Rev.

Engineering Dept,China Manufacturing Center,TCL Multimedia

NO Q'ty

A1

B2

C2

D2

Q'ty E4

2F

2G

H

NO.

1

2

3

4

38s

Prepared:Bin Tang Checked by: Approved by:

S.T Total:

PRECAUTIONS

1.The real goods used above items must be the same as BOM list's goods.

2.Operator should wear Gloves when operating.

3.The processes is operated on a strict self-test, to prevent defective products into the next process.

4.Order by serial hit the screw (take a hit one), can not appear tainted play, missed, slip teeth, etc.

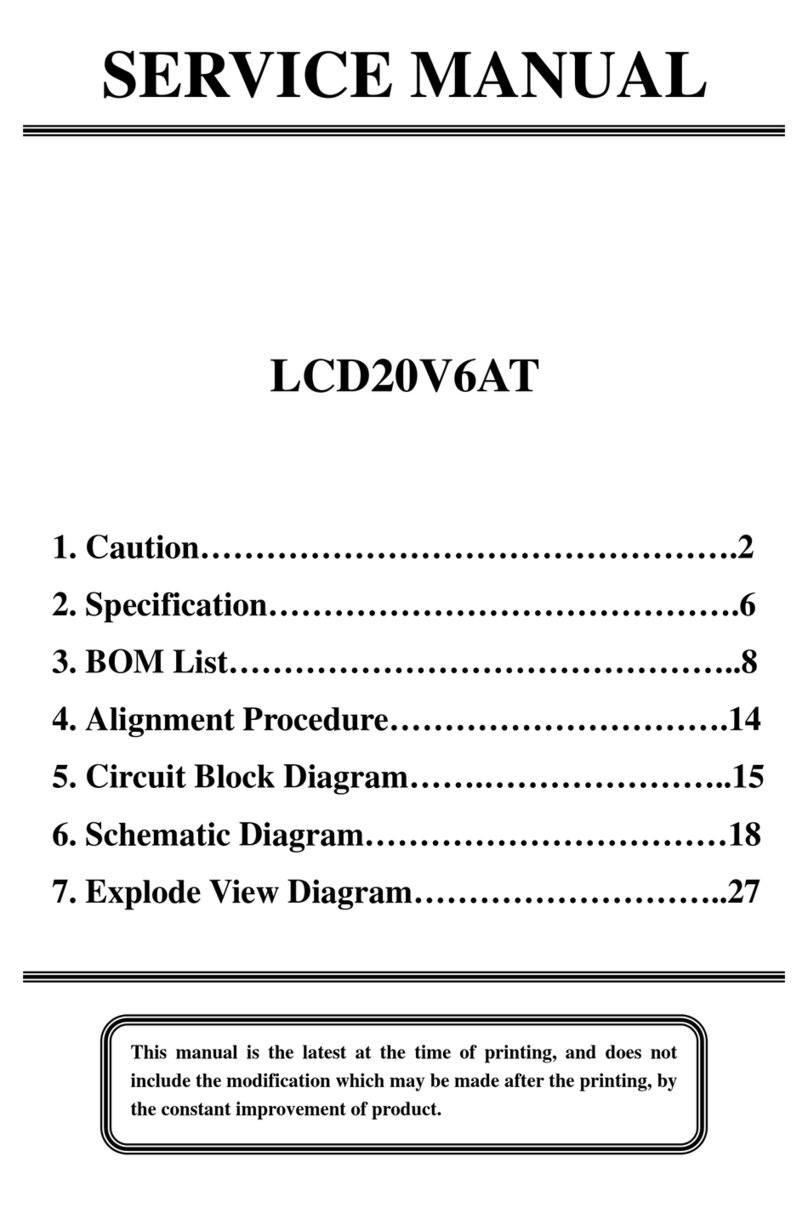

Stick the mylar on the support pin as fig.2.

4)Check the T-CON board must be completely on the lock .

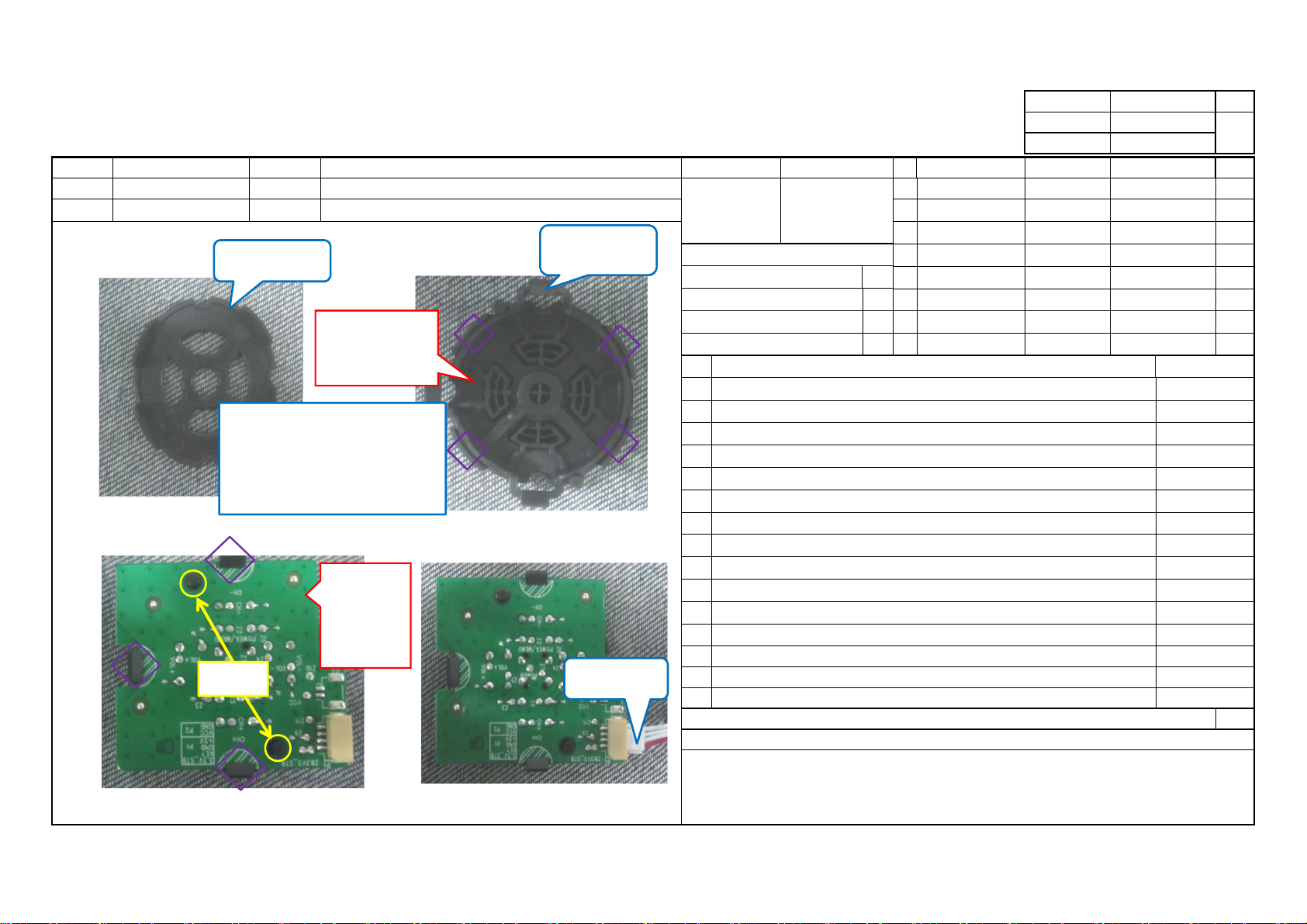

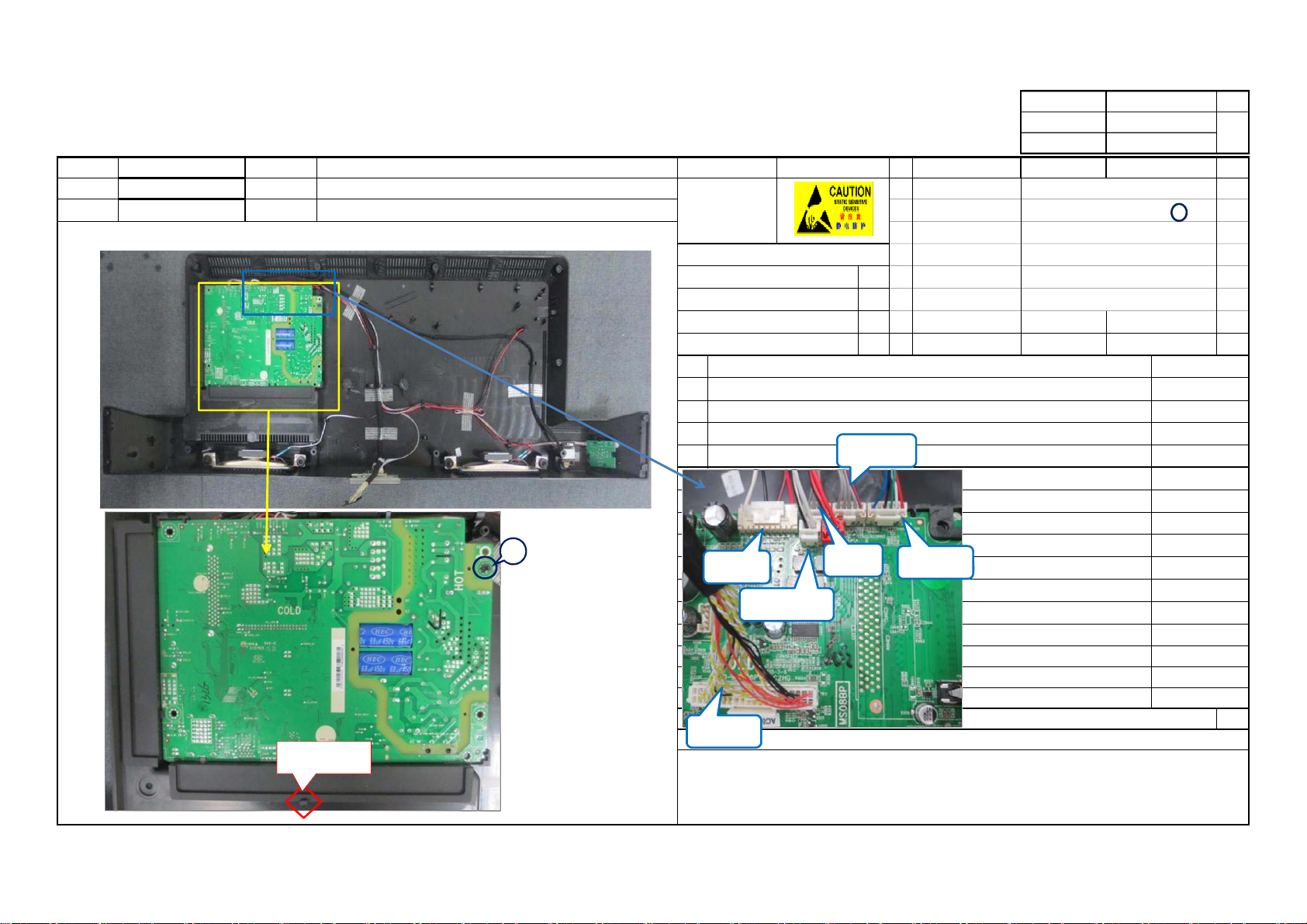

Fix the vesa support(1~2)with screws on the module as fig.2. k=8±1kgf.cm

Fix the base connector (3~6)with screws on the module as fig.2. k=8±1kgf.cm

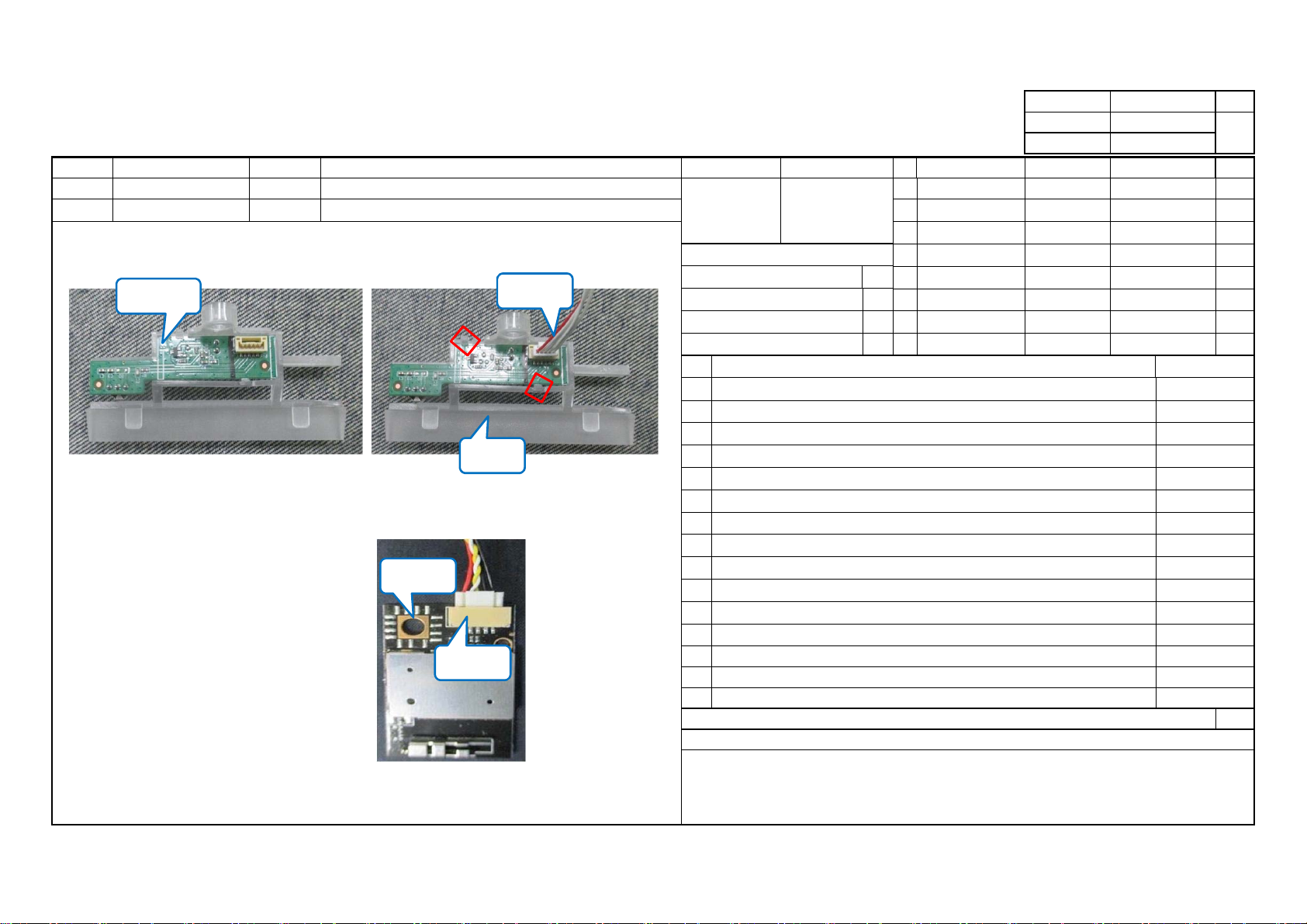

2)Examine the LOGO is right for the machine .

3)There should be no deformation of the surface shell, de-oiling, no scratching and other

undesirable phenomena.

Take out screen module on the workpalce shown in the left pictures,then check as follow:

1)To be sure that the LCD panel can not have a scratch, cracks or damage and other

adverses,then put it on sponge pad without any foreign matter.

PROCESS DESCRIPTION Oper.Parameter

Pair of Electrostatic Gloves

electronic screw driver

FIXTURES & INSTRUMENTS 62-529910-0HJ

Name 64-B40060-104G

base connector

screw for base connector

Ass'y No.

H7-KD270NZG-UR0 Section CTV ASSEMBLY 67-M52727-0G0

64-B40060-104G

Model

40D2700B MS08BP-AP

NO. 9/23

T8-40D2700B-LPM10

Customer Oper. Name Process 2 of taking the module

1.0

odified Date:

Remark Electrostatic Mark

WORK INSTRUCTION

File No.:

Part Number Description Specification

screw for vesa support

vesa support

OS-C000390.00

Issue Date:2015/11/13

module

Fig.1

1 2

Fig.2

3

4

anchorpoint

baseconnector