TAWI Light60 User manual

TAWI Lightweight Lifting Trolley

This is the original version of the TAWI High Frequency Lifter user manual.

Manufacturer:

Business name: TAWI AB

Address: Transportgatan 1, 434 23 Kungsbacka, Sweden

Hereby declares that:

Type of machinery: Lifting Trolle

y

Product name:

Light60

Complies with the requirements of Machinery Directive 2006/42/EC

Complies also with applicable requirements of the following EC directives:

2014/30/EU

2011/65/EU (RoHS)

The following other standards and specifications have been applied:

EN ISO 12100:2010

EN 349+A1:2008

ISO 22915-16:2015

EN ISO 3691-5:2015

EN 12895:2015

EN 1175-1+A1:2010

EN ISO 13849-1:2008

EN 60204-1

Person authorized to compile the technical file:

Name: David Ranfal

k

Business name: TAWI AB

Address: Transportgatan 1, 434 23 Kungsbacka, Sweden

Signature:

Place and date: Kungsbacka 2021-02-01

Name: Thomas Bräutigam

Position: President Lifting Automation Division

EC DECLARATION OF CONFORMITY OF THE MACHINERY

Original

Directive 2006/42/EC, Annex II, A

This declaration is applicable only if the product(s) has/have been installed according to TAWI’s

instructions and provided that the product(s) has/have not been modified in any way.

Contents

1 Safety & important information 04

WEEE, RoHS and REACH 07

Do not make modications 07

Markings and labels on the TAWI Light Trolley 07

2 Warranty 09

3 Overview 10

Loading 11

4 Assembly 12

Unpacking 12

Mounting 13

5 User instructions 14

Start the lifter 14

Charge the battery 14

Battery charging indicator 15

Operating panel 15

Brakes 16

6 Service & maintenance 16

Inspections 17

7 Troubleshoot 18

Page 04

1 Safety & important information

This chapter presents safety information about the TAWI Light Trolley lifter (hereafter referred to as

lifters). Some of the information is divided in Warning, Caution and Important. This division is based on

the severity of the consequences that may occur if the instructions are not followed. Stickers and labels

are explained in this chapter and information is provided about directives that TAWI follows.

This manual and the Declaration of conformity is only valid when using TAWI authorised tools.

WARNING: Risk of personal injuries or major material damages.

Caution: Risk of material damages.

Important: Important information is highlighted.

Page 05

WARNING

• Before operating a lifter, this manual must be read and understood.

• Always apply brakes to the rear wheels when loading and unloading.

• NEVER exceed the indicated max load capacity on the lifter.

• Make sure to load according to the load diagrams including y-distances. See Labels on TAWI Light

trolley and Loading on page 7-8.

• Make sure loads are distributed evenly on the platform and always load according to load diagram.

• If any unexpected movement of the lifter occurs, press emergency stop.

• In case of emergency, engage the emergency stop, see Operating panel on page 15.

• Make sure to control and solve any potential errors before resetting the emergency stop.

• The operator’s position should always be behind the lifter when it is used. From this position the

emergency stop is within reach.

• Stay clear of the area underneath a tool at all times.

• Stay clear of moving parts.

• During all service and maintenance, lay the lifter down on the oor (on its back).

• In order to deal with the lifter’s cables and wiring, a good knowledge of electricity and TAWI elec-

trical schedules of the lifters is required. Faults can cause damage to people and property.

• NEVER climb on the lifter.

• NEVER stand on the cover or any other part of the lifter.

• It must never be used to lift living humans or animals.

Caution

• The lifters are made for indoor use on a smooth, even oor/surface. Max allowed inclination is 4%.

• The recommended temperature range for the lifters is 10 - 50°C (50 - 122°F). The lifting performance

may vary when the temperature deviates from 20°C (68°F).

• Make sure there is good lighting in areas where the lifter is operated.

• Use caution when passing over thresholds, oor drains, hoses or cables.

• Never spray or pour water onto the casing containing the battery, charger and motor. Clean with a

damp cloth only.

• Recharge the battery in a designated dry area.

• Any part of this lifter or accessories that show signs of wear or other damage must be replaced

immediately. The lifter must not be used before the damaged part is replaced.

• Do not use the lifter while it is plugged into an outlet.

• Only run the lifter when it is completely assembled.

• Wear steel toe shoes with good grip when operating the lifter.

• NEVER adjust the limit switch setting on the limit switch module.

Page 06

Important

• To prevent damages and injuries caused by improper use and not to compromise the warranty and

liability: Follow the instructions in this manual at all times!

• Keep this manual accessible to all sta.

• The lifters are not intended for use by persons (including children) with reduced physical, senses or

mental capabilities, or lack of experience or knowledge, unless they have been given supervision or

instruction concerning use of the appliance by a person responsible for their safety. Children should

be supervised to ensure that they do not play with the lifters.

• Use only TAWI original spare parts.

• Always follow any local/national recommendations as well as the instructions in this manual.

• The lifter should only be used when they are in perfect working order.

• If the lifter is to be out of use for a longer period, ensure that the battery is connected to an outlet

for the charger to maintain the battert.

• Intermittent-duty: 10%.

• Emission sound pressure level: <70 dB (A).

• The lifters max load capacity has been tested with 10% dynamic overload and 25% static overload.

Page 07

WEEE, RoHS and REACH

TAWI follows the WEEE (Directive 2012/19/EU), RoHS (2011/65/EU) and REACH (EC 1907/2006)

regulations.

A used battery and/or circuit board should either be returned to an authorised TAWI/Lifting Light

Trolley representative or handed over to a station for chemical waste. All other parts can be discarded

and assorted for recycling.

Do not make modications

Welding and other mechanical modications to TAWI Light Trolley or accessories must be carried out

by TAWI authorised sta. According to ISO 3691-5, only if TAWI is no longer in business and there

is no successor interested in the business, the user may perform a modication/alteration to a TAWI

Light Trolley. If this is done, the modication/alteration must be designed, tested and implemented

by experts in TAWI Light Trolley and their safety. Also, a permanent record of the design, test(s) and

implementation of the modication/alteration must be maintained. Appropriate changes to the capaci-

ty stickers, labels and user manual must be made, see Markings and labels on the TAWI Light Trolley. A

permanent and visible label must be fastened on the lifter that states how the lifter has been modied/

altered together with the date it was performed. The name and address of the organisation that per-

formed the modication must also be included.

Markings and labels on the TAWI Light Trolley

Identication plate Tool Identication plate

.

Page 08

Do not use as a passenger lift! Do not

stand underneath a raised tool.

Risk of hands and feet getting caught

in machine! Do not put hands or ngers

on the mast or close to the sleigh or

belt. Risk of crushing/pinching!

Do not stand on or rest your feet on the

legs or battery casing!

This symbol precedes stated max load

capacity. Never exceed the indicated

max load capacity! Also see Loading on

page 09 for information on how to load.

Labels on TAWI Light Trolley

Always transport the lifter with the load

LOWERED Disconnect power supply before

servicing.

Read manual instructions! The oper-

ator must read and understand this

manual before using the lifter.

Take precaution!

Page 09

This chapter presents warranty information about the TAWI Light Trolley .

If a TAWI Light Trolley is used according to all instructions in this manual it will perform well for many

years. TAWI oers a one year limited guarantee, excluding transportation charges, provided that the

lifter has been used under normal working conditions (one shift and then recharged) and in accordance

with the instructions in this manual. Non compliance with rules and instructions in this manual will

result in complete exclusion of TAWI´s liability.

Please contact your TAWI representative for further information.

2 Warrant

Page 10

3 Overview

a

b

d e

j

i

f

g

c

h

a. Mast

b. Control panel

c. Emergency stop

d. Leg

e. Identication plate

f. Rear wheels with brakes

g. Battery charging indicator

h. Handle

i. Platform

j. Front wheels

Page 11

Loading

The max lifting capacity of the lifters depends on where the mass centre of the load is located in terms

of x. The graphs in the load diagram display allowed x-distances.

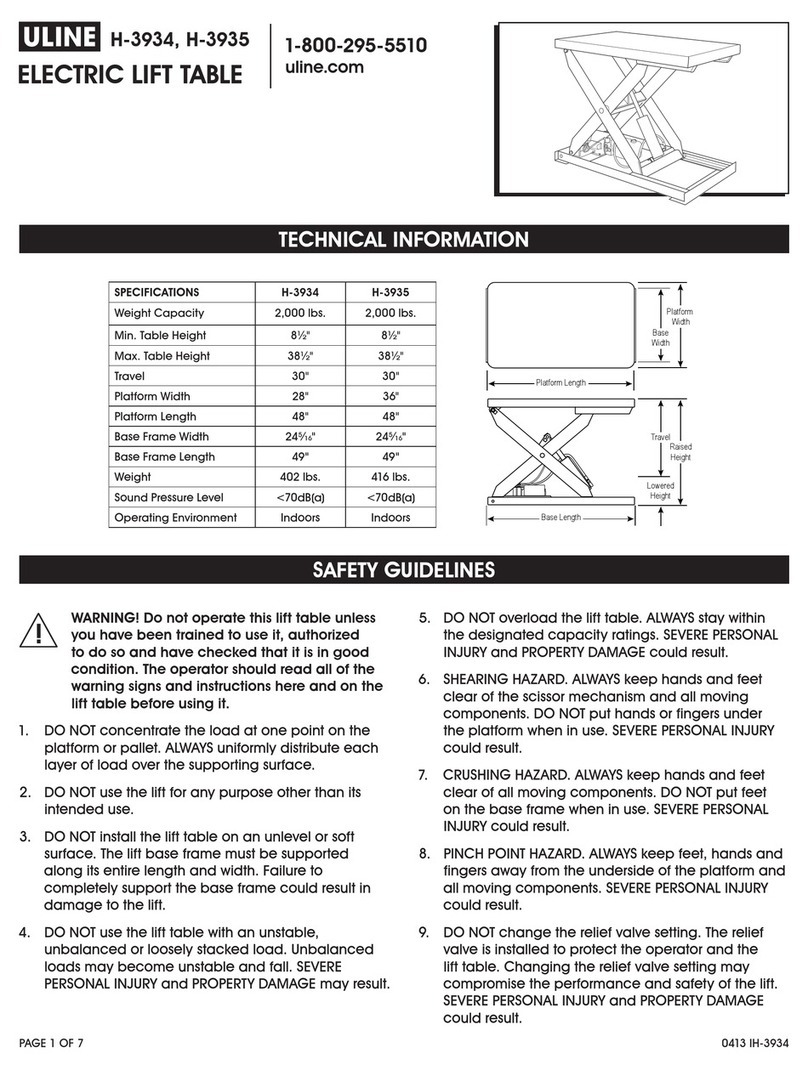

Description Specications

Lifting capacity 60kg

Min/max lifting height 120mm - 1705mm

Weight of unit 35kg

Total height of unit 1980mm

Battery charger 100-240V, 40W, 50-60Hz

Battery 2×12V 7Ah

Lifts per charge 60kg x 1m x 100 times

Up and down motions Push buttons

Front wheels Swiveling

Brake system Individually brake rear wheels

Overload protection Individually in curcuit board

Lifting speed 125mm/s

Page 12

4 Assembly

This chapter presents what comes in the package and how to assemble the trolley and fasten the tool.

The following images shows how to fasten the legs and the platform to the base unit.

a b

c

d

e

f

g

Unpacking

a. 1 x Base unit

b. 4 x Screw covers

c. 3 x M6 screws (platform)

d. 4 x M10 screws (legs)

e. 1 x Platform

f. 3 x Power cables, US/EU/UK socket

g. 2 x Legs with wheels mounted

Page 13

• Make sure the screws are fastened correctly and that the correct torque is applied on each

screw.

2. Fasten the platform

1. Fasten the legs

Mounting

Following is images of how to fasten the legs and the platform. The following images shows how to

fasten the legs and the platform to the base unit.vthe legs and the platform to the base unit.

• See the torque table on page 17.

Page 14

Charge the battery

The battery can not be charged too often. It is recommended to charge the battery as soon as it is not

in use. full charging cycle takes 8h.

• Never use a damaged powercord, it can lead to electrical shock! Replace it immediately!

• Never touch any parts inside the battery pack when charging. Touching electrical parts can

cause an electric shock.

Start the lifter

• The lifter can be stopped at any time by pressing the emergency stop on the control panel.

• Only run the lifter when it is completely assembled.

• Check the lifter for safe functionality prior to each use, for instructions.

• The lifters has overload protection which will prevent tools from being raised when the specied

max load is exceeded. If the overload protection is activated, reduce the load and try again.

5 User instructions

This chapter describes how to operate the TAWI Light Lifting Trolley.

Page 15

Battery charging indicator

The color of the battery charging indicator communicates the following information:

Operating panel

Grab the handles and push the lifter to move

it forward.

To move the platform up and down push the

buttons a and c.

The emergency button is found in the middle

of the control panel, b.

• Always move the lifter with the load in a lowered position.

• If platform is lowered onto an object and is prevented from beeing lowered further down,

will belt still run. If belt hasn't fully tension there is a risk of platform falling down if object is

removed.

a b c

• Make sure that the load is stable and secured on the platform.

• Make sure the platform is loaded according to the load diagram at page 14.

• The lifter can be switched on or o when charging the battery. It is recommended that the lifter

is switched o when not in use.

• To make sure not to damage the cord when pulling it out of the electrical outlet - grab, and apply

the force to the plug. To prevent damage to the cord, never pull the cord itself always pull on the

plug.

• It is recommended to charge the battery in a full cycle.

• Never operate the lifter when the battery is charging (plugged in).

• Charge the battery in a designated dry area.

• Normal charging of the battery creates very small amounts of hydrogen. However, the casing is

ventilated, and thereby the risk of hydrogen collection is minimal.

Red Chargin

Green Ready/Standby

a. Down

b. Emergency stop

c. Up

Page 16

If a tool hits an object or surface during lowering, a safety mechanism will stop the downwards

movement. This is to prevent accidents.

• Always apply brakes when loading and unloading.

Brakes

Rear wheels separately braked

Engage or disengage the brakes on both rear

wheels.

a. Neutral

b. Brake

a b

• Service must be carried out on a yearly basis.

• If any damage/wear is detected on the lifter, this must immediately be reported to TAWI or au-

thorisedTAWI representative. The lifter must be taken out of commission and not be used until

the damage has been repaired.

• All service must be carried out with the battery disconnected.

• In order to deal with the lifter’s cables and wiring, a good knowledge of electricity and TAWI

electrical schedules of the lifters is required.

• If the battery needs to be replaced, make sure that an original battery is used. If assistance is

needed, contact TAWI.

• Keep the lifter clean, use a damp cloth. Do not use chemical cleaners.

6 Service & maintenance

This chapter provides information about service and maintenance of the lifters. The chapter is divided

into three sections based on who is to perform the inspections and how often the inspections are to

be carried out. Daily by the operator, quarterly by inhouse maintenance and yearly by PIAB authorised

service technician. For technical service, maintenance or repairs contact your PIAB representative or

la.info@piab.com. PIAB must authorise all modications to this product. PIAB assumes no responsibility

for unauthorised modications and guarantees will automatically become invalid if unauthorised modi-

cations have been made.

Page 17

Inspections

The following inspections are to be carried out.

1. Double check (carry out) all daily inspections mentioned in Daily inspections by operator.

2. Check all screws and nuts for damage/wear.

Quarterly inspections by inhouse maintenance

1. Check that CE mark and serial number on the identication plate are visible.

2. Make sure all screws and nuts are tightened according to Torques to apply on page 17 (Pay extra attention

to screws and nuts on mast, legs and tool attachments).

3. Check belt wheels for signs of damage/wear.

4. Check the belt for wear and tear and make sure that it is properly secured.

5. Check belt wheels for signs of damage/wear.

6. Check the belt for wear and tear and make sure that it is properly secured.

7. Make sure that upper and lower switches are functioning correctly.

8. Control that the battery voltage level is sufficient.

9. Control that the charger is supplying correct voltage.

10. Check all wiring for signs of damage/wear and make sure all connections are correct.

11. Control screws and safety functions on tool.

12. Control welds for damage/wear on legs and tools caused by misuse, overload etc.

Torque table

Daily inspections by Operator

Type M5 M6 M8 M10

Torque (Nm, class 8.8) (ft/lb) 6 Nm (4.4 ft/lb) 10 Nm (7.3 ft/lb) 24 Nm (17.7 ft/lb) 47 Nm (34.6 ft/lb)

1. Check that the yearly maintence sticker is valid, and that yearly inspection is performed.

2. Check that the max lifting capacity signs and warning/operating labels are visible.

3. Make sure wheels/brakes are functioning correctly and check for signs of damage.

Yearly inspections by TAWI authorised service technician

Page 18

7 Troubleshoot

This chapter provides information on how to investigate or rectify problems that may occur. Actions

marked with (*) must be carried out by PIAB or a TAWI authorised service technician.

Problem Likely caused by Action required

Tool does not move up or down

Main switch is turned o. Turn main switch on.

Emergency stop is engaged. Disengage the emergency stop.

Batteries need charging. Charge batteries according to manual. See (A) on page

16.

Batteries are drained. Change batteries.*

Charger is damaged. Check if charger supplies correct voltage, if not

replace charger.*

Limit switches are broken/damaged. Check functions of limit switches, replace if

needed.*

No signal from operating panel. Check signal from the control panel to circuit

board.*

Wires or connections are loose on

battery.

Check wire connection on batteries. Connect if

necessary.

Fuse has tripped. Check fuse, replace if broken.

Circuit board damaged. Replace circuit board.*

Tool moves

slowly up/down

down

Batteries are weak. Charge batteries according to manual.

Brake does

not work

Brake has been misused. Replace rear wheels.

Charge

indicator

Charger is broken. Replace battery charger.*

*Must be carried out by authorized TAWI service technician.

1. Platform surface

2. Platform frame

3. Lifting belt

4. Battery

5. Front wheel

6. Rear wheel

7. Emergency stop

8. Up/down button

9. Top cover

10. Motor

11. Limit switch module

12. Battery charger

13. Electric control board

7

8

3

11

10

13

12

46

5

1

29

4305349

4305348

4305344

4305296

4305308

4305235

4305294

4305297

4305360

4305301

4305320

4305373

4305372

TAWI AB

Box 102 05

Transportgatan 1

434 23 Kungsbacka

Tel: +46 (0) 300 -185 00

la.info@piab.com

tawi.com

REV0 EN

A brand by Piab Group

Table of contents

Other TAWI Lifting System manuals

Popular Lifting System manuals by other brands

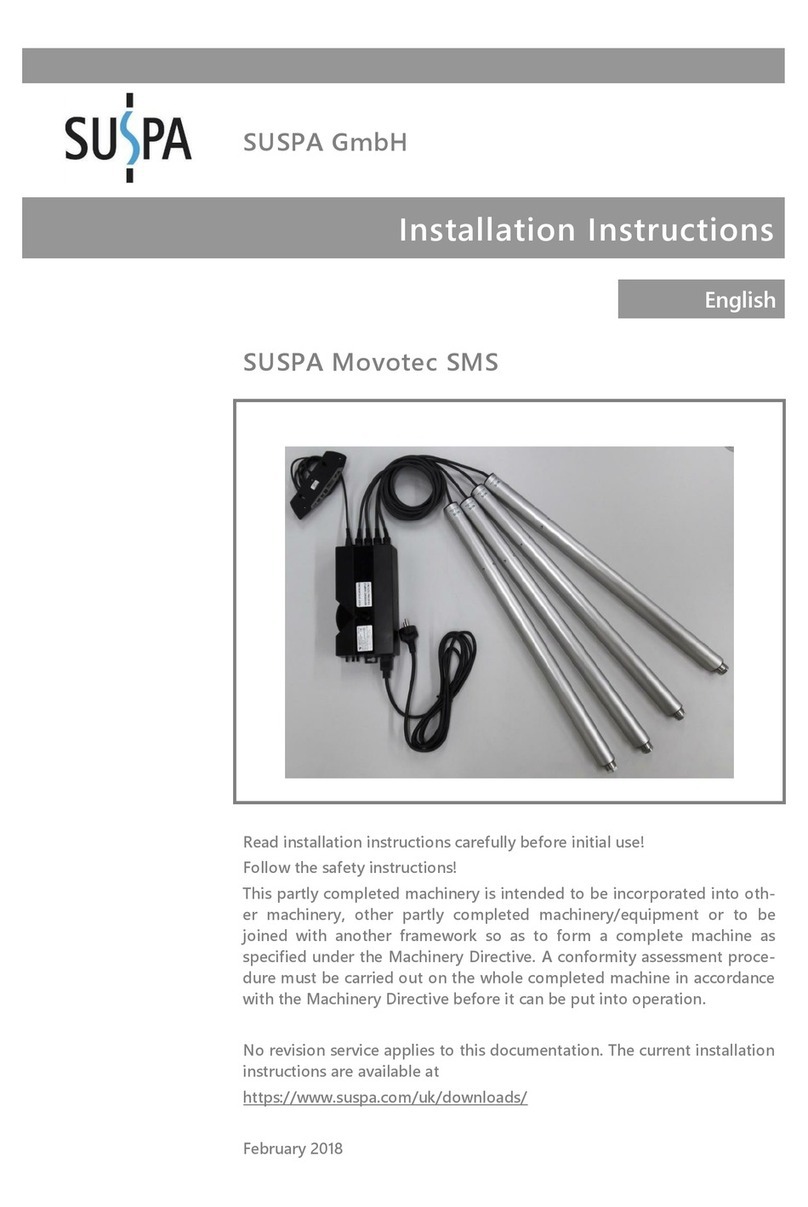

Suspa

Suspa Movotec SMS installation instructions

Pressalit Care

Pressalit Care R4822 Mounting instruction

Lockhard

Lockhard UP Lift 5 HD200 operating manual

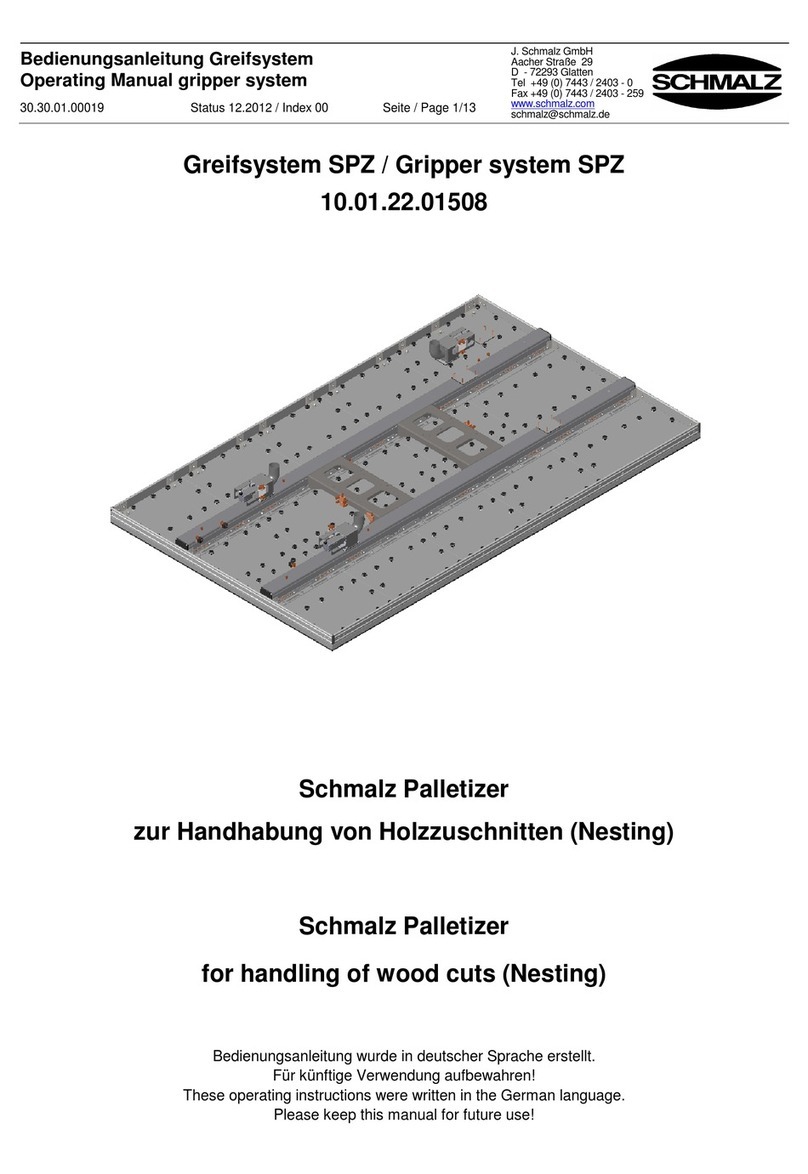

Schmalz

Schmalz SPZ Series operating manual

Norco

Norco 72675 Setup, operating, maintenance instructions

Omer

Omer Kar 350 Operation and maintenance manual