TCi HarmonicGuard HGP User manual

HarmonicGuard®Series Drive-Applied Harmonic Filter

Installation, Operation, and Maintenance Manual

No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written

permission of TCI, LLC. The information in this manual is subject to change without notice. Every

precaution has been taken in the preparation of this manual. TCI, LLC assumes no responsibility for errors

or omissions. Neither is any liability assumed for damages resulting from the use of the information

contained in this publication.

Table of Contents

Introduction..............................................................................................................................5

Receiving Inspection and Storage............................................................................................7

Pre-installation Planning.......................................................................................................... 8

Installation Guidelines.............................................................................................................9

HGP Filter Operation............................................................................................................. 10

Installation .............................................................................................................................11

Maintenance and Service....................................................................................................... 12

Product Description............................................................................................................... 14

Standard Option (S)...............................................................................................................17

Contactor Option (C).............................................................................................................18

Fuse Monitor with Contactor Option (F)..............................................................................19

Fuse Monitor without Contactor Option (G) .......................................................................20

CP Kit Enclosure (8) with Option (0)....................................................................................21

Line Reactor Installation........................................................................................................22

Typical Voltage Distortion Option (0)..................................................................................23

High Voltage Distortion Option (1).......................................................................................24

Introduction

Safety Instructions Overview

This section provides the safety instructions which must be followed when installing, operating, and

servicing the HarmonicGuard Passive (HGP) filter. If neglected, physical injury or death may follow,

or damage may occur to the filter or equipment connected to the HGP filter. The material in this

chapter must be read and understood before attempting any work on, or with, the product.

The HGP filter is intended to be connected to the input terminals of one or more VFDs. Three-phase

power is connected to the input terminals of the HGP and power is supplied to the VFD or VFDs

through the HGP. The instructions, and particularly the safety instructions, for the VFDs, motors, and

any other related equipment must be read, understood, and followed when working on any of the

equipment.

Warnings and Cautions

This manual provides two types of safety instructions. Warnings are used to call attention to

instructions that describe steps that must be taken to avoid conditions that can lead to a serious fault

condition, physical injury, or death.

Cautions are used to call attention to instructions that describe steps that must be taken to avoid

conditions that can lead to a malfunction and possible equipment damage.

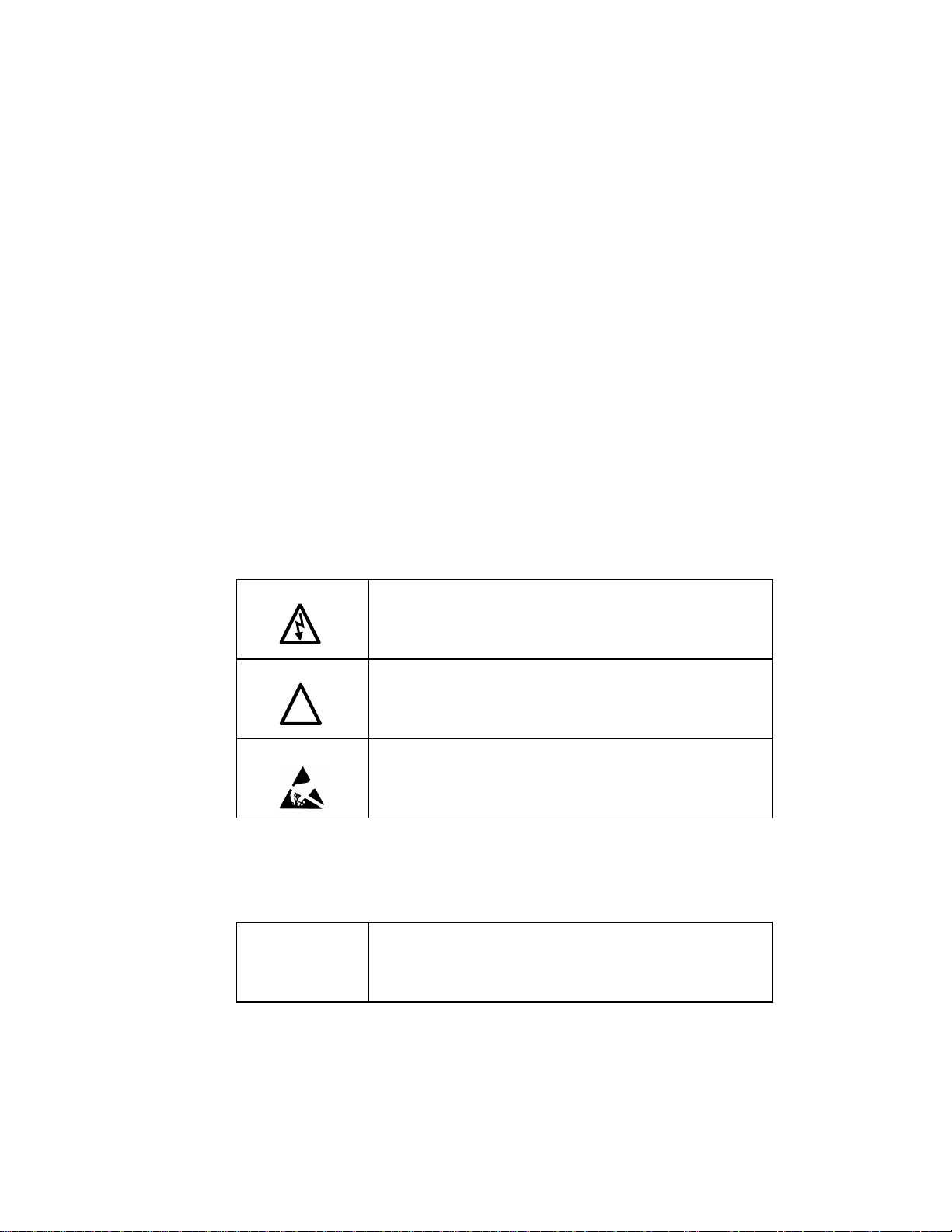

Warnings

Readers are informed of situations that can result in serious physical injury and/or serious damage to

equipment with warning statements highlighted by the following symbols:

Warning Dangerous Voltage Warning: warns of situations where high

voltage can cause physical injury and/or damage equipment.

The text next to this symbol describes ways to avoid the

danger.

Warning General Warning: warns of situations that can cause physical

injury and/or damage equipment by means other than

electrical. The text next to this symbol describes ways to avoid

the danger.

Warning Electrostatic Discharge Warning: warns of situations in which

an electrostatic discharge can damage equipment. The text next

to this symbol describes ways to avoid the danger.

Cautions

Readers are informed of situations that can lead to a malfunction and possible equipment damage with

caution statements:

Caution General Caution: identifies situations that can lead to a

malfunction and possible equipment damage. The text

describes ways to avoid the situation.

!

This manual suits for next models

1

Table of contents

Other TCi Industrial Equipment manuals