Introduction

Command Closing Coil:

Command Close coil is used to switch ON the

Power Circuit Breaker remotely. When

commanded it releases the spring charged

mechanism thus ensuring a rapid connection of

the main contacts. The Command Close coil

offers an extended functionality in addition to all

the features of the standard closing coil.

Additional connections allow it to be wired out

through the trip unit to be commanded through

the communications bus. An optional electrical

close pushbutton that fits onto the breaker front

fascia is available to command the accessory

from the breaker directly.

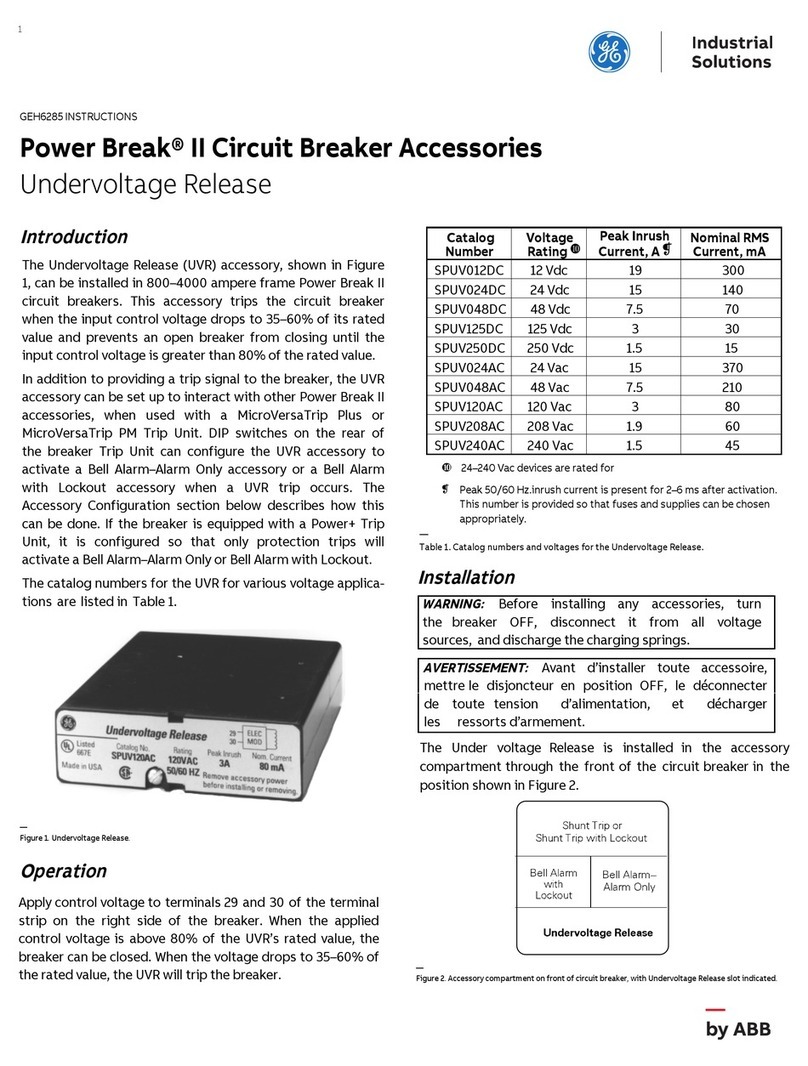

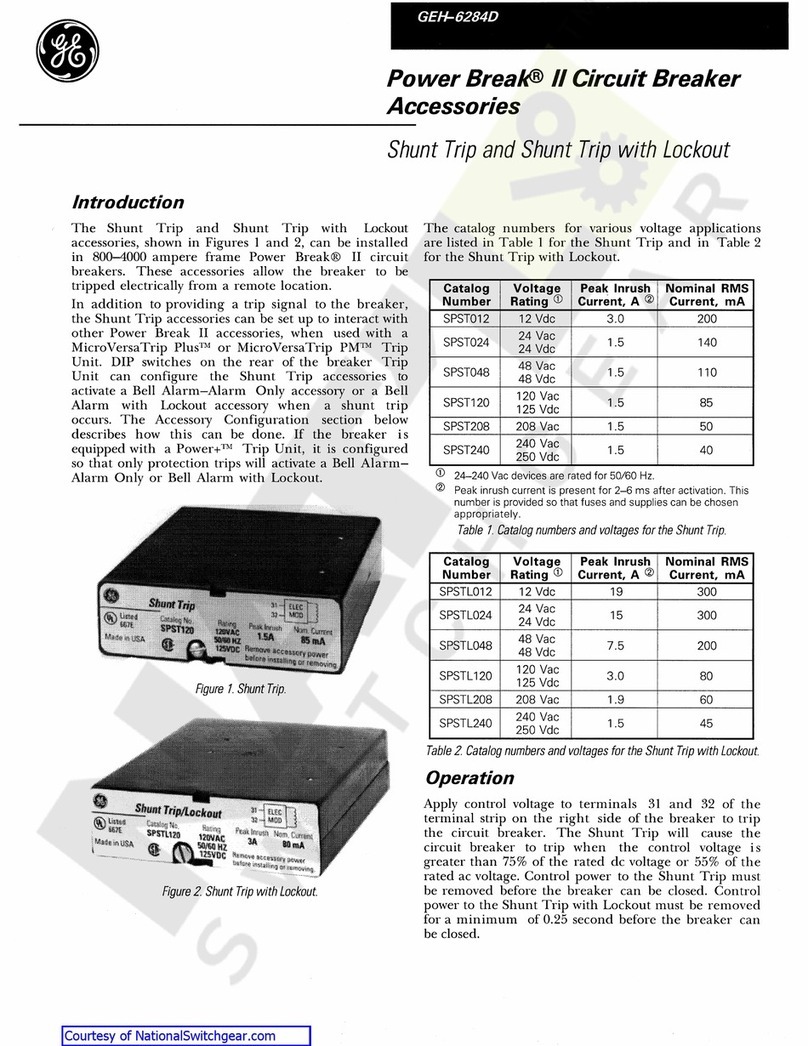

Table 1.

▪Inrush Power: 350VA

▪Steady state : 50VA

Use the following procedure to install the

Command Closing Coil accessory into the circuit

breaker.

1. Verify that the rating on the Command Closing

Coil identification plate matches the voltage

rating required for the application, as listed in

Table 1.

2. Turn the breaker off and discharge the closing

springs by depressing the OFF and ON buttons in

the sequence OFF-ON-OFF. Verify that the

breaker OFF-ON indicator shows OFF on a green

background and that the charge indicator shows

DISCHARGE on a white background. If installing

in a draw-out type breaker remove breaker from

adaptor (cassette) before continuing.

3. Loosen the 6 screws on front cover (fascia)

using a posidrive screw driver as shown in Fig 1.B

Rotate the charging handle down and slide the

front cover over the handle to remove the front

cover as shown in Fig. 1.C.

DEH-41418 Installation Instructions

EntelliGuard ®G Circuit Breaker

Accessories

Command Closing Coil

WARNING: Before installing any accessories, turn the

breaker OFF, disconnect it from all voltage sources,

and discharge the closing spings.

AVERTISSEMENT: Avant d’installer tout accessoire,

mettre le disjoncteur en position OFF, le déconnecter

de toute tension d’alimentation , et décharger les

resorts d’armement