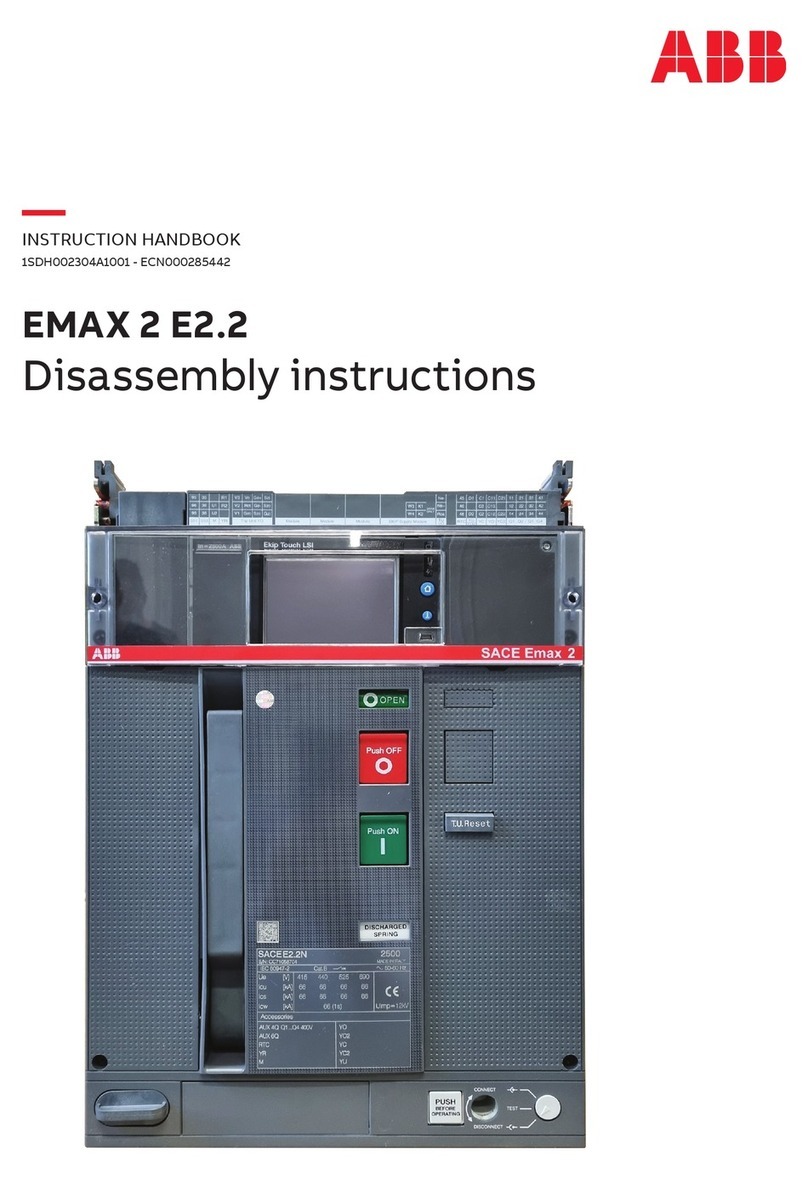

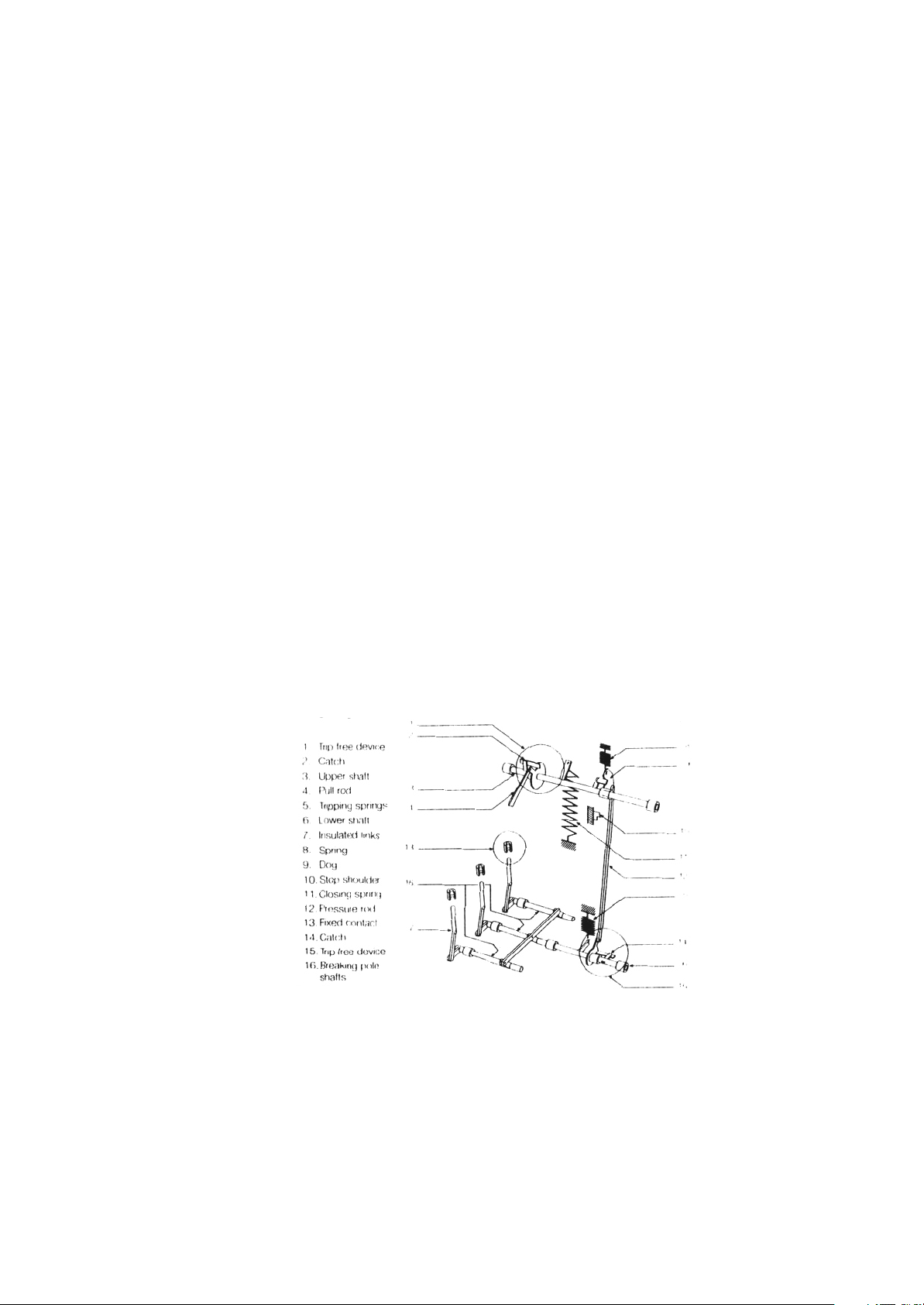

1.2.2 Operating mechanism

The operating mechanism has a spring charging device which can be

operated by motor or by hand. Once a closing command has been given it is always

completed by the breaker; this is important in the event of short circuit. Since, the

circuit breaker closes completely before it opens, the correct contact speed and full

breaking capacity are obtained. The operating device has compression springs for

closing and opening. The opening spring is charged automatically when the breaker

is closed. A closed breaker with charged closing springs can be operated open - close

- open without intermediate motor or manual charging and the breaker can therefore

be used for auto re-closing. Charging of the closing spring can be discharged by

disconnecting the voltage to the motor and manually operate the breaker close -

open.

An indication shows whether the closing spring are charged or not and the number of

opening operations are recorded on a counter.

The motor can be supplied via a station battery, a network or via a voltage transformer

with a limit load of at least 300 VA. The motor starts after each closing operation and

charges the closing springs within 9 seconds. The breaker is fitted with a knob for

mechanical openings and with magnetic coils for closing and openings. The same

operating mechanism is used for all types of HPAbreaker.

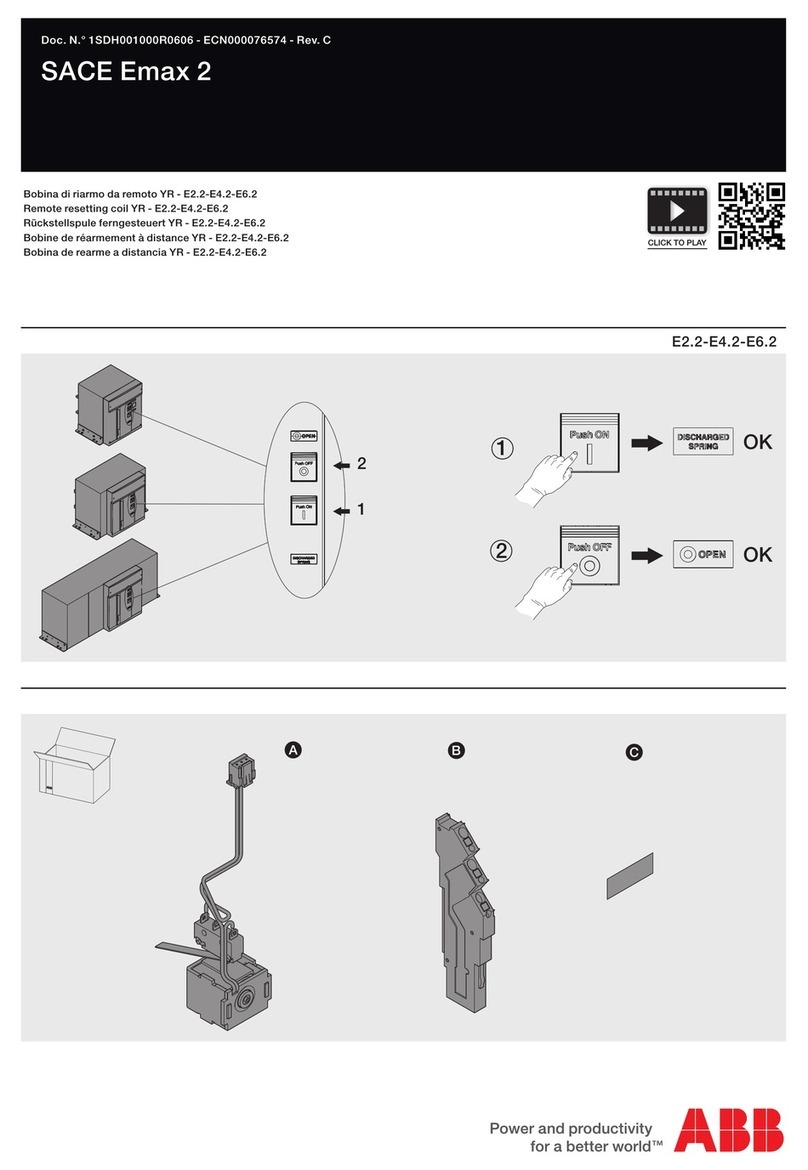

The construction of the operating mechanism is shown in fig. 4. The device has two

shafts. The lower shaft (6) is connected to the breaker poles via links and is directly

actuated by the openings springs (5). The upper shaft (3) is connected directly to the

closing spring (11). These two shafts are linked via the driving disc (9) and the link

(12), and by the trip free device (14). The upper shaft is also connected to the charging

device via the trip-free device (1) and the link (4).

The latching and trip-free devices (1) and (14) are of the same type that have been

used inABB equipment since 1950 and have proven extremely reliable.

The motor operated unit consists of a toothed transmission gear with an eccentrically

driven tooth wheel as a last step. The operating device also contains auxiliary

contacts and trip coils.

(6)

Fig - 4

(Principle diagram of Circuit Breaker)