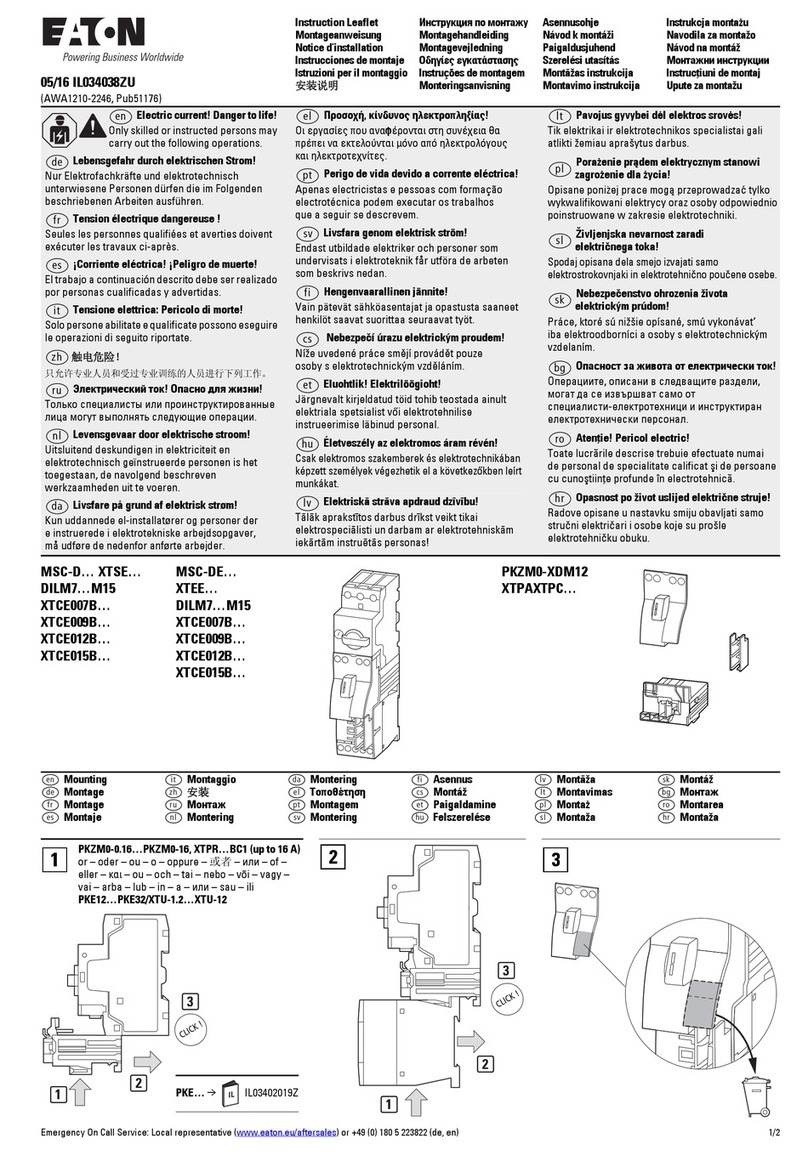

Eaton MSC-D XTSE Series Instruction leaflet