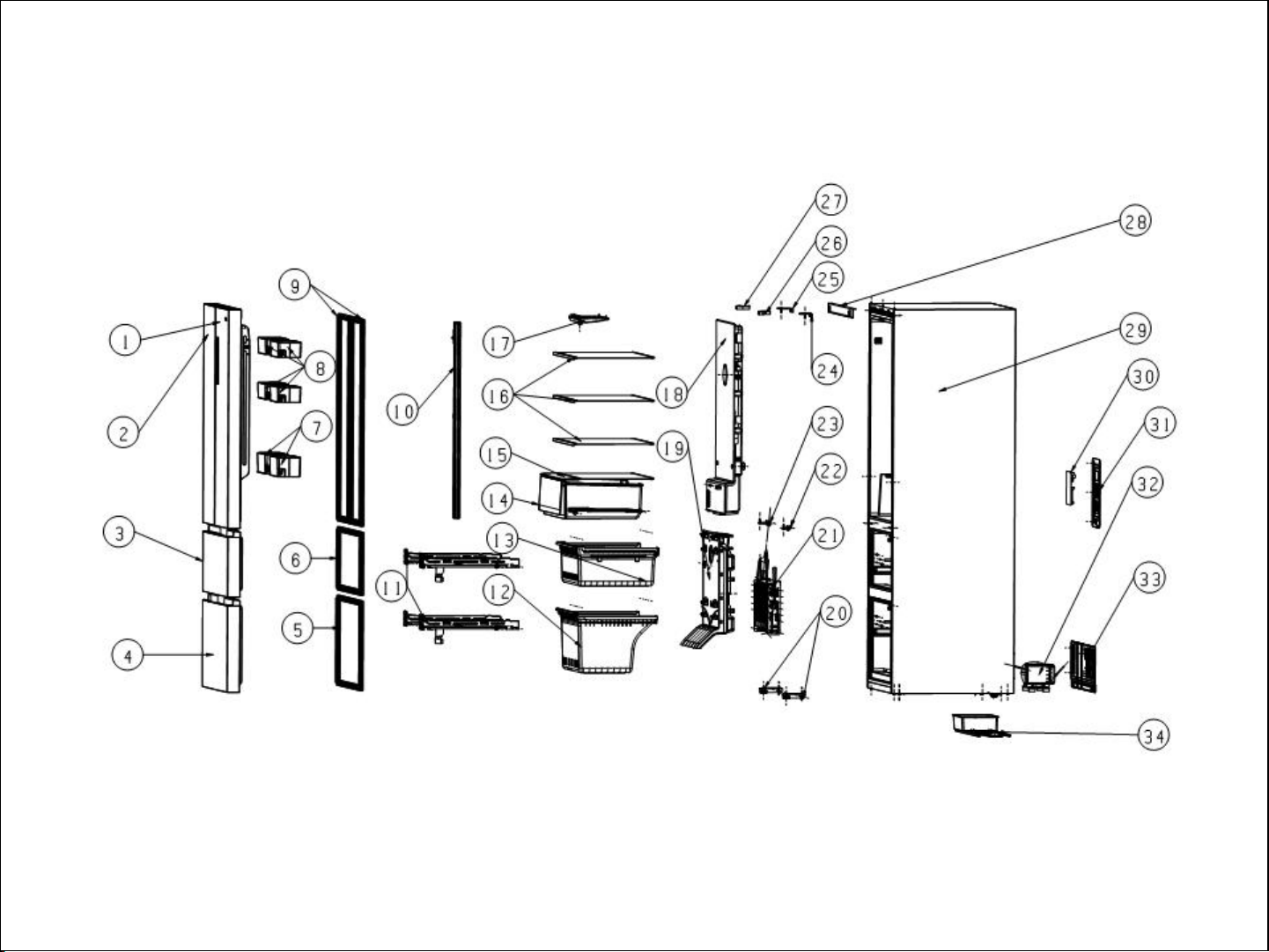

3.Refrigeration system

The refrigeration circulating system is as shown in the figure. TRF-436WEXPA+ is a single-system

full air-cooling frost-free refrigerator. The components of the refrigeration system are, in order,

compressor, evaporation coil, condenser, anti-condensation pipe, filter drier, capillary tube, fin

evaporator, return pipe and return transition pipe in the direction of refrigerant flow. The

schematic diagram of refrigeration is as follows:

Compressor

Filter drier

Capillary tube

Condenser

Anti-condensation pipe

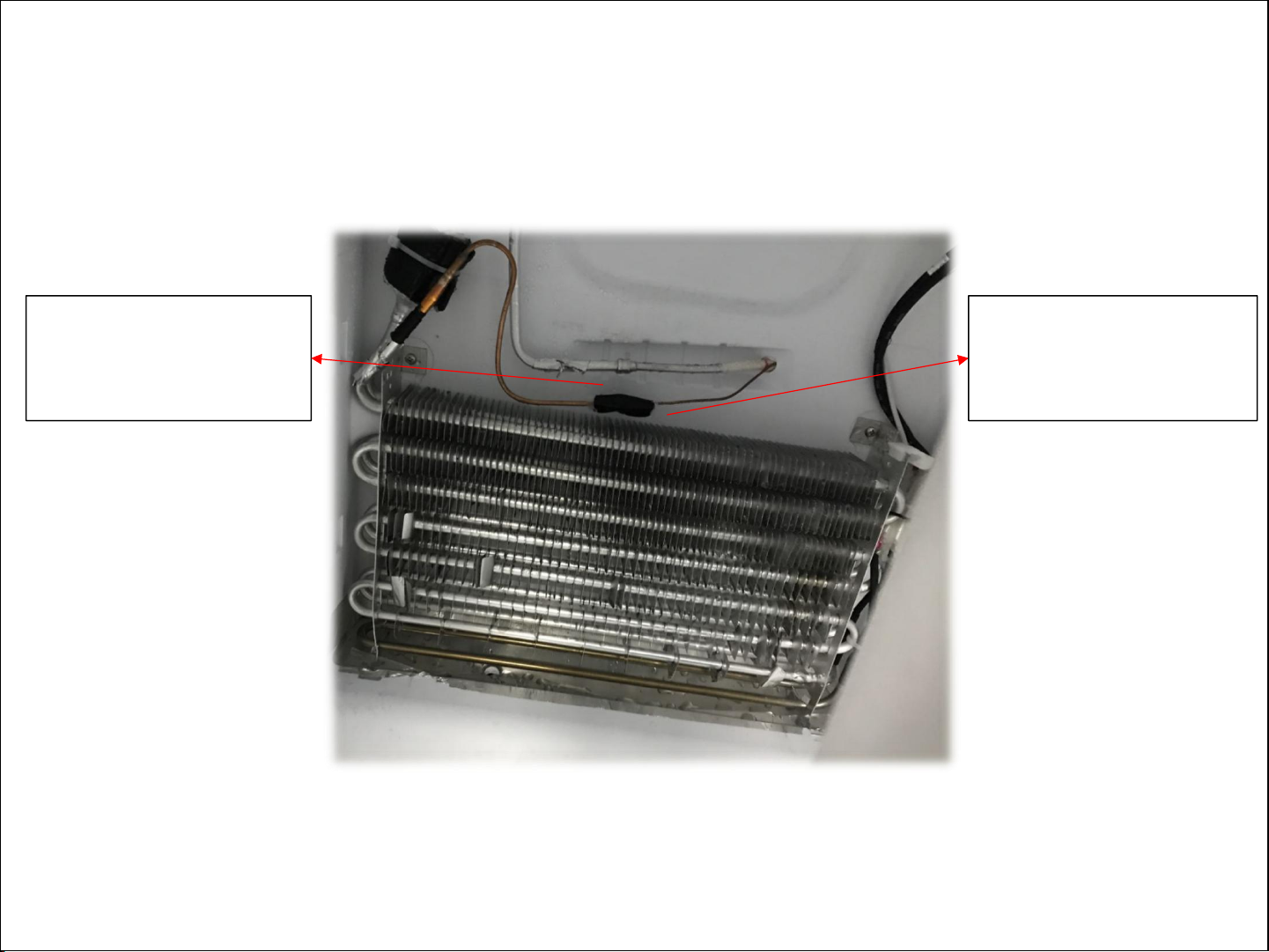

Fin evaporator

Evaporation coil