TAWI Mobile Order Picker User manual

User manual for

TAWI Mobile Order Picker Compact

Declaration of Conformity

According to 2006/42/EG Annex IIA

This manual and the Declaration of conformity is only valid when using TAWI authorised tools.

Manufacturer

TAWI AB

Box 10205, Transportgatan 1, 434 23 Kungsbacka, Sweden

Authorised representative

Name:

Company:

Address:

Machine description

Product group: TAWI Mobile Lifters

Product type:

Serial number vacuum lifter:

Serial number vacuum pump:

Serial number MOP:

It is hereby conrmed that the machine mentioned is in compliance with the following directives:

• 2006/42/EG Machine Directive

• 2014/30/EU EMC Directive

The following harmonised standards have been used:

• SS-EN ISO 12100:2010 Safety of machinery - General principles for design – Risk assessment and risk

reduction (ISO 12100:2010)

• SS-EN 14238:2004+A1:2009 Cranes. Manually controlled load manipulating devices

• SS-EN 1012-1:2010 Compressors and vacuum pumps – Safety requirements – Part 1: Air compressors

• SS-EN 1012-2+A1:2009 Compressors and vacuum pumps. Safety requirements. Vacuum pumps

• SS-EN 60204-1 Safety of machinery – Electrical equipment of machines – Part 1: General requirements

• SS-EN ISO 3744:2010 Acoustics – Determination of sound power levels and sound energy levels of noise

sources using sound pressure – Engineering methods for an essentially free eld over a reecting plane

• SS-EN 61000-6-3 Electromagnetic compatibility (EMC) - Part 6-3: Generic standards - Emission standard

for residential, commercial and light-industrial environments

• SS-EN 61000-6-2 Electromagnetic compatibility (EMC) - Part 6-2: Generic standards - Immunity for

indutrial environments

• SS-EN ISO 13849-1:2008 Safety of machinery - Safety-related parts of control systems - Part 1: General

principles for design)

• SS-EN 13001-1:2004 + A1:2009 Cranes - General design - Part 1: General principles and requirements

• SS-EN 13001-2:2004 + A3:2009 Cranes - General design - Part 2: Load eects

• SIS – CEN/TS 13001-3:2004 Cranes – General design – Part 3-1: Limit states and proof of competence of

steel structures

Date:

Place: Kungsbacka, SWEDEN

Signature:

Thomas Bräutigam, CEO TAWI Holding

Signature:

David Ranfalk, Responsible for the technical dossier

Contents

1 Safety & important information 05

Markings and labels on TAWI Mobile Order Picker Compact 08

WEEE, RoHS and REACH 10

Do not make modications 10

2 Warranty 11

3 Overview 12

4 Quick start 15

Unboxing instructions 15

Install suction foot 17

Working area 18

5 User instructions 19

Control panel 19

Start lifter 20

Move lifter 21

Raise and lower tower 22

Use lifter 23

Charge battery 25

Change battery pack 27

Clean suction foot lter 30

Clean vacuum pump lter 30

Change position og the jib arm 31

Change position of the outer arm 32

6 Service & maintenance 33

Inspections 34

7 Troubleshoot 35

Codes on the battery status display 37

SAFETY&IMPORTANTINFORMATION•1

05

1 Safety & important information

This chapter presents safety information about the TAWI Mobile Order Picker Compact lifter (hereafter

referred to as lifter). Some of the information is divided in Warning, Caution and Important. This

division is based on the severity of the consequences that may occur if the instructions are not

followed. Stickers and labels are explained in this chapter and information is provided about directives

that TAWI follows.

This manual and the Declaration of Conformity is only valid when using TAWI authorised tools.

This is the original version of the TAWI Mobile Order Picker Compact lifter user manual.

Caution: Risk of material damages.

WARNING: Risk of personal injuries or major material damages.

Important: Important information is highlighted.

06

1•SAFETY&IMPORTANTINFORMATION

WARNING

• Before operating a lifter, this manual must be read and understood.

• NEVER exceed the indicated max load capacity on the lifter or on a tool.

• Make sure loads are distributed evenly under the tool.

• Stay clear of the area underneath the TAWI Mobile Order Picker Compact at all times.

• Stay clear of all moving parts.

• Stay clear of the area underneath the unit when changing between park and transport mode.

• When the pump is switched o, the articulating arm must be attached to the safety lock.

• In order to deal with the lifter’s cables and wiring, a good knowledge of electricity and TAWI Mobile

Order Picker Compact electrical schematics is required. Faults can cause damage to people and

property.

• NEVER hang in the lifter.

• NEVER climb on the lifter.

• NEVER stand on the cover or any other part of the unit.

• If any unexpected movement of the lifter occurs, or in case of emergency, engage the emergency

stop. See Control panel on page 19.

• Make sure to control and solve any potential errors before resetting the emergency stop.

Caution

• The lifter is made for indoor use on an even oor/surface. Use caution when passing over

thresholds, oor drains, hoses or cables.

• Make sure the work light is switched on when operating the lifter in poor lightning.

• Keep clean. Never spray or pour water onto the casing containing the battery, the vacuum pump or

electrical cables. Clean with a damp cloth only.

• Any part of the lifter or accessories that show signs of wear or other damage must be replaced

immediately. The lifter must not be used before the damaged part is replaced. A damaged power

cord may only be replaced by TAWI authorised service technicians.

• Only run the lifter when it is completely assembled.

• Wear steel toe shoes with good grip when operating the lifter.

• The recommended temperature range for the lifters is 10 - 50 degrees Celsius (50 - 122 degrees

Fahrenheit). The lifting performance may vary when the temperature deviates from 20 degrees

Celsius (68 degrees Fahrenheit).

• Recharge the battery in a designated dry area.

SAFETY&IMPORTANTINFORMATION•1

07

Important

• To prevent damages and injuries caused by improper use, and not to compromise the warranty and

liability: Follow the instructions in this manual at all times!

• Use the TAWI Mobile Order Picker Compact or accessories only in accordance with all instructions in

this manual.

• Keep this manual accessible to all sta.

• Always follow any local/national recommendations as well as the instructions in this manual.

• The lifter is certied as a unit together with a specic tool. If the tool is changed, this must be

checked with TAWI. If a tool is used that is not authorised by TAWI, a new nal certication of the

complete lifter must be implemented.

• The lifter is not intended for use by persons (including children) with reduced physical, sensory or

mental capabilities, or lack of experience or knowledge, unless they have been given supervision

or instruction concerning use of the appliance by a person responsible for their safety. Children

should be supervised to ensure that they do not play with the lifters.

• Use only TAWI original spare parts.

• The lifter and accessories should only be used when they are in perfect working order.

• The lifter’s max load capacity has been tested with 10% dynamic overload and 25% static overload.

• If the lifter is to be out of use for a long period, ensure that the battery is maintained (not drained).

• Emission sound pressure level: <70 dB (A).

• Unit can be operated with charger plugged in. Note that the charger will not generate enough

power only to run the unit.

• Continuous duty cycle

• Unit is equipped wit foot safety switch, to prevent one from lowering the full load of the unit on feet

when changing from parking to transport mode. When foot safety switch is engaged the unit will be

turned o instantly.

• Unit is equipped with a safety function which will turn pump o, if unit is elevated with truck/pallet

jack during pump is running. As soon as stabiliser legs are put back onto rm ground the pump will

restart.

08

1•SAFETY&IMPORTANTINFORMATION

Transportgatan 1

SE-434 37 Kungsbacka

www.tawi.se

WN88.2-37

type

frequency Hz

speed min

power required kW

inlet capacity

pressure

vacuum mbar

mbar

m /h

year

No

Made in Germany

+

-

3

-1

Identication plate, MOP Compact

Identification plate, pump

TAWI AB Transportgatan

Box 10205 SE-434 23

Kungsbacka SWEDEN

www.tawi.com

Model/Type:

Serial no.:

Max load:

Prod. year:

Labels on TAWI Mobile Order Picker Compact

Read manual instructions! The

operator must read and understand

this manual before using the lifter.

Warning! Take precaution!

Warning for hot air! Burn hazard. Warning for electricalshock!

Markings and labels on TAWI Mobile Order Picker Compact

Identification plate, tool

SAFETY&IMPORTANTINFORMATION•1

09

LOWER

RELEASE

LOAD

This symbol precedes stated max

load capacity. Never exceed the

indicated max load capacity!

This symbol shows operator

handle use. Read the manual

before using the lifter!

Warning! Stand clear of

moving parts!

10

1•SAFETY&IMPORTANTINFORMATION

WEEE, RoHS and REACH

TAWI follows the WEEE (Directive 2012/19/EU), RoHS (2002/95/EC) and REACH (EC 1907/2006)

regulations.

A used battery and/or circuit board should either be returned to an authorised TAWI representative or

handed over to a station for chemical waste. All other parts can either be recycled or assorted as waste.

Do not make modications

Welding and other mechanical modications to TAWI Mobile Order Picker Compact (MOP Compact)

lifters or accessories must be carried out by TAWI authorised sta. If TAWI is no longer in business

and there is no successor interested in carry on the business, the user may perform a modication/al-

teration to a MOP Compact lifter. If this is done, the modication/alteration must be designed, tested

and implemented by experts in MOP Compact lifters and their safety. Also, a permanent record of the

design, test(s) and implementation of the modication/alteration must be maintained. Appropriate

changes to the capacity decals, tags and user manual must be made, see Markings and labels on the

MOP Compact lifter. A permanent and visible label must be fastened on the lifter that states how the

lifter has been modied/altered together with the date it was performed. The name and address of the

organisation that performed the modication must also be included.

WARRANTY• 2

11

2 Warranty

This chapter presents warranty information about the TAWI Mobile Order Picker Compact.

If a TAWI Mobile Order Picker Compact is used according to all instructions in this manual it will

perform well for many years. TAWI oers a one-year limited guarantee, excluding transportation

charges, provided that the lifter has been used under normal working conditions and in accordance

with the instructions in this manual. Noncompliance with rules and instructions in this manual will

result in complete exclusion of TAWI´s liability.

12

3 • OVERVIEW

3 Overview

TAWI Mobile Order Picker Compact is a mobile lifter that provides lifting and transportation aid for loads

up to 35 kg (80 lbs) by using vacuum. TAWI Mobile Order Picker Compact can be picked up and moved

with any kind of forklift or fork truck. An articulating arm enables the user to reach far into pallet racks,

shelves or conveyors.

The lifter can be equipped with dierent tools and accessories depending on the user’s need. This

chapter presents an overview description and illustration of the lifter, a table containing characteristics

of the TAWI Mobile Order Picker Compact, and an illustration of the center of gravity.

a. Mounting positions

b. Outer arm

c. Inner arm

d. Arm friction brake

e. Work light

f. Control panel

g. Service lid

h. Base

i. Battery box

j. Fork tunnels

k. Arm locks

l. Top swivel

m. Suction head

n. Tool (not showed in illustation)

o. Frame

p. Clamp protection

q. Back plate

ab

c

d

f

g

h

i

j

k

l

m

n

o

p

q

OVERVIEW• 3

13

Model C35

Lifting

capacity (kg)/(Ibs)

35 kg/

77 Ibs

Arm tube ø (mm) 100

Stroke vacuum lifter (mm) 1340

Stroke Tower (mm) 500

Noise level, Idle (dB) 76

Noise level, In operation (dB) 75

Max lifting height*

with lowered tower (mm)

2066

1566

Battery charging procedure Plug in to an electrical outlet (100-240 V. For 110V, use 3-phase charger. For

230V, use

singel-phase charger. Grounded, 50 – 60 Hz)

Recommended 8 hours of continuous charge

Lift per charge 3 hours constant use

Up and down motions of tower 52 - 68 mm/. s

Weight of unit 630 kg

This table presents information about TAWI Mobile Order Picker Compact.

• The max lifting capacity specied above are valid for standard congurations of the lifters. Check

the sticker on the lifter for applicable max load.

*From bottom of suction head (excl. suction foot)

14

3 • OVERVIEW

• The max lifting capacity of the external fork system will be reduced with the weight of the lifter.

Pay attention to the center of gravity of the lifter, so the external fork system is not overloaded.

Center of gravity

The center of gravity of the unit is illustrated below.

b

c

Disposition from the left (a) 575 mm

Disposition from the bottom (b) 550 mm

Disposition from the rear (c) 300 mm

• Note that depending on mounting position of the jib arm lift the center of gravity will change

laterally.

b

a

QUICK START• 4

15

• The lighting in the place of installation must be adequate, during installation and operation.

• Re-tighten all bolts within 1-2 months of installation.

4 Quick start

This chapter presents how to fasten tools and equipment and install the TAWI Mobile Order Picker

Compact lifter before rst use.

For more instructions see the movie: https://www.youtube.com/watch?v=ppRlJmY7AC0

Unboxing instructions

1. Remove the transport bracket (a) from the end of the arm. The bolts (b) will be used to attach the

vacuum lifter to the end of the arm. Remove the bracket from the tower as shown in the picture.

Reinstall the bolt to the tower.

16

4 • QUICK START

c

d

e

e

f

g

2. Connect the unit power connector (d) to

the Power pack connector (c) in order to

restore main supply power for the unit

and make it operational.

3. Remove the two top boards (e)

and any protecting padding

(f) from the pallet (g) on top of

the forks. When the unit is to

be unloaded from the pallet, or

elevated during service, the lifter

can either be lifted with a fork lift

or by fastening a strap around the

tower.

• The lifter must NOT be laid down. It could cause serious damage to the lifter, battery and the

pump.

QUICK START• 4

17

Install suction foot

1. Fit the suction foot or quick change

attachment with two or four M6

(VM30-VM40) directly to the suction head.

Use a torque between 2-3 Nm for the bolts.

• Make sure to use the correct torque for the bolts when installing the suction foot. Do not over- or

undertighten. Air leakage may occur otherwise, reducing lifting capacity.

• Tools that will t TAWI Mobile Order Picker Compct is VM30 and VM40.

VM30 VM40 VM50 VM60 VM80 VM100 VM120 VM180 VM270

18

4 • QUICK START

• The lifter must only operate within the restricted working area. Failure to do so may cause the unit

to tip and cause bodily injuries.

• Position the lifter so that the articulating arm can move freely within the permitted working area

and thus not be subject to a collision risk.

Working area

The grey area of the illustration below shows the permitted work area of the articulating arm.

There is an option to retrot a work area limiter that facilitates operations when the movement of the

articulating arm can be restricted.

USER INSTRUCTIONS• 5

19

5 User instructions

This chapter describes how to operate the TAWI Mobile Order Picker Compact.

Control panel

The control panel is equipped with push buttons that allow the user to integrate with the lifter.

Battery status display

The battery status is indicated by the number of lit bars in the battery status display. The number of

ashing bars communicate dierent messages, see Codes on the battery status display on page 37.

A. Emergency stop

B. Pump switch

C. Work light switch

D. Transport mode

E. Park mode

F. Lower tower

G. Raise tower

H. Main switch

I. Service indicator

J. Battery status display e

c

a

g

d

b

h

f

i

j

b

g

c

f

20

5 • USER INSTRUCTIONS

• A damaged electrical cable could cause electrical shock.

• The operator must be educated in handling the lifter and all instructions in the manual must be

followed.

• When in operation the operator must not place his head above the unit.

• When in operation the operator must not be under a hanging load.

Start lifter

Make sure that the lifter is standing directly on the ground and that the battery is charged. Review and

perform relevant inspections. See Weekly inspections by operator on page 34, Quarterly inspections by

inhouse maintenance on page 34 and Yearly inspections by TAWI authorised service technician on page

34.

1. Press the main switch on the control panel to turn the

power on (h).

>>Response: The battery status display flashes for

approximately three seconds and is thereafter lit.

2. The lifter is now ready for use.

• The lifter can be stopped at any time by pressing the emergency stop on the control panel. Turn the

emergency stop button to reset the emergency stop.

• Only run the lifter when it is completely assembled

• Check the lifter for safe functionality prior to each use, for instructions, see Service &

maintenance on page 33.

• The articulating arm can only be attached in the safety lock when the pump is switched o.

h

Table of contents

Other TAWI Lifting System manuals

Popular Lifting System manuals by other brands

Oshkosh Corporation

Oshkosh Corporation JLG 830P Operation and safety manual

Rotary

Rotary SM65-51 Operation and maintenance manual

Lippert Components

Lippert Components ground control 3.0 Service manual

morse

morse 185A-HDSS Operator's manual

BraunAbility

BraunAbility 02 Series Service manual

Simpro

Simpro QUIKSTAK QS10MM user manual

MAHA

MAHA ZS SQUARE II 3.5 Original operating instructions

TECO

TECO 300 SPECIAL instruction manual

Gude

Gude GHT 500 Translation of original operating instructions

Dhollandia

Dhollandia DH-L Series Operation manual

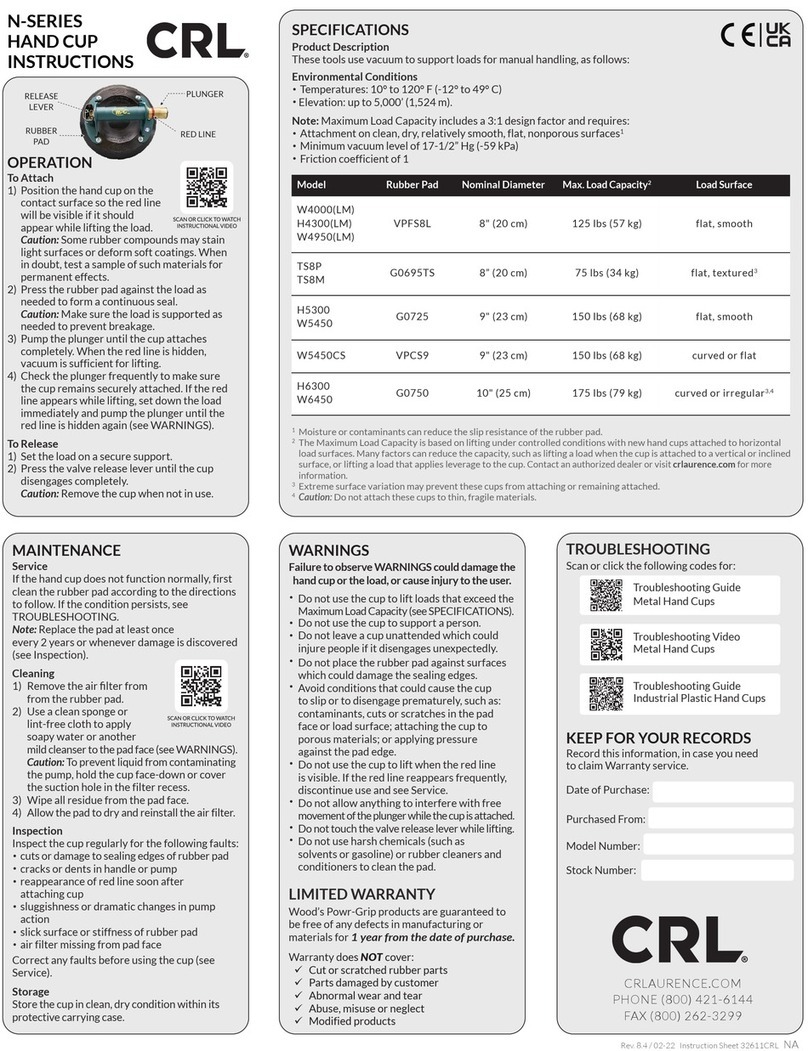

CRL

CRL N Series instructions

APlusLift

APlusLift HW-9KOH Installation manual & operation instructions